Affordable Connectivity in EV: Ensure Long-lasting, High-quality Connection, Safe Charging with Johoty Custom Pogo Pins. Get Best Offer Now!

Introduction: The significance of affordable connectivity in electric vehicles

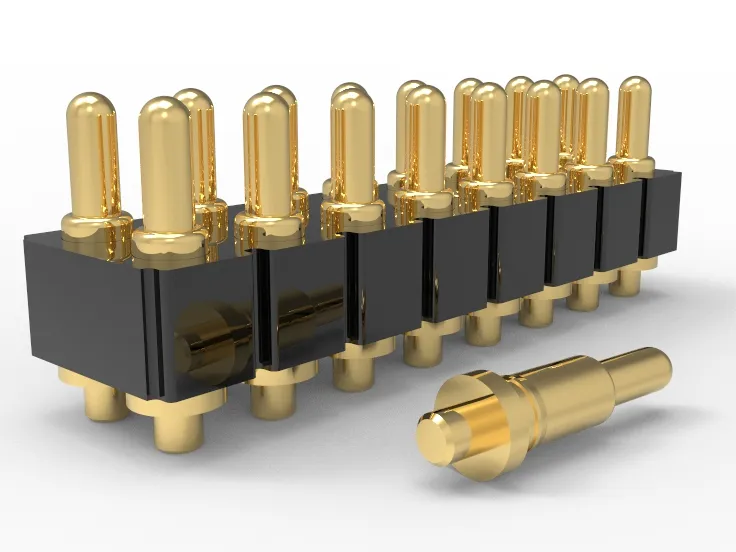

Affordable connectivity is Johoty’s price advantage. It is a long-term stable connection capability in the core components of electric vehicles. Every charge and discharge in the high-voltage system of an EV is completed through high-speed power transmission. If the channel is unstable, the efficiency of the customer’s EV will decrease, and it will also pose safety hazards. Johoty’s pogo pin or pogo pin connector serves as the gateway for the channel within EVs. It is often required in compact spaces with high-frequency use and extremely high demands for long-term reliability. Our custom 50A pogo pins are a solution validated by Mercedes.

