SMT connector, Custom-engineered High-Frequency Pogo Pin for reliability in medical, aerospace, and test. Request a Quote for Your Project.

Introduction: Why is SMT connector crucial?

In modern medical, aerospace, and testing industries, the quality and reliability of connectors are crucial to overall system performance. Especially Johoty’s SMT connector provides stable and efficient connection solutions for various precision systems. In high-frequency communication requiring strict accuracy, SMT connector is the core component.

However, many traditional connectors can’t meet the stringent requirements of these high-end systems due to design limitations. And Johoty’s customized high-frequency pogo pin solves these challenges. It provides higher stability, longer service life, and better performance. This article will delve into why SMT connector is crucial for high-end systems? And how can Johoty’s innovative products solve your related problems?

What is SMT connector?

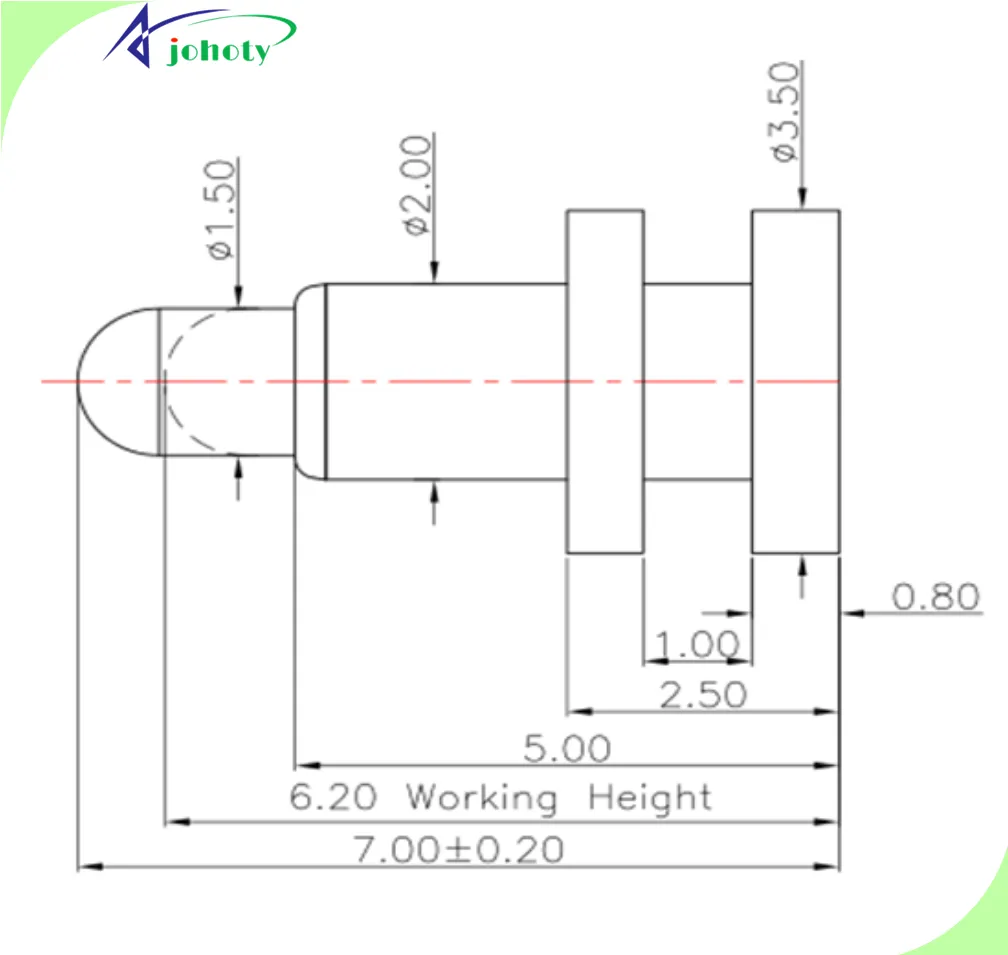

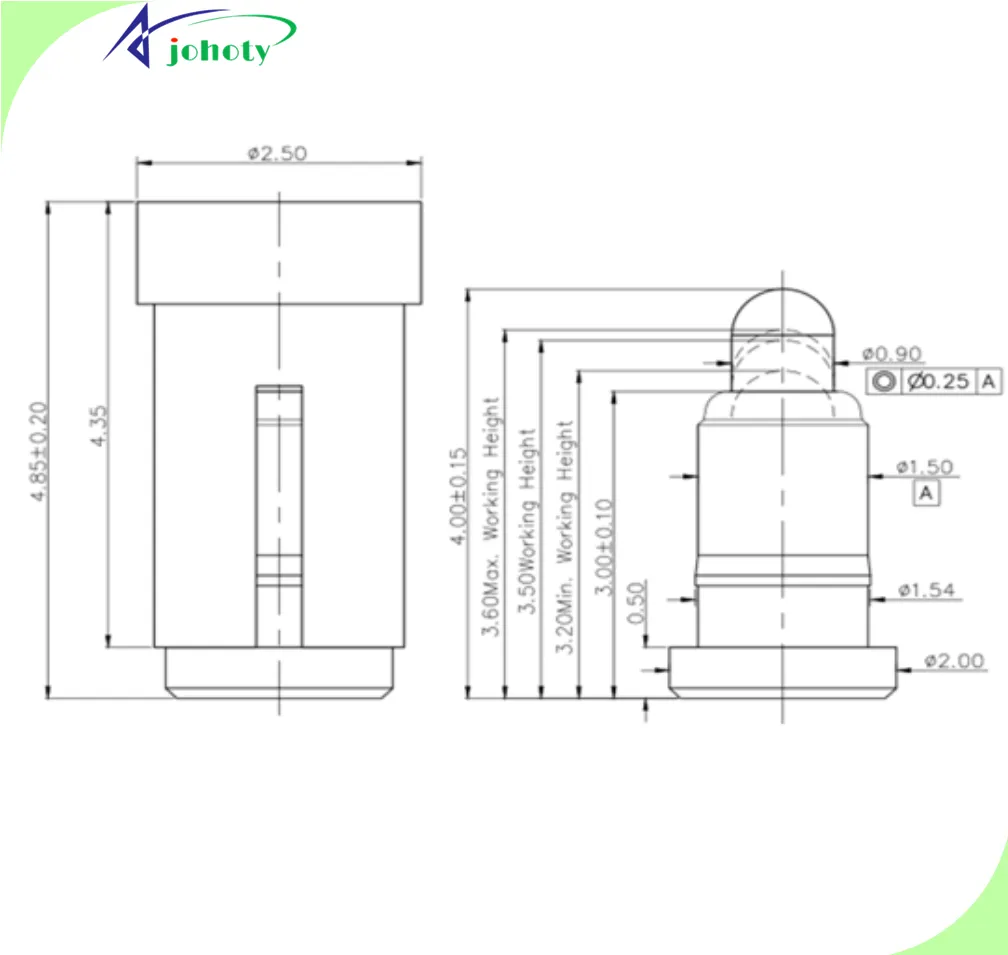

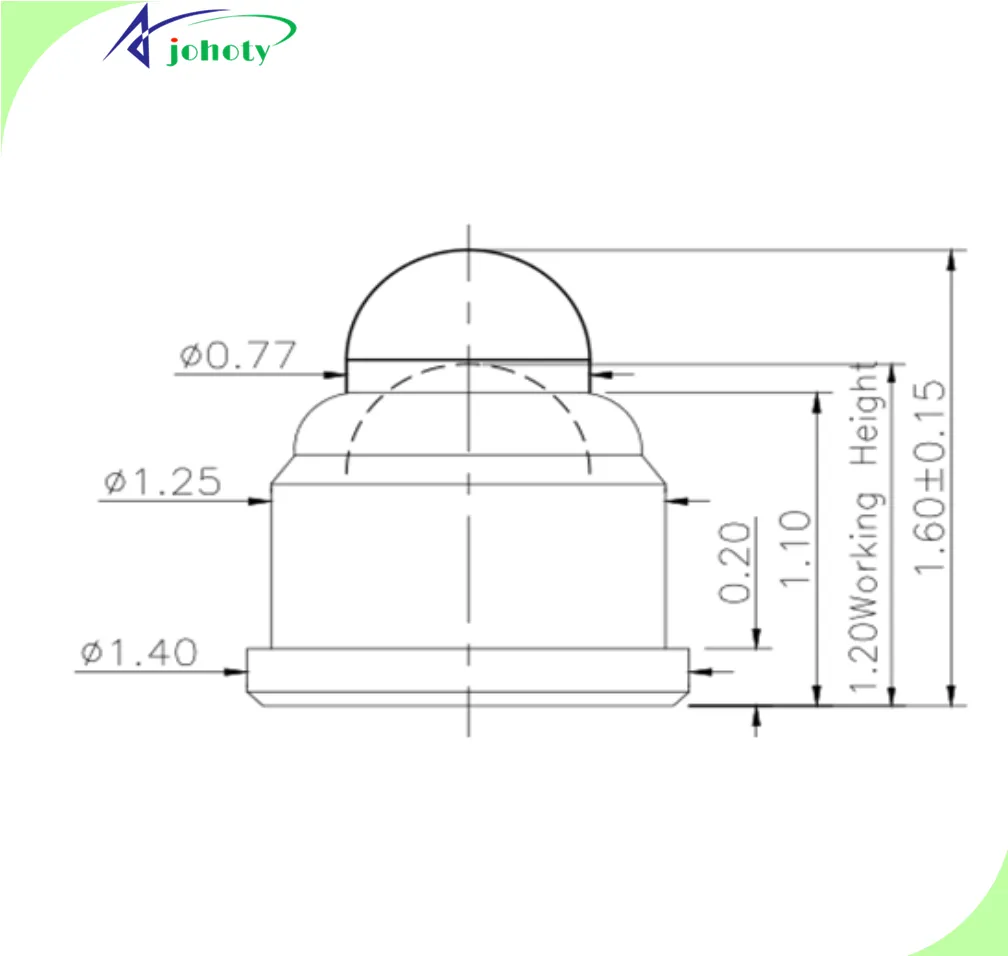

