Johoty’s Services of Magnetic Pogo Pin Connector

Prototype magnetic pogo pin connector: standardized process + parallel technical interface.

Mold sampling cycle: produce drawings within 3 days and complete CNC structural component initial sample molding within 5 days.

Electrical performance verification method: Provide a 0.5A~50A current carrying capacity + dynamic contact resistance <50m Ω + magnetic retention force measurement report.

Communication cooperation mechanism: synchronized approval of structural and functional diagrams, engineers coordinate design documents (SolidWorks, STP).

Data synchronization method: Provide impedance, elasticity, and failure life (>100,000 cycles) curve graphs for each iteration.

Quality control: full process inspection + key parameter retention.

Inspection standard: The contact resistance of each piece is 100% tested, and it is considered qualified if it is below 50mΩ (measured average: 46.2~47.4mΩ).

Plating control: default 0.5 μ m gold plating, salt spray 96H, optional Ni lower layer (compliant with RoHS, REACH).

Pogo pin consistency: pogo pin elasticity fluctuation ± 0.15N.

Appearance tolerance standard: The flatness of the metal end face is less than 0.02mm, without any sharp edges, oxidation, or finger marks.

Delivery time of magnetic pogo pin connector: Dual-dimensional inversion of structure and function.

Sample delivery time: 2 weeks for sample production, standard ≤14 days (including customized strength values and minor revisions).

Production lead time: 2-3 deliveries (≤5,000pcs) after placing an order for standard models, including assembly and testing.

Delivery time for customized parts: Provide customized sample production Gantt chart, visualize all key nodes before customer approval.

MOQ for magnetic pogo pin connector: Set according to customer application requirements and compatible with engineering verification requirements.

Standard sampling MOQ: Starting from 5 sets, including packaging and testing reports.

Small batch: Starting from 100 pcs, it can be put into production and supports pilot or validation line use.

Standard model customers: Enjoy bulk unit price discount starting from 3,000 pcs (average unit price reduced by 25%).

Logistics method: precision parts dedicated line + status visible.

Sample: FedEx Priority, UPS Express Saver, can reach major cities in Europe and America within 72 hours.

Official order: DHL, FedEx + SF international route combination. Normally applicable FOB, supports tariff payment, DDU, DDP mode.

Packaging: Customized EVA shock-absorbing groove box + moisture-proof sealed bag, with labels containing batch, inspection, and traceability information.

Contact person qualification: dual background of technology and supply, ensuring closed-loop communication.

Engineering background: The docking person is a structural engineer with a background in magnetic pogo pin connectors and SMT technology.

English proficiency: seamless communication through technical and business bilingual email.

Time zone response: Online from 8:00 to 24:00 Beijing time, 72% of customer issues are resolved within 6 hours.

Background of the case: Previously led service clients including Tesla, McMurtry Automotive, TUBITAK, Shivey Bros, SAFRAN, etc.

Click: More Catalog

Performance Test of Magnetic Pogo Pin Connector

Contact resistance stability testing: Under a working current of 5A, the contact resistance is ≤ 30mΩ, and the resistance value changes by <5mΩ after 10,000 insertion cycles. The conductivity stability is maintained under high-frequency mechanical action.