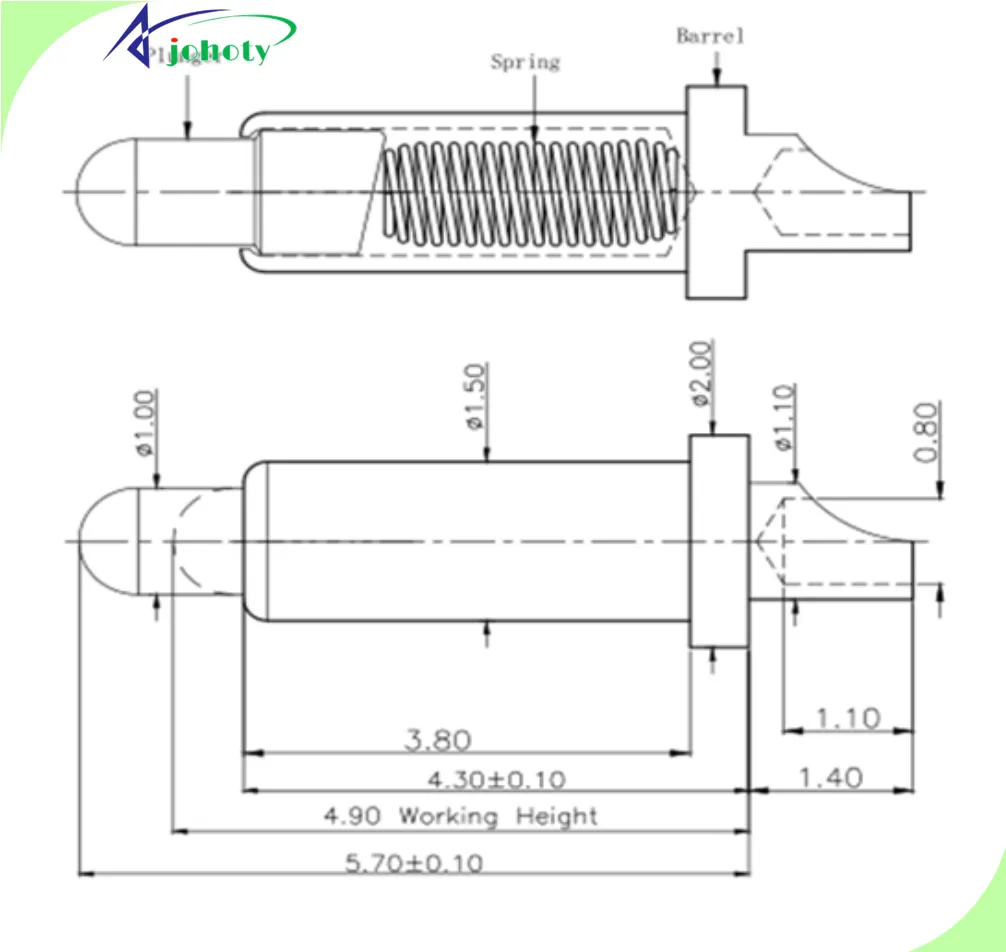

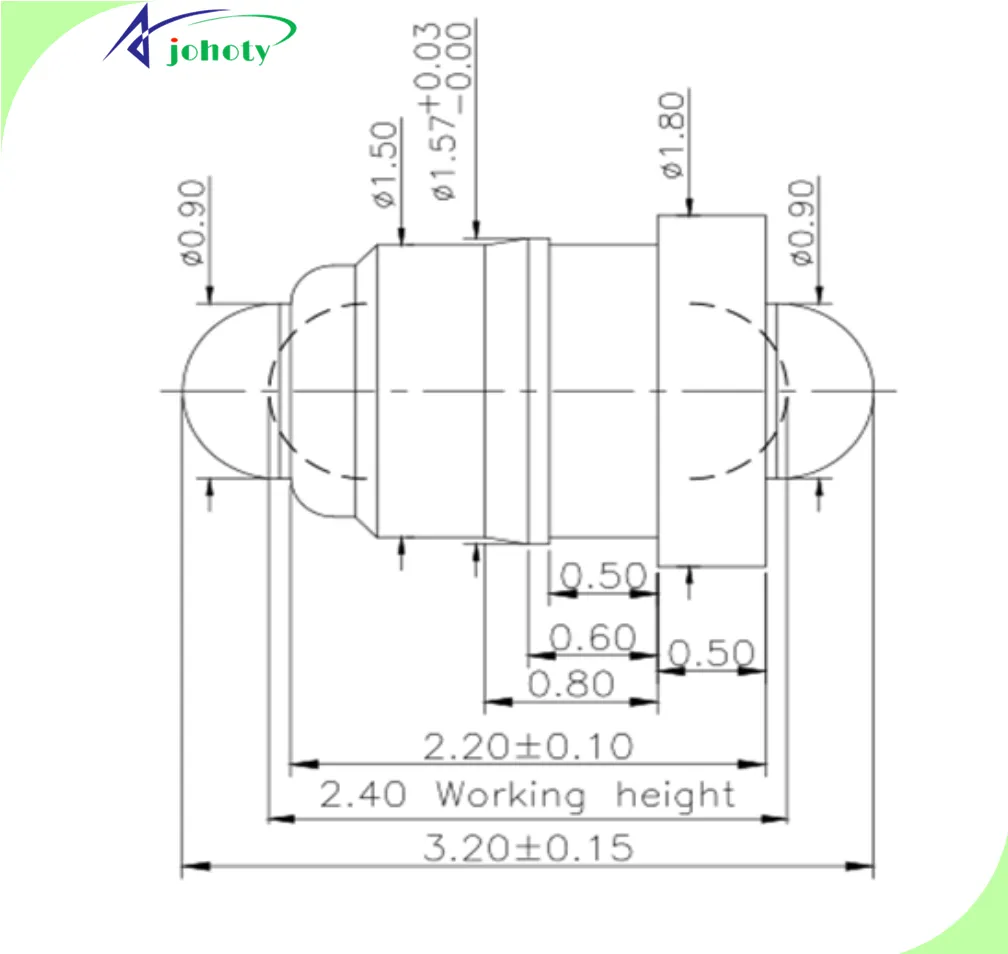

The micro spring pins of the pogo pin maintain stable contact pressure even after hundreds of thousands of press cycles. During daily charging and discharging in EVs, it maintains low contact resistance and stable transmission performance. Customers always need to balance safety, durability, and cost. Johoty’s customized pogo pin solution makes affordable connectivity no longer just an ideal. It helps customers achieve safety, reliability, and timely affordable connectivity.

Why is affordable connectivity more difficult to achieve in compact EV architectures?

