Waterproof Wire Connectors built for critical systems in motion. Compact, sealed IP67, and field-proven. Get Full Specs and Quote in Minutes.

Introduction: Pogo pin waterproof wire connectors ensure the stability of electrical connections

In dynamic modern industrial applications, the stability of electrical connections is the cornerstone of normal system operation. Customers often require high reliability and long-term operation of their equipment. Waterproof wire connectors can provide stable electrical connections and isolate moisture and dust in the environment. They have become key components in many industries to ensure clients’ various equipment long-term stability.

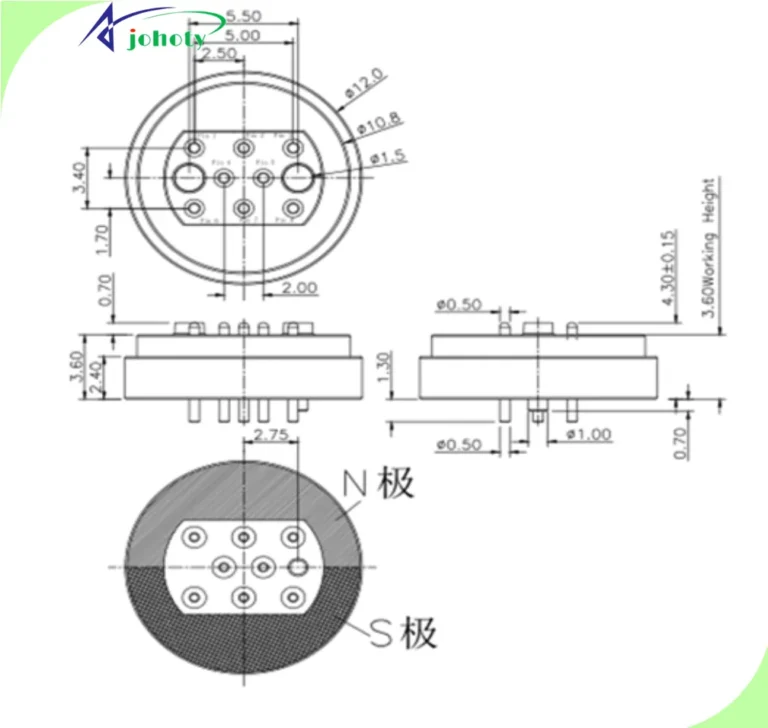

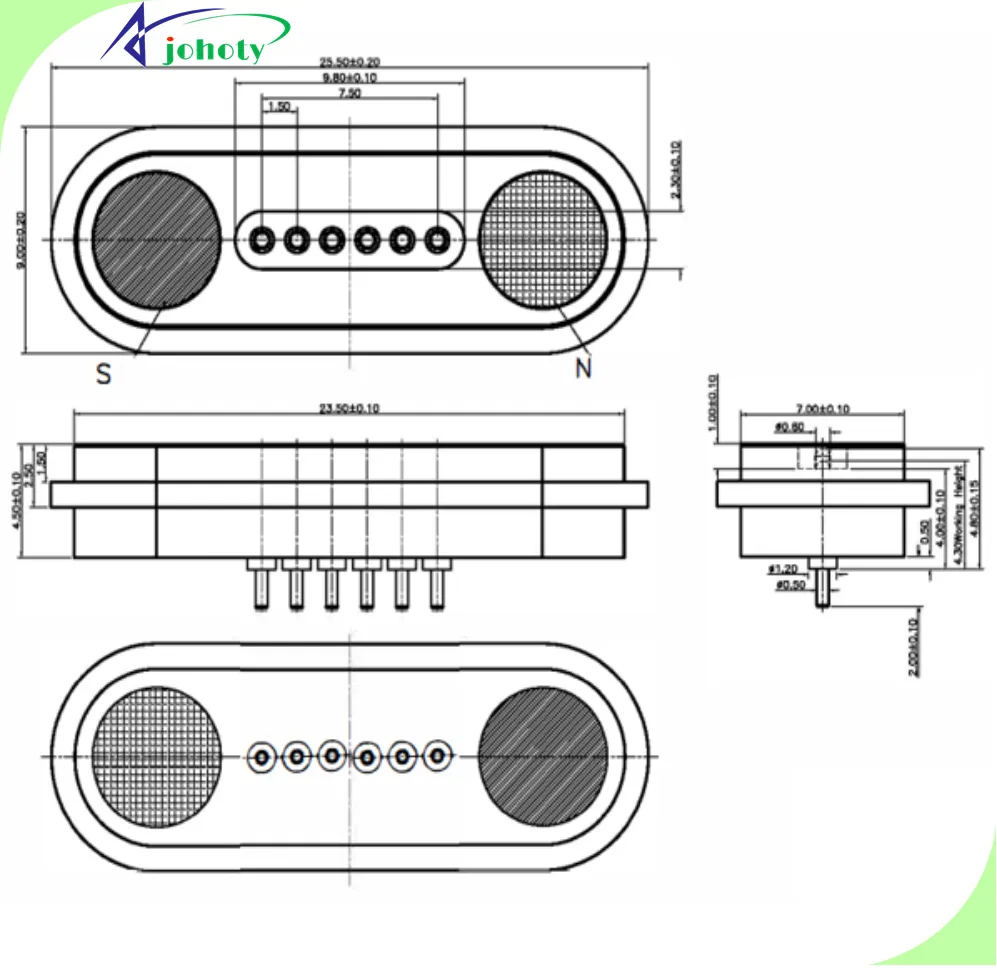

Pogo pin waterproof wire connectors have unique design and performance. Suitable for use in critical systems with high loads and dynamic movements. Compact size and IP67 waterproof rating enable normal operation in harsh environments. Provide long-lasting and stable electrical connections for your device. Commonly used in complex automated production lines, communication equipment, high-precision medical equipment, and vehicle systems. And demonstrate unparalleled advantages.

This article will show their working principle of pogo pin waterproof wire connectors. And their technical characteristics and practical applications. Help you gain a comprehensive understanding and provide reference for selecting the appropriate waterproof connector for your device.

Pogo pin waterproof wire connectors: providing reliable electrical connections for dynamic systems

