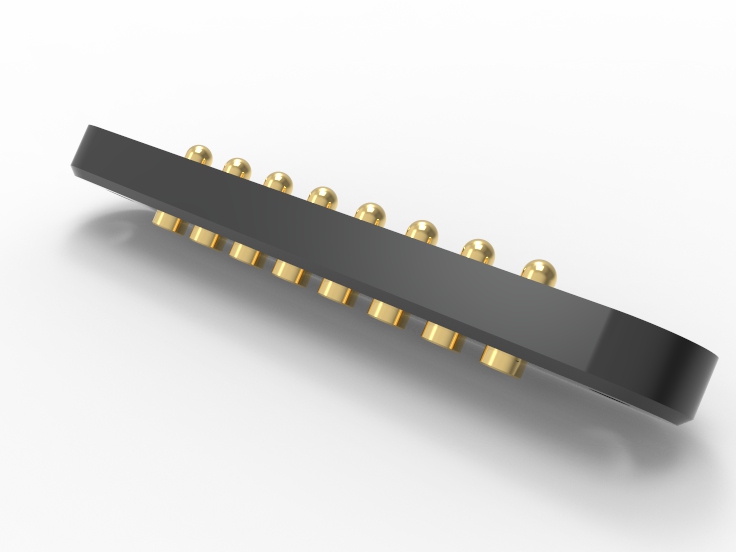

Johoty’s Services of 8 Pin Connectors

Sample 8 pin connectors: Support engineering drawings, deliver initial structural samples within 14 days after evaluation of key parameter lists. During the sampling stage, 3-5 sets of physical samples and 1 electrical and mechanical performance testing report are provided by default. Meet 90% of the project’s pre validation cycle requirements.

Quality control standard: The entire batch sampling and mass production process shall comply with ISO 9001. Each pogo pin undergoes conductivity, elasticity, and impedance testing, with batch Cpk ≥1.33. The shipment comes with a pogo pin dimension detection curve chart.

Sample delivery time: Standard structural components should be delivered within 3 days, while customized pogo pins and housing samples should be produced within 3-4 weeks. Excluding repeated confirmation cycles, the actual average project lead time is 2 weeks.

MOQ policy: Adapt to the expected quantity of customers in small batches and support functional sampling of ≤ 10 sets during the engineering verification phase. The minimum order quantity for bulk production is 3,000 sets, which can lower the product validation threshold.

Logistics method: Supports direct delivery of engineering samples by DHL, UPS, and FedEx, with no additional charges on the waybill during the sampling stage. Customers can choose their own shipping payment method. The formal mass production stage supports FOB delivery to the customer’s office, and the delivery cycle is subject to the agreement.

Matchmaker qualification: Must have at least 8 years of experience in developing 8 pin connectors. Direct communication with project engineers familiar with automotive/engineering regulations/model aircraft/medical standards. Capable of DFM evaluation, stack layout coordination, and optimization of poog pins electrical matching. We can provide one-on-one technical follow-up at the project level throughout the entire process.

Sample consistency guarantee: all 8 pin connectors for proofing use the same equipment and the same mold for mass production. Unless specified by the customer, materials, bullet wire diameter, and gold plating thickness will not be changed. Johoty ensures evaluation conclusions can be smoothly transferred to mass production.

Additional optional services: Support customers to provide packaging sockets or PCBA structural components for direct nested assembly evaluation and fit testing. Return compatibility structure feedback and assembly tension data. Docking with aviation mother end, military standard circular interface or multi board stacking module.

Click: More Catalog

Performance Test of 8 Pin Connectors

Contact resistance consistency testing: Refer to IEC to apply 250g standard contact pressure to 8 pins respectively. The contact resistance of each pogo pin was measured to be 18.2-19.1mΩ under constant current 1A condition. The maximum deviation is less than 0.9mΩ, and the 8 pin connectors meet the requirements of differential signal consistency.

Insertion lifespan test: The male and female seats undergo 5,000 full stroke insertion and extraction cycles under a loading condition of 0.6N/Pin. The contact resistance change ΔR of all pogo pins is ≤ 1.3mΩ, with no physical wear or spring deformation. Johoty can provide a cyclic resistance curve graph for 8 pin connectors.

Waterproof rating certification test (IP67): Soak in 1 meter deep water for 30 minutes in the assembled state before removing. Perform insulation resistance and conductivity tests, and the insulation resistance between 8 pins is >1,000MΩ. The 8 pin connectors have no leakage, short circuit, or water ingress marks. The testing environment has a temperature of 23℃ and 60% relative humidity.

Blind insertion test of foolproof mechanism: A total of 300 tests were completed by 30 engineering personnel simulating blind insertion actions. The correct connection rate reaches 100%, and the insertion failure rate in the wrong direction is 100%. Mechanical limits are installed in all directions for industrial, automotive, and medical applications that do not require visual insertion and removal.

