Johoty’s Services of Spring Loaded Connector

Sample Spring loaded connector: Provide DFM feedback on standard drawings within 3 days and produce the first round of samples within 14 days. Support STEP,IGES source files, receive modular design with parameter calls (including elasticity,displacement curve calibration).

Quality control: Follow the IPC customized Pogo wear testing process. Spring loaded connector life test ≥10,000 times,single pin resistance change <5mΩ.

Delivery time capability: Samples can be delivered within 14 days. The delivery cycle for small batch production is 14 days (≤10Kpcs). The complex customized structure cycle is 2-3 weeks, and the production capacity schedule can be immediately locked after order confirmation.

MOQ for Spring loaded connectors: Standard needle MOQ=3,000 pcs,batch, minimum order for customized structures is 3,000 pcs. Allow single project samples to be placed as needed.

Logistics method: DHL, FedEx Priority service is used by default for sample and small batch stages. Large quantities can be selected from UPS or designated freight forwarders.

Qualification of liaison personnel: The technical liaison team is composed of structural, process, project third line engineers, with an average industry experience of over 10 years. Ability to interpret cross-language drawings and familiarity with third-party certifications such as UL, CE.

Design feedback efficiency: After the customer submits the structural model, a feasibility report will be issued within 48 hours. The content covers: verification of pogo pin arrangement density, recommendations for current distribution, and analysis of compatibility between female and male sockets.

Elasticity and displacement curve optimization: Support customers to provide Z-direction stacking load, displacement tolerance, and reverse spring selection solutions. Curve control error <±5%, with ≥3 calibration points.

Structural compatibility collaboration: Supports multi-layer PCBs, irregular panels, hot swappable sockets, structural height enhancement, and magnetic assisted assembly. Output 3D interference simulation images to avoid rework during the trial production period.

Customized support range: Pin count ≥14 pins, pitch can be as low as 1.00mm, pogo pin length difference ±0.05mm. Supports signal + power mixed fabric, plunger tip customization flat, flat head, spherical, double head, etc.

Risk response: One project manager shall be assigned to follow up on all sample or drawing projects and record changes throughout the process. If quick revision is required, it supports re sampling within 7 days.

Verification cooperation: Can cooperate with customer EMI testing, heat rise testing, aging verification, and provide matching wiring harnesses with environmental parameters. Elastic compensation components and PCB plug-in solutions can shorten the system verification cycle by ≥30%.

Click: More Catalog

Performance Test of Spring Loaded Connector

Contact resistance detection: When the single pin contact resistance is ≤50mΩ under full load, the four wire method is used for testing. Randomly sample 30 samples, with data variance ≤1.5mΩ.

Verification of elastic stroke curve: The measured elastic displacement curve of the full stroke is compared with the theoretical curve, with a deviation of ≤±5%. Each batch is recorded with sample lines for easy archiving and comparison of the project.

Plug life test: After 10,000 mechanical plug and unplug cycles, the resistance drift is controlled within ±10%. Using an automatic plugging platform to simulate actual usage frequency (adjustable from 0.5Hz to 2Hz).

Constant temperature and humidity aging test: Resistance deviation<3% after continuous exposure for 168 hours in an environment of 85°C and 85% RH. Spring loaded connectors are required for outdoor, medical, industrial, and other high humidity and high temperature applications.

Salt spray corrosion test: 96 hour neutral salt spray test. The thickness of the gold plating layer is ≥1.0μm without peeling or oxidation spots, and the contact performance of the metal surface does not decrease.

High and low temperature cycling test: 20 cycles at -40°C~+125°C, with no cracks or plastic deformation in the spring loaded connector structure.

Transient current impulse test: 1A~3A pulse current is loaded for 10ms × 1,000 times, and there is no ablation or blackening in the contact area. Support mixed signal and power.

Anti vibration and impact test: Conduct 10Hz~2,000Hz sweep frequency test and 50g impact test in the XYZ three-axis direction. The structure is tightly locked without looseness, and the pogo pins rebound without hysteresis.

Consistency testing of plating thickness: XRF equipment detects that the thickness of the gold plating layer is controlled within 1.5 μ m ± 0.03 μ m, with oxidation resistance and low resistance performance.

