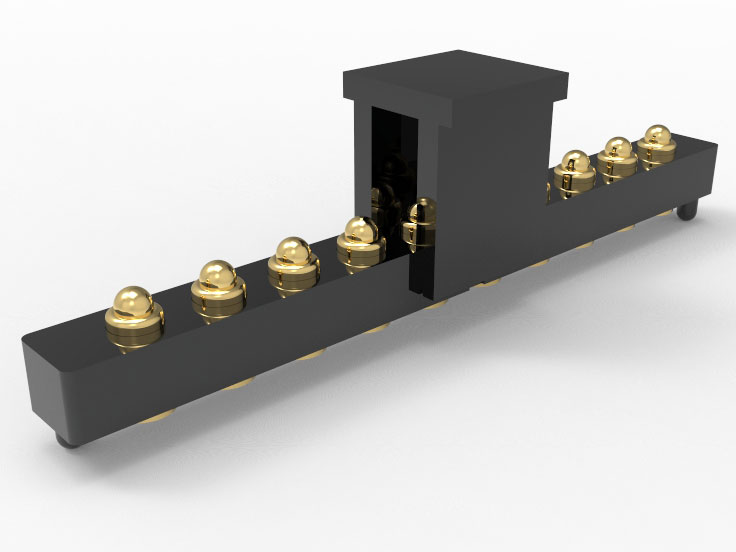

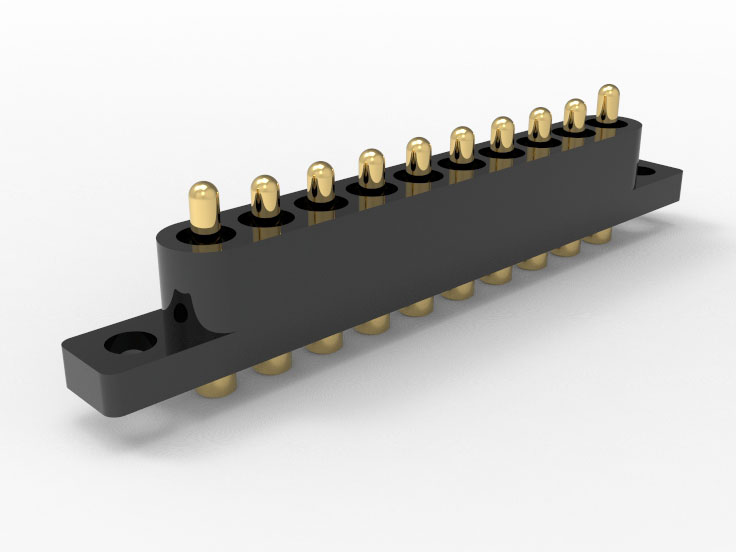

Johoty’s Services of 10 Pin Electrical Connector

Sample 10 pin electrical connector: Engineering straight through NPI quick sampling, 1:1 review of exclusive design engineering drawings. The preliminary DFM review report will be output within 48 hours, and the first sample will be completed within 2 weeks.

Quality standard: The entire process complies with ISO 9001, and the thickness standard for the pogo pin hard gold plating layer is ≥0.5μm. Contact resistance ≤30mΩ, plug-in life ≥10,000 times. Salt spray test for 24, 48, 72, 96 or 120 hours without corrosion.

Delivery time: 14 days for standard customized project sampling, 2-3 weeks for mass production after design confirmation. Having a continuous production capacity of more than 365 days a year, with high fluctuation delivery stability.

10 pin electrical connector MOQ: Small batch verification is 5 sets. After confirming that the sample is normal, the MOQ is 3,000 sets. Follow the rhythm of product design verification throughout the process, without the need for one-time large-scale financial pressure.

Logistics methods: Supports EXW, FOB, DAP, DDP. Priority will be given to UPS Express and FedEx Priority for door-to-door delivery of engineering samples in European and American regions. Full process insurance visualized logistics node monitoring, standard voyage arrival within 5-8 days.