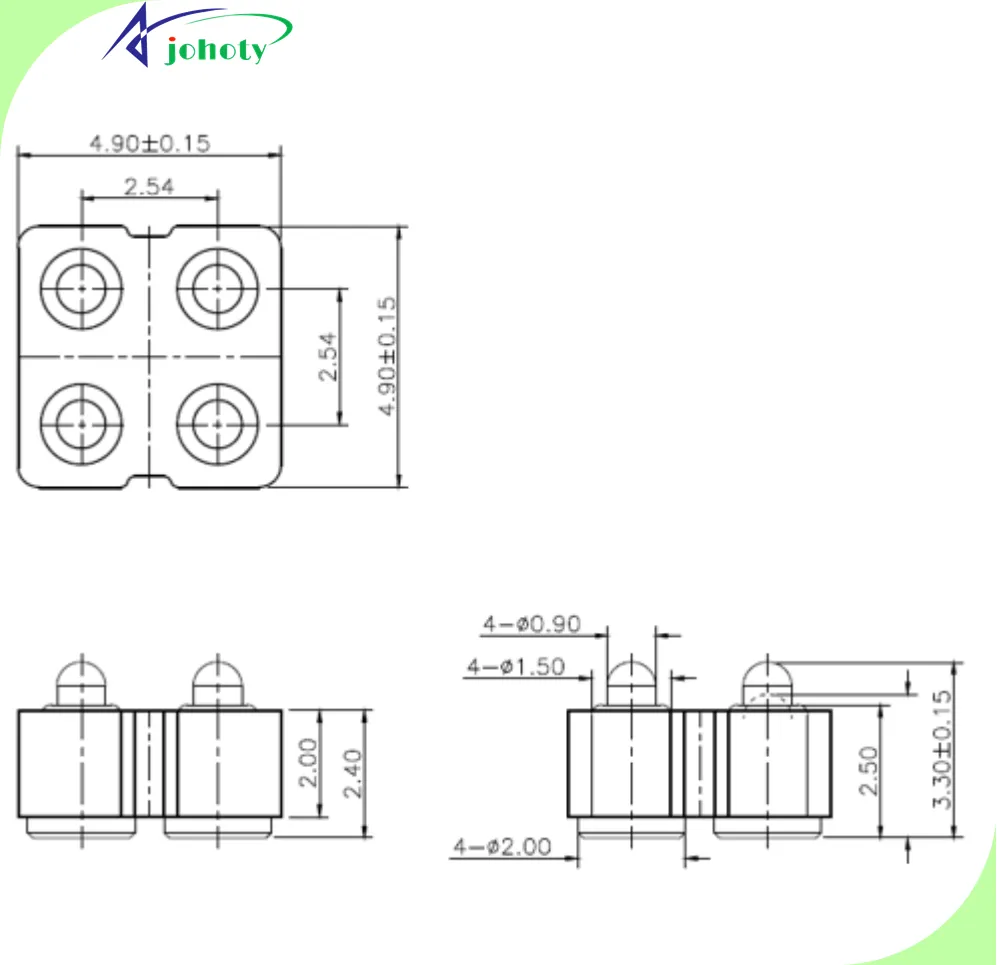

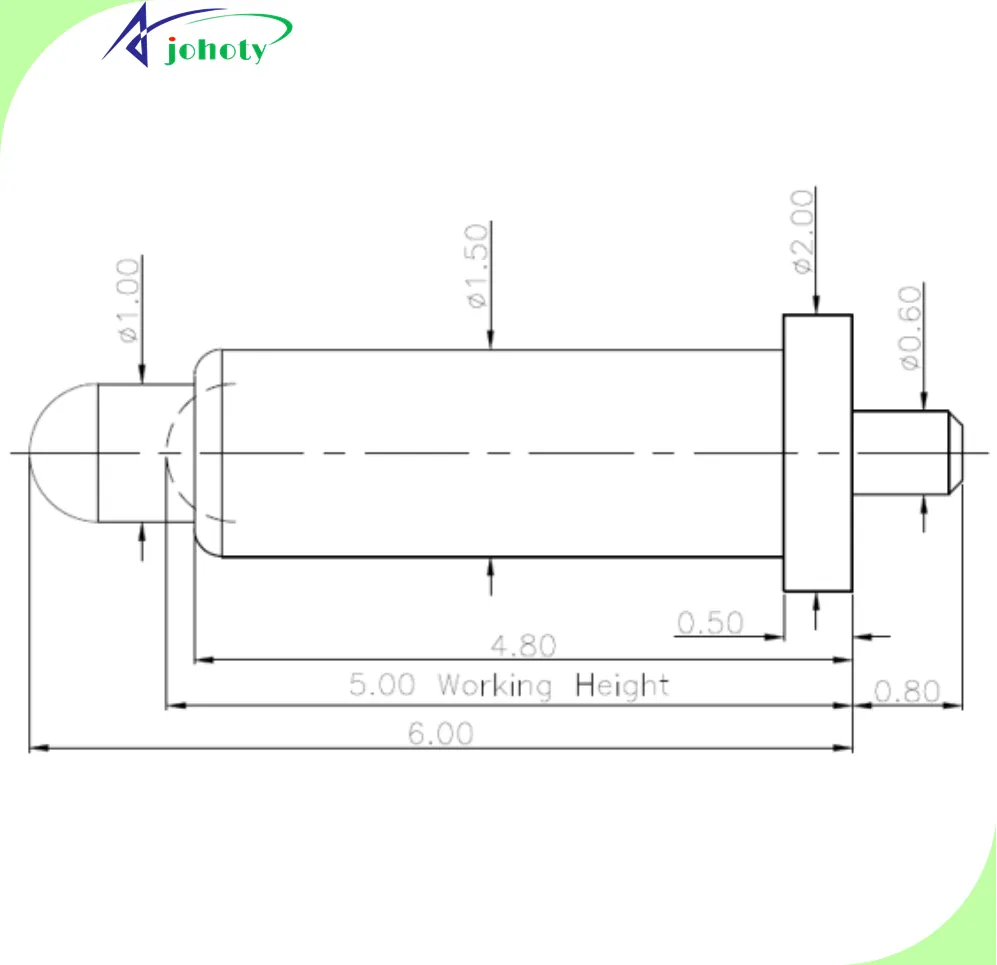

In electric vehicle powertrains, space utilization and thermal management are the primary design constraints. The connection distances between modules such as the battery pack, BMS, and OBC are short but require extremely high power carrying capacity. Connectors must withstand high currents while maintaining sufficient contact area and pressure in confined spaces.

