Best Pogo Pin Connectors China Manufacturer Multiple Pins

Features:

- High-precision pogo pins ensure stable electrical contact.

- Long-life design, supporting >10,000 operation cycles.

- Ultra-high-density layout for compact design requirements.

- High-temp, earthquake-resistance for extreme environments.

- Automatically clean plunger tip to keep high performance.

- High-speed signal transfer for high-frequency applications.

Pogo Pin Connectors Series

Pogo pin connectors series has 12 categories, Johoty’s clients often customize multiple functions in one connector:

Ultra-high density: Pitch ≤1.27mm, supports precise arrangement of hundreds of pogo pins, designed specifically for multi-point connections in extremely small spaces. Used for high-frequency communication, micro-devices, smart wearable devices, and medical sensors.

High-temperature durable type: Maintains stable electrical contact and spring compression performance at+250℃. Used for aerospace and military equipment that require high-temperature stability.

High frequency and high-speed data transfer: low impedance, reducing signal loss and delay, used for high-performance computing, 5G communication, and high-definition image transfer.

Self-cleaning type: Automatically cleans contact points to reduce oxidation and pollution, used for automated testing and medical equipment.

Waterproof and dustproof: IP67, IP68 waterproof, Used for outdoor equipment, industrial control, and ocean exploration.

Magnetic type: magnetic assisted docking, automatic engagement, precise docking, and stable connection, used for wireless charging, high-frequency electronics, medical equipment.

Waterproof magnetic connector: Combination of waterproof and magnetic technology, used in automotive electronics, outdoor, industrial, and medical equipment.

Ultra small: Extremely small size and compact design, used for wearable devices, portable electronic devices, sensor systems.

Seismic resistant type: Maintains good electrical contact under severe vibration or impact, used for military, automobiles, and aerospace.

Low resistance type: Designed with low contact resistance to ensure low power consumption during high current transfer, used for BMS, high-power equipment, and energy transfer systems.

Multi-functional integrated type: Data transfer, power connection, signal detection, etc., reducing the number of connectors, used for high-end electronic products and intelligent hardware.

Ultra-durable: Made of highly corrosion-resistant materials that maintain excellent performance for a long time, used in the oil and gas industry, chemical equipment, and medical instruments.

Specifications of Pogo Pin Connectors

| Parameter | Value Range |

|---|---|

| Total Pin Count | ≥14 (Common: 16,18,20,22,24,64, 128, 256, 320,598), custom |

| Size(L/W/H) | ≥11.80mm x 2.00mm x 2.50mm, custom |

| Stroke | ≥0.15mm, custom |

| Spring Force (per pin) | ≥5 gf, custom |

| Pin Pitch | ≥1.00 mm (common: 1.27mm, 2.54 mm, etc), custom |

| Rated Current per Pin | ≥0.1A/pin, up to 50A/pin, custom |

| Rated Voltage per Pin | ≥3.0V/pin, up to 550V/pin, custom |

| Contact Resistance (per pin) | ≥10 mΩ per pin, ≤200 mΩ per pin, custom |

| Plunger Tip | Round, pointed, flat, claw, ball, star, custom |

| Mechanical Durability (cycles) | 10,000 – 500,000 cycles (structure and material dependent), custom |

| Insulation Resistance | ≥ 1000 MΩ @ 100 V DC |

| Dielectric Withstanding Voltage | 100 V – 500 V AC (between pins) |

| Operating Temperature | -40℃ to +125℃ (up to +150℃ for high-temp variants),custom |

| Contact Material | Gold-plated copper alloy, BeCu, stainless steel, phosphor bronze, custom |

| Barrel/Shell Material | Nickel-plated brass and gold-plated, or stainless steel, composite coating, custom |

| Mounting Method | SMT, DIP, Solder-cup, Right-angle, Double-ended, Press-fit, Custom mounting options |

| Protection Rating (optional) | IP50 – IP68 (based on sealing design), custom |

| Signal Integrity Support | Differential pair capable, high-speed signal ready (USB3.0, PCIe, SerDes), custom |

| EMI Shielding Capability | Optional metal housing or dedicated grounding features, custom |

Applications of Pogo Pin Connectors

Wearable devices (smart wristbands/headphones): charging, Bluetooth antenna contacts, physiological sensing synchronization, pin spacing <1mm, low voltage and low current. Ultra thin design, charging base + PCB pin + magnetic positioning module, pogo pins provide stable connection.

CT/MRI medical imaging system: module interconnect bus + pogo pin array + anti-interference filtering layer. Image module high-speed data + synchronous clock transmission. 40 Pogo pins, 10Gbps high-speed transmission, support 120℃ heat resistance, medical insulation design.

