Johoty’s Services of 12 Pin Electrical Connector

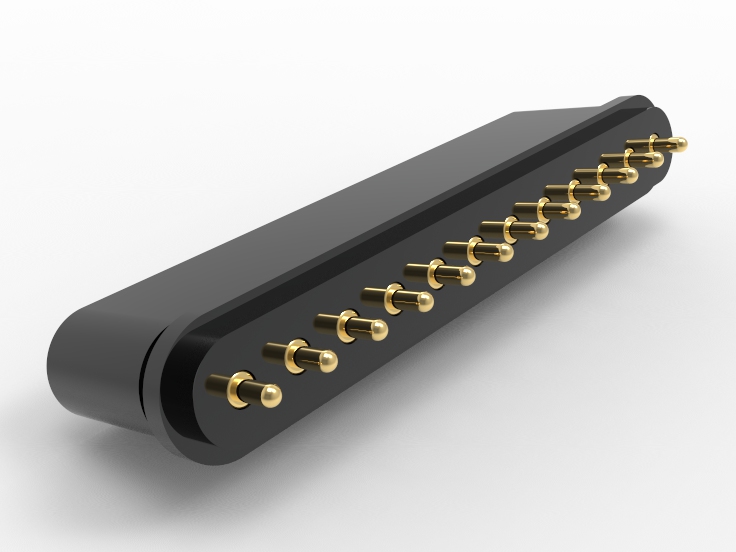

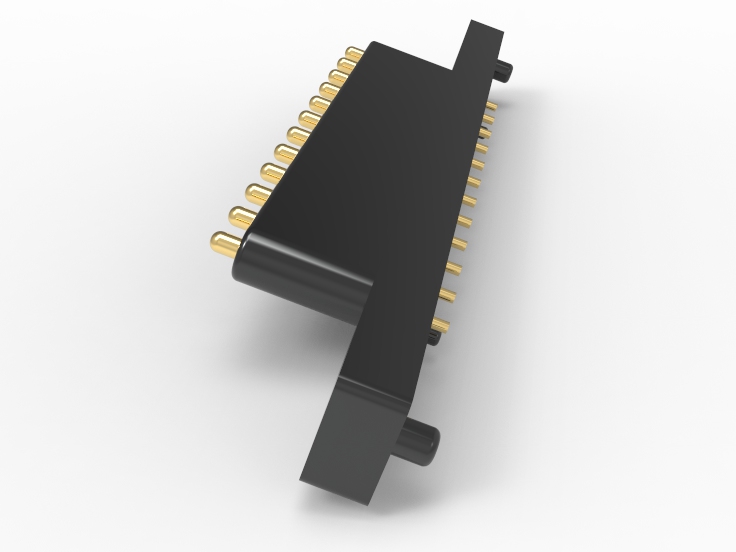

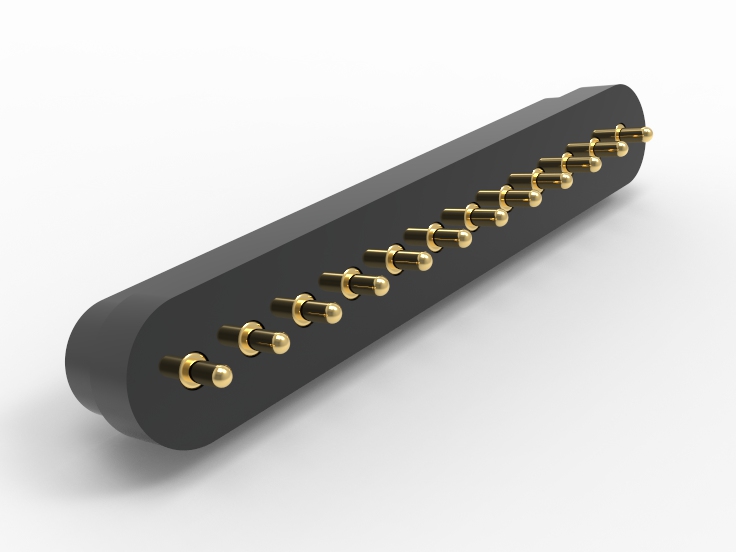

Sample 12 pin electrical connector:

Sample delivery: Original DFM+DFX review, engineering confirmation drawings. CNC rapid prototyping, complete engineering inspection report delivered with the sample.

