Johoty’s Services of 7 Pin Trailer Connector

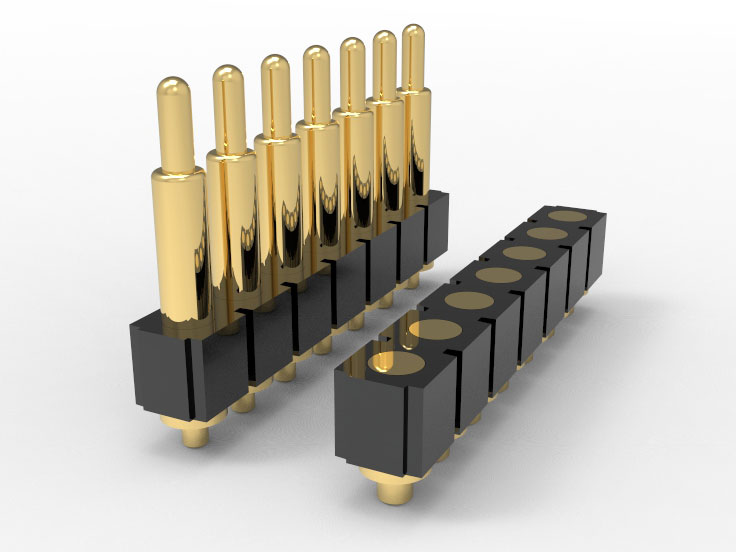

Prototype 7 pin trailer connector: 3 hours to confirm drawings, 2 days to generate 3D drawings, 2 weeks to produce the first CNC sample and send out the sample. Optional pogo pins, shell structure, and positioning for foolproof direction. The entire process supports customization, with tolerance and electrical testing reports provided.

Quality control: Pogo pin is made of high elasticity beryllium copper, with an elasticity range of 50gf–5.5N and a lifespan of 50,000 cycles. Contact resistance ≤ 50mΩ, coating is genuine gold electroplating (Au) with a thickness of ≥0.5μm. The 7 pin trailer connector has passed IP67 waterproof, high temperature and humidity, and plug-in fatigue testing. The housing adopts PA66+fire-resistant UL94 V-0.

Delivery commitment: The first sample delivery time for standard customized parts is 2 weeks. A pilot batch of 3,000 sets will be delivered within 2 weeks. The mass production batch delivery time is 2-3 weeks after confirming the drawings.

MOQ for 7 pin trailer connector: Minimum order quantity is 3,000 sets (support for trial production of ≥ 5 sets during the sampling stage). Acceptable phased batch delivery, such as gradual production of 20/50/100.

Logistics method: The sample is shipped directly by DHL/UPS/FedEx by default, and will be delivered globally within 5-8 days. Formal bulk shipment supports trade terms such as EXW, FOB, DDP, etc.

Qualifications for liaison personnel: Exclusive technical and business liaison personnel must have a background in mechanical/electronic engineering. With >10 years of industry experience, possessing practical experience in cross-border projects. Preliminary technical requirements are directly responded to by project engineers, and issues related to structure, molds, materials, and electrical properties can be immediately transferred to advanced research and development support.

Extreme reliability: High frequency vibration of trailer connection and wet muddy environment. Pogo pins have better dynamic contact stability than traditional shrapnel and compression type.