Voltage withstand and insulation testing: Pin to pin voltage withstand ≥500VDC, insulation resistance >1,000MΩ. Spring loaded connector is used for multi-channel high-speed signal isolation and mixed wiring.

Measurement of PIN coaxiality and height difference: 100% of the shipped samples are confirmed to have pin spacing through CCD, with coaxiality of ≤±0.02mm and height difference of ≤±0.05mm. Spring loaded connector iscompatible with SMT or precision docking.

Residual stress and plastic deformation detection: Conduct thermal stress analysis and infrared thermal imaging verification on precision plastic structures and pogo pins. There is no risk of plastic displacement during the assembly process.

Click: More Catalog

Customization of Spring Loaded Connector

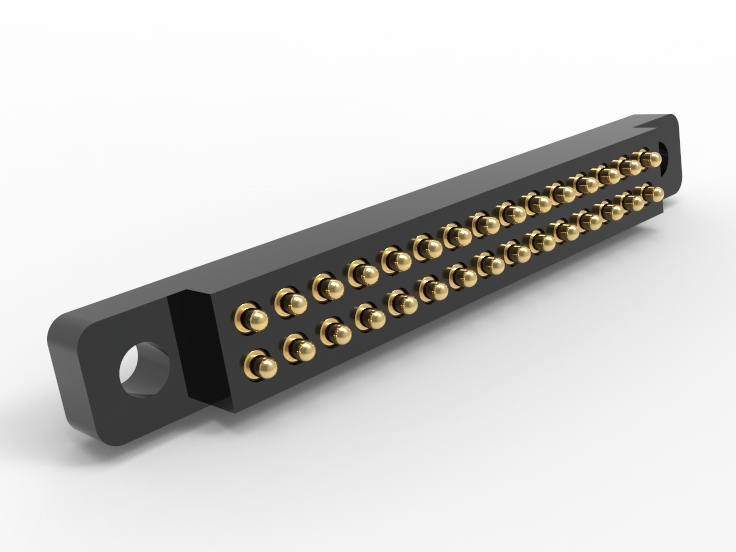

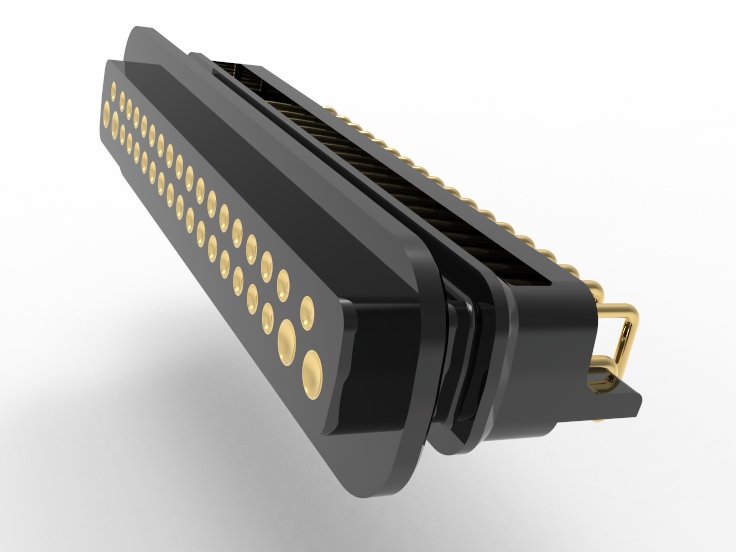

Wide range of pin customization: supports structure customization from 2 pins to 4,000 pins. Layout options include single row, double row, multi row, matrix, and high-density modular design.

