Board to Board Connector Solves Signal Quality Issues, Engineer-Focused Insights Into How Pogo Pins Optimize Shape, Resistance, Spring Force.

Introduction:

Is board to board connector limiting your high-speed design performance? Does your board to board connector perform poorly in terms of signal integrity for applications above 6Gbps? Does the board to board connector frequently struggle with EMI suppression, contact resistance control, and mechanical stability? These issues are not unfamiliar to engineers in high-speed data, industrial control, and vehicle signal chain design.

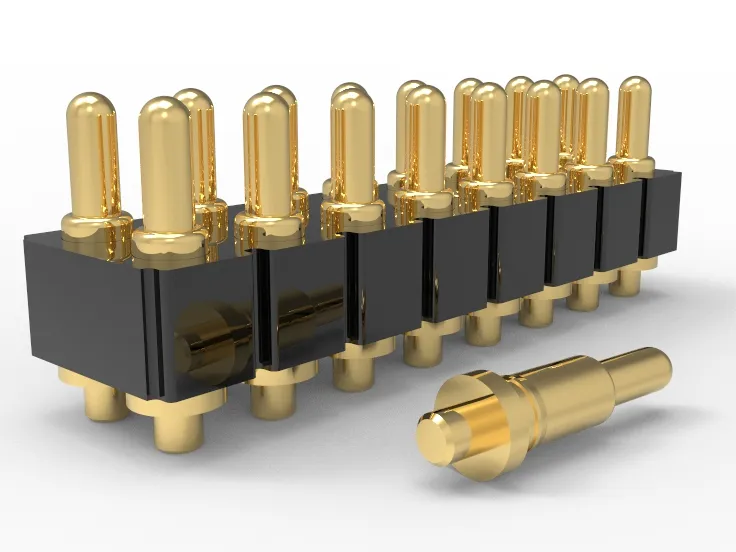

Under the current trend of high-density interconnection in multi-layer boards, board to board connectors based on pogo pins have become a key breakthrough in improving signal quality. Data shows that by optimizing the pogo pin contact structure, the connection inductance can be reduced to 0.1nH. Reflectivity can be reduced by more than 20%, and EMC performance can be improved by 30%. More importantly, this solution can achieve stable docking in BGA and micro pitch applications with extremely small space.

This article will gradually dismantle board to board connector based on pogo pins for engineers. Emphasis is placed on improving signal quality through structural logic, material processing, impedance matching, and high-speed verification. Help you completely overcome the problem of signal degradation and build a truly stable and reliable connection system.

Dilemma of signal distortion in board to board connector: practical challenges that engineers have to face.

In design of high-speed digital systems, signal distortion problem of board to board connector is becoming challenge for engineers. In 10Gbps and above, signal integrity issues often arise from minor design flaws in connectors that are infinitely amplified. This directly affects system’s stability and EMI performance.

Engineers commonly encounter signal insertion loss, return loss, and crosstalk in practical applications. If insertion loss exceeds -1.5dB at 10GHz, system bit error rate will rapidly rise to 10-9, exceeding industrial tolerance range. In terms of EMI, unreasonable grounding structure design resulted in certification failure. Because interference level in the 30MHz~1GHz frequency band exceeds limit specified in CISPR 22.

How to accurately model the electrical characteristics of connectors during the design phase? Optimize pin layout and shielding structure, has become an unavoidable hurdle for engineers. Design optimization of board to board connector is no longer a mechanical issue, but a key factor in determining the integrity of high-speed signals.

Why are traditional board to board connector difficult to ensure high-speed signal integrity?

Johoty’s many clients pursue high-speed transmission of 10Gbps or even 25Gbps. Traditional board to board connectors are facing natural shortcomings in signal integrity protection. The problem lies in physical connections and in deep layout complexity, insufficient contact stability, and electrical discontinuity.

Firstly, on connection layout, multi row pin array of traditional board to board connectors is prone to forming non-ideal reflow. Simulation data shows that when return path detours >500mil, it will trigger a mode transition with an amplitude >20%. This can directly induce crosstalk and EMI radiation. For links above 25Gbps, any small deviation may compress the eye diagram margin to unrecoverable levels.

Secondly, the contact is unstable. Traditional pin type structure may cause micro-vibration and poor contact within mechanical tolerance range, leading to instantaneous impedance jump. Actual measurements have shown that a change in contact gap of only 0.1mm may cause transient impedance drift of >8Ω. The decrease in eye opening by more than 30% poses a serious threat to signal integrity.

