Johoty’s Services of Magnetic Electrical Connector

Sampling of magnetic electrical connector: Standard samples will be produced within 3 days, and customized structures will be delivered within 14 days, including actual test reports. Support synchronous confirmation of structural diagrams, encapsulation diagrams, and 2D,3D models.

Quality System: Compliant with ISO 9001, magnetic electrical connector undergoes 100% electrical and visual inspection. Contact impedance ≤50mΩ, plug-in life verification >10,000 times.

Delivery time for magnetic electrical connectors: Standard parts can be shipped in batches within 2-3 weeks, with support for phased delivery and flexible material preparation mechanisms. Meet the requirements of parallel engineering verification.

Minimum order quantity: 3,000pcs, suitable for project management from Prototype, EVT, DVT, PVT to mass production stages.

Logistics method: Default DHL, UPS air freight, supports EXW, FOB, DDP, etc. Match customers’ overseas warehouse direct delivery or domestic consolidation and transportation.

Matchmaker qualification: Matchmaker engineer with over 10 years of experience in pogo pin connector and magnetic electrical connector. Support English technology integration and BOM structure matching analysis. Through professional training on REACH and RoHS regulations.

Engineering cooperation: Support collaborative development review. Including circuit interface specifications, structural interference checks, assembly path analysis, interface definition document organization, etc.

Customer NPI support: We can provide sample log tracking and process control point reports. Inspection record sheet, functional test report, and RoHS,material certification.

Sample follow-up: Sample progress is updated every 48 hours. Please provide screenshots of 3 key dimensions, impedance, and force test data before submission.

Packaging support: Supports tape, disk mounting, bubble shell, and complete magnetic structure assembly. Dual process of SMT and assembly.

Risk control: There is engineering exception handling, feedback within 1 hour, and preliminary reasons and handling suggestions within 24 hours. Project risks are controllable.

Best price: Transparent tiered unit price for standard magnetic electrical connectors. Customized magnetic electrical connectors support both shipping quotes and annual framework agreement quotes.

Click: More Catalog

Performance Test of Magnetic Electrical Connector

Contact impedance test: Each pin impedance is ≤10mΩ, sampled by a four wire micro resistance tester to ensure current stability.

Lifespan verification: Contact resistance change ≤20% after 10,000 cycles. Simulate real loads and verify reliability attenuation curves.

Elasticity consistency test: The single pogo pin elasticity deviation of the magnetic electrical connector is ≤±10%. Using an automatic loading device to ensure consistent insertion and removal feel.

High and low temperature cycling test: -40℃ to +85℃, with no abnormalities in electrical and structural properties after 10 cycles. The magnetic electrical connector complies with industrial,vehicle temperature standards.

Salt spray corrosion test: 5% NaCl solution, no blistering or peeling of the coating after 96 hours. Gold-plated thickness should be ≥0.5μm and kept intact.

Vibration and impact test: three-axis vibration of 10~500Hz, with no intermittent contact after frequency scanning. Magnetic electrical connectors have excellent performance in mobile and industrial high-frequency disturbance applications.

Boiling high humidity test: 85℃ water bath for 1 hour, no oxidation black spots on pogo pins, and no expansion or delamination on solder joints.

Current carrying capacity test: A single pogo pin can withstand a continuous current of 3A for 2 hours, with a thermal rise of ≤30K and thermal stability without drift.

Dielectric strength test: The insulation voltage withstand between each pogo pin is greater than 500V DC, and the magnetic electrical connector has no breakdown discharge.

Solderability test: Tin furnace at 260℃±5℃ for 3 seconds, tin adhesion rate ≥95%, magnetic electrical connector with no cold solder,virtual solder areas.

Material testing report: Provide material composition spectrum and RoHS report, and indicate the source and processing technology of pogo pin and housing materials respectively.

Packaging protection verification: The packaging strength remains intact after 10 drops, and the shipping process does not affect the structure and electrical performance of the magnetic electrical connector.