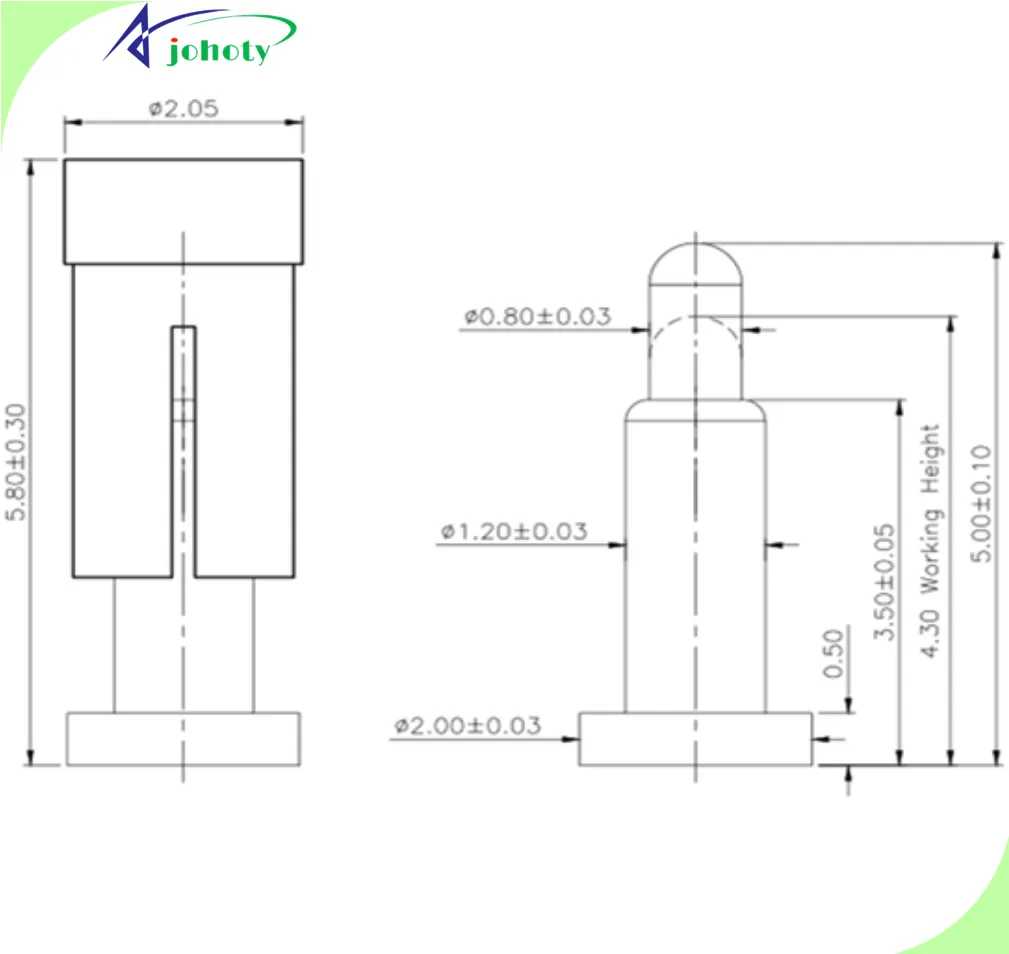

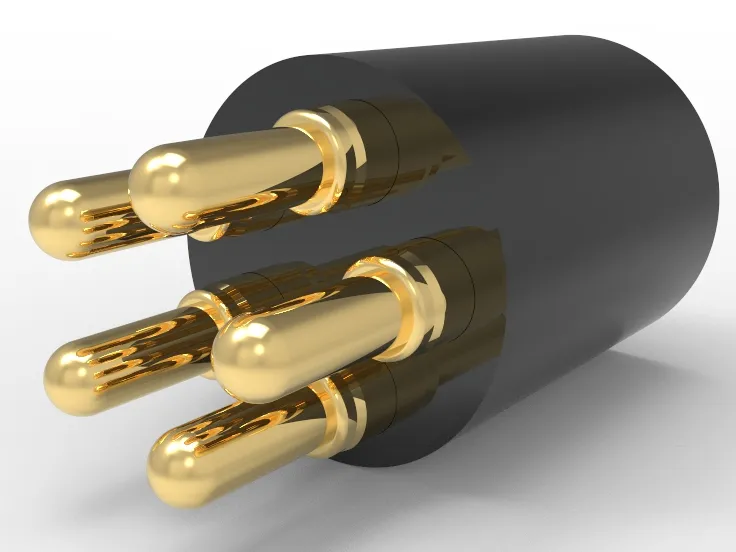

SMT connector, as the name suggests, is a connector installed through surface mount technology. Unlike traditional pin connectors, SMT connector is directly soldered to the surface of the PCB. Having a smaller volume and higher density. It’s suitable for modern electronic products, limited space, and required high efficiency.

It’s often mounted in high-end medical equipment, aerospace and testing equipment. The reliability and durability of SMT connector directly affect its stability. In high-frequency applications, the quality and performance of connectors are crucial. It requires a stable electrical contact to ensure clarity and accuracy of signal transmission.

Why is SMT connector crucial for high-end system?

In the high-end medical, aerospace, and testing industries, connectors are the bridge between electrical components. It carries high-frequency signals. Therefore, connector quality always directly affects the performance, reliability, and lifespan of the entire system.