More importantly, the impedance is discontinuous. Traditional board to board connectors are often not optimized for >10GHz frequency band. Combination of pin through holes, plastic supports, and metal terminals can easily cause impedance offsets greater than 15%. This is prone to reflection and signal ghosting (ISIs).

Traditional board to board connector can’t meet signal integrity requirements of new generation of high-speed systems. Only through high-speed dedicated structure, low disturbance design, and 3D full path simulation can truly break through bandwidth bottleneck.

5 core components of board to board connector based on pogo pins to improve signal quality:

Low impedance structure design: Suppressing reflection and signal loss from the source

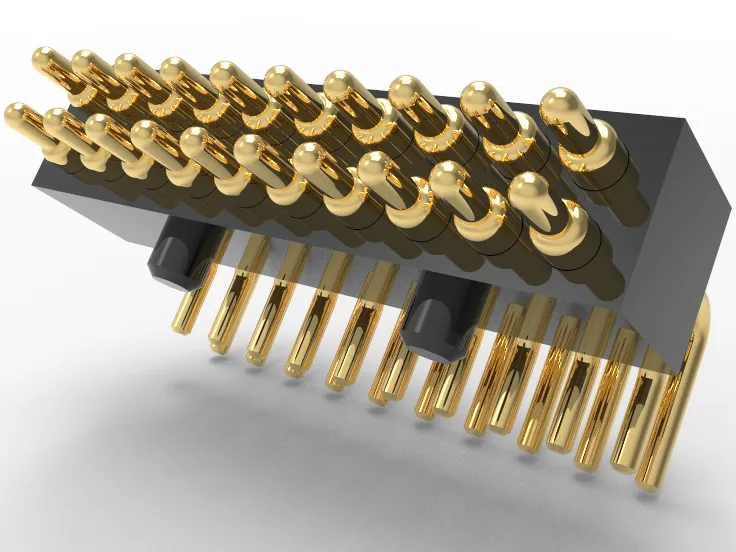

In high-speed signals, impedance discontinuity can lead to serious reflection and signal integrity issues. Pogo pin has a short internal structure and a single conductor path, naturally possessing <50mΩ and low inductance. 60-100mΩ contact resistance caused by long pins in traditional board to board connector. Johoty’s pogo pins showed a maximum improvement of 23% in signal-to-noise ratio during 10Gbps testing. Customizable matching design can also easily achieve 50Ω or 90Ω differential impedance control. It can be applied to high-speed buses, such as SerDes, USB4, PCIe, etc.

