Waterproof & Dustproof Pogo Pin Connector? Our IP67 solution, ensured by injection molding, protects in any harsh environment. Find Yours Here.

Introduction: How to ensure waterproof and dustproof performance of IP67 pogo pin connector through injection molding?

Injection molding technology? It can help designers and engineers achieve reliability and durability of equipment in harsh environments. The IP67 pogo pin connector under injection molding can operate in environments with high temperature, extreme cold, humidity, and dust. How to guarantee clients’ equipment continuous and stable operation has become the most common requirement for Johoty’s high-end customers. Many customers require Ip67 pogo pin connectors with excellent waterproof and dustproof performance in devices that require precise connections. Because it directly determines the lifespan and operational efficiency of customer equipment.

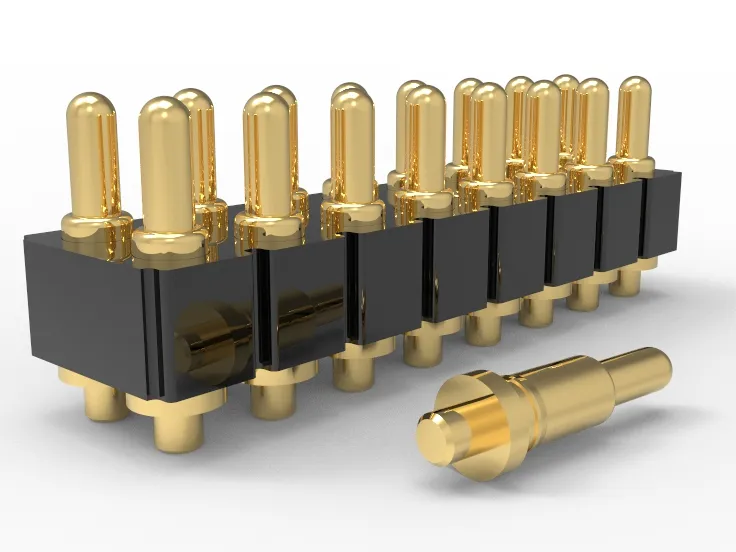

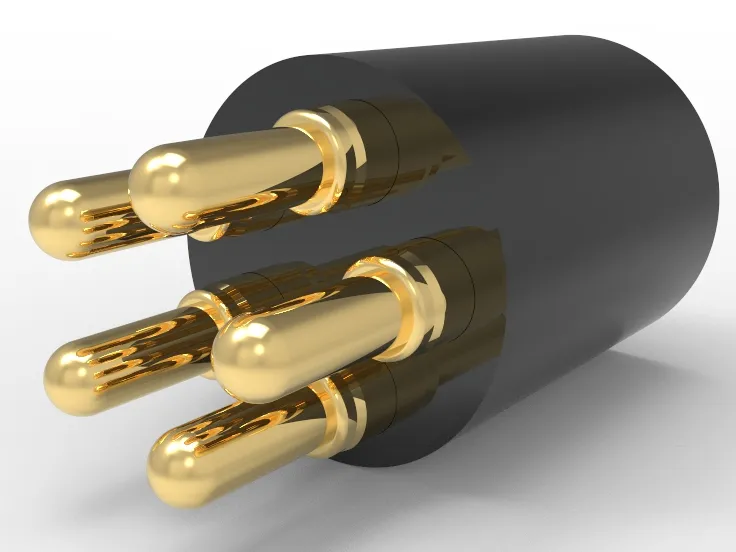

IP67 pogo pin connector, Excellent protective performance and precise design. It has become a key technology to solve this problem. It can be used in automotive electronics, automation equipment, robotics technology, and medical devices. Johoty’s IP67 pogo pin connectors are ubiquitous, ensuring the safety and stability of customer devices.

But what makes IP67 pogo pin connectors work stably in extreme environments? The answer lies in the advanced manufacturing process and injection molding technology adopted by Johoty. In this blog post, Johoty will delve into injection molding technology. Ensure the strong waterproof and dustproof capabilities of IP67 pogo pin connectors. Help your device stand out in various challenges and maintain outstanding performance.