Core technical guarantee: The foolproof mechanical limit design can tolerate ± 1.2mm insertion and extraction errors. IP67 fully sealed type suitable for outdoor, military, and medical complex applications. Pogo pins dynamically compensate for micro vibration impact, with high dynamic electrical contact stability >99.98%.

Design intervention depth: Support joint design of pin layout, current path, and signal integrity SI simulation from the customer’s original application. Anticipate long-term risks such as EMI, contact resistance, thermal drift, and stress fatigue in advance.

Certification capability: All raw materials and critical components comply with RoHS and REACH. Mass production can support customers to trace the complete third-party laboratory testing documents for all projects.

Failure mechanism plan: Establish a full process FMEA failure mode analysis, conduct 100% full inspection of the first article, and monitor the process SPC in real-time. Long term shipment batch internal control defect rate ≤30PPM.

Secondary development capability: We can provide long-term version iteration support and adapt to customers’ new platform iteration projects. Long term stable and continuous supply of 10 pin electrical connector.

Risk control system: equipped with Level 2 safety stock locking for critical raw material supply chain, ensuring long-term stability of critical supply. Adapt to the multi-source security delivery needs of large European and American manufacturers.

Click: More Catalog

Performance Test of 10 Pin Electrical Connector

Plug life test: After 10,000 cycles, the contact resistance drift is ≤ 10mΩ, and the electrical on-off stability is >99.98%.

Contact resistance stability test: The contact resistance is 50mΩ, and the dynamic drift control in the full temperature range is within ± 5mΩ. Application in high-frequency dynamic vibration environment.

Salt spray corrosion test: After 48 hours of neutral salt spray test, there was no needle corrosion and the coating peeled off. Abnormal drift of contact resistance, verifying long-term sealing performance in IP67 environment.

High and low temperature cycling test: Temperature cycling from minus 55℃ to 125℃. Complete 500 cycles without cracks, detachment, or contact performance failure. Verify long-term reliability under extreme temperature conditions.

Dynamic mechanical impact test: 10G acceleration pulse impact, frequency 20 to 2,000Hz. Stability verification of full frequency resonance zone, simulating long-term micro vibration impact of equipment.

Verification of tolerance for foolproof insertion: Mechanical tolerance design ±1.2mm misalignment insertion can still lock the contact normally. No jamming, no short circuit, no virtual connection.

Waterproof sealing integrity test: IP67 rating, submerged for 1 meter for 30 minutes. After the water comes out, the contact resistance is stable and there is no sealing failure.

Electrical load impact test: pogo pin has a short-term high current impact capacity of 50 amperes for 1 second, and effective arc suppression. Pogo pin temperature rise control within 15℃, suitable for power composite interface applications.

Thermal shock tolerance: Quickly switch between hot and cold within 10 seconds, with an extreme temperature difference of 60℃. After 30 cycles, the barrel expands and contracts stably without micro cracks or contact drift.

EMI electromagnetic compatibility verification: When the interface is in a conducting state, the electromagnetic leakage complies with IEC. Meet the EMC standards for aviation, medical, and military systems.

Metal fatigue life analysis: Through finite element simulation and accelerated life testing, Spring fatigue life is estimated to be greater than 10,000 complete cycles. Long term maintenance of stable elastic contact force.

High humidity and high temperature aging test: Aging continuously for 1000 hours in an environment of 85℃ and 85% humidity. The insulation resistance remains above 1,000MΩ, and there is no abnormal drift in the contact resistance.

Click: More Catalog

Customization of 10 Pin Electrical Connector

Pin configuration customization: The flexible arrangement of pogo pins allows for mixed arrangement of signal and power pins. Single pin supports 0 to 50 amperes, with independent grounding isolation design. High complexity multi-channel parallel application architecture.

