Johoty’s Services of 6 Pin Pogo Connector

Sample 6 pin pogo connector: supports standard engineering drawing confirmation within 3 days and sample production within 2 weeks. The response cycle for engineering changes is less than 24 hours, and the design traceability is recorded throughout the entire process.

Quality control: The process is based on ISO 9001, and key pogo pins are monitored using online 100% elasticity curves and contact impedance.

Sample consistency verification: Complete batch Cpk data is attached upon sample release. Pin high consistency ±0.02mm, elasticity deviation ≤±5gf, fully inspected before leaving the factory.

Batch delivery time: Standardized mature process delivery takes 10-14 working days. The customized complex specifications will be completed within 14 to 21 working days without any unnecessary scheduling or waiting.

Minimum order quantity (MOQ): 3000pcs minimum order, ensuring low-cost and fast verification of new projects.

Core raw material: High precision turning brass HBi59, coated with 0.5μm hard gold (Ni/Au), with a coating uniformity deviation of ≤±0.02μm.

Logistics mode: Supports UPS/DHL/FedEx global first-line channels. Standard samples can be shipped by air to European and American customer laboratories within 5-8 days, and commercial batches support DDP and DAP customs clearance services.

After sales guarantee terms: The batch number of the entire batch can be traced, and the after-sales technical response should be in place within ≤12 hours. Engineer remote real-time parallel technology intervention.

Qualification requirements for liaison personnel: Directly responsible for engineers with more than 10 years of experience in 6 pin pogo connector projects. Have experience in integrating product and system aspects.

R&D technical capability: Support analysis of micro high-precision mechanisms with pitch ≤2.54mm. And pogo pin simulation, life fatigue analysis, and dynamic contact stability modeling.

Multi industry standard coverage: compliant with IPC, IEC mechanical and electrical standards, supporting medical ISO 13485. MIL-STD for military use and AEC-Q200 specification import for vehicles.

Click: More Catalog

Performance Test of 6 Pin Pogo Connector

Contact impedance stability: The contact resistance is within 50mΩ, and the resistance fluctuation throughout the entire stroke range does not exceed 10 mΩ. 100% detection is carried out by pogo pin, and the curve traceability is recorded.

Consistency of elasticity curve: Pin elasticity full stroke dynamic monitoring, initial elasticity consistency deviation ≤±3gf. Dynamic offset rate <2% (10,000 cycles).

Life fatigue test: standard 10,000 mechanical insertion and extraction tests, dynamic contact resistance drift rate <3%. Maintain effective contact force closed-loop monitoring throughout the entire journey.

Wear resistance of coating: After ASTM B611 standard wear resistance test, the surface integrity maintenance rate of the 5μm gold plating layer is >98%.

High and low temperature impact test: According to IEC standards, the contact resistance deviation is less than 1 mΩafter 100 cycles of cold and hot impact from -55℃ to +125℃.

Vibration and shock stability: IEC and MIL-STD vibration and shock tests, with no false connections or disconnections under high-frequency vibrations of 6 degrees of freedom.

Salt spray corrosion resistance: Passed ASTM B117 continuous 48 hour salt spray test. The surface has no cracks or peeling, and the electrical stability retention rate is >99%.

Protection level verification: IP67 water seal test. There is no risk of short circuit caused by water vapor erosion within 24 hours in the dynamic plugging state.

Maintain force consistency: Insertion force deviation is≤±10%, and pull-out force stability deviation is ≤±8%. Compliant with long-term consistency of high-frequency docking modules.

High frequency signal integrity: S-parameter testing under signal conditions <1GHz. Insertion loss is <-1.2dB, and Return loss is better than -20dB.

Insulation resistance performance: Insulation resistance ≥1,000 MΩunder normal temperature and humidity conditions. Maintain ≥500 MΩunder harsh high humidity conditions (95% RH).

Short circuit and withstand voltage performance: In the DC 500V withstand voltage test, there is no dielectric breakdown or leakage. The pressure tolerance margin is more than 20% better than conventional designs.

Click: More Catalog

Customization of 6 Pin Pogo Connector

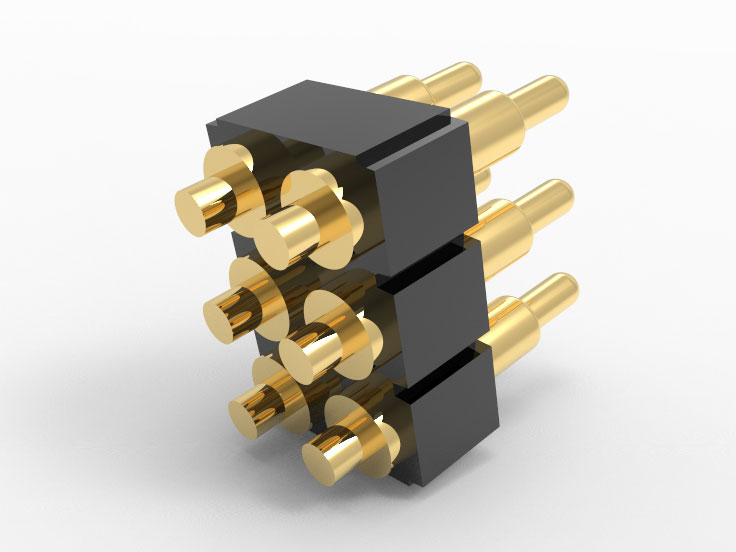

Extreme Pitch Customization Capability: Supports minimum spacing up to 1.00 mm, with a tolerance control of ± 0.02 mm for single pogo pin alignment accuracy. Meet the demand for ultra-high density stacking connections.

Customized stroke and elasticity curve: The effective stroke range can be customized from 0.10 to 3.50 mm. The elasticity curve design supports controllable elasticity range of 5gf to 350gf for a single pogo pin.

