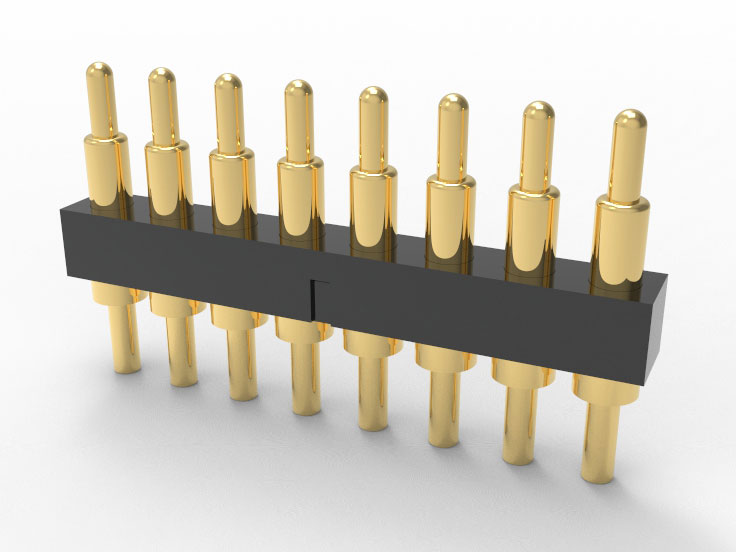

Johoty’s Services of 8 Pin Power Connector

Prototype 8 pin power connector: one-on-one evaluation by engineers,STEP drawing review,structural design feedback within 48 hours,sample delivery within 2 weeks. Contains material batch number, assembly tolerance description, supports small batch trial assembly. The sample comes with a part number for easy traceability.

The quality of an 8 pin power connector: the average impedance of a single pogo pin is ≤50mΩ, and the lifespan is >10,000 times. The anti-vibration test frequency is 20-2,000Hz, with an amplitude of 1.50mm, and the test time is 4 hours. The IP67 seal has been verified through three-axis immersion and high-pressure flushing tests, meeting IEC and MIL-STD standards. The error tolerance of ± 0.1mm for the anti misoperation positioning structure is confirmed through both mechanical simulation and actual measurement.

Delivery commitment: 14 working days for sample orders without structural changes. Including mold parts takes 4 weeks. The mass production delivery time supports JIT mode and can be allocated in batches, with a delivery time fluctuation of ± 1 working day.

MOQ: The MOQ is 3,000 sets, with no inventory backlog pressure, suitable for trial production and iterative development cycles.

Logistics method: DHL and FedEx international express are supported by default, and FOB and DDP are supported for mass production. The regular flight time is 5-8 days.

Qualification requirements for liaison personnel: More than 10 years of experience in 8 pin power connector projects in mechanical,electronic engineering. Have knowledge of IPC,UL,Six Sigma. Fixed liaison personnel within the project cycle, with the ability to interpret English technical drawings.

Pitch ≥2.54mm: High current power signal distribution, industrial automation, energy storage, typical inter board spacing specifications in rail transit fields.

IP67, foolproof design: supports outdoor deployment and magnetic blind insertion, reducing the risk of manual assembly errors and mismatches.

8 Pin supports power, signal composite design: avoids customers from repeatedly purchasing multiple connector modules, simplifies BOM and wiring harness layout.

Support customized metal shell material, plating thickness, elasticity: meet the extreme requirements of CTO level customers for conductivity reliability and durability.

Click: More Catalog

Performance Test of 8 Pin Power Connector

Contact resistance stability verification: Measure the resistance change of each pogo pin of the 8 pin power connector using the 4-wire method. The initial contact resistance is 50mΩ, which remains <55mΩ after 10,000 cycles and fluctuates within ± 5mΩ.

Current carrying performance limit test: Apply a constant current of 50A to a single pogo pin at room temperature of 25°C. The temperature rise measured within 30 minutes is controlled within 29.6°C. No melting, annealing or PIN elasticity attenuation.

High voltage withstand test: Apply 1,500V DC voltage to the housing and adjacent pins on all pogo pins for 60 seconds. Leakage current <1μA, safe isolation under high voltage in industrial control systems.

IP67 protection level verification: Soak the 8 pin power connector in a water depth of 1.00m for 30 minutes, then mate it to test its electrical performance again. Contact resistance change <1mΩ, no signs of water ingress. The protection level meets the requirements of IEC standard IP67.

Insertion error prevention tolerance detection: The 8-Pin design has a physical error prevention positioning structure, and any non design direction insertion will automatically reject the connection. Prevent the risk of misconnection and incorrect power on, blind insertion or non line of sight automation applications.