Click: More Catalog

Customization of Magnetic Electrical Connector

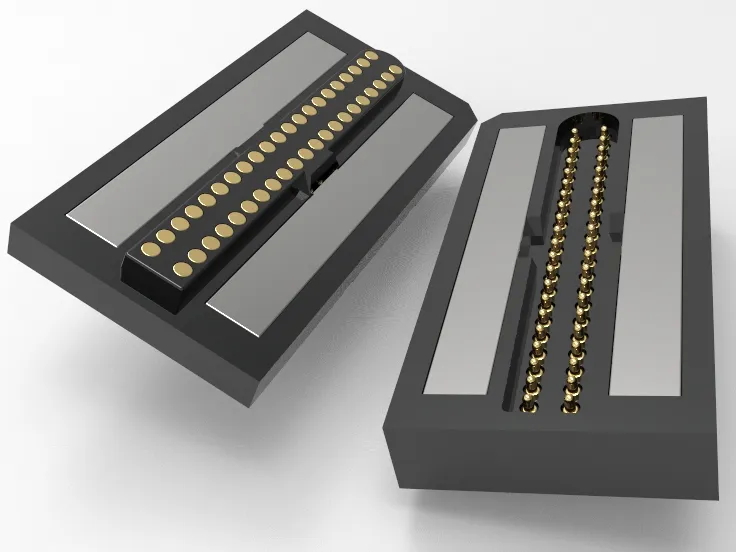

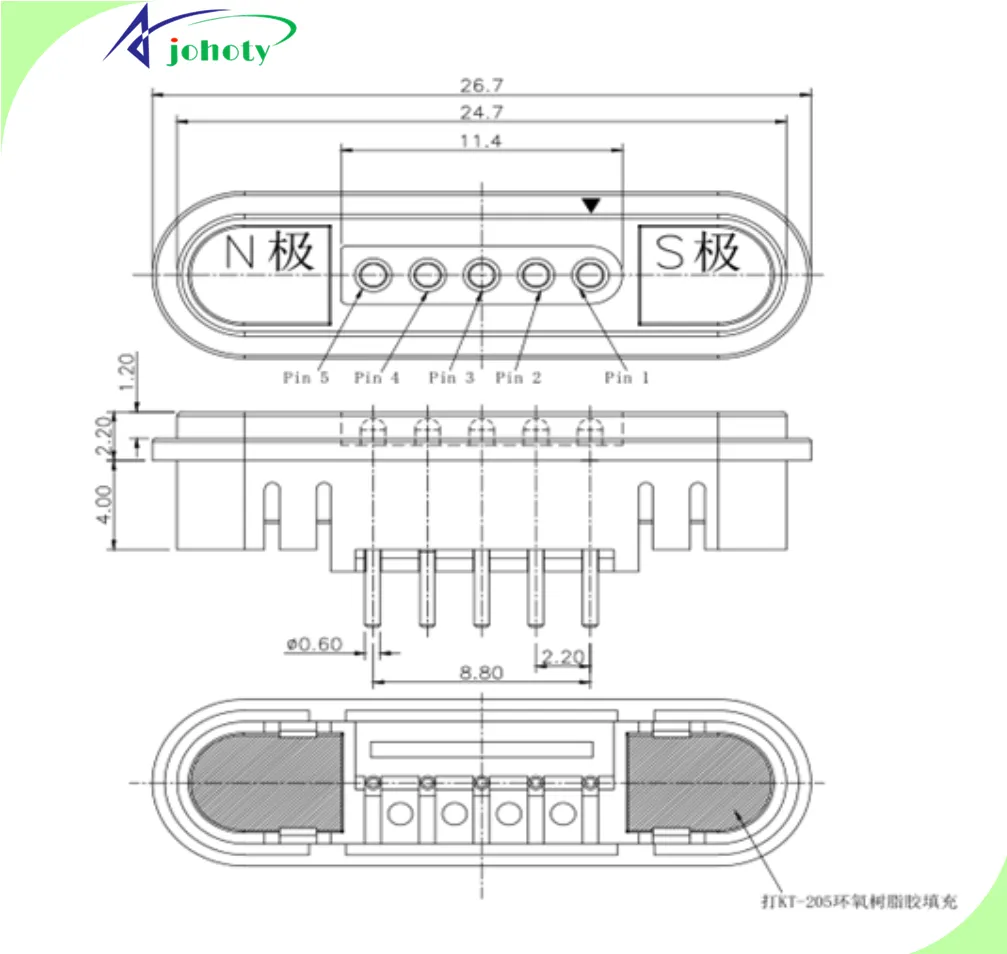

Customization of Pin Quantity: The magnetic electrical connector supports any combination of 5 to 40 pins. Single pin supports mixed definitions of power, signal, ID, and other functions, with multifunctional integration.