High frequency performance: SMT connectors can handle high-frequency signals. Johoty always uses high-quality beryllium copper raw materials and precise designs. It can withstand interference from high-speed currents and high-frequency signals, and accurately transmit data. Traditional connectors have significant interference in high-frequency signal transmission. Many customers use high-speed Johoty, which is prone to distortion and packet loss.

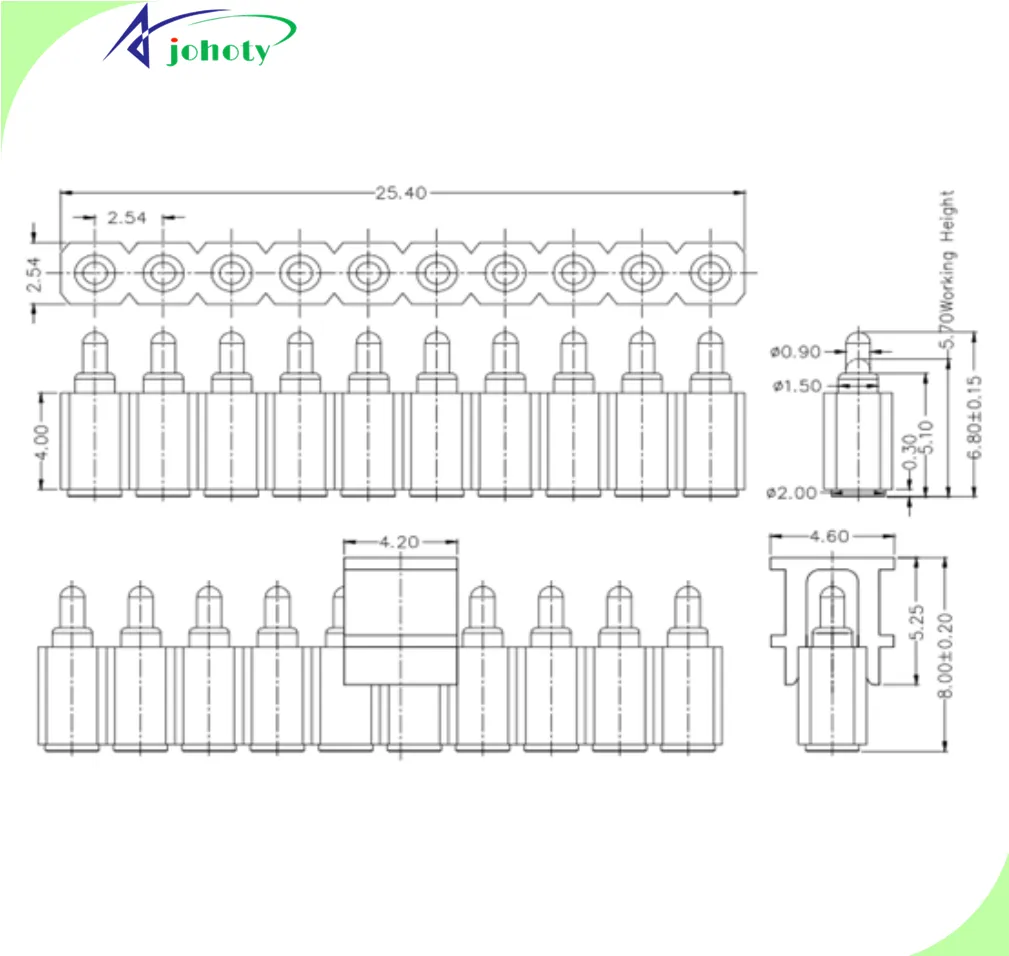

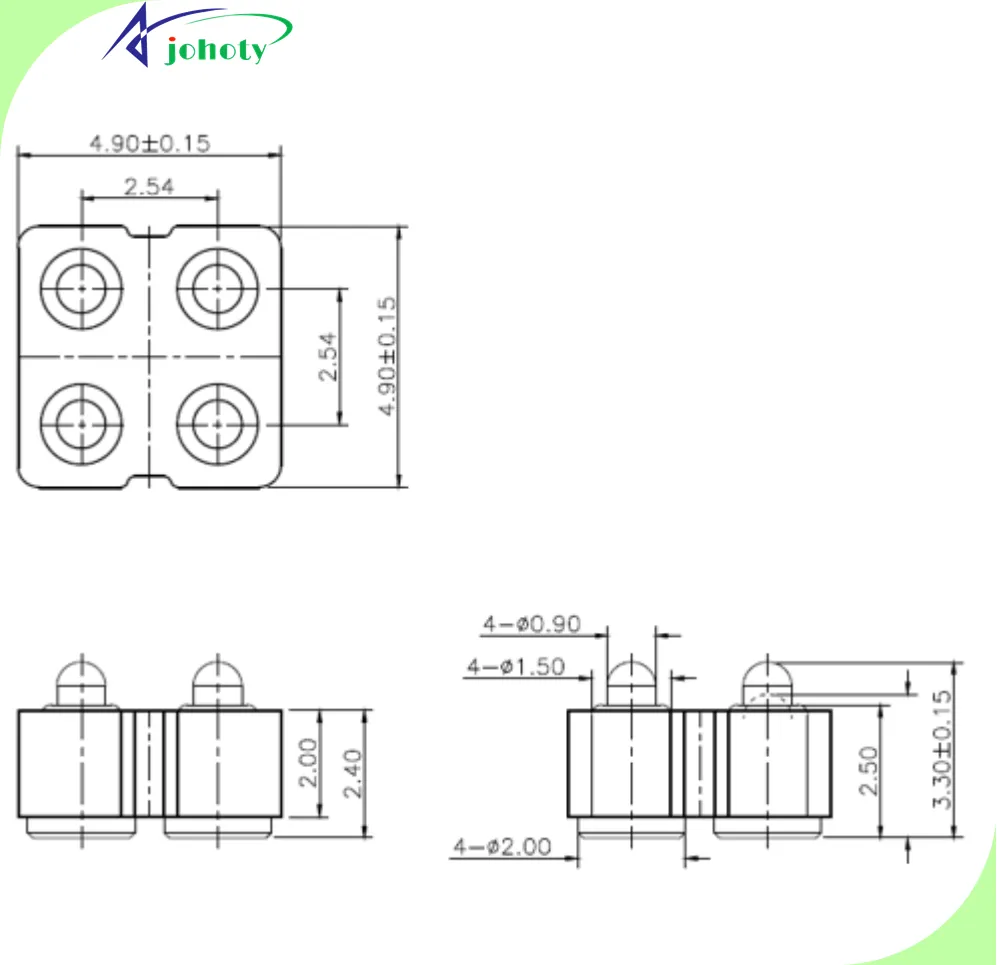

Compact design: Limited space is a common challenge in modern electronic products. The compact design of Johoty’s SMD connectors provides powerful functionality within a limited space. It is suitable for miniaturized medical equipment and aerospace products.

High reliability: The reliability of aerospace and medical systems is crucial. Our SMD connectors typically have higher durability. It can withstand extreme high temperatures, vibrations, and electromagnetic interference (EMI). Johoty can ensure the long-term stable operation of your device.

Lightweight: High end systems often require lightweight design, and SMD connectors can significantly reduce equipment weight compared to traditional connectors. It can meet the strict weight requirements in aerospace and other fields.

Corrosion and environmental resistance: Johoty’s SMT connectors are made of corrosion-resistant SUS304 or brass plated with thick gold. It can withstand humidity, corrosion, and other harsh environments. Many customers have high demands for aerospace equipment, such as Johoty.

Low cost and efficient production: The production process of SMD connectors is highly automated. It has lower costs and higher production efficiency in mass production. For high-end products manufactured on a large scale, this is an undeniable advantage.