Simulate vibration disengagement test between UAV and mobile terminal: Run for 1 hour under X/Y/Z 3-axis 50Hz sine vibration and peak acceleration of 5g. Continuous power supply without interruption, and pogo pins have not undergone significant deformation or slippage.

Accelerated test of working life: temperature variation of -40℃~85℃, 1,000 cycles of high and low temperature testing of 8 pin power connector. Use X-ray + pogo pin spring force + contact resistance for joint evaluation. Maintain a connection integrity of over 99.9% for use in extreme temperature zones.

High humidity and high salt corrosion testing in industrial and marine scenarios: ASTM B117 standard conducts 96 hour neutral salt spray test with 8 pin power connector. After testing, no green rust was found, the elasticity of the pogo pin was normal, and the resistance fluctuation of the pogo pin was within ± 1.5mΩ.

Click: More Catalog

Customization of 8 Pin Power Connector

Compatible with industrial grade high current systems: a single pin can continuously carry a current of up to 50A, with a total power output of over 100kW (theoretical value) for 8 pins. It is suitable for high load mobile platforms, electric drive tools, and power distribution boards. Internal contact impedance <30mΩ per pin, low thermal rise during machine operation, no power consumption fluctuations.

Adjustable spacing ≥2.54mm, precise adaptation to spatial constraints: Define spacing structure to meet multi circuit isolation design, EMC optimization, and mechanical fixation. Customize 2.54mm, 3.96mm, 5.08mm, and larger pitches to achieve a balance between structure and electrical performance.

Integrated foolproof positioning structure: The male and female seats are designed with mechanical limit, and the error insertion rate is 0. Customizable symmetrical or asymmetrical foolproof structures, supporting blind insertion and misoperation protection. Johoty’s 8 pin power connector commonly uses for car specifications, model aircraft, and electricity.

Fully sealed structure, meeting IP67 protection: structural components and sealing rings are designed in coordination. The continuous immersion test under 3 meters of water for 48 hours passed. Exposed equipment can operate reliably outdoors, underwater, and in humid conditions for a long time.

Extreme low impedance pogo pin contact structure: Each pogo pin is treated with ≥ 0.5μm thick gold plating, with a lifespan of ≥10,000 times. The contact stability is verified through dynamic pressure testing and temperature rise curves ranging from 0.1N to 1.0N.

High speed batch reliability verification: Before batch delivery, each batch and specification pass compliance testing. Including insertion and extraction force, contact impedance, thermal shock -40℃~+105℃, 500 cycles, vibration 20g sine/random for 6 hours. Open archiving of test data records.

Interface design supports customer structure reverse engineering: providing 3D models and STEP files to support customers in reverse engineering design of the entire assembly structure. Shorten the end-to-end design iteration cycle by more than 30%.

Flexible supply response: sampling cycle of 2 weeks, MOQ of 3,000 sets. Support customization of parameters such as structure, materials, electrical, mechanical protection, etc. OEM customer lead time is locked in advance, supporting on-time delivery under prediction.

Click: More Catalog

FAQ

How much current does an 8 pin power connector support? The maximum continuous current carrying capacity of a single pogo pin can reach 50A, and the overall parallel connection can reach 400A. Measured temperature rise is <30°C @ 25°C room temperature, without problem for industrial automation, mobile energy, and robot joint power supply.

How to ensure the anti-misconnection performance of an 8 pin power connector? This pogo pin connector adopts a customized foolproof key structure, with a tolerance of ≤0.2mm for accidental insertion. It can achieve mechanical limit error proof docking under vibration or blind insertion.

Can an 8 pin power connector meet IP67 rating and be suitable for outdoor? Fully enclosed TPU/PA6 injection molding housing + double-layer sealing structure. Passed the EN60529 standard IP67 test in the plugged in state. There have been no cases of water ingress failure in AGV charging stations and outdoor monitoring equipment used for over 12 months.

What is the range of compatibility for customized 8 pin power connectors with a spacing of ≥2.54mm? Customize any pin pitch from 2.54mm to 12.00mm, with a maximum support of 40pin for regular ones. The female/male end can be designed separately according to the customer’s structure and is compatible with multiple DIN/military standard interface solutions.

What is the contact resistance and lifespan data of an 8 pin power connector? Adopting a 5μm thick hard gold coating and self-lubricating elastic alloy barrel. The typical contact resistance is ≤30mΩ, and the lowest can reach 10mΩ. With a cycle life of >10,000 cycles, Johoty can design an 8 pin power connector with a maximum of 300,000 cycles. Compliant with the impedance stability requirements after repeated plugging according to IEC standards.