Core advantages of injection molding technology

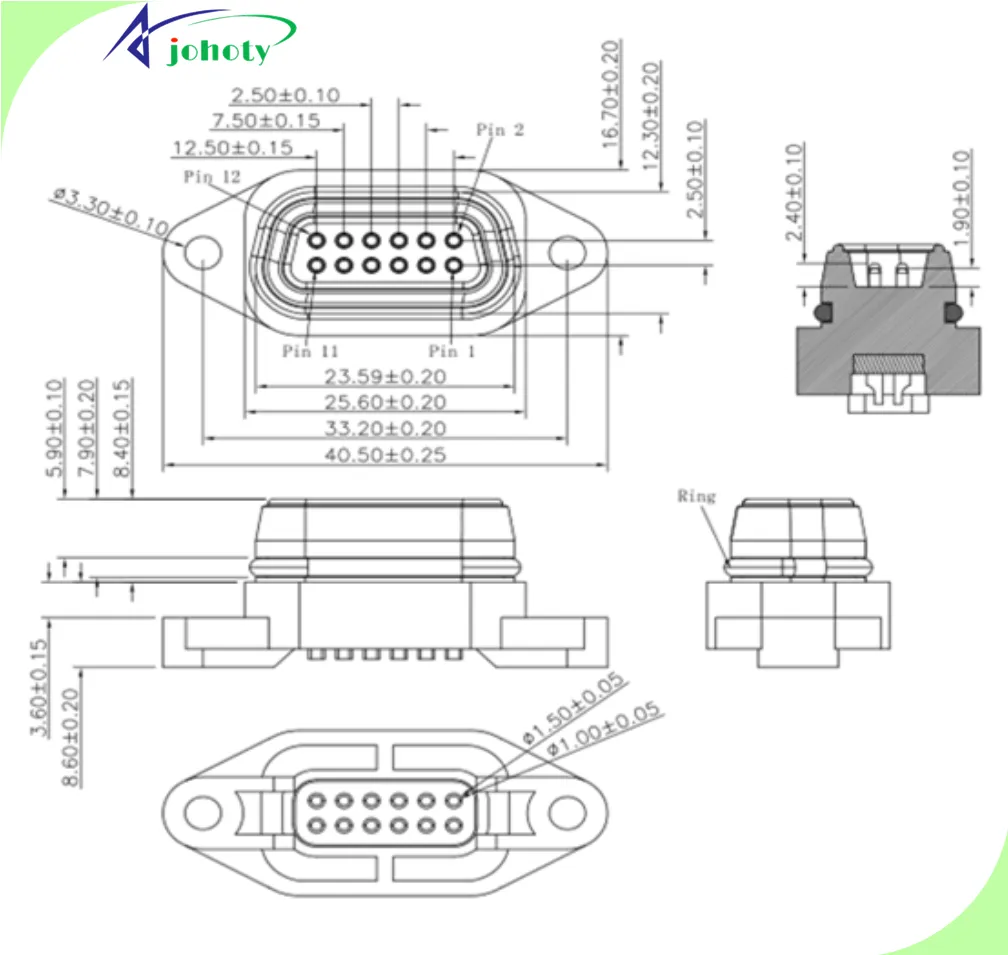

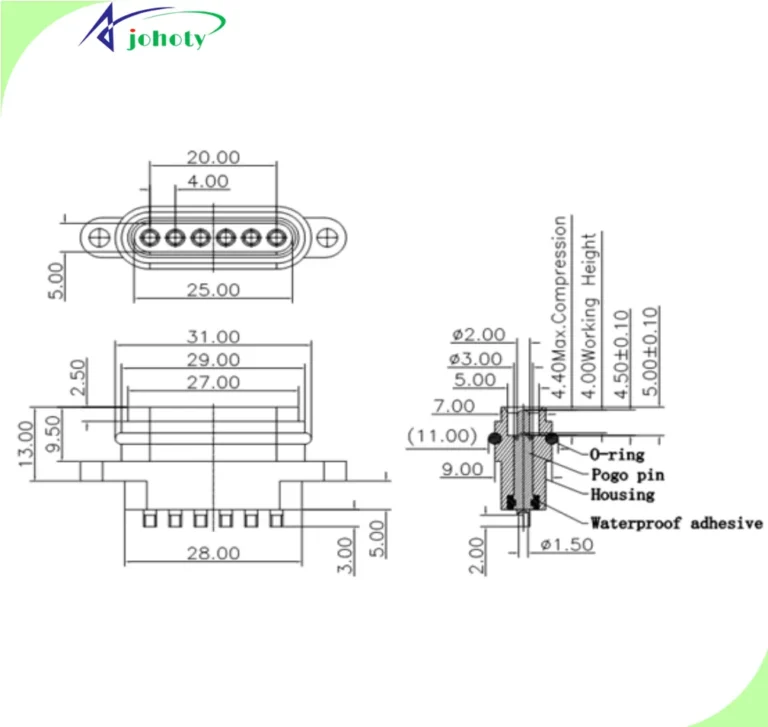

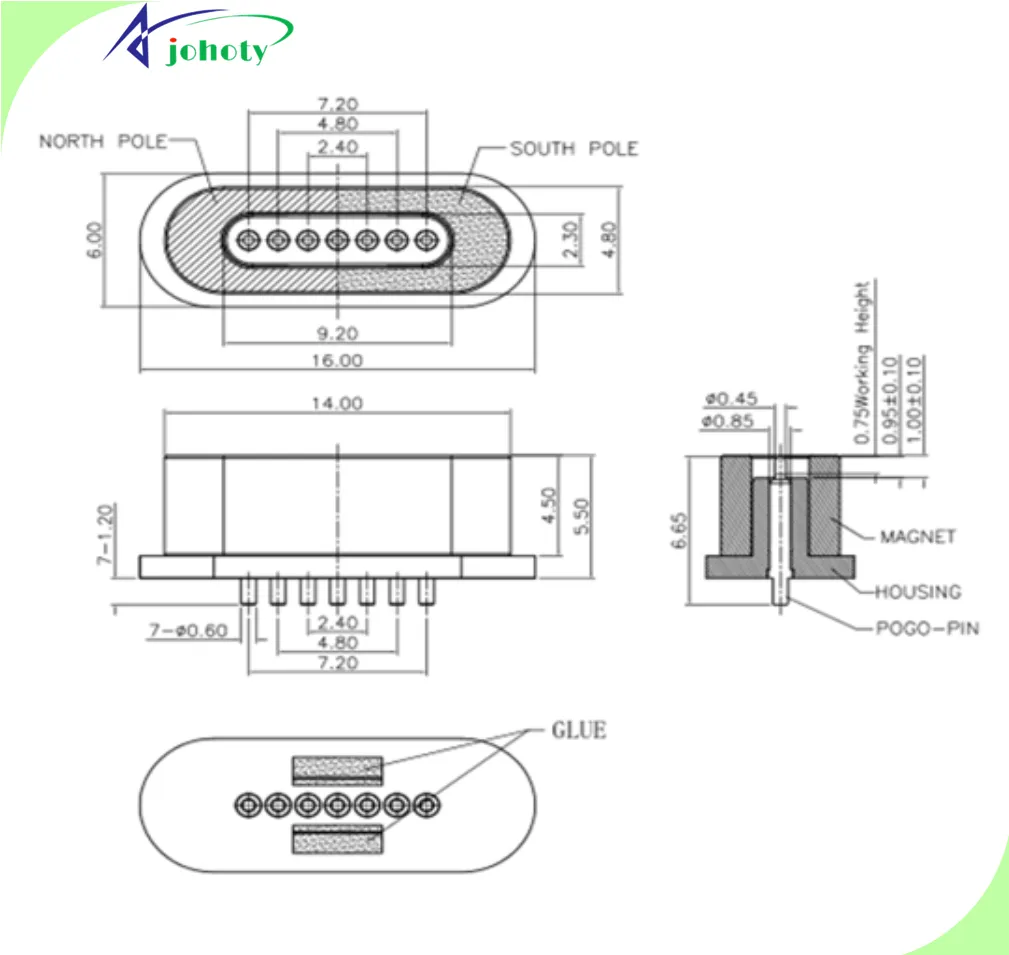

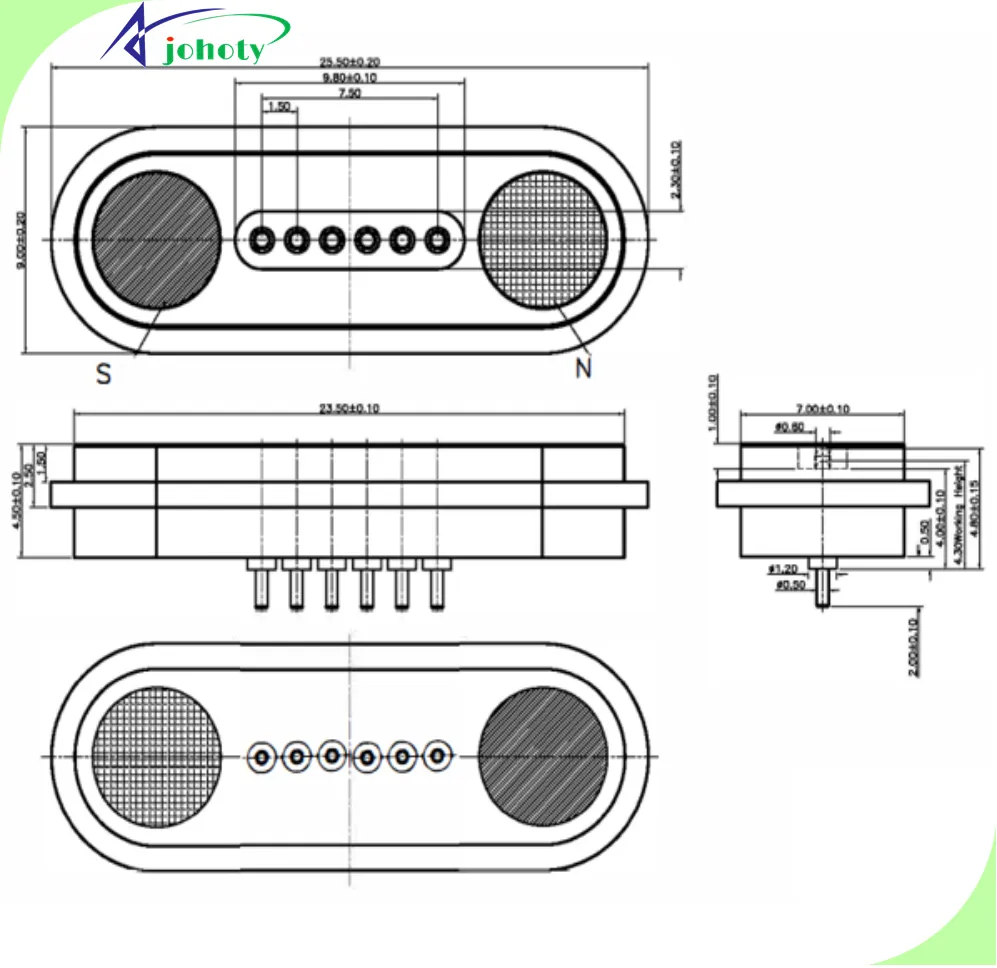