Introduction to Pogo Pin Technology

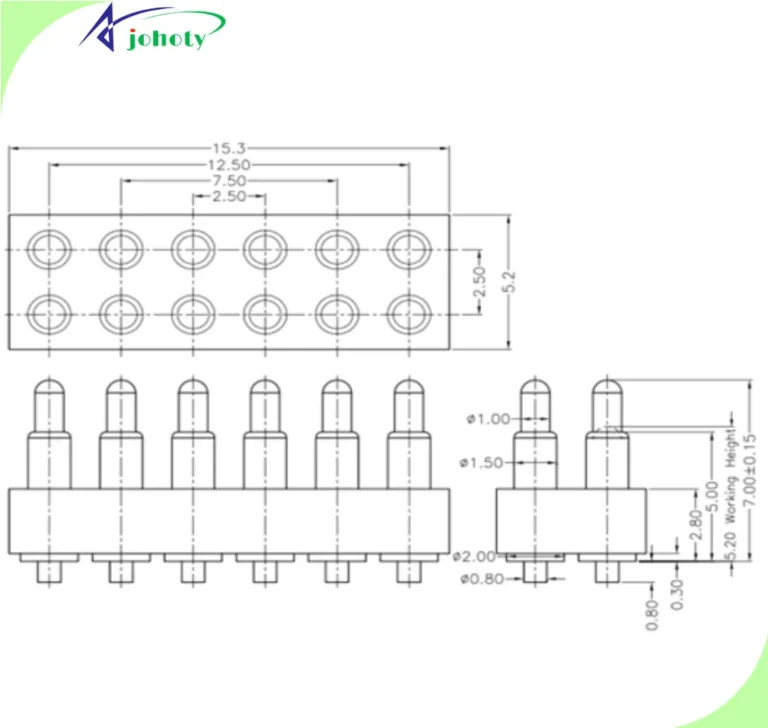

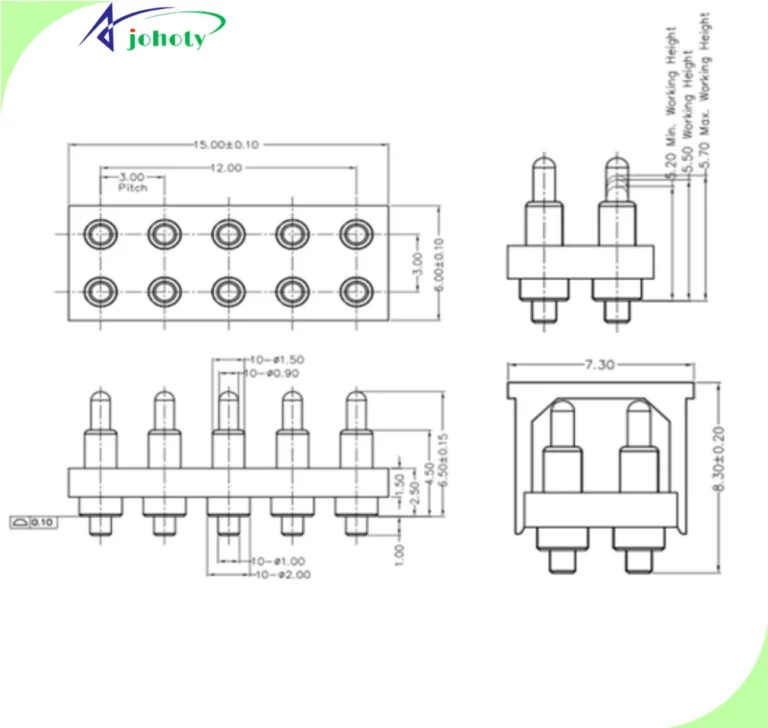

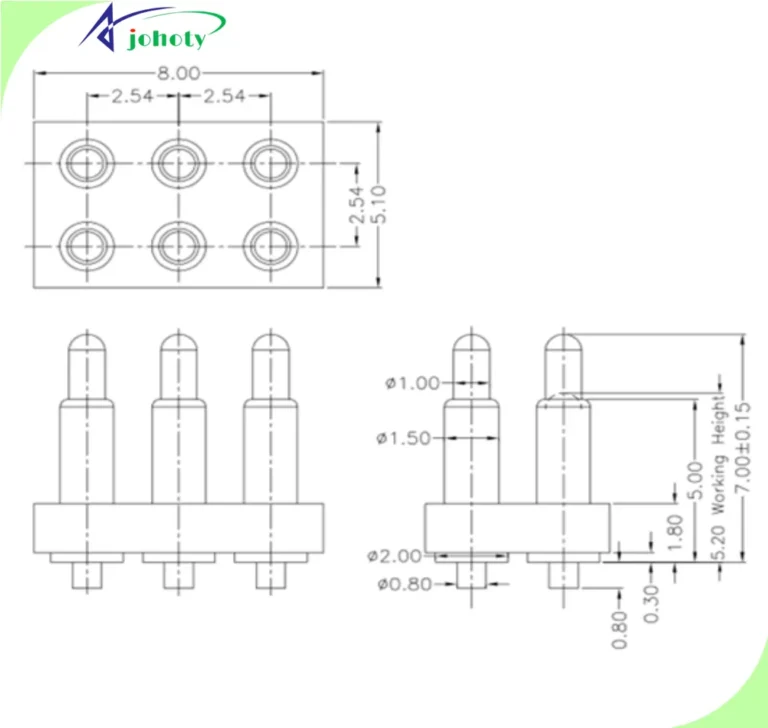

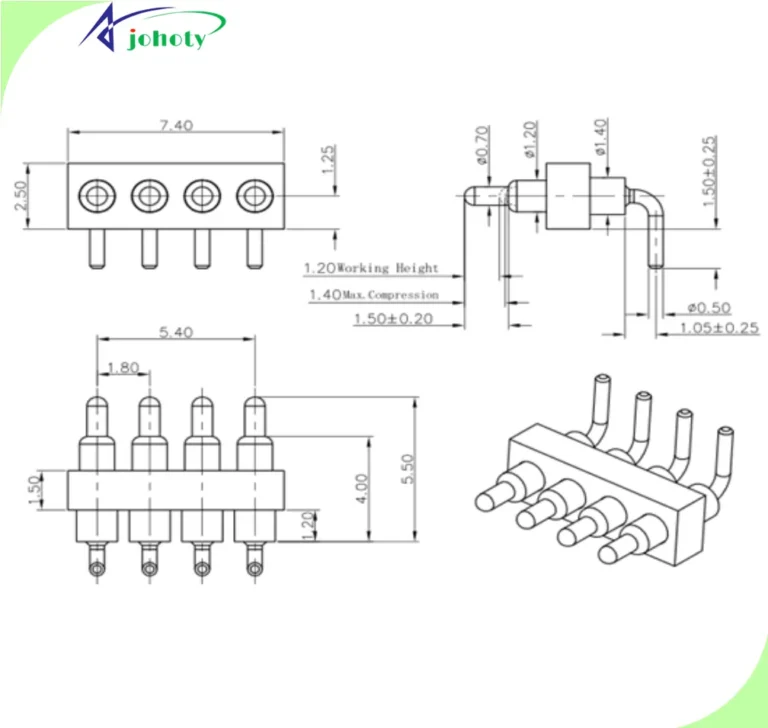

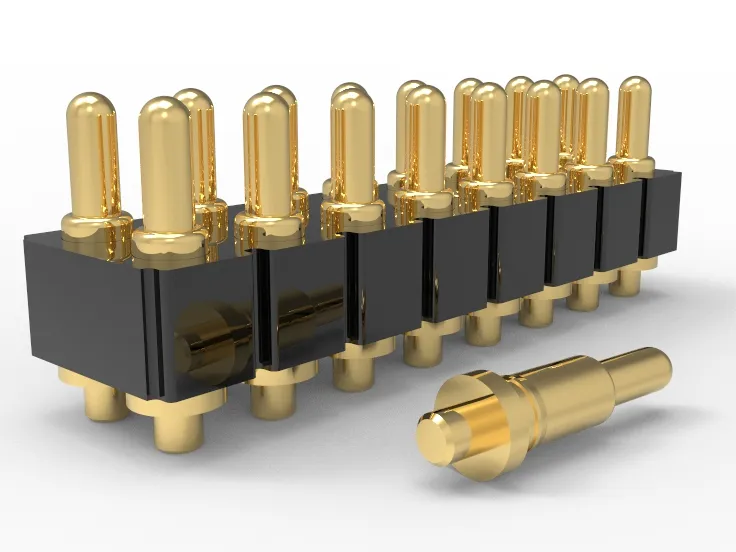

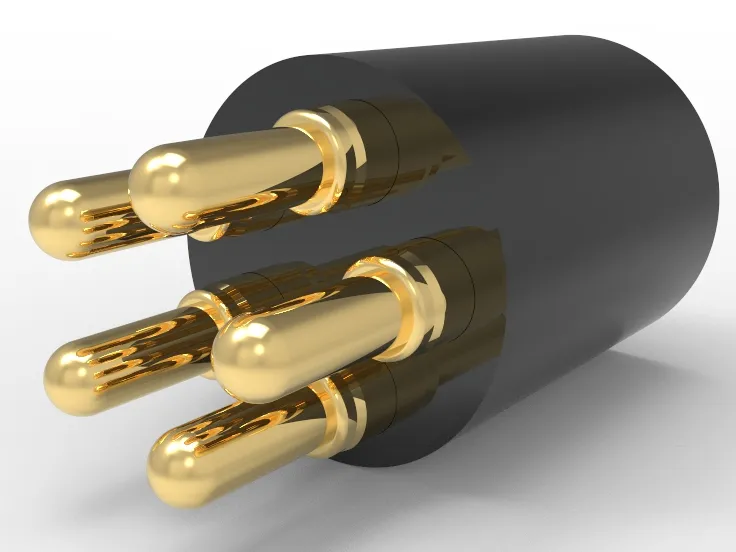

Pogo pin, As an elastic contact technology, it is applied in various precision equipment. It consists of a spring structure and metal contacts. Capable of maintaining stable electrical contact between connection and disconnection. Unlike traditional plug-in connectors, pogo pins can withstand more movement and vibration through flexible springs. It can greatly improve connectors’ stability and durability.

For systems that require stable operation, pogo pin connectors provide stronger durability and resilience. The system is capable of maintaining stable electrical transmission under extreme conditions. The combination of pogo pin technology and sealing structure in waterproof wire connector. Ensure that the connector can work effectively under water and dust.

Waterproof performance and IP67 rating of waterproof wire connectors

The IP67 rating of waterproof wire connectors is crucial for reliable operation in harsh environments. IP67 represents that the connector can operate normally for half an hour at a depth of 1 meter underwater. The equipment can ensure stability when working in rainwater, humid climates, or other liquids.

Johoty precisely designs the sealing structure of pogo pin waterproof wire connectors. It can effectively protect connection area from moisture and dust. Avoid short circuits and poor electrical contact caused by moisture or external pollutants. Used for external devices or embedded in complex automated production lines. Pogo pin waterproof wire connectors can provide excellent protection for your system.

