EMI shielding Ensures Stable Signals In Any Chaos. Custom Pogo Pin Connectors Keep Devices Reliable, Smooth, And Ready To Launch. See How Now

Introduction: Johoty’s EMI shielding pogo pin connector for maintaining stable connections in electromagnetic chaos

In a complex electromagnetic environment, any small instability can amplify into a catastrophic system collapse. EMI shielding is crucial in devices where high-speed signals, dense modules, and microstructures coexist. EMI has become a key challenge for system certification and mass production launch. The engineering team often spends several months on motherboard layout and filtering design, but in the final stage, the certification progress is slowed down by a seemingly insignificant connector.

Traditional pogo pin connectors emphasize elastic conductivity in their design, but overlook EMI shielding and high-frequency integrity. When the system is in a high radiation scenario, connectors become the most vulnerable entry point for signals. Spectrum distortion, data packet loss, clock jitter, module downtime, often point to connected nodes.

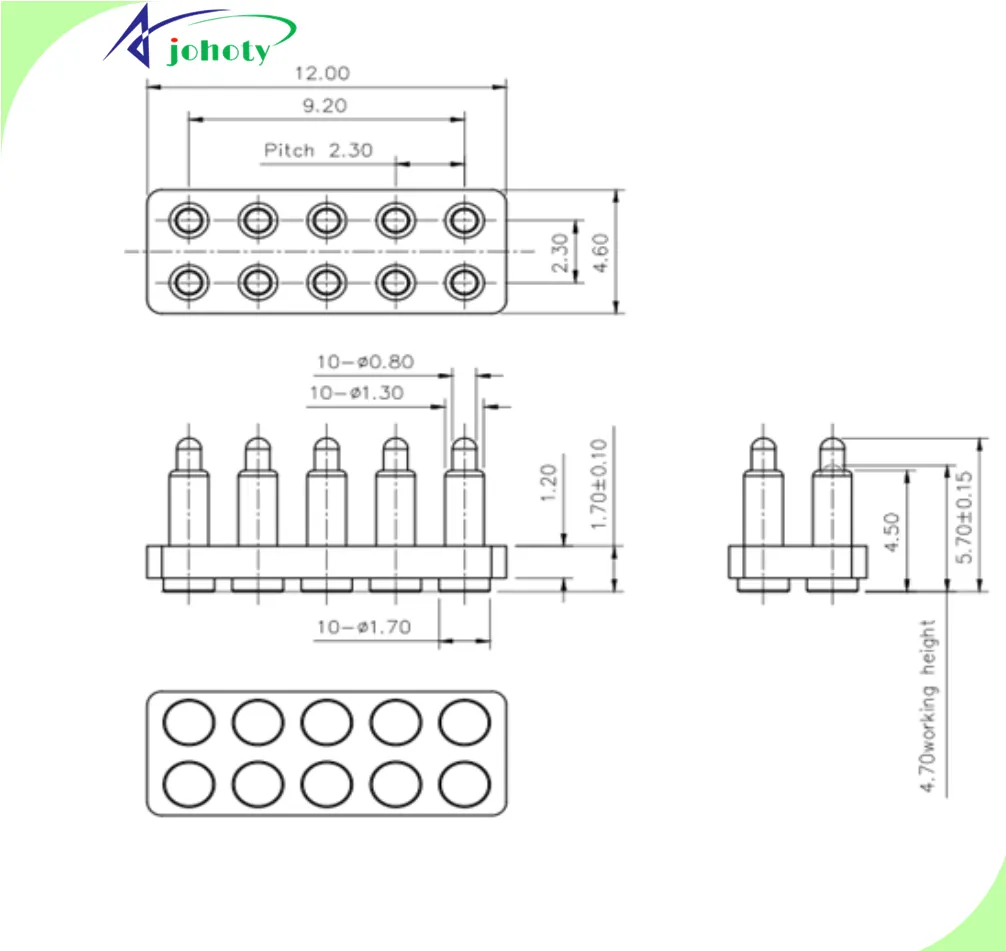

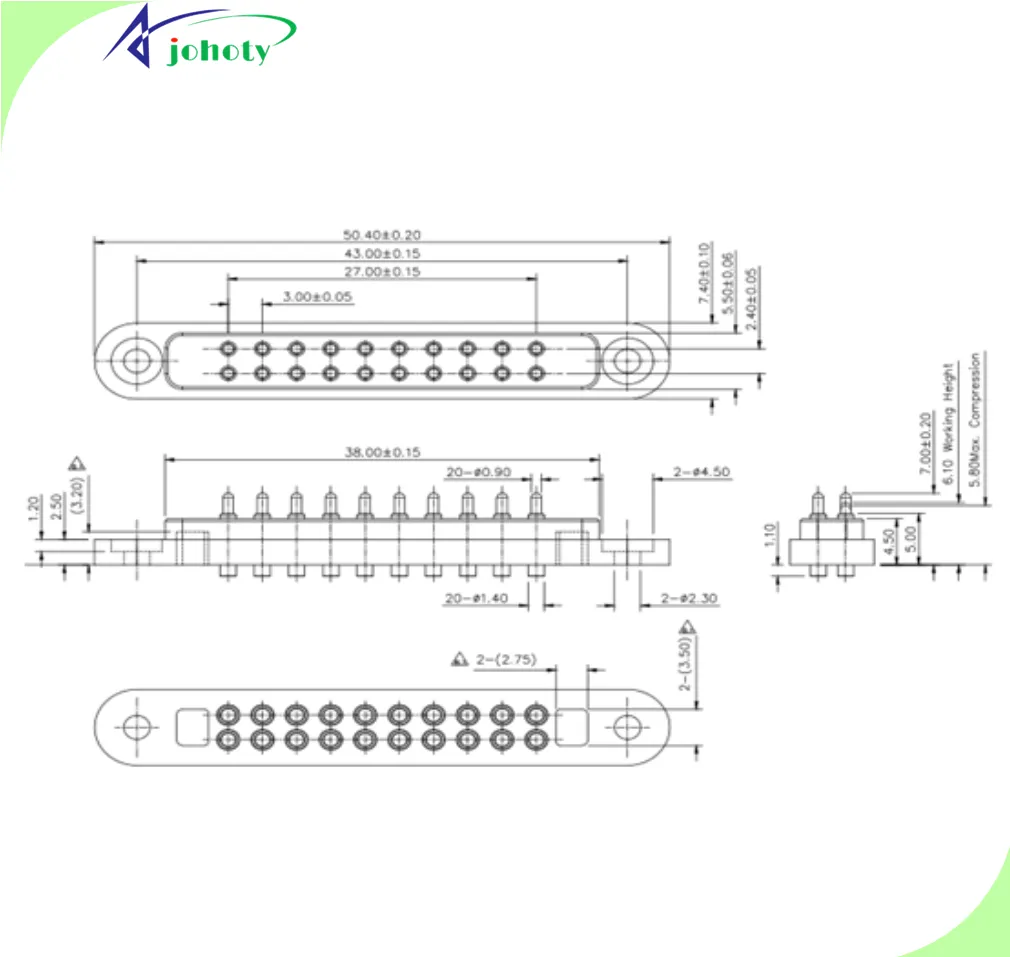

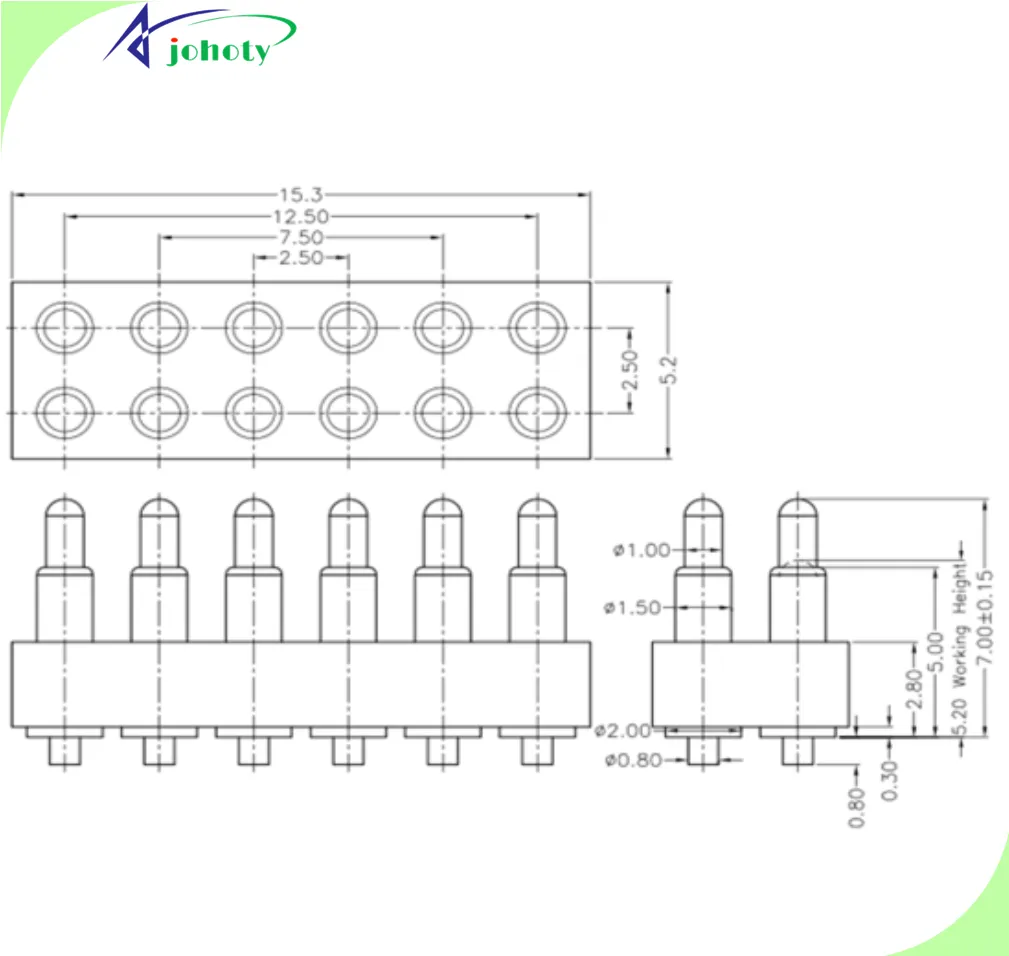

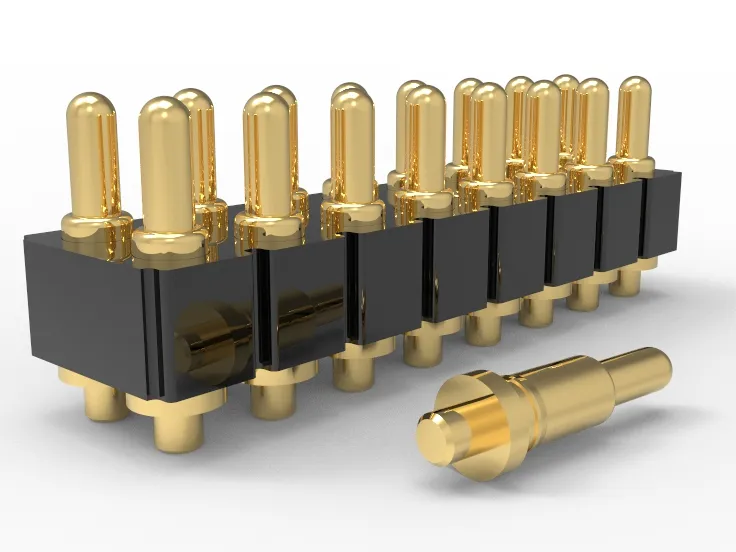

Johoty’s EMI shielding pogo pin connector integrates shielding, contact, high frequency, durability, and lightweight design. Every micro detail of it is designed to solve the five most headache inducing problems for engineering teams:

- Certification delay or failure due to EMI loss of control.

- The equipment exhibits unstable performance or crashes in complex electromagnetic environments.

- The high-speed signal path is restricted, forming a system bottleneck.

- Intermittent faults are caused by connector wear and oxidation after long-term use.

- It is difficult to balance lightweight and high reliability in product design.

Resolve authentication delay risk through EMI shielding pogo pin connector

For any electronic device planning to enter the European and American markets, EMI certification is often the biggest uncertainty factor. On average, about 12% of products are stuck due to EMI exceeding standards during the certification stage each year. About one-third of the issues arise from the connector area.