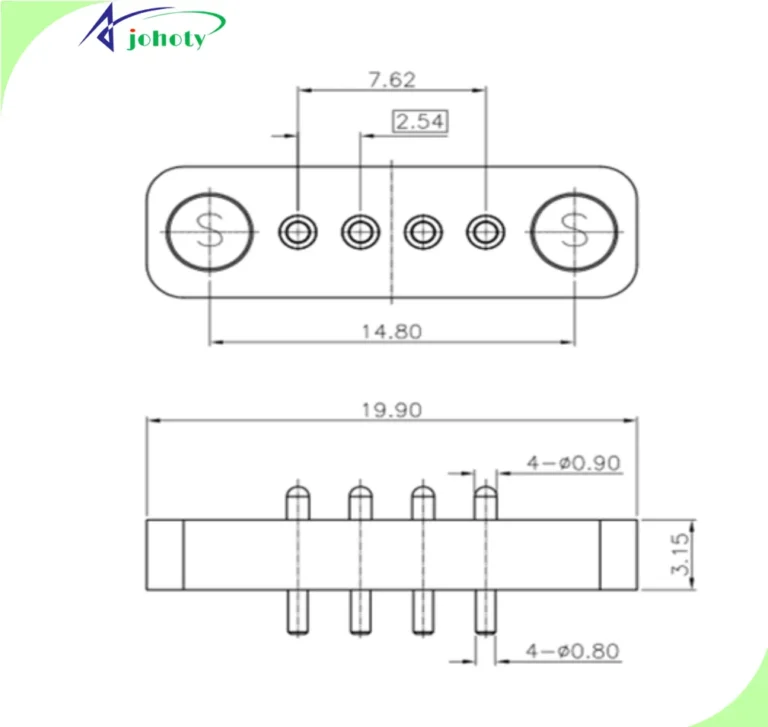

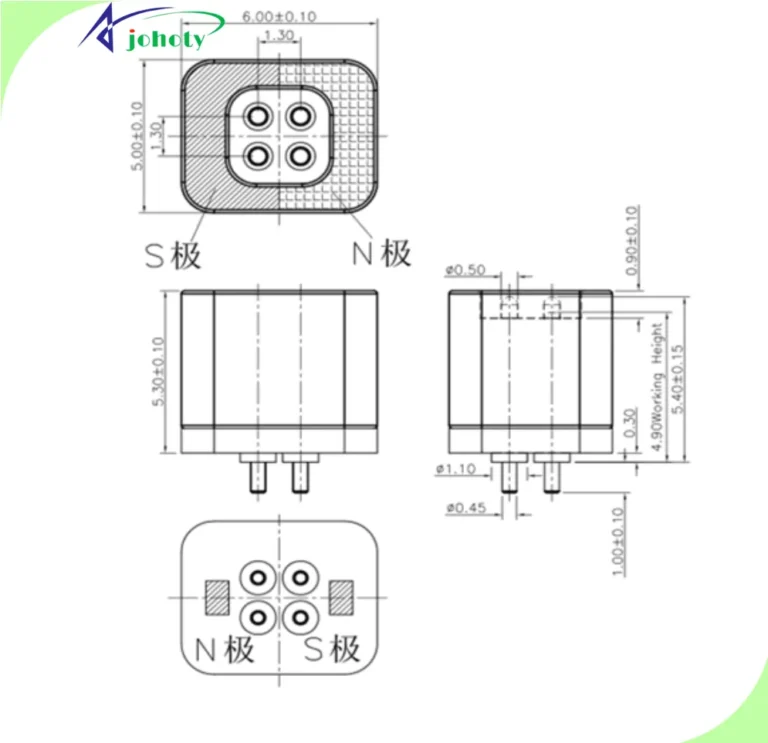

Magnetic positioning consistency test: 4-Pin magnetic suction offset ≤0.05mm, omnidirectional suction average time <0.2 seconds. High precision alignment reduces mechanical error tolerance.

Temperature rise test: Under rated 5A full load current, the temperature rise is ≤20℃ after continuous power on for 60 minutes. The magnetic pogo pin connector operates continuously with thermal stability and no local overheating.

Corrosion salt spray test: After 96 hours of neutral salt spray test, the gold plating layer is intact without peeling, and the contact resistance change is ≤1mΩ. The magnetic pogo pin connector can reliably contact in the exposed environment for a long time.

Mechanical strength destructive testing: The maximum tensile strength of a single pogo pin is ≥0.8kg, and the lateral bending resistance is ≥0.3kg. The magnetic pogo pin connector has strong mechanical impact under repeated insertion and complex applications.

Dynamic high-frequency signal integrity test: At a transmission frequency of 1GHz, the reflection loss of socket S11 is less than -20dB, and there is no significant echo distortion. High speed data synchronization and complete high-speed signal chain.

Insulation withstand voltage test: The withstand voltage between pogo pins is ≥500V DC, and the leakage current is ≤1μA. The magnetic pogo pin connector has high insulation safety margin in small high-density connections.

Instantaneous anti-interference ability: Under vibration acceleration of 10G, continuous conduction without disconnection phenomenon, contact reliability >99.99%.