The advantages of customized high-frequency pogo pins by Johoty

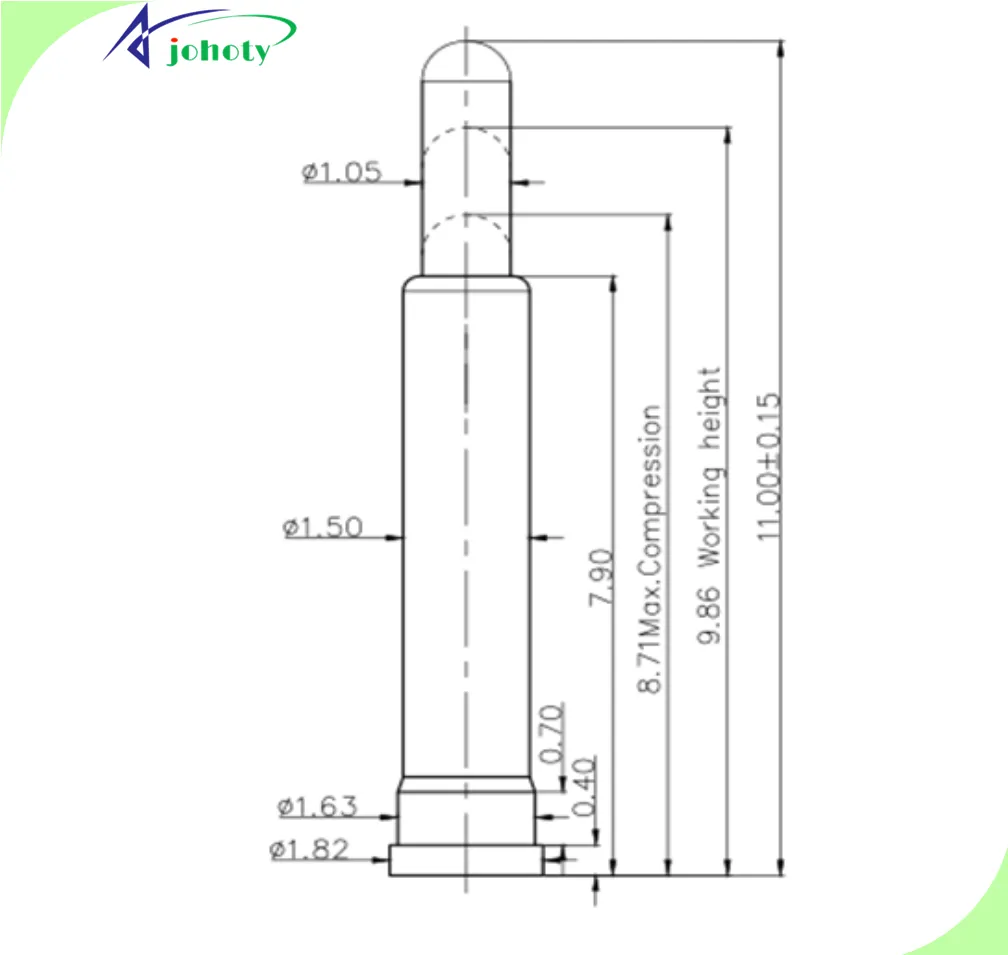

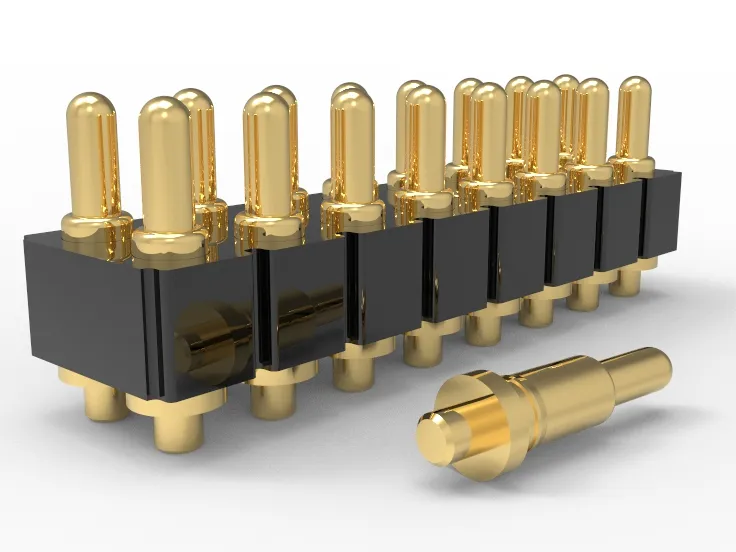

On the basis of SMT connector, Johoty’s customized high-frequency pogo pin further optimizes the electrical contact performance and mechanical stability of high-end systems.

Accurate contact performance: Johoty adopts the most advanced design and gold-plated brass material to produce pogo pins. At high frequencies, it can provide stable and efficient electrical contacts. It can ensure the clarity and accuracy of data transmission, avoiding signal loss or interference.

Customized service: The pogo pin provided by Johoty is customized flexibly based on clients’ specific needs. This includes different sizes, shapes, contact impedance, elasticity, and operating frequencies. It can meet requirements of different high-end systems. Johoty can provide the most suitable solutions for medical equipment, aerospace applications, and other high-precision fields.

Durability and Long Life: Johoty’s high-frequency pogo pin has a durability of up to 200,000 cycles. It can maintain stable electrical contact. Reduce the need for equipment maintenance and extend the service life of customer products.

Low contact resistance: A contact resistance as low as 10mΩ is the key to ensuring stable transmission of high-frequency signals. Johoty’s pogo pin is optimized through contact design. It has low resistance and low noise, improving system overall performance significantly.

Diverse application scenarios: high-speed data transmission, precision measurement, high-frequency communication, Johoty’s SMT connector can provide reliable connections. It is often mounted by SMT machines in high-end medical, aerospace, and testing equipment.

Flexible design solutions: Johoty supports flexible design adjustments. We can optimize the contact method and spring force of pogo pins according to customer needs. Achieve optimal performance to flexibly meet customer applications.

How does Johoty high-frequency SMT connector solve the challenges of high-end systems?