Smartphone camera module connection: compression stroke <1.2mm, high-density layout, 18 Pogo pins. Power supply + image data + control signal connection, motherboard module + module docking array + flexible FPC transition.

Semiconductor testing (ATE): 80 Pogo pins, chip burning, electrical parameter and high-speed signal testing. Pin array socket + probe module + automatic fixture platform, supporting 40GHz frequency. Impedance matching design with extremely low inductance interference.

Communication base station RF module: RF signal transmission, module to module shielding and docking, 32 Pogo pins. Each pin supports a current of 12A and the shielding layer isolates interference. Low contact impedance, RF motherboard + Pogo pins female socket + multi-layer PCB common ground structure

Automotive LiDAR system: Supports AEC-Q200 automotive specifications, high temperature resistance, vibration resistance, and bending resistance, with 48 Pogo pins. Radar module backplane + vertical pin docking + shielding shell. Data acquisition, power supply, and synchronization signal interface.

Industrial automation PLC system: 64 Pogo pins, module hot swappable power supply + IO communication. PLC motherboard + modular IO unit + sliding rail docking pin array. IP67 package, corrosion-resistant gold-plated pogo pins, supports hot plugging.

Drone flight control and battery system: flight control terminal + battery holder Pogo terminal + protective shell packaging, 20 Pogo pins. Resistant to 100,000 insertions, earthquake resistant, and anti-reverse connection design. Power supply, data link connection, status feedback.

Intelligent warehousing robot docking module: charging + control command issuance + position feedback synchronization. AGV bottom power supply terminal + ground charging interface module. 48 Pogo pins, made of high wear-resistant alloy material, supporting automatic mechanical docking.

Server motherboard and submodule connection: high-speed bus + auxiliary power supply + control commands, motherboard vertical pin connection + heat dissipation frame fixation. 80 Pogo pins, low latency <5ns, resistant to high-frequency signal interference.

High speed train control system: Real time control signal, power, and ground redundant contacts, with 64 or more Pogo pins. Modular control box + multi-channel pin interface + safety isolation framework. 99.9% signal integrity, redundant channels support hot standby.

Aerospace data bus docking: bus main control cabin + Pogo connection module + integrated structure of protective shell. Vibration resistant, pressure resistant, supports redundant communication, 96 Pogo pins. Power supply, MIL-STD-1553 data, ground wire isolation.

Why Choose Johoty's Pogo Pin Connectors?

Choose Johoty’s pogo pin connectors based on innovative technology, precise craftsmanship, and strong R&D capabilities. Can solve engineers’ difficult problems and meet high-end applications. Our pogo pins can provide excellent performance, and customers can also reduce costs and enhance project competitiveness.

Classifications of Pogo Pin Connectors

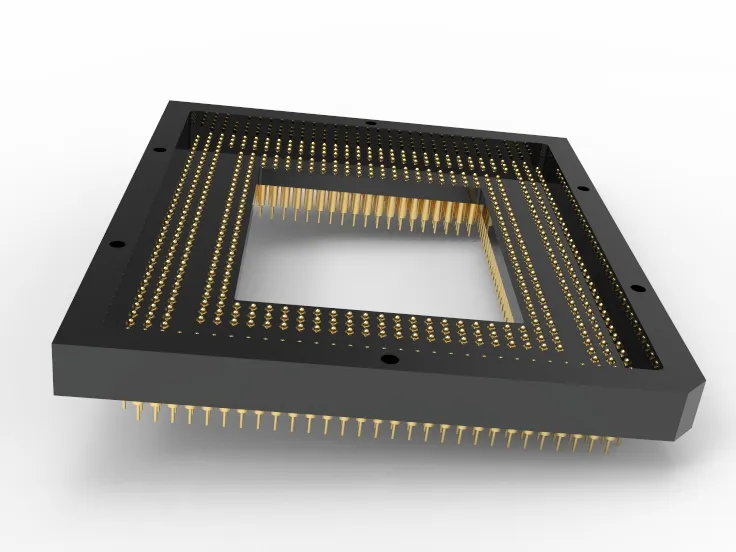

High-density arrangement type

Suitable for 1.00mm~1.27mm spacing design, supports 64pin+configuration. Used for communication modules and chip testing bases to ensure signal integrity.