Pin arrangement density optimization: minimum center distance of 1.00mm, supporting non-uniform spacing mixed arrangement. Space optimization of ultra small terminal device control board >35%.

Customization of foolproof mechanism: Multi level mechanical positioning supports multi-directional anti misoperation, with a maximum tolerance for insertion deviation of ±1.50mm. Blind insertion reliability verification has passed IEC standards.

Customization of contact materials: Pogo pins can be selected from high elasticity beryllium copper, phosphor bronze, and high-strength stainless steel. The surface can be customized with a gold plating layer thickness of 0.1μm to 5μm. Wear resistance life >10,000 contact cycles.

Customization of environmental adaptability: Supports IP67 waterproof and dustproof packaging, with 500 hours of salt spray corrosion protection. Long term stable operation with high humidity and high temperature, suitable for outdoor, aerospace, ship and medical environments.

Customization of temperature control and power distribution: Multi channel independent current path thermal balance design to avoid the accumulation of hot spots in a single channel. The temperature rise during continuous operation is controlled within 15℃, and the overall power consumption balance is optimized to be greater than 22%.

EMC shielding customization: can integrate fully enclosed metal casing, single port shielding effectiveness >35 decibels. EMI interference control is superior to IEC standards and suitable for harsh electromagnetic environments in aviation and military industries.

Modular interface system customization: supports cascading design of multiple interfaces, locking multiple channels at once for closure. Backend PCB interface with multi angle output, compatible with highly integrated backplane and multi-mode group collaborative system architecture.

Customization of structural mechanics: supports curve optimization of anti-vibration and anti-impact reinforced syringe springs. The contact stability under vibration in the buffer frequency range of 20 to 2,000 Hz is greater than 99.98%.

Regulations and Certification Customization: The 10 pin electrical connector supports ROHS and REACH as needed, adapting to different national/industry regulations.

System interface compatibility customization: It can support connection with existing client wire harnesses, backplane sockets, and automated testing fixtures. Reduce the overall system renovation cost by more than 30%.

Click: More Catalog

FAQ

Can the waterproof and airtight performance of 10 pin electrical connector meet stringent industrial protection requirements? The 10 pin electrical connector has passed the IEC standard IP67 certification. Exposed to 1 meter underwater for >30 minutes without penetration. The sealing material has undergone ASTM D471 immersion testing, and the airtight leakage rate is <0.5. Outdoor, marine, medical, and military industries have high stability.

Is high current stability of 10 pin electrical connector sufficient to support dual tasks of power and signal? Each pin has a rated continuous current of 3A and a peak load capacity of 5A. The contact resistance is stably controlled within 10mΩ, with fluctuations of <± 2mΩ after 10,000 mechanical life cycles. It can simultaneously transmit medium power supply and high-speed signals, ensuring long-term low loss and reliable impedance characteristics.

How does the 10 pin electrical connector fail safe design ensure fault tolerance for blind and incorrect insertion at high densities? The plastic housing adopts a special-shaped Keying structure, with a tolerance of ≤0.05mm for the guiding structure inside the male and female seats. The tolerance for blind insertion error angle is ±5°, and there is no risk of accidental insertion in fully automatic or manual assembly. Support quick docking without alignment.

Does the 10 pin electrical connector support flexible customization to adapt to complex packaging and space constraints? The pitch of each pogo pin can be arranged at a minimum of 1.00mm. Support custom signal definition, current distribution, and mechanical layout for any pin position. Circular, square, irregular and other packaging shells. Robot, wearable, medical miniaturization, design response cycle ≤3 working days.

Has the reliability life data of the 10 pin electrical connector been verified by third-party testing? It has been tested for mechanical durability in the laboratory based on IEC standards. After 10,000 cycles of plugging, the contact resistance stability of the 10 pin electrical connector is over 95%. Environmental tolerance includes thermal shock in the full temperature range of -40℃ to +125℃, with a 100% pass rate in the 96 hour salt spray test. Reliable operation under harsh working conditions.