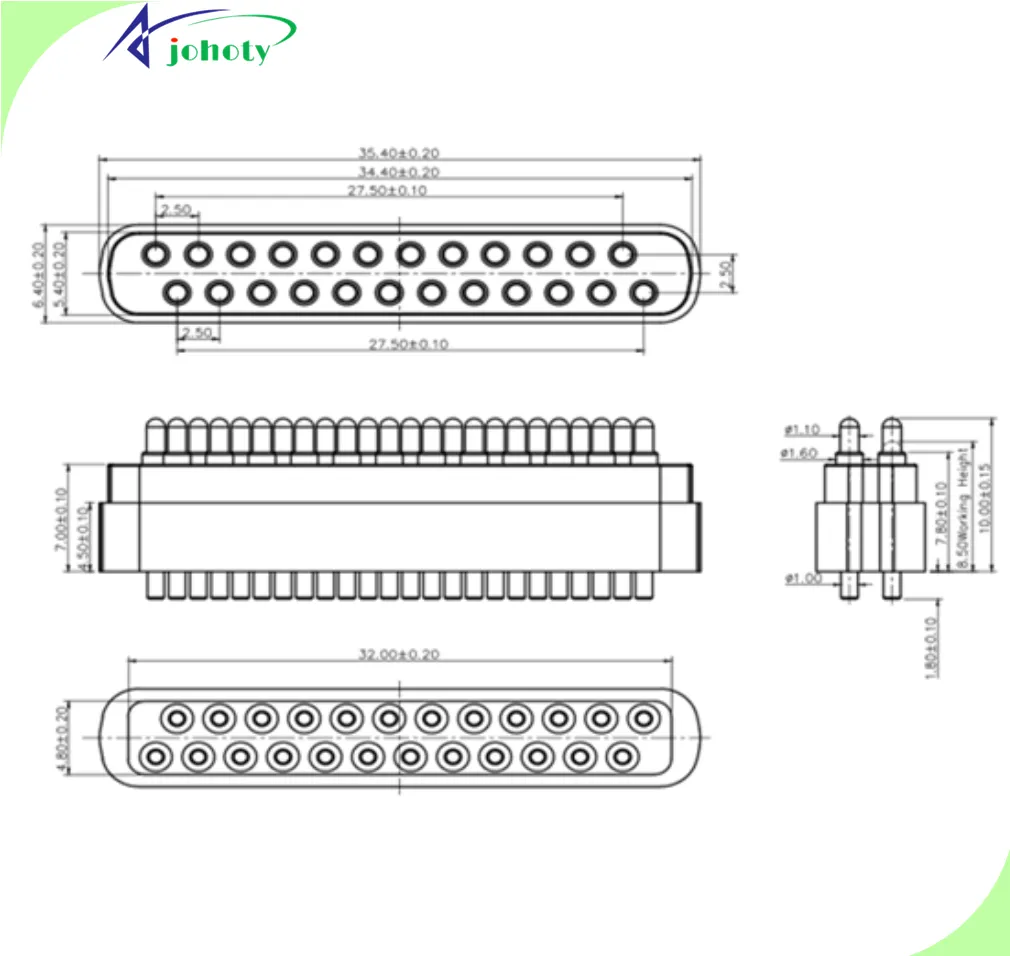

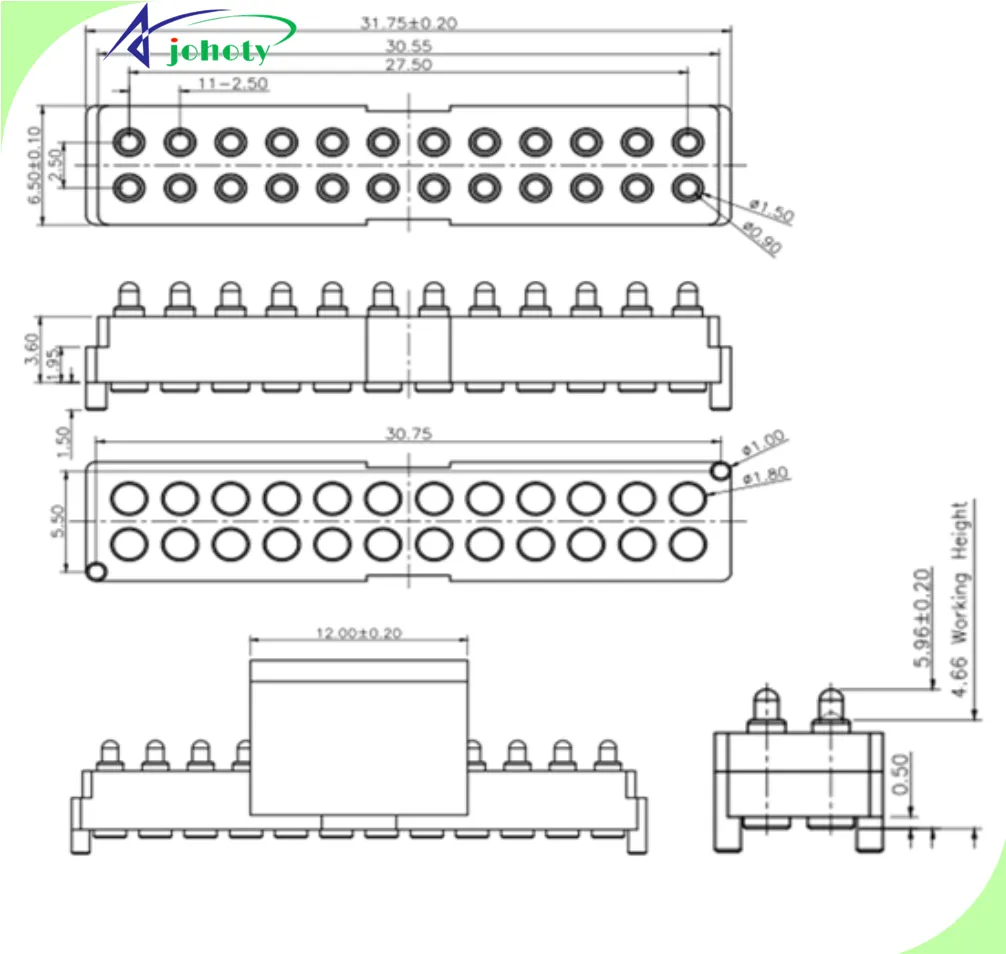

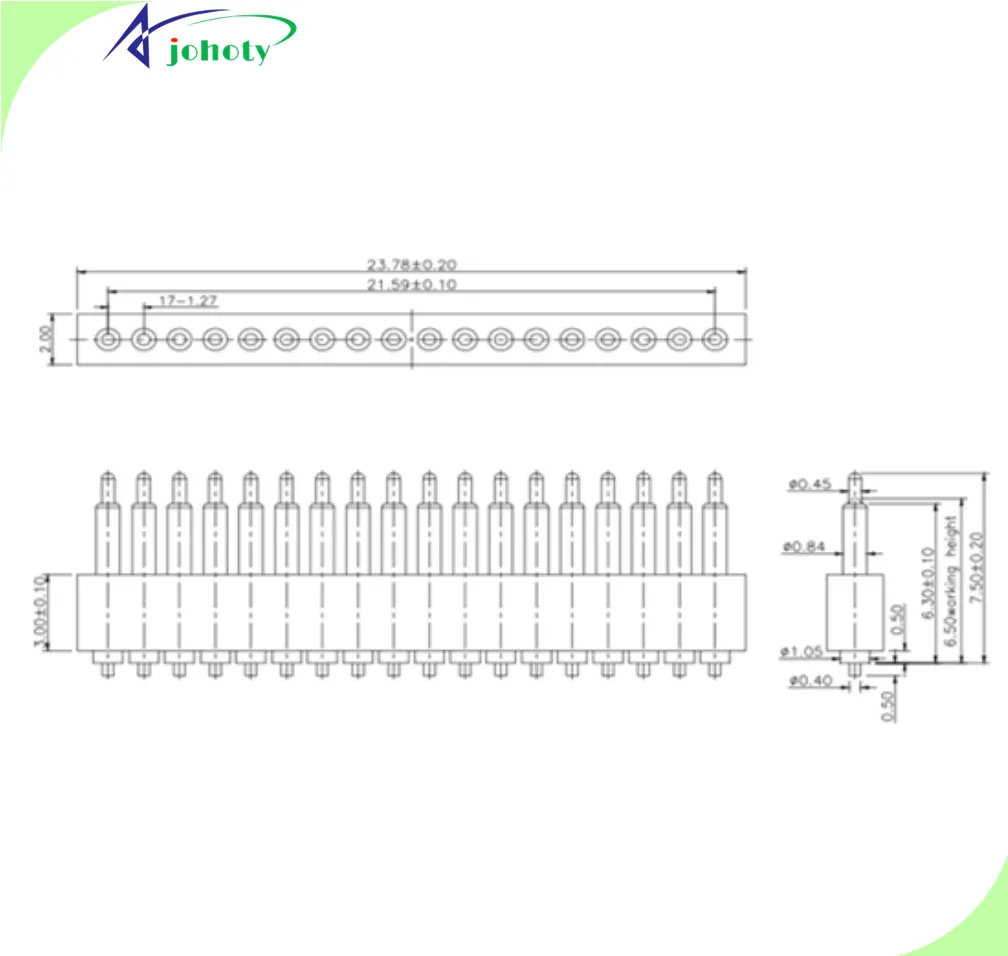

Precise control of minimum pin spacing: The minimum pitch supports 1.00mm, and the center distance tolerance is controlled to be ≤±0.02mm. Spring loaded connectors connect multi-layer stacking and precision docking.

Integrated design of mixed signal and power pin: 0.3A signal pin and 10A high current pin can be combined within the Spring loaded connector. Equipped with insulation partitions and built-in EMC shielding design.

Adjustable elastic stroke in both directions: single needle elastic force can be customized according to needs within the range of 0.05N~3.5N. Support compression stroke of 3.50mm and different contact surface and load requirements.

Flexible design topper tip: Available in spherical, flat head, flat head, oblique cut, bi-directional plunger, probe type and other head shapes. Cooperate with different PCB solder pads or gold-plated contact structures.

Coating thickness can be configured as needed: The thickness of the gold coating on the contact surface can be customized between 0.1μm and 5μm. Support Ni-P alloy bottom plating to enhance corrosion resistance, and provide XRF thickness verification report.

Height limiting structure and floating design: Supports floating pogo pin design and limit structure design, compensating for ± 0.20mm assembly height tolerance. Spring loaded connector is commonly used for automated plugging and module assembly.