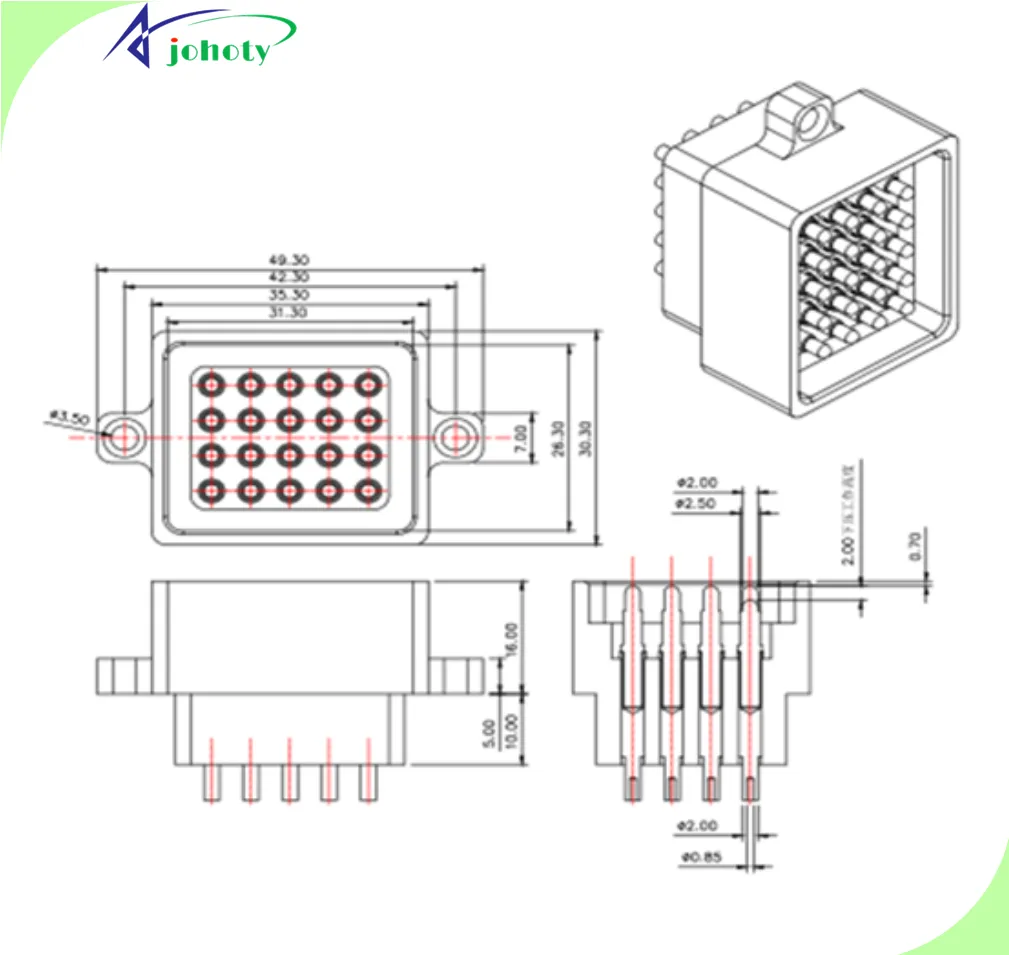

Johoty’s EMI shielding pogo pin connector completely changes this risk with an integrated shielding structure. Our design uses a 360 ° full circumference metal shielding layer to wrap around the contact area. Connect directly to the motherboard ground plane through a low impedance path to reduce the radiation leakage point to a negligible level. Experimental data shows that in the frequency range of 1-6 GHz, the average radiation energy leakage is reduced by 58 dB, and the overall EMI peak of the system is reduced by more than 30%.

The customer’s entire machine no longer experiences sudden spikes due to connection point leaks during certification testing. After being applied in laptops, smart home modules, and military communication equipment, the EMI acceptance rate of customers has increased to 98.7%.

By constructing an active shielding wall at the connector level, engineers do not need to repeatedly modify the PCB or add filtering networks. In this way, Johoty can significantly shorten the certification cycle for Johoty’s customers. For high-end manufacturing enterprises, EMI shielding pogo pin connectors are a key link in ensuring that products are launched on schedule.

EMI shielding pogo pin connector that maintains stable operation in complex electromagnetic environments

Certification is just the starting point, the real challenge comes from the long-term operation of the device in complex environments. Elevator control systems, medical imaging equipment, and industrial automation equipment all operate under continuous electromagnetic disturbances.