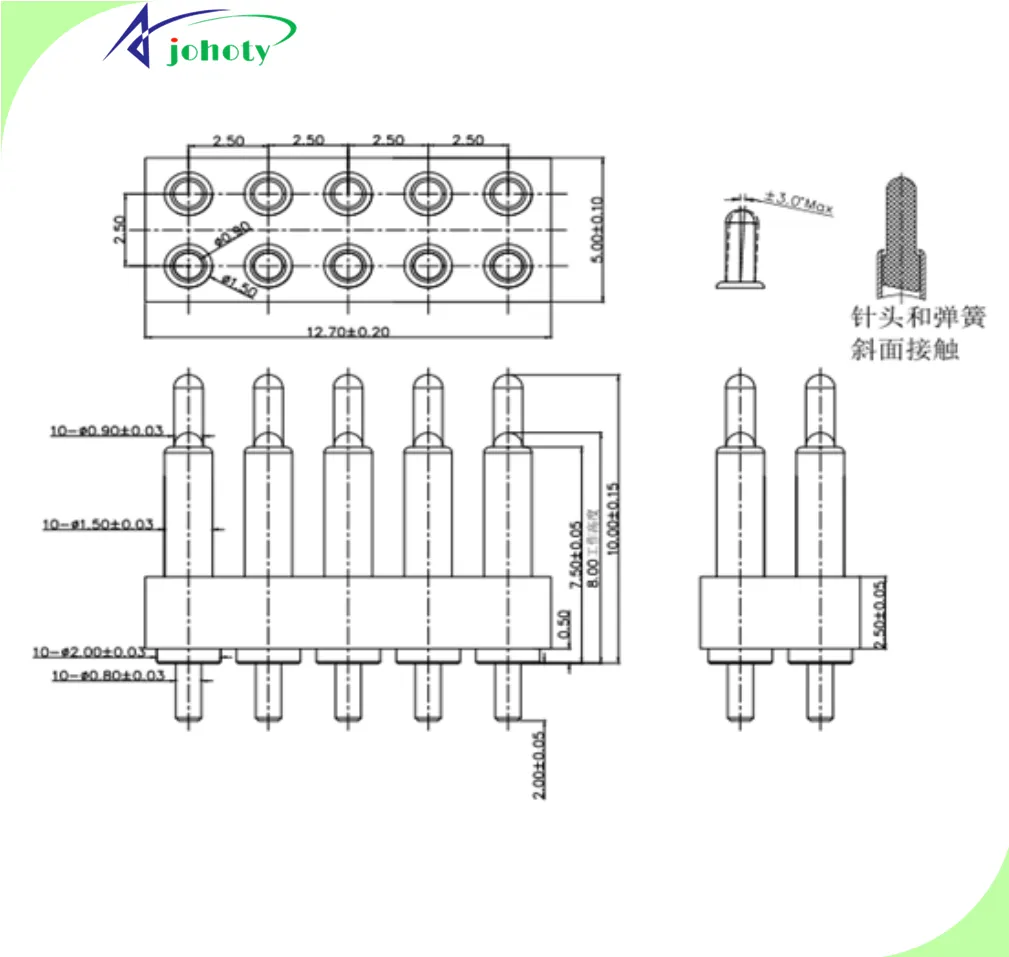

IP67 or IP68 injection molding technology is a critical process for manufacturing high-quality and reliable IP67 pogo pin connectors. Through injection molding, the size and shape of each connector can be precisely controlled. This ensures that the pogo pin connector has good sealing performance. The IP67 standard requires connectors to be able to soak in water up to 1 meter deep for 30 minutes without any water damage. This standard enables IP67 pogo pin connectors to work stably in harsh conditions. Injection molding provides extremely high precision and consistency, which can meet this strict requirement.