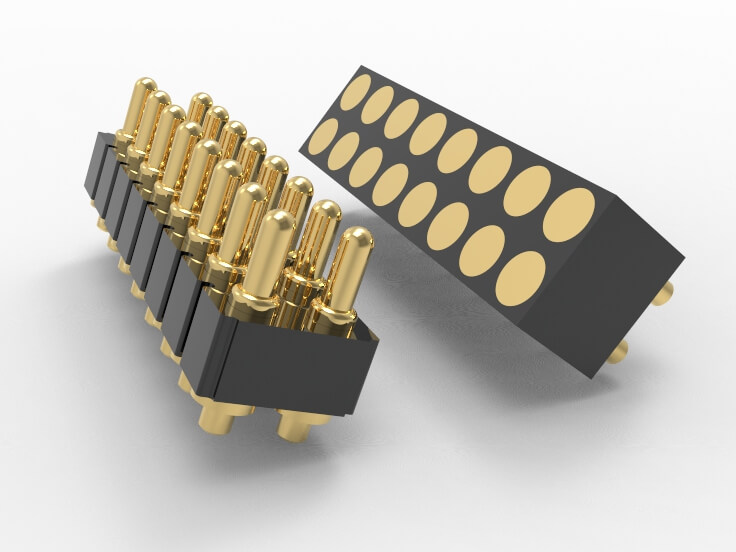

High frequency signal support type

Integrated EMI shielding cover, supporting high-speed signal transmission of>3GHz. Satisfy crosstalk and reflection control in high-speed SerDes, MIPI, and LVDS applications.

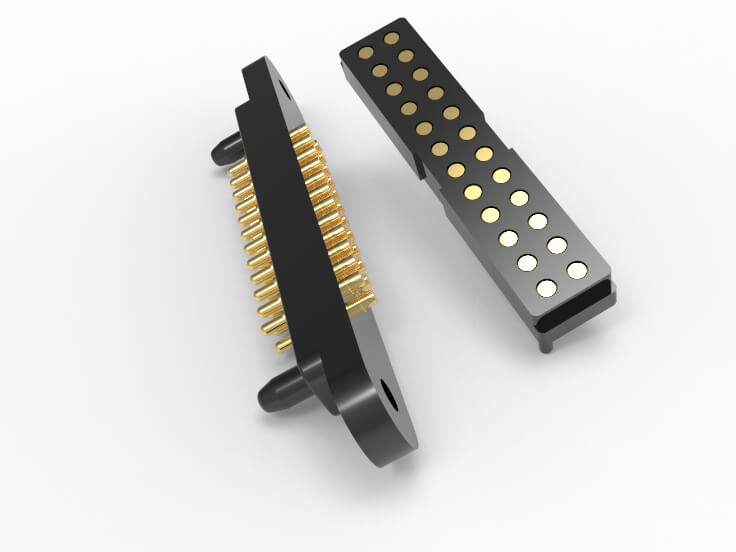

High current hybrid type

Single mode group supports signal + power mixing, such as 48 signal + 8 power configurations. The maximum single pin current is 5A, suitable for interface between battery/motor and motherboard.

Multi mode group docking type

Support customized matrix arrangement, such as 12×12 pin array. Combined with precision positioning structure, it is used for module stacking connection and multi-channel synchronization.

Challenges and Solutions of Pogo Pin Pins

Serious signal crosstalk: a common issue for customers in high-speed multi pin design. By using EMI shielding structure, crosstalk below 3GHz is effectively controlled and verified to be reduced by 30%.

Unstable contact resistance: Pogo Pin is prone to fluctuations due to frequent insertion and removal. Select ≥ 1.27μm gold-plated and precision spring needle, with stable resistance <50mΩ and a lifespan of 100,000 cycles.

Excessive alignment deviation: High density multi pin docking is prone to misalignment. Design a 0.2mm floating structure, adaptive tolerance superposition, and reliable tolerance compensation.

Overheating caused by overcurrent: High power pin load can easily lead to thermal runaway. Supports 5A continuous current, alloy shell thermal conductivity, heat rise <25℃, stable in actual testing.

Unstable stacking connection: Multi mode stacking is prone to breakage due to uneven force reception. Provide customized matrix and positioning structure, supporting high pin multi-point synchronous connection.

Pin density limitation: Traditional designs are difficult to achieve high integration. Johoty supports 1.00mm pitch arrangement, and the integration of signal and power breaks through the 100pin packaging limit.

Clients’ Feedback on Johoty’s Pogo Pin Connectors

US communication equipment hardware architect: 2.4GHz signal integrity meets expectations, EMI processing is effective, and there is no crosstalk. Used for communication testing of base station modules.

German Automotive Electronics Engineering Manager: The floating design of the connectors is reliable, compatible with robot automatic assembly, and there is no pin damage under batch tolerances.

Japanese battery management system integration engineer: Good control of 5A high current channel thermal rise, stable <25℃ within 30 minutes, no need for additional heat sinks.

Swiss medical device procurement engineer: Good consistency of conductivity resistance, with no deviation of more than ±10% in 500 sets of samples, which is conducive to high-frequency connection accuracy control.