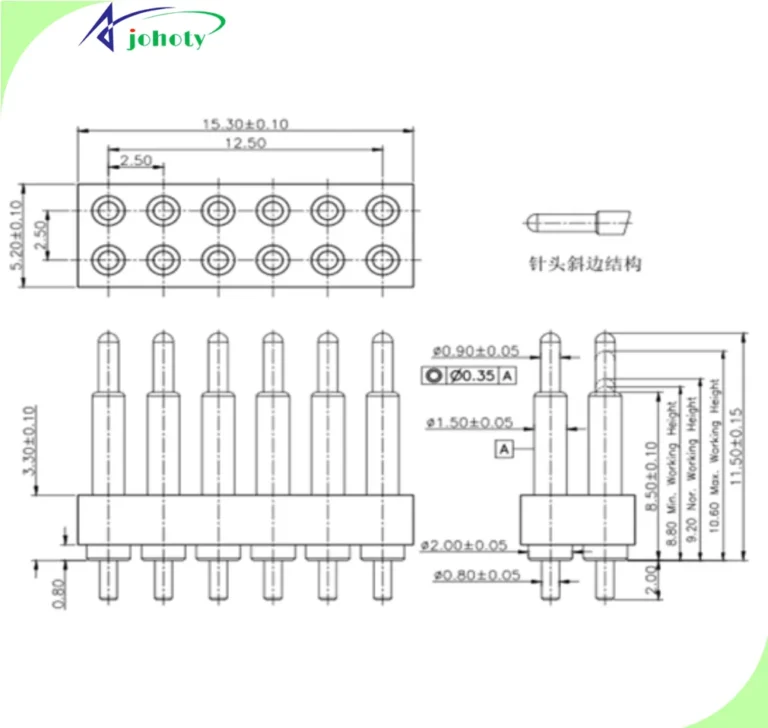

Sample fidelity accuracy: single pin tolerance ±5μm, cumulative deviation of pin positions in the entire array ≤±15μm. The uniformity of the end face coating Cpk is greater than 1.67.

Sample traceability record: Full record of material batch, processing batch, and testing batch, in compliance with ISO 9001.

Process reusability: The sample batch and mass production processes are completely reused, and there is no risk of process exceptions during the sample stage.

Quality of 12 pin electrical connector:

Protection level: IP67 immersion test for 100 hours, salt spray test for ≥ 48 hours, meeting IEC and ASTM B117 standards.

Electrical performance: Contact resistance ≤ 50mΩ, stability verification after 10,000 dynamic plugging and unplugging cycles.

Mechanical performance: resistant to lateral bias load of 30N without failure, with a control range of 3.5~5.5N for insertion and extraction force. The 3D fitting accuracy of the anti mistake and anti misplacement mechanism is ≤± 10μm.

Material consistency: High conductivity copper alloy HBi59, 0.5 μ m precision controlled hard gold coating, compliant with all RoHS & REACH requirements.

Delivery time of 12 pin electrical connector:

Sample delivery cycle: 14 natural days after confirming the drawings.

Delivery cycle for the first production order: 2-3 weeks after confirming the small batch validation is passed.

Steady state mass production delivery cycle: 14 day rolling delivery under customer standard framework agreement.

Exception plan: The dedicated engineering manager pre sets a multi application rapid response process.

MOQ of 12 pin electrical connector:

Engineering sampling: minimum order of 5 pieces.

Small batch verification: minimum order quantity of ≥50pcs.

Production minimum order: ≥3,000pcs minimum order, supporting quarterly rolling demand locking and dynamic adjustment.

Core logic: Fully compatible with engineering verification, small batch verification, and designated mass production for general procurement in European and American enterprises.

Logistics method of 12 pin electrical connector:

Sample section: DHL Express/FedEx IP direct delivery within 5-8 days.

Mass production stage: Air freight directly to the factory or designated EMS, with local customs clearance support capabilities.

Full process logistics visualization system: real-time order node feedback, no blind spots.

Person qualification:

Background of the liaison: ≥10 years of experience in designing and developing precision 12 pin electrical connector. Proficient in pogo pin matrix reliability design, familiar with automotive, medical, and military standards.

Language support: Direct integration with technical English, accessible in European and American technical contexts.