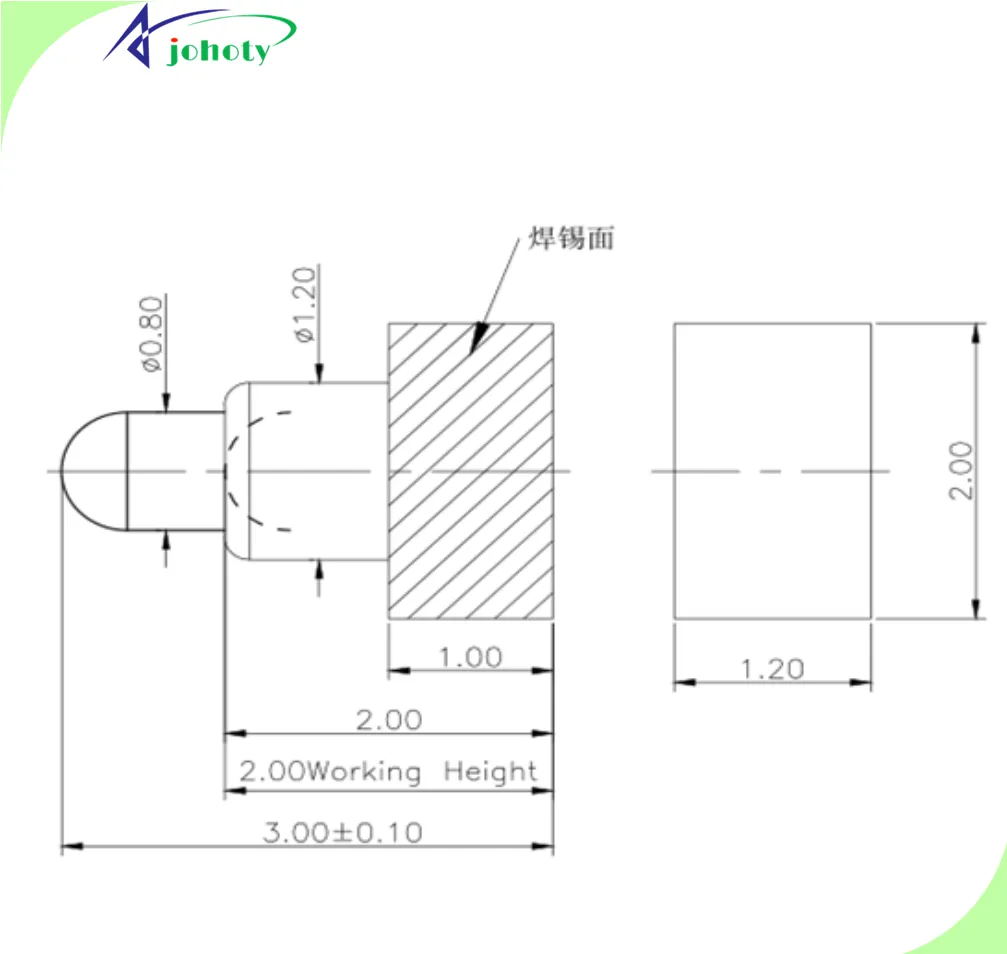

Traditional board-side or cable-side connectors are prone to increased resistance due to contact surface fatigue in micro-vibration environments. This can lead to temperature rise under high current conditions. For every 10℃ increase, the rate of material aging may double. The elastic structure of pogo pins can automatically compensate for minor deformations of the contact surface while operating in space-constrained environments, thereby reducing the risk of contact resistance increase over long-term use. Achieving affordable connectivity under physical constraints.

How can cost-effective connectivity be implemented in EVs?

Cost-effectiveness is not simply about low prices, but rather achieving the optimal balance between performance and cost over the entire lifecycle. Johoty’s custom pogo pins may have a higher initial unit cost than standard terminals. However, over a ten-year period, their lower failure rate, reduced maintenance requirements, and more stable energy consumption performance will significantly lower total costs.