Reconfigurable Spring loaded connector profile and port shape: The shape of the male and female seats can be oriented and bent according to the spatial layout of the structure, straight out or side out. Implement stacking, rotation, and embedded installation as requested by customers.

Plastic and insulation structures support collaborative development: housing materials such as high-temperature LCP, PPS, or PA66 are optional. Meet structural constraints such as SMT furnace passing, board to board locking, and buckle positioning.

Collaborative design with clients for mechanical, thermal, and electrical parameters: supports providing simulation input files. Perform mechanical loading, thermal rise simulation, and electrical path optimization.

Multiple packaging and assembly forms supported: Tray, Reel, Tube, vacuum tray and other packaging supported. Suitable for automatic mounting machines, clamping equipment, or manual assembly production lines.

Rapid development of tooling molds and fixtures: output assembly fixtures for customized structures, and plug and unplug tooling. Design sketch of calibration platform to shorten the manpower investment in the verification phase.

Click: More Catalog

FAQ

Does spring loaded connector support mixed power and signal pin layout? Support, different electrical channels ranging from 0.3A to 3A can be configured within the Spring loaded connector. Interference between signal lines is less than 50mV, based on the 1GHz signal frequency band.

What are the minimum achievable pin pitch and maximum supported pin count for a spring loaded connector? The minimum pitch is 1.00mm, and max 4,000 pins can be arranged (double row, multi row, array). The contact resistance is stably controlled at ≤10mΩ.

Is spring loaded connector suitable for high-speed plugging or dynamic load conditions? Adaptation, single pin supports high-frequency plugging and unplugging for over 10,000 times, with a rebound speed of less than 3ms. It is suitable for dynamic operation of robot grippers and vehicle mounted modules.

Does spring loaded connector support docking with irregular structures or finite space assemblies? Support, can provide curved needle, short needle, and floating end designs according to customer structure. The length difference of Pogo pin is controlled within ± 0.05mm, and the minimum assembly space is <5mm thickness.

What is the customization cycle and minimum order quantity for spring loaded connector? Standard parts should be sampled within 7 days, and non-standard structures should be sampled within 15 days. MOQ starts at 3,000 pcs, and the complex structure of spring loaded connector will be evaluated and confirmed by the project manager.