Click: More Catalog

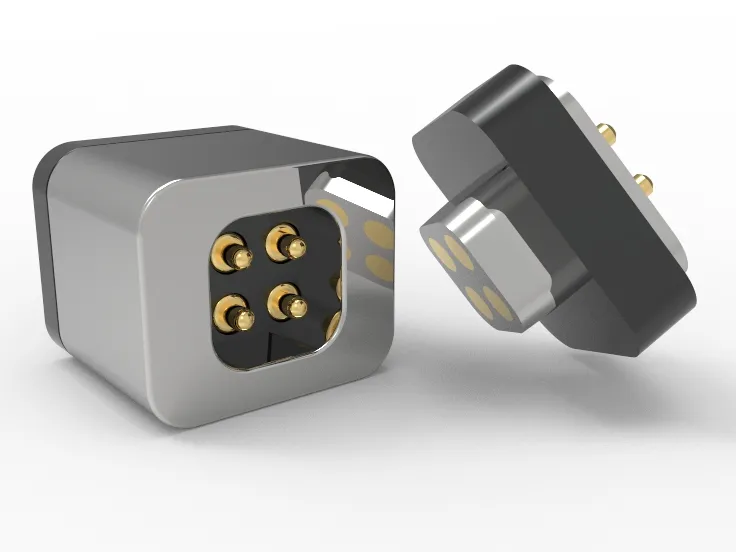

Customization of Magnetic Pogo Pin Connector

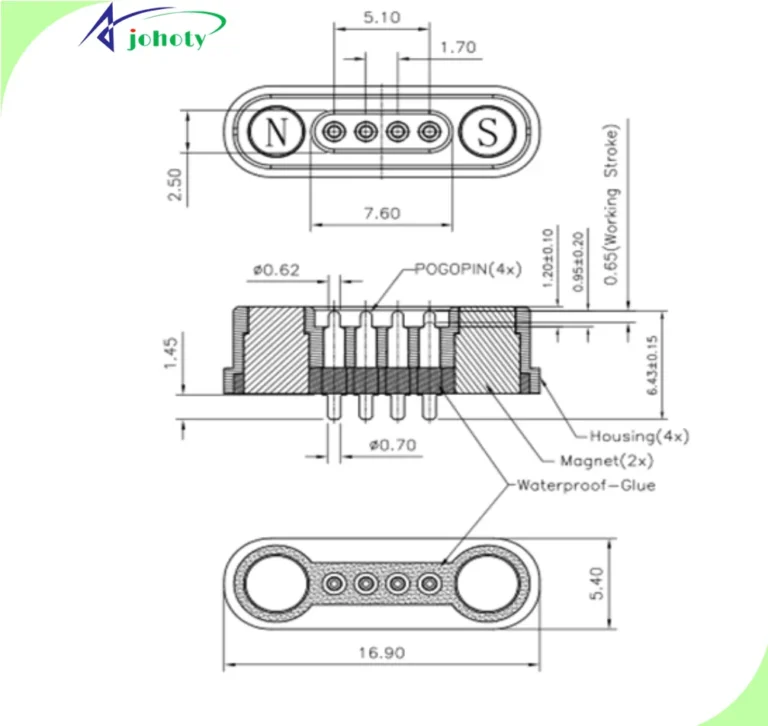

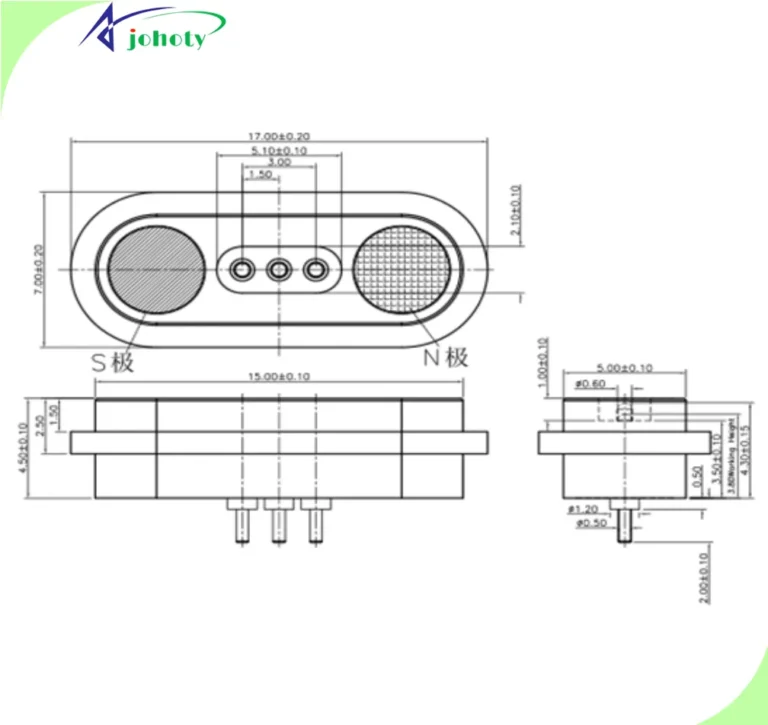

Adjustable range of pin spacing: 1.00mm to 2.54mm or larger, with a step accuracy of ± 0.01mm. The magnetic pogo pin connector supports high-density miniaturization layout and different packaging space limitations.

Customization of single pin current carrying capacity: 0.3A to 50A, designed to match the contact according to the load current characteristics of the application end. The magnetic pogo pin connector can control power consumption and balance heating.

Customized stroke capability: stroke range of 0.10mm to 4.00mm, adjustable rebound force range of 5gf to 300gf. Supports different pressing stroke requirements, optimizes contact force and tactile sensation.