Canadian Industrial Automation CTO: The 128Pin matrix module has been successfully integrated, and the auxiliary positioning design significantly reduces assembly errors and saves manual calibration time.

FAQ

Are pogo pin connectors reliable in the long term?

Pogo pin connectors maintain good contact performance over time through spring design and precision CNC manufacturing. Spring pressure and material selection of pogo pins can ensure that they aren’t easily worn or loose after 10,000 uses. In addition, precise dimensions and fit effectively prevent poor contact caused by pressure changes or vibration. This spring loaded connector can handle high-frequency and maintain long-term stable electrical connections in various environments. Excellent materials and design help pogo pins adapt to complex environments and avoid failure.

How much current can pogo pin connectors support?

The current carrying capacity of pogo pin connectors depends on diameter, material, and design of pogo pins. Usually, pogo pins can support currents ranging from 0.01A~50A. Larger pins and high conductivity copper alloy gold plating can support higher currents. During design, current requirements will directly affect the selected pogo pin specifications. By precisely controlling the pitch and contact force, pogo pin connectors can maintain stable electrical performance under current loads. It won’t overheat or damage due to excessive current.

How to solve poor contact of pogo pin connectors?

Poor contact is usually caused by pogo pin contamination, damage, or insufficient pressure. Firstly, ensure that surface of pogo pin pins is free of stains or oxides to prevent contamination from affecting conductivity. Secondly, check if contact pressure is appropriate during insertion and removal, as excessive or insufficient pressure can lead to poor contact. Precisely tuned pogo pin connectors can effectively avoid these issues and ensure connection stability. In addition, using more durable materials and optimized designs, including appropriate electroplating, are effective solutions. In this way, it can enhance wear resistance of contact points, thereby extending their service life.

What are pogo pin connectors life cycles?

Standard pogo pin connectors can support >10,000 insertions and removals. Johoty’s specially designed pogo pin connector can achieve 200,000 or more connections. The lifespan is closely related to raw materials, spring design, and contact force. High quality pogo pins are based on wear-resistant alloy and precise spring design, which can significantly extend their lifespan. Choosing durable pogo pins is crucial for high-frequency automation equipment or consumer electronics. In frequently, it’s used automated testing, it can also ensure stable connections and avoid performance degradation caused by repeated connections.

What is temp-range of pogo pin connectors?

Temperature resistance range of pogo pin connectors is usually between -40°C and+85°C. Johoty can achieve high temperature pogo pin connectors up to +250°C. They can maintain stable performance from extremely cold Arctic to high-temperature industrial sites. It often uses in industrial control, automobiles, etc. with large temperature differences. By selecting high-temperature alloys or special coating, this spring loaded connector can maintain high efficiency at extreme temperatures. It can effectively avoid material expansion or contraction caused by temperature changes, ensuring stable electrical connections.

How to choose pogo pin connectors that are suitable for your product?

The selection of suitable pogo pin connectors depends on the current, size, space, shape, and usage conditions of the application. Firstly, it is necessary to confirm required current carrying and pogo pin pitch. Secondly, considering the temperature, pH, and humidity of the working environment, choose materials and coating designs that are resistant to high temperatures and corrosion. Finally, pay attention to the size, stroke, contact resistance, function distribution of pogo pin to ensure that it can adapt to device’s space. After reasonable selection, the stability, aesthetics, and durability of this spring loaded connector can ensure its good performance.

Can pogo pin connectors improve signal transfer stability?

To ensure stable signal transfer, pogo pin connectors typically use highly conductive gold and copper alloys to produce pogo pins. Johoty precisely controls contact force of pogo pins for reliability of electrical contact. In addition, contact surface can be polished or coated to reduce signal loss and noise interference. During design, the pitch, contact impedance, rated current, pressure, and conductive materials of pogo pins all affect signal quality. Johoty’s pogo pin connectors can effectively avoid communication errors caused by poor contact or signal attenuation. They can ensure stable transfer of high-frequency or speed signals, at the same time, their appearance is very exquisite and beautiful.

Does appearance design of pogo pin connectors have an impact on usage?

Appearance design of pogo pin connectors has a direct impact on their performance and user experience. The shape, stroke, impedance, length, pitch, and spring design of pogo pins all determine their contact force and stability. A suitable exterior design can reduce friction during insertion and removal. The operation will be smoother, reducing wear and extending lifespan of this spring loaded connector. In high-density connectivity applications, precise design ensures that each spring loaded pin has sufficient contact surface and pressure. This can effectively prevent poor contact caused by inappropriate appearance. Therefore, optimizing exterior design is critical to improve connection stability and reliability.