Johoty’s Services of Multi Pin Connector

Sample Multi pin connector: Supports dual channel of standard and customized samples, with samples delivered within 14 days and 3,000 pieces of multi pin connectors delivered within 2-3 weeks.

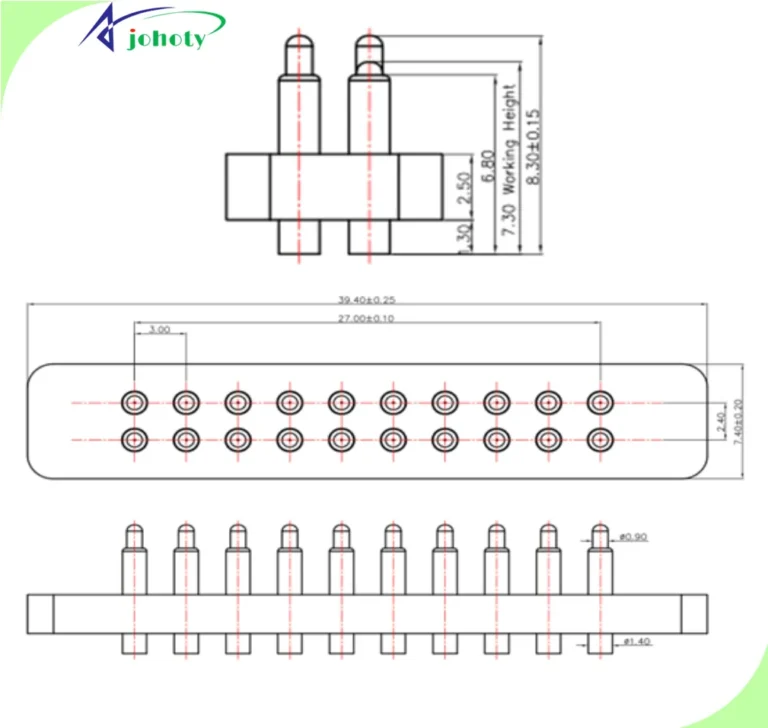

Multi pin connector consistency control: All pogo pins are coated with ≥0.5μm gold, and the contact resistance is fully checked to be ≤50mΩ with a tolerance of ±0.05mm.

Batch delivery time: 14 days for standard models, 2-3 weeks after confirming the drawings for customized multi pin connector.

MOQ for multi pin connector: 3,000 sets for standard or customized products, which can also flexibly meet customer needs. Ranked by steps, the quotation is clear.

Quality traceability system: Batch identification + retained samples for each batch + signature records of responsible personnel for each workstation, supporting ISO and customer audit docking.

Sample verification support: Free 3D models and dimensional drawings are provided. Recommend PCB packaging layout and structural interference inspection opinion letter.

Logistics method: Supports DHL, UPS, FedEx air freight, with delivery time 5-8 days. Default includes export hard cardboard boxes or customized vacuum formed trays.

Packaging protection level: default use of earthquake resistant EVA compartments, capable of long-distance transportation of multi pin connector and multiple handling in storage.

Factory qualification: Equipped with ISO 9001 and automated multi pin connector assembly and testing lines.

Qualifications for liaison personnel: Technical liaison with >10 years of experience in multi pin connector engineering. Sales liaison has experience in landing overseas projects.

Engineering modification response: Two structural and pogo pin distribution modifications are acceptable during the sampling phase. Provide feedback and confirmation within 1-2 working days.

Multi pin connector sample confirmation process: The entire process is documented and delivery milestones are traceable. For the first cooperation, assembly risk assessment recommendations can be provided.

Click: More Catalog

Performance Test of Multi Pin Connector

Contact resistance detection: Multi pin connector batch sampling ≤50mΩ, 100% static measurement + dynamic plug-in cycle resistance tracking.

Lifespan test: Plug and unplug at a frequency of 1 time per second, with a resistance change of ≤5mΩ after 10,000 cycles.

Current load test: Apply 10A current to a single pogo pin for 60 minutes, with a temperature rise of <30°C, in compliance with UL1059.

Temperature and humidity cycling test: 25°C~85°C, humidity 90%RH, cycling for 96 hours, without drift in electrical performance.

Salt spray corrosion test: 168 hours of neutral salt spray, with no oxidation or corrosion in the contact area.

Mechanical strength testing: Single pogo pin radial push-pull force ≥0.5N, withstand ±0.20mm docking offset without failure.