Compact design and high reliability of waterproof wire connectors

Another feature of pogo pin waterproof wire connector is its compact design. They provide high reliability electrical connections and can be flexed well in limited spaces. Devices are often limited in space and subjected to a large amount of vibration or frequent plugging and unplugging in dynamic environments. Pogo pin waterproof wire connectors can provide an ideal solution.

Pogo pin waterproof wire connector is commonly used in industrial automation equipment, medical devices, and spacecraft. Due to their high durability and compact design, they can be used in critical parts of various electrical connections. These pogo pin connectors can carry a large amount of data transmission and electrical connections in limited space. Ensure that the system remains stable throughout operation.

Working principle and application advantages of pogo pin waterproof wire connectors

Working principle: Stable electrical contact and high anti-interference ability

Working principle of waterproof wire connectors is very simple and effective. Each pogo pin consists of a spring contact. When contact, the spring ensures stable contact and can resist poor contact caused by vibration, external forces, etc. This design gives pogo pins significant advantages in dynamic environments.

In addition, pogo pin waterproof wire connectors have high anti-interference ability. In complex industrial environments, EMI and electrical noise are often one of the main causes of system failures. Pogo pin effectively avoids such problems through its excellent contact design.

Stability in Extreme Environments

Automobiles, electricity, aerospace, and communication equipment need to operate for long periods of time in various harsh environments. Waterproof connectors are particularly important for outdoor equipment or equipment exposed to moisture, dust, and chemicals. Pogo pin waterproof wire connectors can provide stable electrical connections in these extreme environments.

In the automotive industry, waterproof wire connectors are used in automotive electronic systems, sensors, and control systems. Waterproof design ensures stable operation of electrical systems even in extreme weather conditions, reducing failure rates.

In aerospace, waterproof wire connectors are used in high-end equipment such as airplanes and satellites. They can ensure equipment electrical stability and safety during flight. This pogo pin connector can withstand high temperatures, salt spray, low temperatures, and moisture. Meet the strict requirements of electrical connections for aerospace equipment.

Long term cost savings and reliability improvement

Pogo pin waterproof wire connectors can improve the reliability of devices. They can also effectively save long-term maintenance, daily repair, and replacement costs. Traditional connectors are exposed to moisture and dust, and equipment often requires frequent maintenance and replacement. Pogo pin waterproof wire connectors have excellent waterproof performance and high durability. Being able to work under extreme conditions for a long time greatly reduces maintenance costs.

How to choose pogo pin waterproof wire connectors that meet your needs?

Waterproof grade and sealing performance:

When choosing pogo pin waterproof wire connectors, the first thing to consider is the waterproof rating. IP67 rating is the recommended standard in most industrial applications. As is well known, it ensures the normal operation of equipment at a depth of 1 meter underwater. If higher protection performance is required, you can choose an IP68 pogo pin connector.

Suitable materials:

The raw materials of Pogo pin waterproof wire connectors directly affect durability and suitability for the environment. For highly corrosive, high-temperature, and high-humidity environments, high-temperature resistant and corrosion-resistant stainless steel or gold-plated copper can be chosen.

Size and installation method:

When choosing, you also need to consider the size and installation method of the pogo pin connector. For devices with limited space, compact pogo pin waterproof wire connectors can effectively save installation space. Johoty’s right angle pogo pin, SMT pogo pins, through hole pogo pins, and solder cup pogo pin are good choices.

Conclusion: To provide stable support for critical systems, choose Johoty’s pogo pin waterproof wire connectors

Pogo pin waterproof wire connectors have excellent waterproof performance, high reliability, and durability. It has become a key component for ensuring the stable operation of equipment in many industries. Used in aerospace, automotive, medical healthcare devices, industrial automation, as well as high demand systems. Pogo pin waterproof wire connectors can provide stable electrical connections. Reduce faults and maintenance costs, and improve the long-term reliability of equipment.

If you are looking for pogo pin waterproof wire connectors, Johoty is your best choice. We can ensure that they meet your demanding environmental requirements and high performance. Visit Johoty immediately for detailed specifications and quotes. Improve your system’s stability and reliability. Ensure consistent performance of your device at critical moments!

+86 13590816656

+86 13590816656 +86 13590816656

+86 13590816656