Collaboration mechanism: Project engineers provide full cycle accompanying services without a sales intermediary layer.

Certification Capability: RoHS, REACH.

Failed Mode Database: Accumulated >20,000 pogo pin failure case libraries supporting DFMEA optimization.

Reverse compatibility: Supports compatibility with existing mainstream connector platforms in Europe and America.

Pre validation report: Provide full process engineering validation documents to facilitate decision-making by the customer’s internal procurement committee.

Click: More Catalog

Performance Test of 12 Pin Electrical Connector

Contact resistance detection: All pogo pins are measured using high-precision four wire method. The average initial contact resistance is 48.2mΩ, and the maximum deviation after 10,000 insertions and removals does not exceed 1.1mΩ. The 12 pin electrical connector is reliable for long-term high current signal hybrid connections.

Protection level detection: The 12 pin electrical connector is placed in a sealed state in 1m water for 30 minutes without water ingress. The sand and dust test has no particle intrusion, and there are no environmental barriers for use in electric equipment and outdoor terminals.

Design validation for error prevention: In multiple batches of manual and automatic assembly testing, all operations were completed with an error of ± 0.05mm. No cases of incorrect insertion or damage to the pins have been found, verifying that the anti misoperation system has 100% fault tolerance in practical use.

Vibration resistance test: During the 6-hour continuous vibration test, the contact resistance drift of all pogo pins is less than 1mΩ. The elastic deformation is less than 3%, which is suitable for the vibration of drones, electric vehicles, and industrial control equipment.

Work life assessment: Conduct a 20g metal counterweight vertical insertion and extraction fatigue test. After 10,000 cycles, the elasticity decreased from the initial 2.5N to 2.32N, maintaining a stable contact pressure.

High and low temperature impact resistance test: After 100 cycles from -55℃ to + 125℃, the structure remains intact without cracks. The sample was tested according to ASTM standards and showed no aging of the material and no deformation of the PIN needle after temperature shock. The 12 pin electrical connector is capable of year-round operation in outdoor, high-altitude, or power equipment settings.

Salt spray corrosion test: after 96 hours of 5% NaCl spray, there is no pin oxidation or coating peeling. Adopting a 0.5μm thickness gold electroplating treatment, the surface contact resistance increment of the pogo pin after salt spray testing is less than 0.3mΩ. The 12 pin electrical connector can be used for a long time in marine, oilfield or high humidity environments.