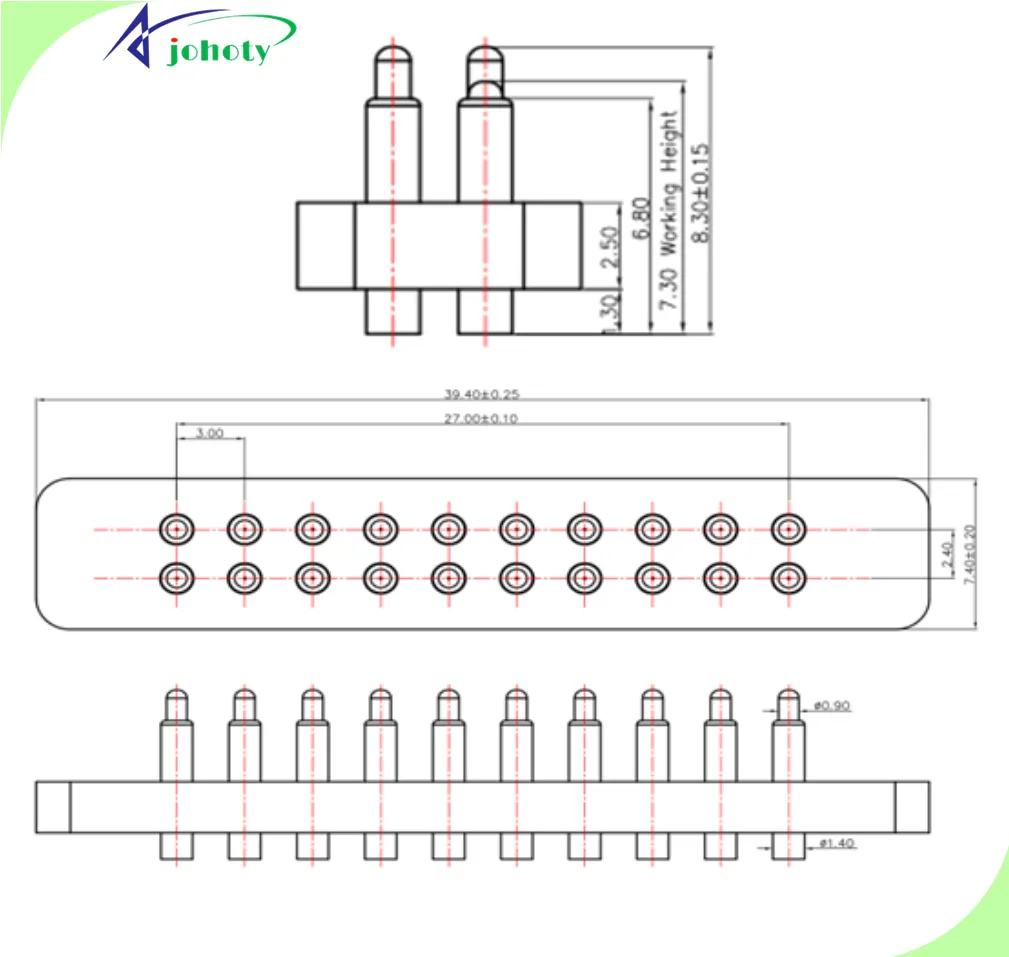

Johoty’s EMI shielding pogo pin connector adopts a coaxial grounding shielding structure. We also use foil and brain to form a nearly closed loop anti-interference barrier. The distance between the shielding layer and the contact pin is only 0.15 mm, ensuring that interference magnetic fields cannot penetrate the signal path. In the simulation, the signal error rate remains below 10⁻¹² under electromagnetic intensity environments ranging from 3 V/m to 20 V/m. We can ensure the stable and uninterrupted operation of customer devices.

At the same time, Johoty has made refined designs for contact stability: the multi segment elastic curve structure can maintain resistance fluctuations of no more than ± 0.3mΩ under 5g vibration. Even if the device encounters continuous impact and high-frequency shaking, the signal path will not be disconnected.

The customer verified in railway communication and radar system testing, testing in high interference scenarios. The average downtime rate of modules using this scheme has been reduced from 0.8% to 0.02%. In other words, EMI shielding pogo pin connectors can resist external interference. It ensures that the device remains stable in electromagnetic chaos.

High frequency performance optimization of EMI shielding pogo pin connector breaks through signal integrity bottleneck

The bottleneck of high-speed signal channels often lies at the connection points. With data rates increasing to 10 Gbps, 25 Gbps, and even 56 Gbps, connectors have become the most difficult part to overcome in the system signal chain. Johoty’s EMI shielding pogo pin connector adopts a coaxial transition structure. Maintain a constant impedance in the signal path to suppress reflection and crosstalk. The test results show that:

- At 10 Gbps differential signal, the insertion loss is only 0.6 dB.