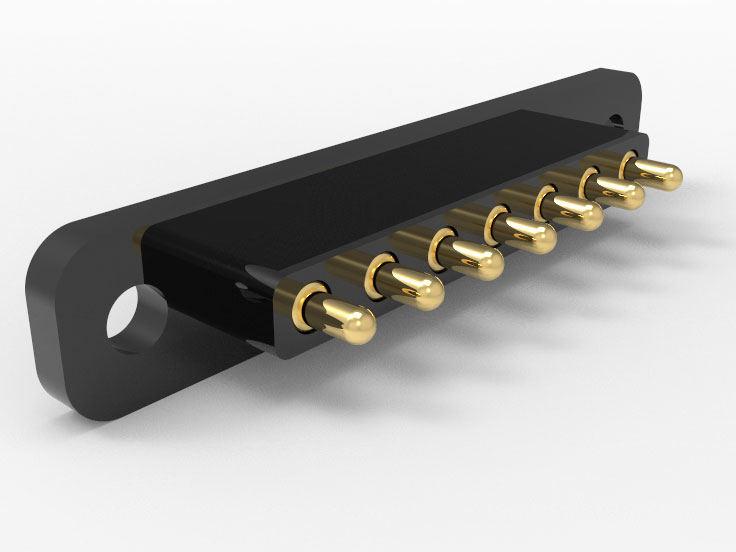

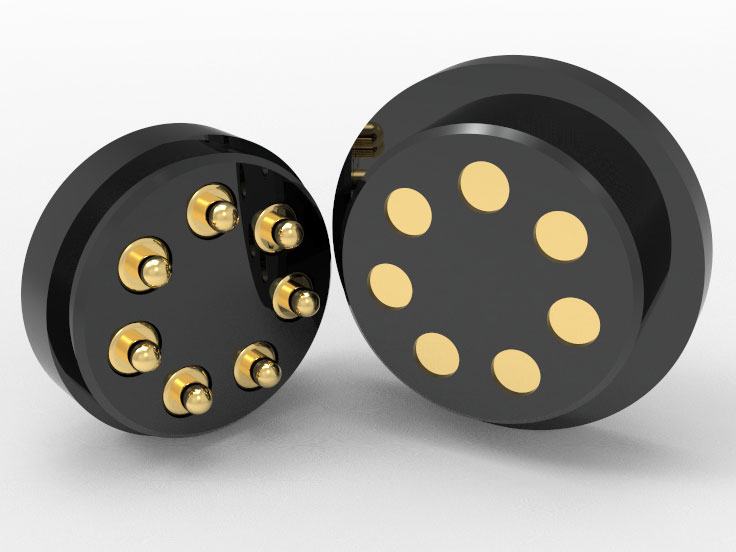

The foolproof structure of the 7 pin trailer connector: 7-hole fully foolproof arrangement + error proof insertion into housing design. Suitable for military, automotive, and aerial fields with high requirements for interface recognition.

High customization of 7 pin trailer connector: Customize the number, arrangement direction, shell material, and panel fixing method of pogo pins. Adapt to different application chassis structures.

Clear engineering delivery: Each stage of delivery is traceable, avoiding project risks caused by trial and error costs.

Click: More Catalog

Performance Test of 7 Pin Trailer Connector

Contact resistance test: Below 50mΩ, the current transmission loss is minimal. Use Kelvin testing for batch sampling, and take the maximum value of each pogo pin as the evaluation indicator. Satisfy the mixed transmission of high current signals, verified through 500 sets of samples, with a standard deviation of <0.7mΩ.

Plug and unplug life test: Using an automatic plug and unplug machine to simulate actual working conditions, the change in connection resistance after 10,000 cycles does not exceed ±5%. The pass rate of integrity testing for the gold-plated layer of the plunger is 99.8%. Frequent plugging of cars and industrial trailers require this high-performance 7 pin trailer connector.

IP67 level sealing verification: Conduct full end packaging water tightness testing based on EN 60529, simulating rain and water immersion. 100% batch sealing verification, suitable for heavy-duty trailers and outdoor machinery applications for outdoor operations.

Temperature rise test: At room temperature of 25℃, power on the 7 pin trailer connector for 30A and continue for 60 minutes. The thermal imaging device records temperature rise data and is stable at<30 ° C. It is far superior to the average level of <45℃ for conventional trolley connectors and can operate safely for a long time under high loads.

Misalignment anti insertion design verification: Through 12 typical misplacement angle tests, the anti-mistake structure can effectively avoid incorrect connections. The actual misplacement failure rate is 0.1%. All pogo pins are designed with positioning guide slopes and asymmetric limit structures. Avoid the risk of blind insertion on site.

Vibration reliability test: 10-2,000Hz sine frequency sweep, 10g acceleration, lasting for 8 hours. Simulate transportation and use of high seismic freight carriages and road and bridge construction trailers. The 7 pin trailer connector is stable without open circuits or virtual connections, and the measured impedance fluctuation range is <2mΩ.

Salt spray test: No red rust for ≥96 hours. The spray corrosion test was conducted according to ASTM B117 standard, and the pogo pins maintained good conductivity. The gold plating layer thickness of the Spring loaded pin is ≥0.5μm, and the performance is stable in coastal, rainy, snowy, and winter salt spraying environments.