High end systems often face multiple technical challenges. This includes issues such as signal stability, durability, and contact reliability. The customized design of Johoty high-frequency SMT connectors is aimed at addressing these issues. Johoty can provide tailored solutions for each customer. It can also ensure that customer products can maintain stable connection even under extreme working conditions. Help customers greatly improve the overall quality of the system.

Improving signal stability: Johoty’s SMT connector ensures high stability and low contact resistance. It can avoid interference from high-frequency signals and ensure the accuracy of data transmission.

Adapting to harsh environments: The temperature resistance, vibration resistance, and other characteristics of high-frequency SMD connectors can adapt to extreme working environments in industries such as aerospace. Ensure stable operation of the equipment under various conditions.

Longevity and Low Maintenance: Johoty’s SMD connectors design emphasizes longevity and low maintenance costs. Reduced the risk of equipment failure and maintenance complexity. Help customers greatly improve equipment availability and work efficiency.

How to choose suitable SMT connector and Pogo pins?

When choosing suitable SMD connector and pogo pin, the first thing to consider is the requirements of the application environment. Choose the most suitable product based on different operating frequencies, currents, space requirements, etc. Johoty’s customization ensures that every SMT connector and pogo pin can perfectly match the customer’s needs. At the same time, it provides the best performance.

Conclusion: Contact us immediately for more customized SMT connector solutions

In high-end systems, the reliability and stability of SMT connector is crucial for the overall performance of the equipment. Johoty can customize high-frequency SMT connector. You can ensure that your device can maintain excellent signal transmission and stability in various high-frequency environments. Contact Johoty immediately for more information about SMT connector and customized pogo pin. Let Johoty help you solve your technical challenges and achieve higher system reliability and performance.

+86 13590816656

+86 13590816656 +86 13590816656

+86 13590816656