- Return loss is significantly better than -25 dB.

- Crosstalk is <-60 dB.

- Group delay jitter is < 3 ps.

Compared to traditional pogo pin connectors (insertion loss of 1.5dB, return loss -15dB), the overall signal fidelity is improved by about 40%. This high-frequency optimization is suitable for consumer electronics. It supports more demanding communication equipment, radar front-end, and industrial grade high-speed data acquisition modules.

For engineers, system design can reduce additional compensation. The network does not require repeated simulation iterations, thereby saving project cycles and budgets. More importantly, EMI shielding pogo pin connectors are no longer a weak point in high-frequency environments. It can become an invisible accelerator to ensure system performance.

Durability and oxidation resistance of EMI shielding pogo pin connector extend connection life and stability

Another hidden danger on the construction site comes from poor contact after long-term use. Microzone oxidation, mechanical wear, or decreased elasticity of connectors often lead to intermittent faults in equipment that are difficult to reproduce.

Johoty’s EMI shielding pogo pin connector adopts a nano coating anti-oxidation system and a multi-layer composite contact structure. The surface layer of the contact is a three-layer composite layer of gold, palladium silver, with a thickness controlled between 0.5-0.8 μm.

In the accelerated aging test, the increase rate of contact resistance was only 0.5%, and the change in insertion loss was less than 0.05 dB. After 100,000 cycles of plugging and unplugging, the attenuation of contact elasticity was less than 3%.

In addition, the shielding layer is made of nickel molybdenum alloy anti-corrosion material, and there are no obvious corrosion marks after salt spray testing (48 hours). In the long-term validation of industrial control equipment by the customer, the system disconnection rate has been reduced from one thousandth to below 5 ppm. This durability not only improves product lifespan, but also avoids after-sales risks and repair costs. For Johoty’s customers, this is the key guarantee for stable operation throughout the entire lifecycle.

EMI shielding pogo pin connector balances lightweight design with high reliability

The industrial design trend of high-end electronic products is becoming increasingly thin and lightweight. But every 0.1 mm reduction in thickness means that the difficulty of shielding and contact increases exponentially. Traditional shielded connectors often sacrifice space for stability.