In the EV environment where thermal cycling and mechanical vibration coexist, the structural advantages of pogo pins manifest as contact resistance changes of less than 10 milliohms. This stability reduces power loss caused by poor connections. In long-term testing, compared to conventional pin-type connectors, pogo pins have an average maintenance interval extended by 1.8 times. This directly reduces cost losses from downtime for repairs, making affordable connectivity a quantifiable benefit.

Safety and reliability: an integral part of affordable connectivity

In electric vehicles, safety and reliability are directly related. Even minor fluctuations in contact resistance can amplify into significant temperature increases in high-current environments, thereby affecting the lifespan of surrounding insulation materials. Johoty’s pogo pin solution uses high-elasticity alloys and gold-plated surfaces to reduce corrosion risks and ensure long-term low-resistance contact.

In durability testing, after simulating 100,000 insertion/removal cycles, the increase in contact resistance was less than 5%. Under the same conditions, the increase for conventional connectors could exceed 20%. In the daily operation of electric vehicles, affordable connectivity is not just about low cost. It also means achieving higher operational stability with reduced maintenance costs.

Affordable connectivity in high-voltage fast-charging applications

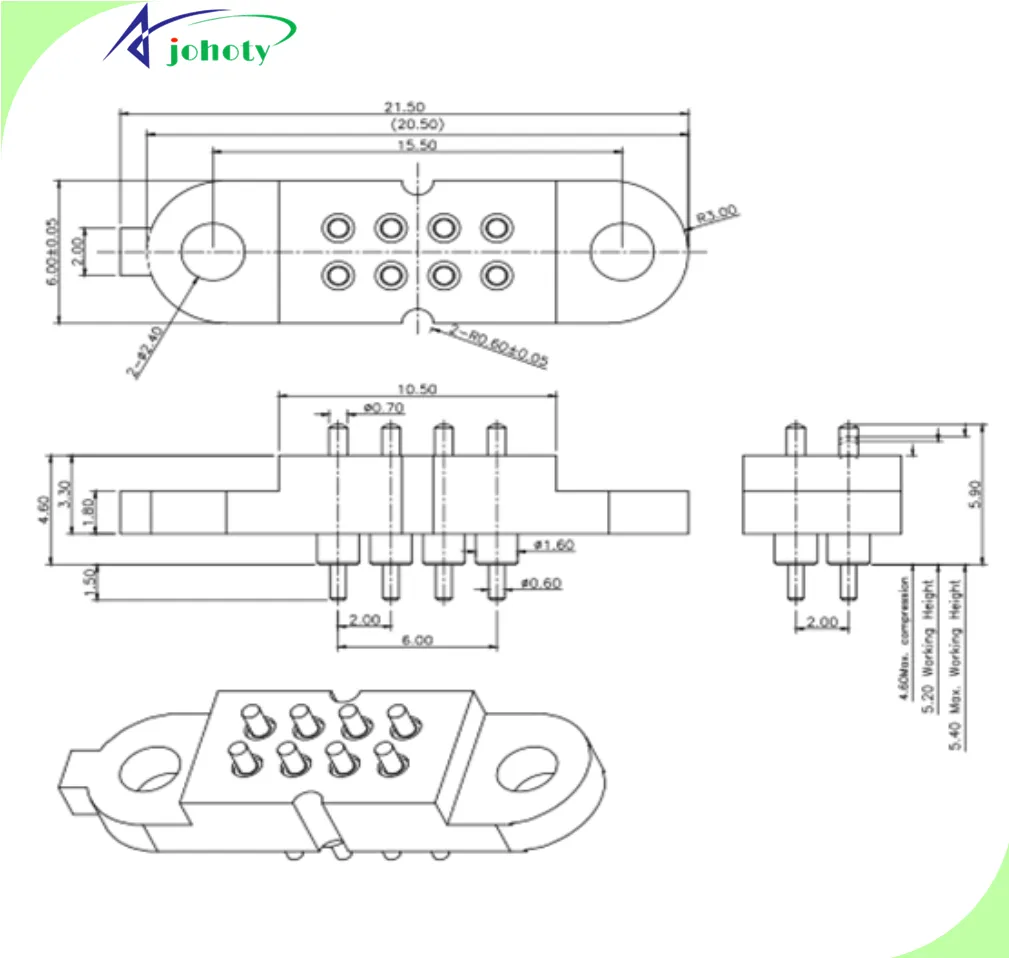

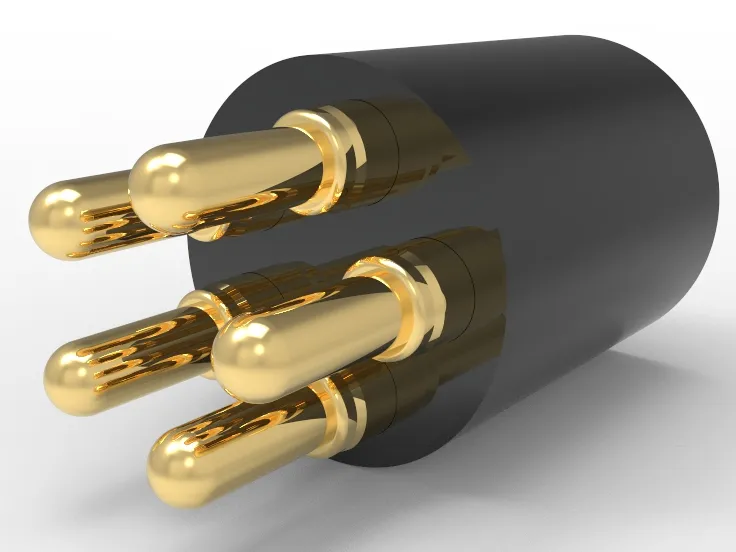

Fast charging means instantaneous power transmission can reach hundreds of kilowatts, which is a rigorous endurance test for connectors. In such an environment, even the slightest contact failure can lead to overheating and power loss. Johoty’s customized pogo pins can be designed with multiple contact points, distributing current evenly across multiple micro-contact points to reduce single-point load.

Italian customers have conducted thermal imaging monitoring of temperature rise under a continuous current of 250A. The temperature rise at the contact points of pogo pin connectors is 12–15°C lower than that of conventional plug-in connectors. This difference can significantly delay the aging of insulating and metallic components over extended use, ultimately translating into longer service life and more stable charging performance. Maintaining stable operation over long-term is precisely where affordable connectivity demonstrates its value in the high-voltage fast-charging sector.

Low maintenance costs are an implicit advantage of affordable connectivity

In fleets or commercial EVs, every maintenance shutdown means increased costs. A connection solution with a long service life and low maintenance frequency can directly translate into improved operational efficiency. Johoty’s pogo pins incorporate dust-proof and moisture-proof structures in their packaging design, reducing the impact of external environments on contact surfaces. Even in dusty and humid conditions, our pogo pin connectors can maintain stable connections.

Based on long-term operational data from users, charging interfaces using pogo pins have an average maintenance frequency that is over 40% lower than traditional interfaces over 3 years. This reduction in hidden costs often yields more significant savings than initial procurement costs. This is also a key manifestation of affordable connectivity in lifecycle cost management.

The precise matching of materials and processes forms the foundation of affordable connectivity.