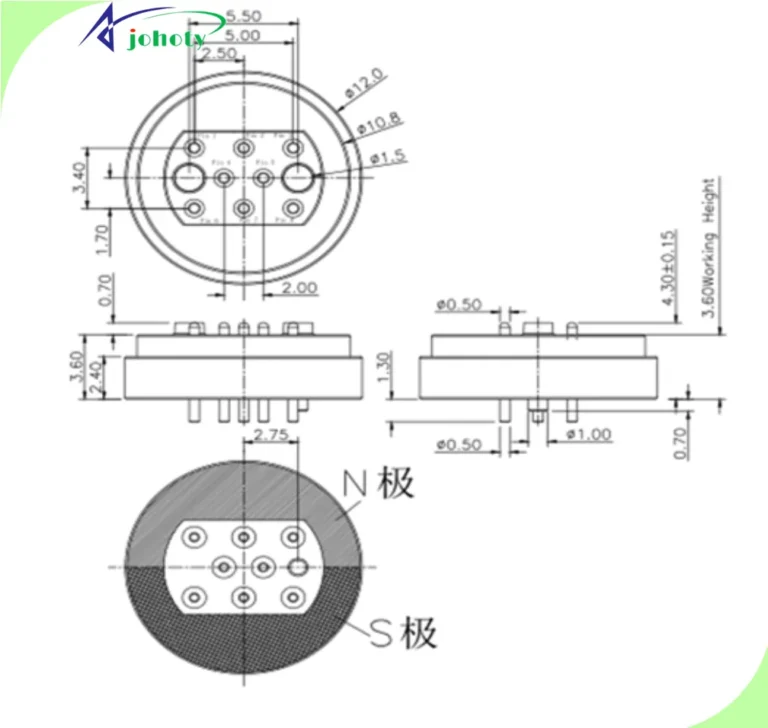

Customized contact arrangement: Magnetic electrical connectors can be arranged in circular, linear, matrix, asymmetric, and other shapes. Minimum center distance of 1.00mm, compact interface.

Housing structure customization: optional nut fixation, buckle positioning, hidden docking and other forms. Different packaging and assembly paths.

Elasticity customization: The single pin elasticity of the magnetic electrical connector can be adjusted from 5gf to 250gf. Different insertion and removal forces and anti drop force of the handheld end.

Customized work schedule: Spring supports effective travel from 0.10mm to 3.50mm. Customers can achieve different magnetic suction and pressing distances as well as PCB height differences.

Material customization: Pogo pins can be made of phosphor bronze or beryllium copper, with corresponding current carrying capacity for different current densities. Housing supports PC, PA, nylon+GF, etc.

Customization of plating scheme: Gold layer ≥0.1μm, ≥ 0.5μm, ≤ 5μm can be selected to meet the different lifespan and corrosion requirements of consumer, industrial, and automotive specifications.