Adjustable magnetic attraction design: The common adsorption force range is 4N to 8N, and the precision of the anti misoperation design is ≤0.1N. The adsorption retention force and the risk of accidental contact are controlled under different installation postures.

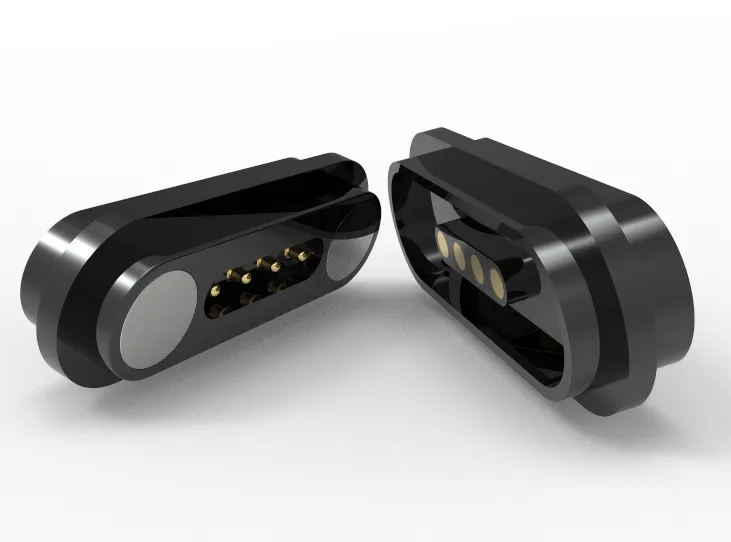

Optional plating process: Standard gold plating thickness of 0.1 μ m to 5 μ m, supporting gold nickel palladium platinum gold multi-layer composite coating. The magnetic pogo pin connector can meet different corrosion resistance levels and plug-in life.

Terminal packaging compatibility: Supports SMT, PTH, FPC crimping, wire harness forming, solder up and other terminal connections. Can flexibly match different production line automation and assembly processes.

Dimensional tolerance control: The overall component dimensional tolerance control is ± 0.02mm. It ensures the consistency of the magnetic fit surface and pogo pin alignment, reducing the accumulation of assembly errors.

Waterproof level customization: The magnetic pogo pin connector supports IP67 or IP68 sealing structure. Used outdoors for sweat and dust prevention.

High temperature and high humidity aging adaptability: After 1,000 hours of aging at 85℃/85% RH, the contact resistance change is ≤2mΩ. The magnetic pogo pin connector can be used with high reliability.

Dynamic mechanical fatigue customization: Supports up to 50,000 mechanical life verifications, with stability changes in insertion and extraction force <10%. Johoty has extensive experience in designing high-frequency operating terminals.

Click: More Catalog

FAQ

Is the stability of magnetic pogo pin connector reliable in high-speed insertion and vibration environments?

Magnetic suction force is usually designed in 4N~8N, combined with precision guiding structures. Small magnetic connector below 4pin maintain >99.95% conductivity reliability after >10,000 connection cycles. Dynamic vibration experiment (10Hz-500Hz, 1.5mm amplitude, 3-axis 24-hour) showed no contact abnormalities.

Is the contact resistance of magnetic pogo pin connector stable over long-term use?

Adopting dual convex head design and high hardness high-purity gold electroplating, initial contact resistance is ≤50mΩ. After 10,000 insertions, drift is ≤±5mΩ. It complies with IEC and MIL-STD.

Can current/voltage of magnetic pogo pin connector cover high-current fast charging and data synchronization?

Johoty’s specially designed single pogo pin has continuous current of 50A (charging) and 500Mbps (data synchronization). Magnetic pogo pin connector complies with USB 2.0/3.0. Short time current surge test can withstand 80A/3 seconds. Portable terminal, wearable, medical small equipment have high efficiency and fast charging without any problems.

What is mechanical life and wear loss of magnetic pogo pin connector?

Under stroke elasticity of 50gf~80gf, spring has ≥3,0000 complete stroke cycles. Friction surface is electroplated with ≥0.5μm hard gold, average wear per 10,000 times is <0.02μm. Magnetic pogo pin connector has highly predictable wear and tear, allowing clients to design maintenance cycles for entire machine.

Can safety and environmental adaptability of magnetic pogo pin connector meet European and American terminal regulations?

All core materials comply with RoHS 3.0, REACH SVHC, UL94V-0 flammability certification. Working temperature -40°C~+85°C, 72 hour salt spray corrosion test and wet heat aging verification. Johoty’s magnetic pogo pin connector meets design standards for industrial, medical, and consumer products in Europe and America.