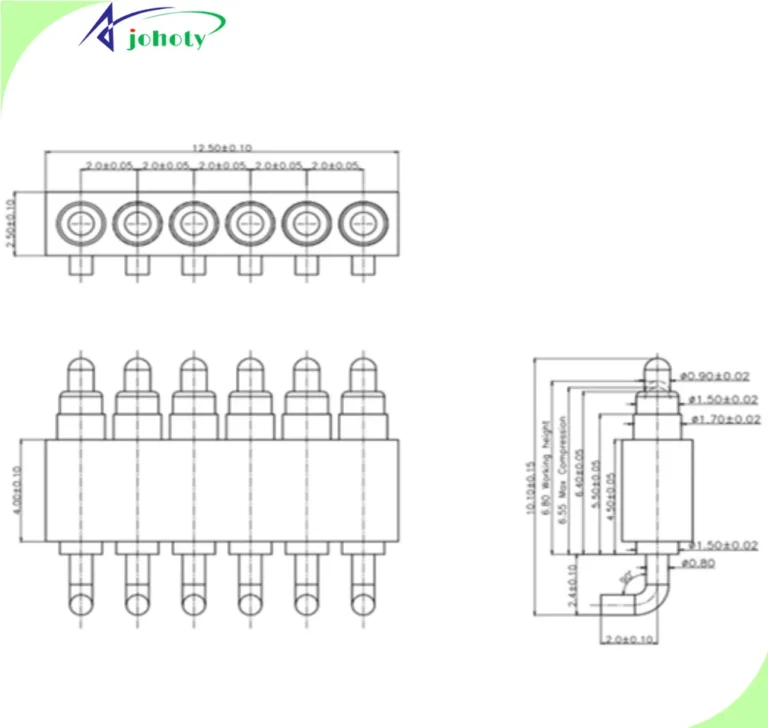

The advantage of custom pogo pins is that they can be fully matched to the operating voltage, current, and environmental conditions of different EV modules. Johoty always selects the most precise design, the most suitable materials, and the most appropriate processing techniques. Our pogo pin connectors use a nickel base with a gold-plated surface coating in high-humidity environments to prevent metal migration. In high-frequency connections, the use of high-elasticity beryllium copper alloy ensures long-term elastic stability of pogo pins.

Targeted design eliminates the need for excessive safety margins in affordable connectivity. Optimal performance is achieved within appropriate parameter ranges, reducing unnecessary material and process waste. Through precise engineering matching, Johoty’s pogo pin connectors are the core solution for reducing long-term costs and enhancing stability.

How does Johoty customize cost-effective pogo pin connection solutions?

Based on the specific application requirements of different customers’ electric vehicles, Johoty conducts a detailed analysis of various factors in the working environment. When designing pogo pins, these factors include vibration frequency, temperature fluctuation range, and humidity changes. These data directly determine key parameters such as the structural design of the pogo pin, spring hardness, and plating thickness.

Johoty always customizes designs based on specific applications to ensure each pogo pin is suited for its target environment. Unlike traditional off-the-shelf products, Johoty’s pogo pins and pogo pin connectors are tailored to meet specific requirements. In our design philosophy, cost-effective connectivity never comes at the expense of performance. We prioritize reliability, stability, and response speed of pogo pins. On this foundation, we balance cost with product lifespan.

Conclusion: Affordable connectivity makes EV connectivity more stable and durable

Affordable connectivity in electric vehicles is not just about cost; it is also about combining high performance with long service life. When Johoty customizes pogo pins, this combination is achieved through precise design, material optimization, and long-term stability verification.

Behind every charge and every power transmission, tens of thousands of tiny contact points are working steadily. This stability translates into less maintenance, higher energy efficiency, and lower total costs. It is ideal for businesses seeking the best connectivity solutions in high-voltage, high-frequency, and high-demand environments. Johoty’s custom pogo pins are the direct path to achieving affordable connectivity.

If your EV project is seeking a connection solution that maintains stable performance over a ten-year cycle, reduces total cost, and enhances safety, Johoty’s CFT team is ready to provide customized designs tailored to your application environment. Contact Johoty today to bring affordable connectivity to your EV project.

+86 13590816656

+86 13590816656 +86 13590816656

+86 13590816656