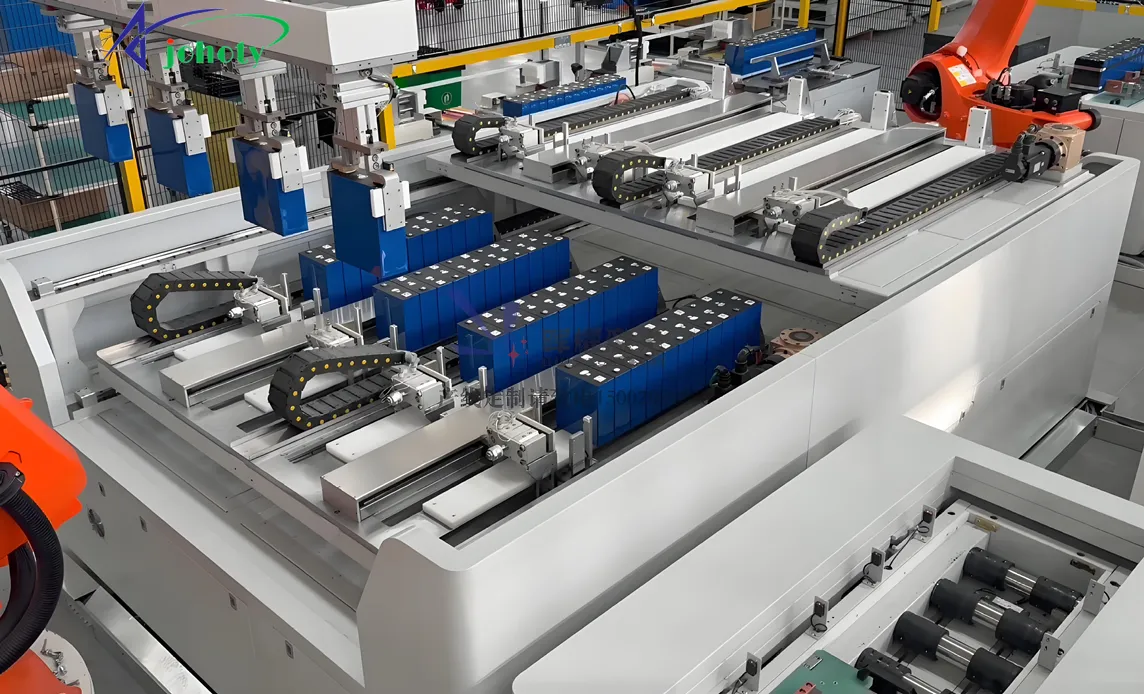

Customization of packaging methods: Tray disk mounting, tape rolling, and patch structure support compatible with automated assembly. Magnetic electrical connectors help reduce costs and improve efficiency in production lines.

Through hole, chip compatible design: The magnetic electrical connector supports SMT+DIP hybrid packaging. Provide process window matching and layout suggestions.

Conductive and magnetic separation design: Supports independent modules for electrical signals and magnetic structures, facilitating overall heat dissipation and multi-mode combination.

Interface definition collaborative design: providing IO port electrical planning, signal recognition, error prevention co construction services, and ensuring stable system operation.

Pre-assembly support for structures: Magnetic electrical connectors can provide pre soldered tail end harnesses or mother seat assemblies. Shorten the customer’s homework time in the later stage by ≥30%.

Click: More Catalog

FAQ

Can contact resistance of magnetic electrical connector meet high current or stable signal transmission?

Using pogo pins with a gold plating of 0.5μm or more, the typical contact resistance is <50mΩ. It has been measured that under 3A constant current conditions, temperature rise is controlled within 20℃. Magnetic electrical connector is used for a composite connection scheme where power and signal are parallel. Support shielded enclosures for EMI sensitive systems.

Does magnetic electrical connector support multi pin parallel stable connections, and what is the actual fault tolerance rate?

It supports custom arrangement of 5-40Pin, and staggered pogo pin structure has a stable contact rate of >99.7%. Offset in ± 0.3mm XY direction, tilted at ±5°, with automatic alignment and recovery capability. Commonly seen in sliding docking or automated assembly.

How to evaluate the lifespan of magnetic electrical connector in high-frequency plugging or vibration environments?

Laboratory verification has passed UL1977, with a mechanical lifespan of over 10,000 cycles and a contact resistance change of less than 5% after insertion. Used for high vibration AGVs, drones, industrial robots, etc. In deployed customer projects, the 3-year no replacement record rate exceeds 95%.

Is magnetic structure of magnetic electrical connector safe and reliable, and is it prone to detachment or interference with other devices?

The magnets of the magnetic electrical connector adopt N52, with a suction force of ≥400gf. It can still provide stable adsorption under an air gap of 0.5mm. Optional unidirectional and bidirectional polarity magnetic control design to avoid the risk of multi-module close-range aspiration. Tested in accordance with IEC anti-interference standards.

Can magnetic electrical connector support customized interfaces and industrial protocol matching?

Supports full customization of pogo pin number, arrangement, pin length, plating thickness, and shell size. The existing supporting cases include CAN, RS485, I2C, USB2.0, etc. Modular adaptation can be carried out based on terminal layout, and magnetic electrical connector can shorten OEM design cycles by >35%.