Click: More Catalog

Customization of 12 Pin Electrical Connector

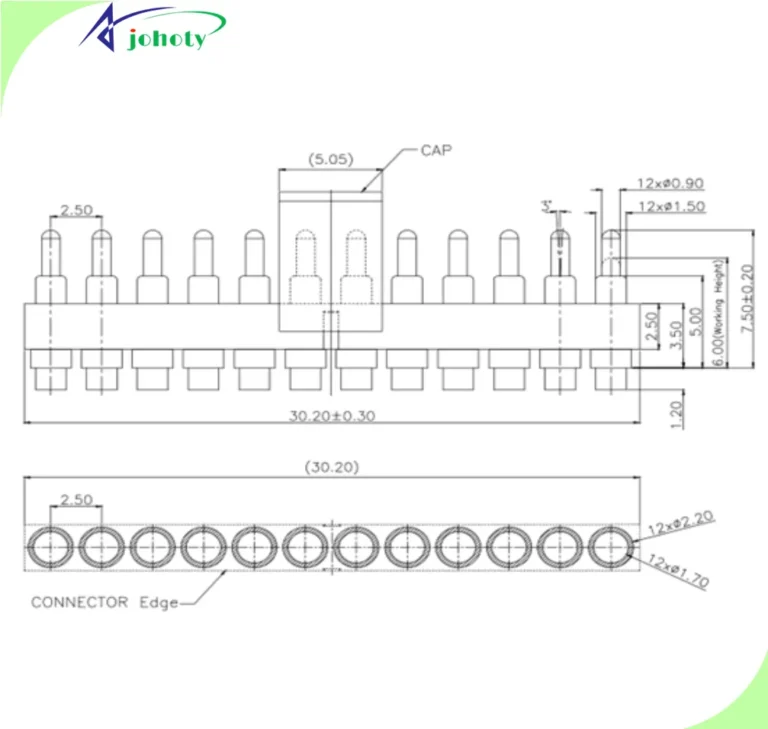

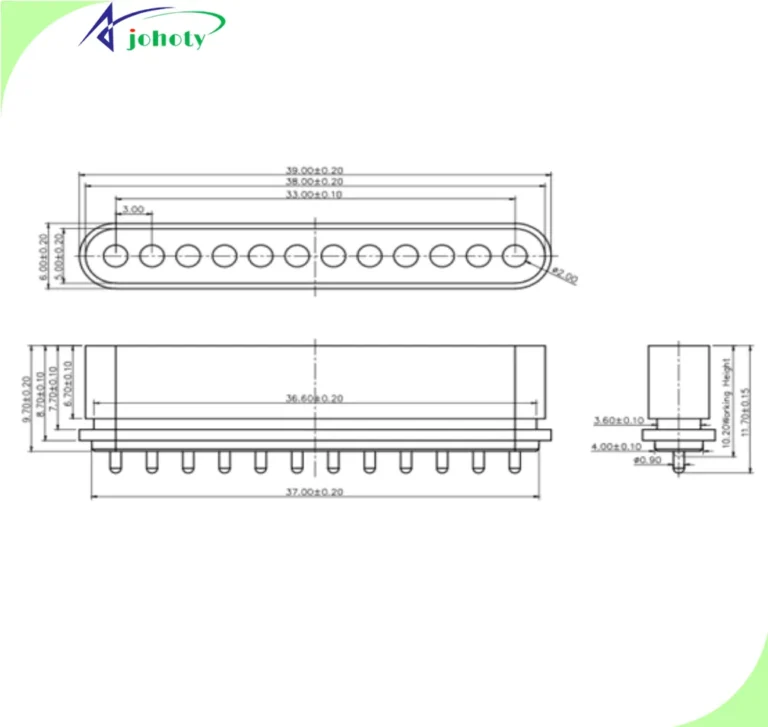

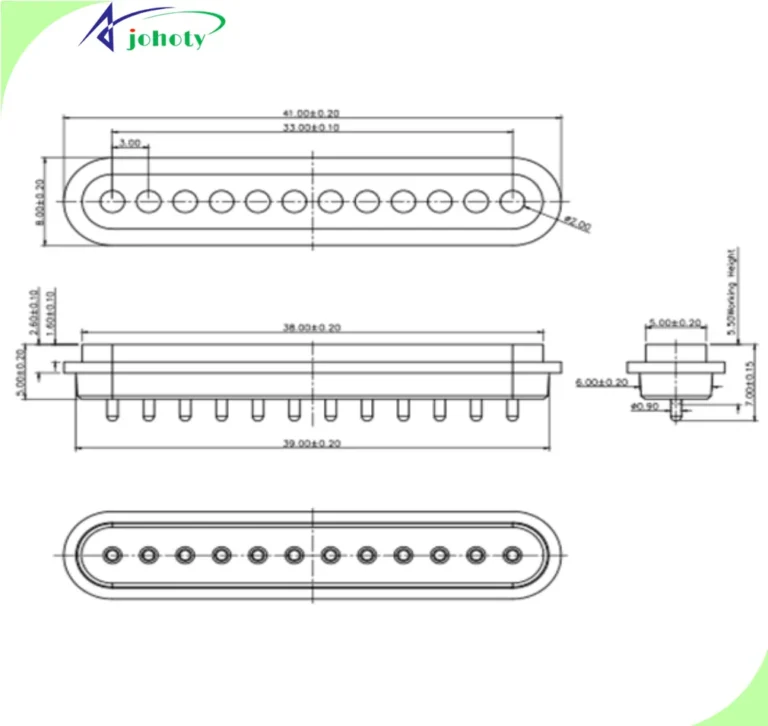

Connection accuracy: Adopting CNC machining + CCD full inspection process, barrel coaxiality control ≤0.01mm. Adaptive alignment within ±0.05mm during insertion and closing process, no manual assistance for positioning. Suitable for high-precision automatic assembly lines, slide rail connectors, cabin pre assembly interfaces, etc.

Current consistency: Continuous power on for 500 hours under full load state of 12 channels, with temperature rise <25℃. Single channel resistance deviation not exceeding 3mΩ, high reliability power supply/signal mixed application. Model aircraft, electric drive, and portable industrial terminals often use Johoty’s 12 pin electrical connector.