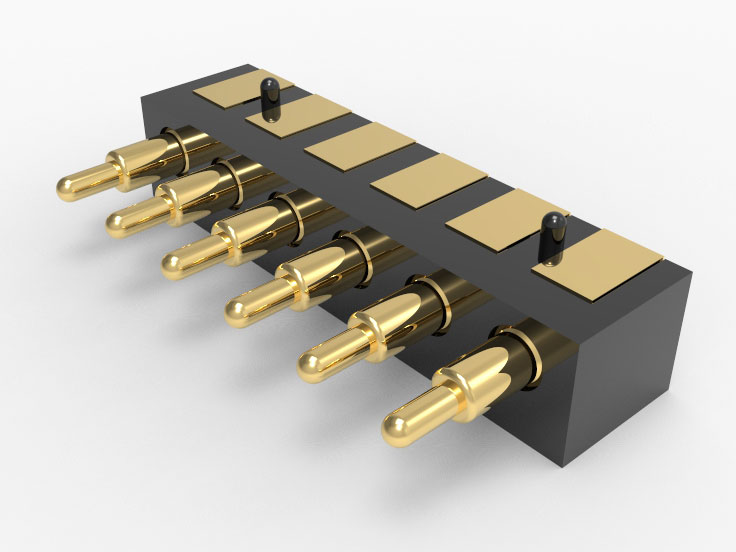

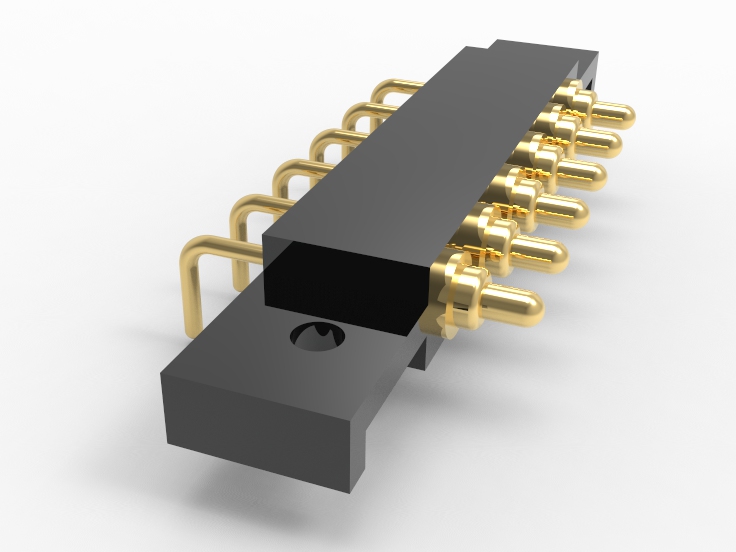

Customized conductive end structure: supports flat, spherical, and cup-shaped designs, ball, Claw head structure. Adapt to different surface contact characteristics and sliding conditions.

Material system customization: High precision brass HBi59, beryllium copper C17200, stainless steel 316L, etc. can be selected to match the target working environment.

Customization of Coating System: Supports Ni-Au Hard Gold, Ni-Pt Platinum, and Ni-Pd Alloy Multi Coating Systems. The coating thickness can be selected from 0.5 to 5.0μm to meet the requirements of high wear resistance and high-frequency transmission.

Mechanical alignment structure customization: can integrate center guide column, chamfer positioning, limit shoulder, self-cleaning sliding end design. Improve the stability of blind insertion.

Terminal socket matching design: Provide a complete matching socket structure design. The mother seat supports multi contact redundancy, reducing the risk of long-term contact failure.

Customized installation and fixed structure: supports SMT mounting, PCB perforation soldering, solder up wire bonding, riggh angle surface mounting, and more.

Customized temperature control and protection design: high and low temperature impact, IP67 protection, long-term stability in salt spray environment. Support customized outdoor, medical, and marine equipment.

Multi Pin Expansion Capability: Supports modular arrangement design from 6 pogo pins to 598 pins. Flexible layout, supporting curved, stepped, and matrix arrangements.

Dynamic high-frequency collaborative customization: Coordinated optimization with EMI shielding and high-speed transmission characteristics. Support digital high-speed signal integrity design below 10Gbps.

Rapid engineering development: DFM collaborative design docking provides feasibility assessment drawings within 48 hours. The sampling cycle standard is to complete the shipment within 14 days.

Click: More Catalog

FAQ

Is contact reliability of this 6 pin pogo connector good under dynamic plugging? After 100,000 cycles of standard testing, the contact resistance drift is less than 3mΩ. The dynamic plugging frequency can reach 60 times per minute without virtual connections.

Can the elasticity and stroke of the 6 pin pogo connector be customized to fit the mechanical space of my product? Of course, it supports customization within the effective range of 0.10 to 5.00 mm. The elasticity of a single pogo pin can be precisely configured from 5gf to 150gf. Meet the dynamic docking requirements of robotic arms, rotating mechanisms, etc.

Can the coating thickness and wear resistance life of the 6-pin pogo connector meet long-term operation requirements? The gold plating thickness can be selected from 0.5μm to 5μm, which meets the ASTM B611 abrasion resistance test. The surface integrity retention rate after 20,000 frictions is greater than 98%.

Does long-term stability of 6 pin pogo connector under extreme temperature, vibration shock, and salt spray have data validation? Has passed IEC high and low temperature impact (-55 to+125 degrees), IEC vibration, ASTM B117 salt spray 96 hour test, with no contact failure.

Does 6 pin pogo connector have standardized quality traceability? ISO 9001, all batches of shipments are accompanied by complete material batch records. 6 pin pogo connector contact impedance dynamic curve, fatigue life data, traceable throughout the entire process.