Solder leg tension test: Multi pin connector pin torsion force ≥10N, no virtual soldering, fracture.

High and low temperature impact: The function remains normal after 100 cycles of continuous switching from -40°C to +85°C.

EMI anti-interference test: The mixed signal pogo pins have no crosstalk when transmitting ± 5V differential signals.

Vibration test: 10Hz~55Hz, biaxial test for 6 hours, contact resistance fluctuation <2mΩ.

Verification of insertion and extraction tolerance: Mechanical insertion and extraction within ±0.20mm is automatically completed without any offset or jamming.

Pogo pin on/off confirmation: Perform automatic detection of on/off and short circuit for each batch of multi pin connectors, with no missing or misplaced installations.

Click: More Catalog

Customization of Multi Pin Connector

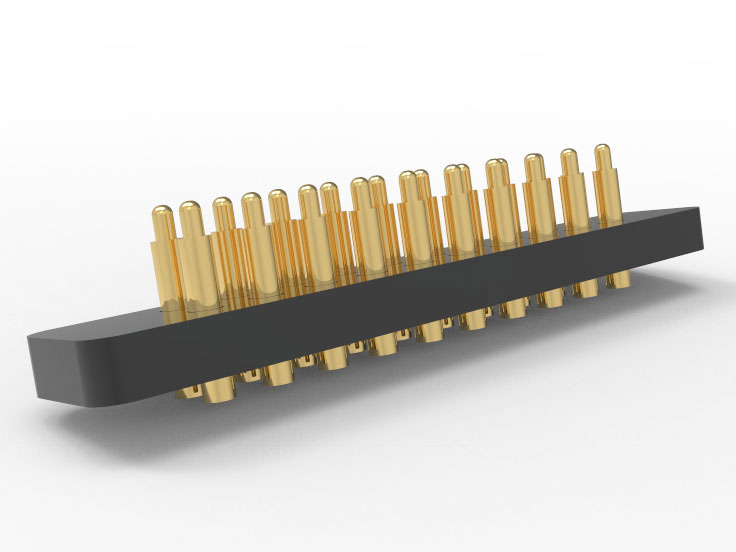

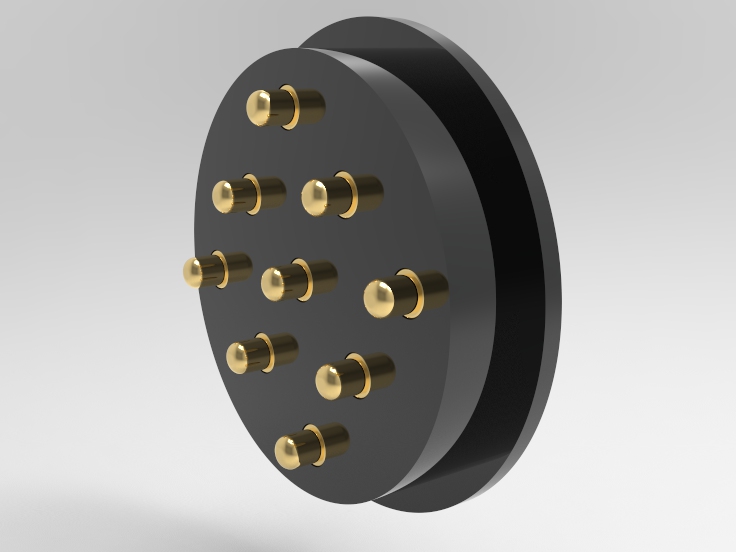

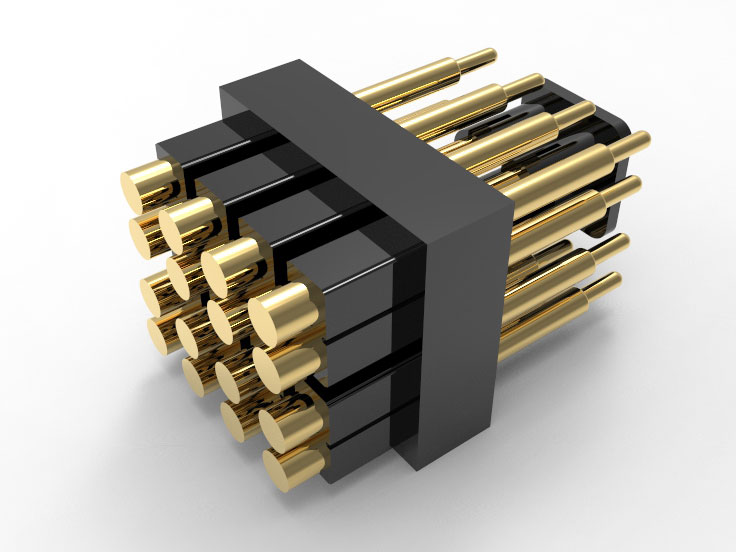

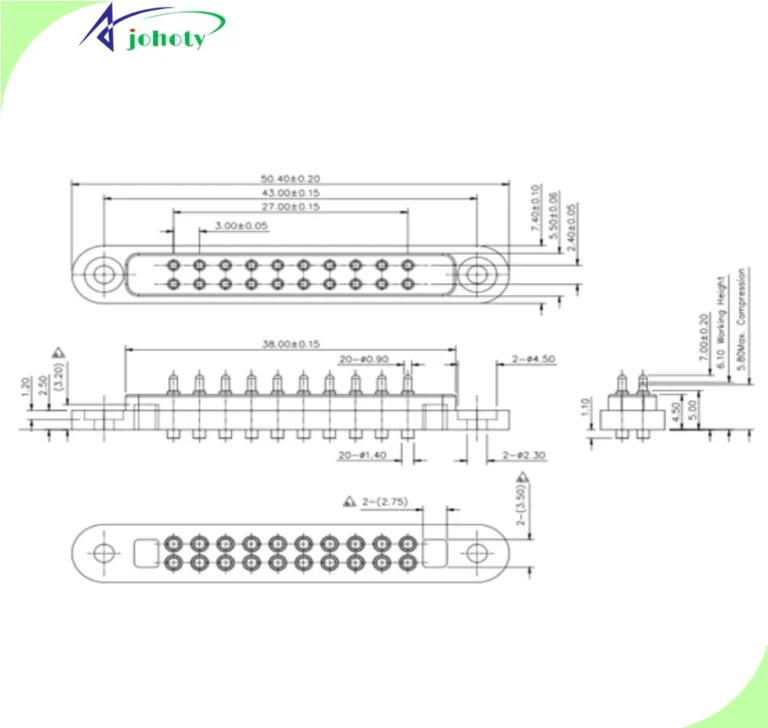

Customization range of pin quantity: Supports on-demand configuration of ≥14Pin, customize single row, double row, and matrix distribution.

Mixing scheme of electrical signal and power supply: A single pogo pin supports 50A current and composite arrangement of analog, differential, and digital signals.

Interface definition customization: Supports reverse definition of pogo pin functionality and sequence according to customer PCB layout, without the need for additional jumpers.

Housing structure customization: Metal or plastic housing can be designed with guide grooves, positioning protrusions, and positioning holes. Multi pin connectors can meet the needs of fast assembly.

Optional insulation materials: Supports high temperature resistant materials such as PBT, LCP, and multi pin connectors commonly used in reflow soldering and chemical corrosion resistant applications.

Customization of mating force: Adjust insertion force of single pogo pin (5gf~2.0N) through spring parameters. Mechanical docking, automatic assembly of fixtures.

Customized conductive layer: Supports nickel plating + gold (≥0.5μm) or full gold plating selection to meet different lifespan and corrosion resistance requirements.

Installation support: customizable welding, bending, SMT installation, nut fixing, snap on, press in, etc.