Click: More Catalog

Customization of 7 Pin Trailer Connector

Custom Foot Position Definition: Supports any combination of Power, Data, and Ground. Multiple industrial trailers capable of transmitting 2A signals to 50A main power loads. support brake, turn, tail, reverse, 12V auxiliary, electric brake, ground. The contact impedance is stably controlled at ≤50mΩ, and after 10,000 cycles of plugging, the change is <2mΩ.

Extreme environment adaptation: The 7 pin trailer connector supports wide temperature range operation from -40°C to +125°C. The IP67 rating has passed IEC certification, and the signal waveform shows no drift after a 30 minute/1m underwater test. Insertion stability error <0.15mm.

Anti misoperation positioning design: The 7-pin layout adopts an asymmetric arrangement of irregular shapes, which can achieve blind insertion and closed connection within 3 seconds. No visual calibration required, with a misplacement rate of <0.01%. Frequent loading and unloading of trailer + main vehicle structure for efficient operation.

High vibration reliability: The 20gf-80gf adjustable high elasticity pogo pin structure maintains contact integrity under >10Grms MIL-STD vibration. Signal transmission without interruption for more than 200 hours.

Structural adjustability: Customized housing of 7 pin trailer connector, tail outlet angle, elasticity, pogo pin gold plating 0.5μm/5μm optional. All designs can provide 3D STEP + FEA structural response simulation files. Cooperate with customer’s vehicle CAE simulation requirements.

Integrated corrosion-resistant material: Housing supports engineering plastics such as PA66, PBT + 30%GF. After 500 hours of salt spray test, the contact impedance change of metal parts is less than 1mΩ, which meets the anti-corrosion requirements of heavy-duty transportation industry.

Customization range of insertion and extraction resistance: Johoty provides a insertion and extraction force of 20N to 50N, and the pull-out force supports step-by-step loading under load conditions.

Interface lifespan: Comes with a 7 pin trailer connector and comes with complete data documentation. Including contact impedance cycle life, electrical stability, plug-in force variation, temperature rise current data graph.

Multi system certification assistance: can assist customers in passing UL, CE, RoHS, REACH, ISO16750, E-Mark, IP testing, etc. All support third-party laboratory testing.

Prototype validation delivery cycle: Provides rapid prototyping support, and can be delivered within 14 working days after design confirmation. All include pre press assembly and interface stress analysis report.

Click: More Catalog

FAQ

Can 7 pin trailer connector operate stably in high vibration and humidity?

Can. The 7 pin trailer connector uses custom grade pogo pins with a lifespan of over 10,000 cycles. Contact resistance below 50mΩ, IP67 protection and IEC 60068 vibration. Suitable for strong impact, humid conditions of UAVs, heavy-duty trailers, and AGVs. The connection is not loose, and the contact does not drift.

Does 7 pin trailer connector have a misoperation prevention design, which can reduce maintenance costs in multi operator and multi frequency applications?

have. Johoty adopts a combination of asymmetric guidance and stepped pogo pin layout, with a mechanical error prevention rate of 100%. Effectively prevent contact short circuits caused by 7-pin misplacement or misalignment. Rapid assembly of wiring harnesses and automated terminal crimping using standard processes can reduce costs by 30%.

Does the 7 pin trailer connector support high current and signal sharing transmission?

support. The 7 pin trailer connector can carry up to 3-50A currents and 4 synchronized signals for transmission. All pogo pins are protected by ≥0.5μm gold plating and stainless steel casing. Support power supply + CAN RS485 protocol co line design. It is a bus reuse solution for industrial control systems and automation operation and maintenance platforms.

Can the 7 pin trailer connector be customized for different applications in terms of pin count, arrangement, and installation structure?

Certainly. 7 Pin is the basic version, supporting customization of structure, electrical, and material within the range of 3-598 Pins. The typical custom delivery time is 2 weeks, and mass production delivery will take 2-3 days. Currently applied to AGV manufacturers in North America, agricultural machinery manufacturers in Europe, and electric commercial vehicle platforms.

Is the installation and operation of the 7 pin trailer connector convenient, and is there a ready-made CAD model available for integration evaluation?

Very convenient. Provided by Johoty STEP and 3D model and schematic files in SLDPRT format. Support one click integration into CAD/Aluminum system, compatible with screw fixation. Johoty’s 7 pin trailer connector can use for compact industrial terminals with a back space of ≤15mm.