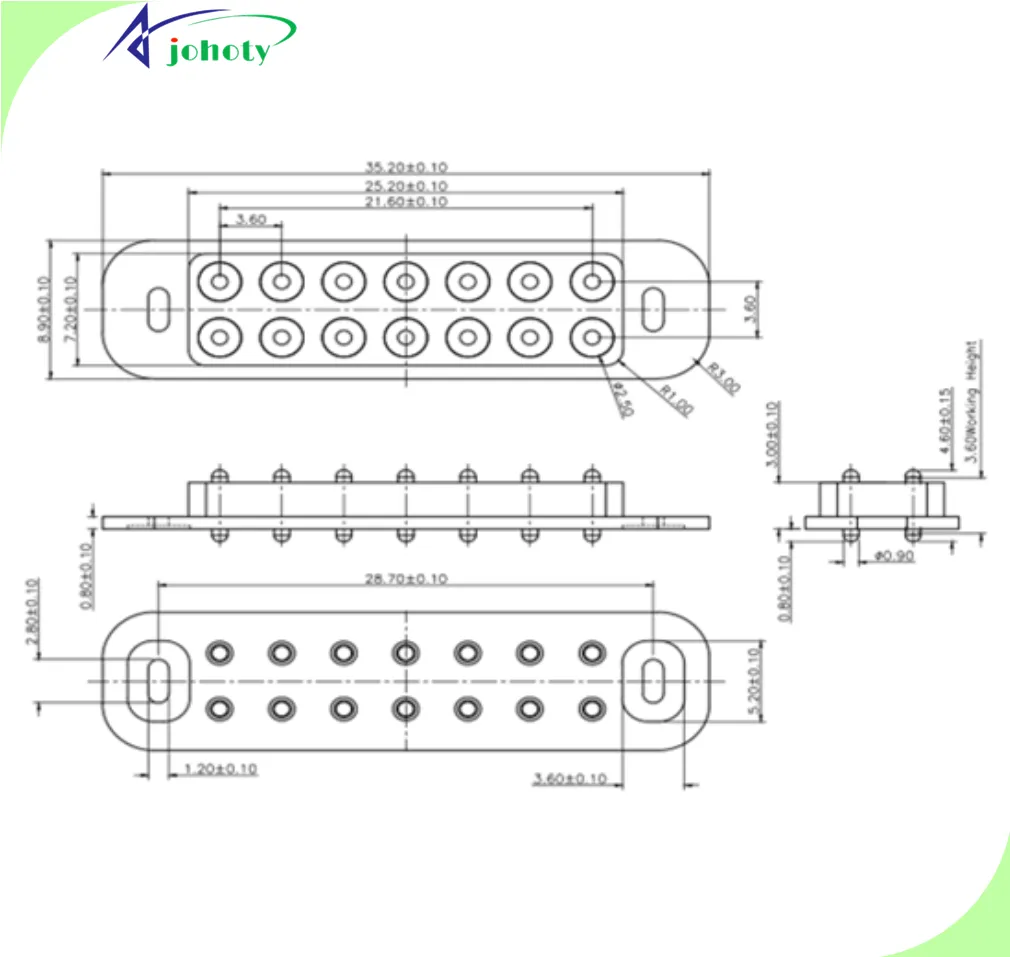

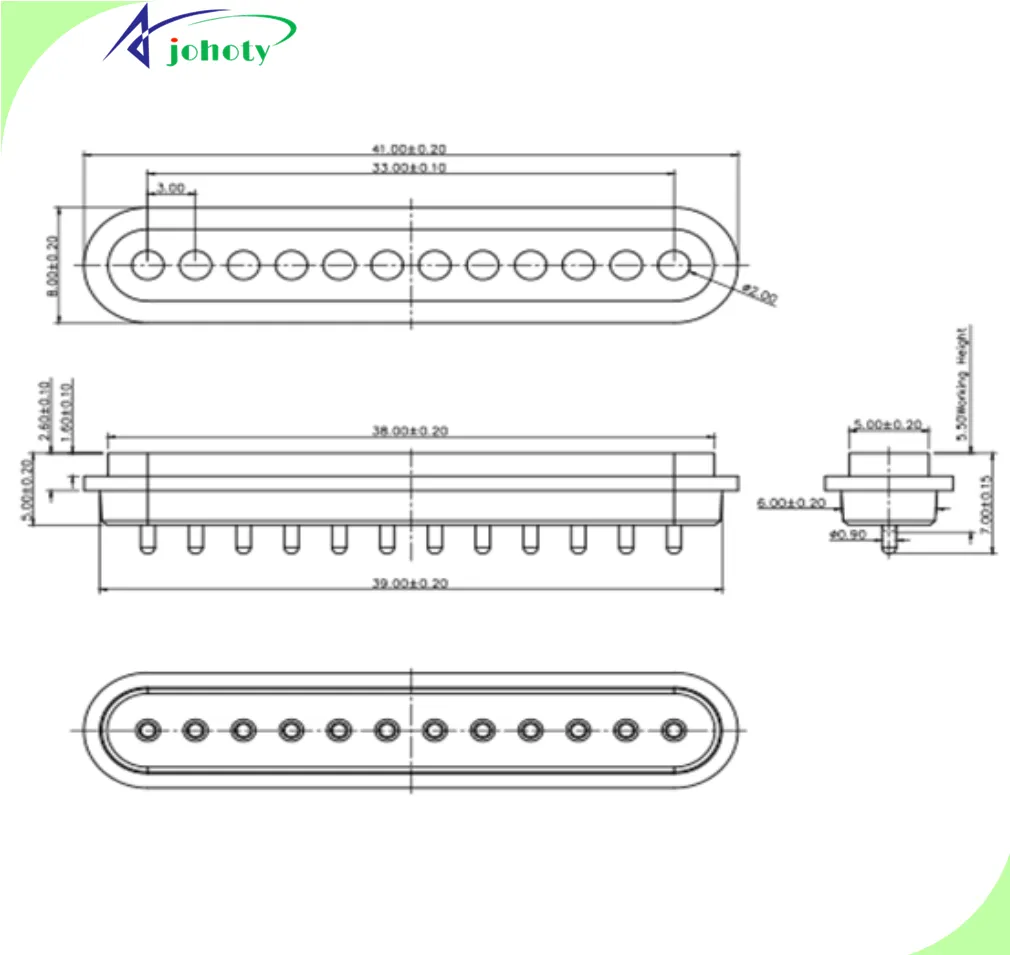

Johoty’s EMI shielding pogo pin connector resolves this contradiction through structural integration and material optimization. Our shielding shell has a thickness of only 0.20 mm, and the total thickness of the pogo pin connector can reach a minimum of 1.80 mm. However, it can still maintain a shielding effectiveness of over -40 dB.