Anti misoperation structure: 90° symmetrical foolproof design, supports blind insertion >3,000 times without contact failure. The 12 pin electrical connector, combined with a guiding step structure, has automatic correction and limit functions during assembly. Anti reverse insertion, anti misalignment, anti pressure deviation, with a lifespan of over 10,000 insertions. Zero contact failure record, used for portable industrial control equipment and medical terminals with limited space and high-frequency maintenance.

Protection level: After assembly, the 12 pin electrical connector passes the airtightness leakage rate test of <10⁻³ Pa·m³/s. Salt spray for 48 hours without corrosion, commonly used in unmanned aerial vehicles, outdoor power sources, underwater measurements, and wind power terminals.

Modular customization: A minimum pitch of 1.0mm can be customized according to customer electrical needs, with an adjustable elastic range of 5gf-5N. The elasticity curve can adjust the elasticity and rebound rate. Gold plating thickness is 0.5μm-5μm, which is wear-resistant and corrosion-resistant.

Real time detection visualization: Provide multi-point impedance spectra before delivery. Each batch of 12 pin electrical connector comes with an inspection report. Whether the docking is good can be judged within 3 seconds, suitable for R&D verification, production line sampling, and after-sales review.

High strength housing structure: The housing is made of PA66 + GF30% engineering material, which undergoes high-temperature aging at 85℃ for 1,000 hours without deformation. After 10,000 repeated impact tests, there was no looseness or displacement in the 12 pin electrical connector interface. Long term structural stability, used for heavy industry, military, and rail transit interfaces.

Reliable life assessment: Mechanical life assessment was conducted according to MIL-STD, and the measured insertion and removal life exceeded 10,000 times. The terminal resistance is controlled to float up within 5mΩ, with a 0.05mm wear-resistant arc top coating. Significantly better than the lifespan of conventional phosphor bronze barrel.

Cross industry engineering support: Existing clients include medical, surveying, electric drive control, new energy, and rail transit systems. Support providing application solution diagrams, assembly simulation diagrams, and mechanical model parameter docking. Ensure that the design selection cycle is less than 3 days and shorten the BOM decision-making process. Adapt to prototype development, validation, pilot production.

Click: More Catalog

FAQ

How many times can 12 pin electrical connector be plugged? Has the electrical performance deteriorated?

The plug-in cycle test is ≥10,000 times, and the Δcontact resistance is ≤ 5mΩ, which complies with MIL-STD. Gold plating thickness ≥0.5μm, stable conductivity under long lifespan, without significant mechanical wear or performance drift.

Does 12 pin electrical connector support blind insertion? Does it have foolproof design?

Supports 360° self alignment and anti misplacement structure, with interface featuring limit and guiding step design. Under blind insertion conditions, if the pin misalignment is less than 0.05mm, it can still self-correct. Frequent maintenance or invisible assembly of the application leads to a near zero misplacement rate.

Has the waterproof rating of 12 pin electrical connector been verified by the entire machine? Can it be used outdoors or in high humidity environments?

Passed IP67 rating test in fully assembled state, with no leakage for 30 minutes at water depth of 1 meter. The supporting sealing components shall withstand high and low temperatures of -40℃~ + 85℃ without failure during cyclic testing. Used for outdoor energy systems, underwater terminals, and high humidity electrical warehouses.

What current/signal hybrid specifications does 12 pin electrical connector support? Is the consistency of conductivity controllable?

The 12 pin electrical connector allows for arbitrary configuration of high current Max 10A continuous and signal channels. Impedance matching supports 85Ω/100Ω differential. Multi channel measured ΔR<3mΩ, with a typical voltage drop error controlled within ± 2%. Meet the integration requirements of synchronous power supply and high-speed signal.

Does 12 pin electrical connector provide customized structural dimensions and performance parameters? What are MOQ and delivery cycle?

Support 2-598 pin arbitrary configuration, pogo pin pitch ≥1.0mm, pin spring force 5gf-5N. Brass is gold-plated, and the coating thickness can be defined as needed. Within a standard delivery cycle of 15 working days, NRE supports small batch orders of up to 3,000 sets for customized 12 pin electrical connector. Provide a sample validation report.