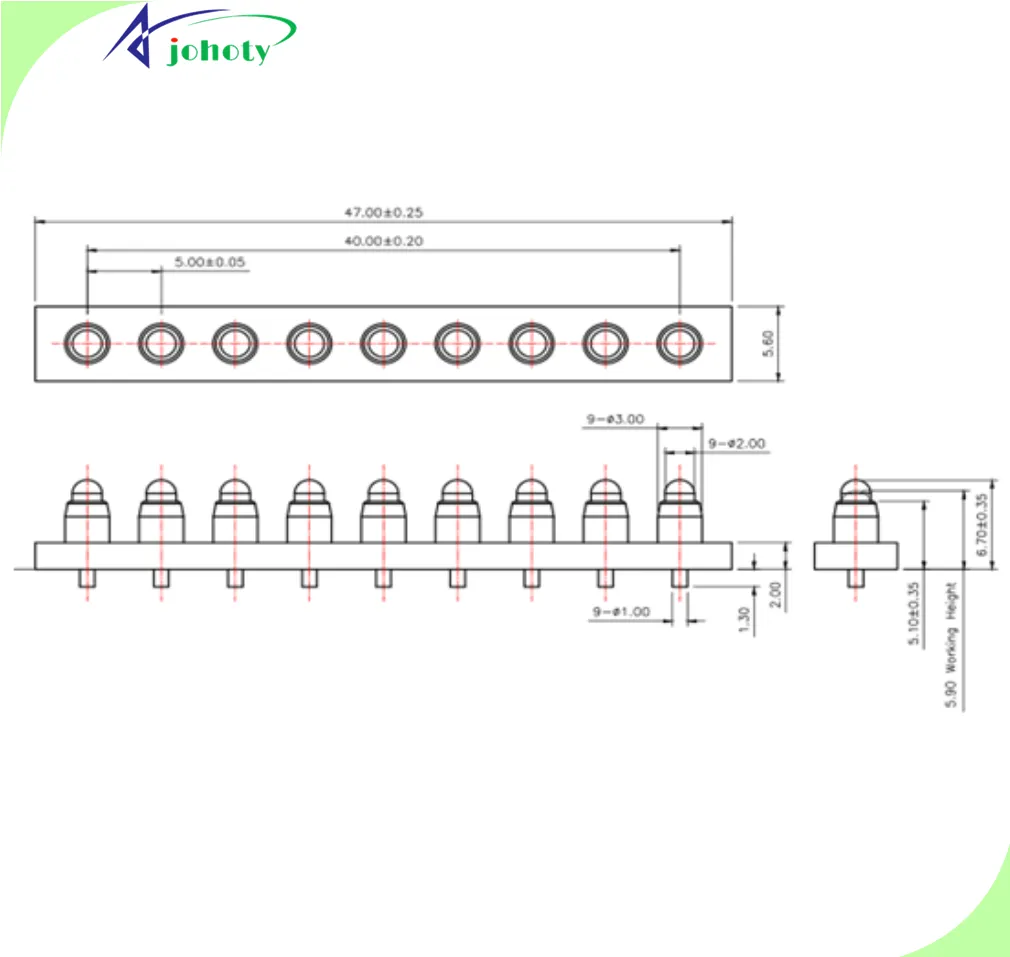

Non standard customization of size and pitch: supports non 2.54mm spacing and irregular layout, corresponding to limited space.

Structural height customization: According to the customer’s mechanical housing space limitations, the multi pin connector supports a height of ≥3.00mm.

Multi interface integration: supports the integration of multiple independent functional areas with a single multi pin connector, achieving rapid replacement of multiple modules.

Design collaboration: Support customers to provide 3D and 2D initial drafts, and return structural suggestions and assembly compatibility assessments within 48 hours.

Click: More Catalog

FAQ

Does multi pin connector support high current and multiple signals?

Support, each pogo pin can sustain a maximum current of 50A. Simultaneously possessing high signal integrity channels, signals and power can be grouped and independently arranged. This pogo pin connector commonly uses in complex industrial control, automation equipment, and modular system bus interfaces.

Does multi pin connector meet high insertion frequency and reliable contact?

Sure, pogo pin often adopts an elastic design of ≥15gf, with a lifespan of over 10,000 cycles. At room temperature of 25℃±5℃, the voltage drop remains ≤30mΩ. It has long-term electrical stability in frequent docking applications.

Is a design with a pitch greater than 2.54mm beneficial for EMI control and heat dissipation management?

Yes, the large pitch design (commonly 3.0, 3.5, 4.0, 5.08mm) helps to improve signal spacing and reduce coupling interference. Multi pin connectors provide better thermal diffusion paths for high-frequency switching power supplies, power modules, and redundant communication systems.

Can multi pin connector support customized terminal numbers and arrangements to adapt to existing structural components?

Support, providing any pin count configuration within 2Pin to 4,000Pin. Support horizontal, vertical, and through plate installation structures. Seamless integration can be achieved with existing mechanical structures and electrical interfaces of customers. Multi pin connector can reduce the cost of assembly design changes for customers.

Does multi pin connector meet international standard certification and reliability testing?

Compliant, the multi pin connector has passed IEC, RoHS, and REACH testing. Under 85℃ and 85% RH conditions, the electrical performance changes by less than 3% after 168 hours. Contact reliability is verified through salt spray, vibration, and thermal shock. Johoty’s multi pin connector can meet the standards of the European and American industrial, rail transit, and energy industries.