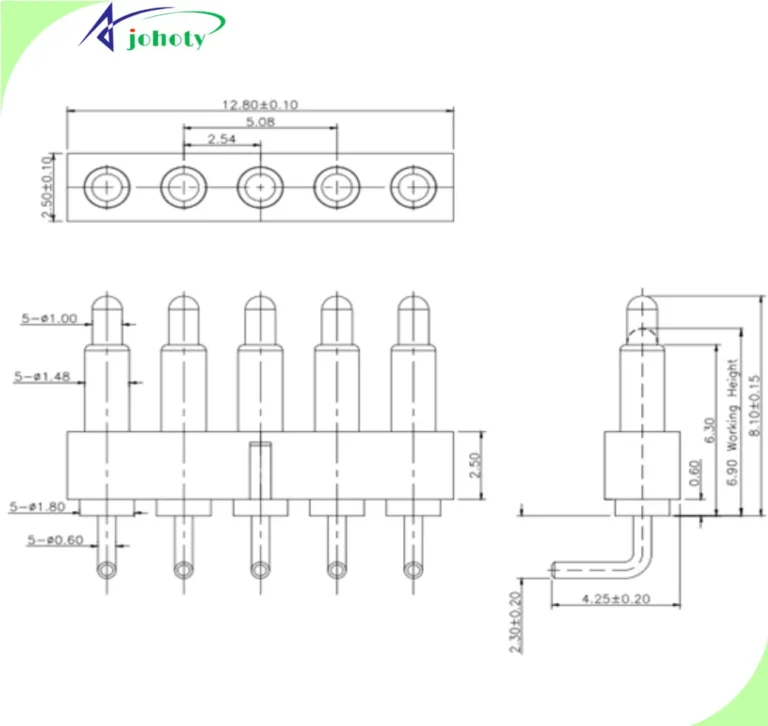

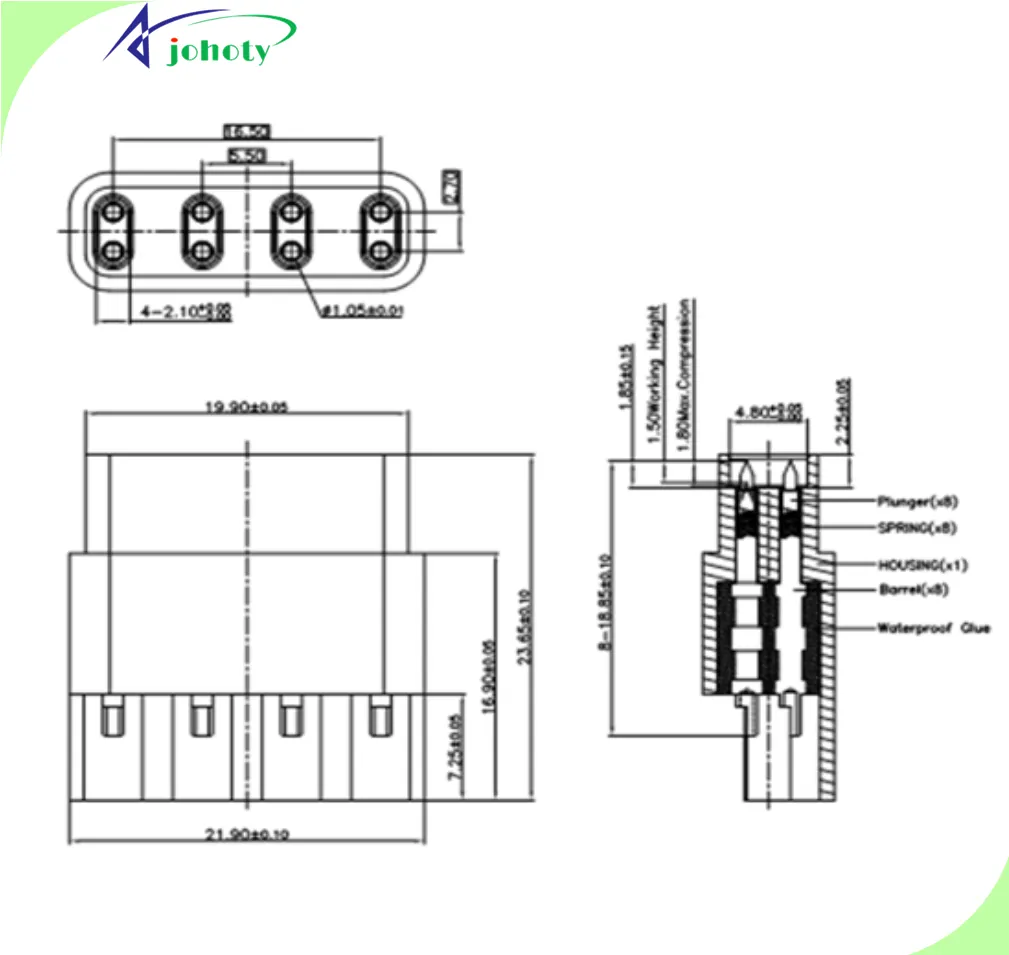

The advantage of injection molding is to ensure product accuracy and provide effective waterproof and dustproof protection. By using precision molds, high-performance plastic or rubber materials are precisely injected into various components of the connector. It ensures that every detail is fully protected. Through injection molding process, Johoty can greatly enhance the protective performance of pogo pin connectors. It can also significantly reduce errors and inconsistencies in production, ensuring stable and reliable quality of each batch of products.

How can injection molding improve the protective performance of connectors?

Injection molding can accurately manufacture the shape of pogo pin connectors. It can also form an effective protective layer on the outer shell of the pogo pin connector. This protective layer can prevent moisture and dust from entering the interior of the connector. Ensure long-term stable operation of the connector. By precisely controlling the temperature and pressure during the injection molding process, Johoty can ensure that the housing of each pogo pin connector is completely sealed. Neither external water nor dust can penetrate into the interior. This process makes the sealing performance of pogo pin connectors far superior to other traditional manufacturing methods.