Through finite element structural analysis, Johoty introduced a stress dispersing skeleton internally. The thin-walled metal layer forms a stable support when subjected to force, without affecting the mechanical strength. In an ultra-thin tablet expansion module project, the design successfully reduced the overall thickness by 12%. At the same time, EMI suppression performance is improved by 30%.

This ability to balance aesthetics and reliability is currently the most scarce connectivity solution in the market. Johoty’s customized EMI shielding pogo pin connector meets performance requirements and gives the product higher structural freedom.

Systematic resolution of EMI shielding pogo pin connector from risk to advantage

Johoty’s EMI shielding pogo pin connector actually solves the problem of risk conversion:

From certification risk to controllable design: eliminate certification obstacles in advance through 360 ° shielding and low impedance grounding.

From unstable operation to continuous reliability: contact interface and elastic control ensure stable operation of the system in interference fields.

Signal bottleneck to high-frequency channel: coaxial transition structure optimizes signal chain integrity.

From lifespan decline to long-term stability: The nano antioxidant layer ensures long-term reliability.

From structural conflict to free design: ultra-thin shielding layer achieves a balance of lightweight and reliability.

Behind every improvement, there are quantifiable data and comparisons with actual measurements. These parameters are not just specifications, but the actual benefits of reducing risks and saving development time. When system designers are no longer constrained by EMI, signal integrity, lifespan, and space, they can focus more on core innovation. Johoty’s customized EMI shielding pogo pin connector has become a stable cornerstone of this innovation.

Conclusion: Stability is the highest level of technology. Contact Johoty immediately

In the electronic world, speed, power consumption, and volume can all be replaced by technological iterations. But stability is always the core that determines products’ success or failure. Every EMI loss of control, every intermittent shutdown, may be a connector that has not been taken seriously.

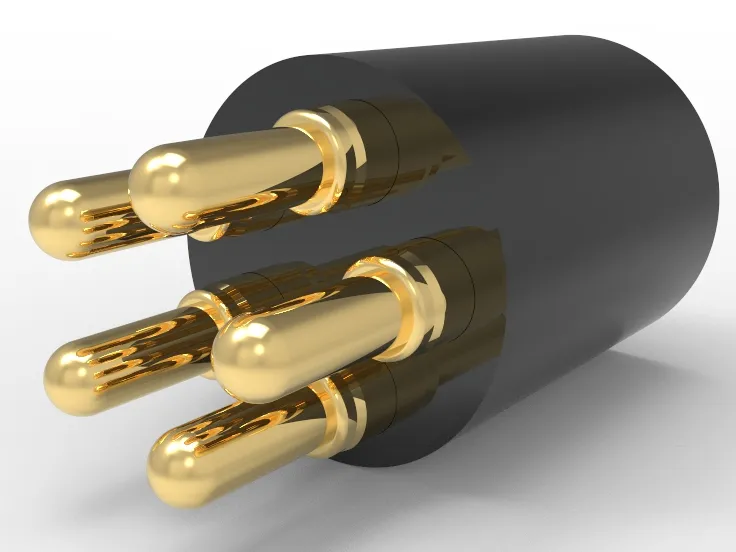

Johoty’s customized EMI shielding pogo pin connector can eliminate your worries. It builds your system stability in five dimensions: shielding, elasticity, high frequency, durability, and lightweight. It is not simply a metal bullet, but a reliable bridge that allows signals to remain smooth in any chaos.

We can solve your EMI certification delays, system instability, high-frequency losses, lifespan degradation, or structural limitations. The solution is clear, are you willing to make the EMI shielding pogo pin connector the most reliable part of the system?

If the answer is yes, please contact Joy immediately. Obtain customized EMI shielding pogo pin connector technology solutions and sample evaluation support. Keep your product as stable as a rock in electromagnetic chaos.

+86 13590816656

+86 13590816656 +86 13590816656

+86 13590816656