High temperature/high humidity stability test: Measure the contact resistance continuously for 168 hours in an environment of 85℃ and 85% RH, with a change of<1.0m Ω. The pogo pins of the 8 pin connectors are not oxidized, and the elastic structure is not attenuated. Meet the climate reliability requirements of industrial grade products.

Dynamic vibration connection stability test: Conduct a continuous test for 6 hours at a sine vibration frequency of 10-500Hz and a 3-axis resonance peak of 1.5mm/10g. Real time monitoring of 8 signals without interruption, failure determination: resistance interruption >1μs. Verify the reliability of 8 pin connectors in high vibration environments.

Salt spray corrosion test: pass the 96 hour 5% NaCl salt spray spray as per ASTM B117 standard. The surface of Pogo pins has no visible corrosion spots, and the increase in contact resistance is less than 0.8mΩ. Johoty’s 8 pin connectors are often required in port, marine, and outdoor terminal environments.

High frequency TDR impedance test (customized for differential lines): The differential pair has a reflection coefficient S11<-18dB within a 50mm connection path. Differential impedance control between 97~102Ω, supporting high-speed serial signal USB 2.0 and RS485 high integrity transmission.

Click: More Catalog

Customization of 8 Pin Connectors

Extreme small pitch compatible with mainstream high-density onboard packaging: supports customization of pitches from 2.54mm to 1.00mm. Realize vertical docking height control at 3.2mm to solve the bottleneck of space limited stacking and wiring.

Verification of current performance carried by a single pin: The pogo pin under a 1.00mm pitch can stably carry a current of 2.0A, with a resistance control of ≤30mΩ. It meets the demanding current requirements of unmanned electromechanical interface and high-speed power supply for embedded modules.

IP67 sealed structure with full PIN sealing: The entire set of 8 pins is immersed continuously for 48 hours in the mating state of the male and female seats. A 3-meter water column spray test showed no signs of water ingress. 8pin connectors support automotive grade outdoor terminals and medical washable devices.

Terminal anti misoperation docking structure: supports up to 4-way mechanical anti misoperation structure: snap limit, inclined guide rail assistance. Avoid manual insertion errors, with a connection accuracy rate of over 99.99%. After blind insertion testing by 50 non-professional operators and 500 insertions and removals.

EMI shielding structure: optional shielding metal shell, 360° grounding spring. Suppress EMI emissions to below -45dB at 10MHz-1GHz. Suitable for high-frequency interference sensitive vehicle radar interfaces and industrial high-speed acquisition modules.

Full pin automated detection compatibility: Each spring loaded pin can be configured with probe travel detection and contact resistance monitoring. During the mass production stage, online probes and fixture resistance determination are used to ensure zero leakage testing.

There are various forms to choose from for plunger tip: Including flat head, ball, cup, and nearly 20 options. The optimal contact can be customized according to thickness coating, tin spraying, and gold deposition of the tested spot welding disc. Typical contact pressure range is 0.25N~0.8N, used in medical terminals, and can be worn with a mold group.

High speed data path expandable: supports USB 2.0/RS485 dedicated structure optimization design. Capable of 100Ω±10% differential impedance control. Adapt to handheld terminal data communication.

Click: More Catalog

FAQ

Is the insertion and extraction force of 8 pin connectors controllable and compatible with automated assembly? The design range of insertion force for each pin is between 0.25N and 5N. Depending on the pogo pin structure and plunger tip shape, the total force can be controlled at 2N. Suitable for robotic arms or Z-axis fixtures.

Can 8 pin connectors mix custom power and signal sharing? Support, a single group can be configured with high current pogo pins 3~5A and differential signal pins. We have mass-produced 2 power supplies, 6 signal structures, and EMI shielding shells. Attached are elastic impedance control and temperature rise curve diagrams.

How to confirm the compatibility between 8 pin connectors and standard connectors? STEP 3D models can be provided for customer board end structure reuse or collaborative design. Support the coordination and verification of customer supplied mother seats or PCBA packaging drawings. Provide an analysis report on contact surface misalignment, pin stress, and tolerance superposition.

Can the minimum pitch of 8 pin connectors be ≤1.00mm without affecting reliability? Support under size limitations. Under the condition of 0.80mm pitch, the fluctuation of connection resistance ΔR is less than 1.1mΩ. The structural stability has been verified through 5,000 insertions and removals. Customized 8 pin connectors are used in high-density environments to enhance plug stability.

Is the IP67 waterproof rating of 8 pin connectors effective when connected? Effective, IP67 testing includes immersion testing of 8 pin connectors after assembly. Soak at 1 meter without any water ingress or insulation failure for 30 minutes. According to IEC, provide a cross-sectional diagram of the sealing structure.