In addition, injection molding is also crucial on selecting raw materials. High quality plastic materials can withstand extreme temperature changes and mechanical impacts. Not only does it provide waterproof and dustproof functions, but it can also maintain its structural stability after long-term use. In this way, Johoty’s IP67 pogo pin connectors can maintain efficient performance in various demanding industrial applications. With the continuous emergence of new high-performance materials, Johoy’s future injection molding technology will provide connectors with stronger protection capabilities and longer service life.

The difference between injection molding and traditional manufacturing methods

Compared with traditional metal processing or manual assembly methods, injection molding technology has significant advantages. Traditional methods are often based on manual operations, which can bring clients errors and inconsistencies. And injection molding technology can produce in high-speed and precise environments. It ensures consistency in the quality of each connector. Metal processing usually requires additional post-processing steps. Injection molding can be completed in one process, and minimizing various interference of human errors and production costs.

Through injection molding, Johoty is able to produce a larger quantity of high-quality IP67 pogo pin connectors more efficiently. And ensure each batch of pogo pin connector meets the same protection standards. This process improves production efficiency and greatly reduces production costs. Therefore, in large-scale production, injection molding technology has become an essential process. The widespread application of injection molding has also provided new ideas for the production of other high standard products, promoting the development of industrial manufacturing.

How to solve practical problems through IP67 pogo pin connector?

In practical applications, many devices need to work in damp, dusty, or even flooded environments. Automated equipment, vehicle electronic systems, medical equipment, etc. all require connectors that can withstand harsh environments. The IP67 pogo pin connector provides excellent waterproof and dustproof capabilities through injection molding technology. Can solve the problem of equipment stability in these industries. These devices often face various challenges brought by the external working conditions during their long-term use. Johoty’s IP67 pogo pin connector helps devices effectively overcome these issues and maintain excellent performance.

In addition, the IP67 pogo pin connector will not affect its electrical performance in extreme environments. Excellent sealing performance prevents external moisture, water and dust from entering connector interior. Effectively avoiding electrical short circuits or poor connections caused by environmental factors. It can ensure the long-term stability and reliability of the equipment. High precision and high stability devices often require our IP67 pogo pin connectors. Because they can greatly improve the service life of guest equipment.

Wide application of IP67 pogo pin connector based on injection molding

IP67 pogo pin connectors are widely used in various fields that require waterproof and dustproof protection. Johoty’s customers often come from fields such as automation control, robotics, automotive electronics, and medical equipment. The demand for our IP67 pogo pin connector is constantly increasing. Because devices in these fields often need long-term stability and high performance in harsh working environments. The protective capability of connectors directly affects the performance and lifespan of equipment. More and more customers from various industries are paying attention to the protective capabilities of their equipment. Johoty’s IP67 pogo pin connector is the best choice to meet these needs.

In these industries, equipment needs to be able to withstand high humidity, high temperature, dust, chemical corrosion, etc. Our IP67 pogo pin connector has excellent sealing performance. They can ensure that guest devices continue to operate stably under these conditions and are not affected by external environmental interference. With the acceleration of industrial intelligence and automation, IP67 pogo pin connectors will be applied in more fields.

Conclusion: Contact Johoty immediately to address your connector needs

Johoty often manufactures IP67 pogo pin connectors using injection molding technology. With excellent waterproofing and dustproofing as well as high reliability, it’s the preferred solution in various industries. If your device requires efficient and stable connectors to cope with harsh environments. Johoty’s IP67 pogo pin connector is undoubtedly your best choice. With its excellent design and advanced production technology, Johoty ensures that every pogo pin connector meets the highest standards. We ensure that they adapt to the most challenging application scenarios.

Contact Johoty immediately to learn more about IP67 pogo pin connectors. Let us help you solve the technical challenges of waterproofing and dust prevention. Based on injection molding technology, ensure that your device maintains optimal performance in any environment.

+86 13590816656

+86 13590816656 +86 13590816656

+86 13590816656