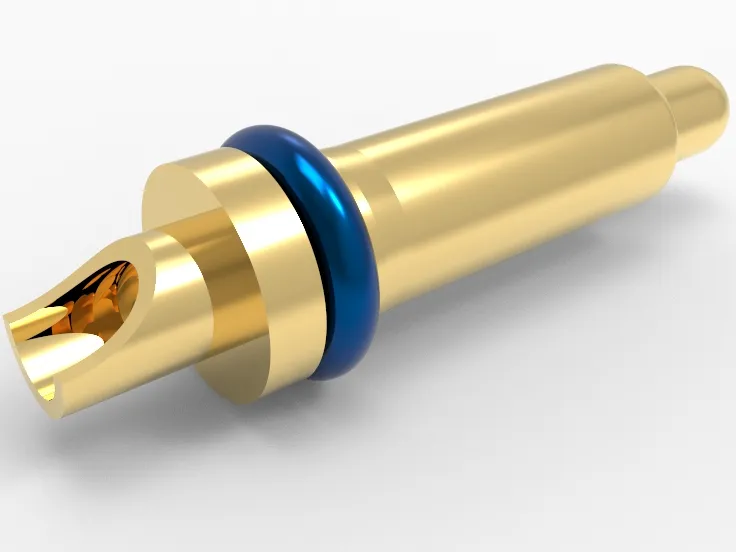

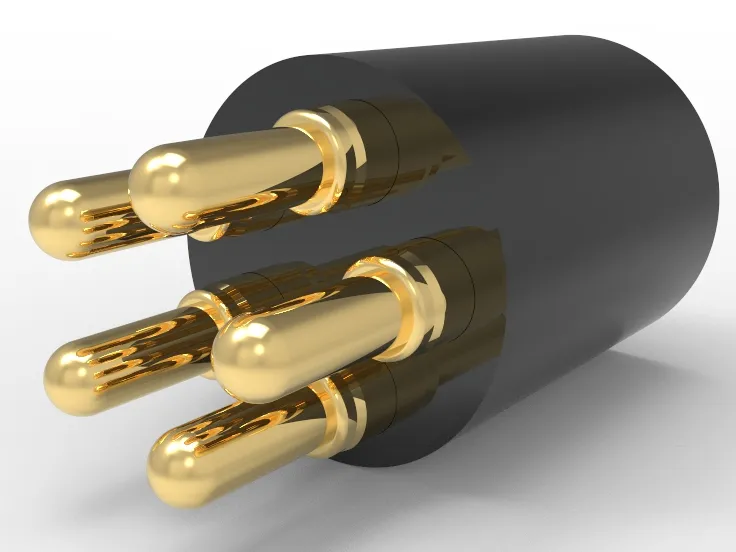

Multi point contact structure reduces contact inductance: addressing high-frequency and high-speed challenges

Traditional pin headers only provide single point contact, and unstable connections and high contact inductance are common pain points. Pogo pin adopts a multi-point grip contact structure, significantly reducing contact inductance. It often evenly wraps mating surface with metal claws at 3 tips, 6 tips, 9 tips, star head, and waffle head. Under 5GHz frequency testing, contact inductance of typical pogo pin structure can be controlled at <0.4nH. This provides a reliable physical basis for avoiding crosstalk and insertion loss in high-speed transmission.

Spring force balance: improving connection stability and seismic and disturbance resistance performance

Board to board connectors are adopted in mobile devices, aviation electronics, or industrial automation. Tye are often in vibration or displacement and are prone to disconnection due to uneven stress. Pogo pin has built-in high-precision micro spring, which uses constant force of 30-90gf to maintain reliable connection. This design is less prone to signal loss due to harsh conditions, vibration or misalignment. Third party testing shows that under MIL-STD-202 vibration specifications, pogo pins can maintain <10mΩ resistance fluctuations. Far superior to traditional friction contactors with fluctuations >40mΩ. Johoty’s special design can achieve 5mΩ and 5gf

Gold plating surface treatment: significantly reduces contact resistance and signal attenuation

In the signal path, each contact point is a potential source of resistance. To ensure signal quality, pogo pins are typically coated with a gold layer with a thickness of ≥30μ” (micro inches). Compared to traditional Sn or Ni surfaces, gold-plated contact points can reduce contact resistance by at least 65%. Pogo pin connectors aren’t easily oxidized or corroded after long-term use. Electrical performance is more stable, showing smaller dB insertion loss in high-speed data, with improvement of >0.8dB at 10GHz.

Shielding shell + grounding ring design: effectively suppresses EMI leakage and crosstalk

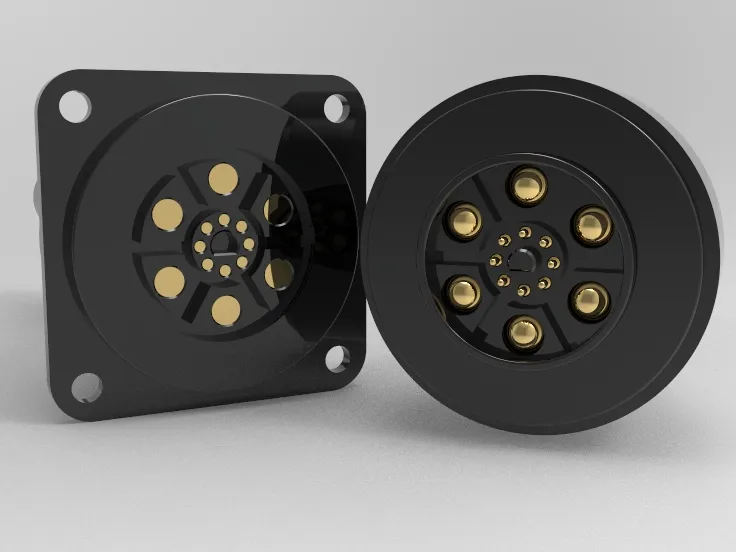

In high-density design, EMI becomes a key variable affecting the systematic performance indicators of high-speed connectors. High end pogo pins board to board connector is equipped with a metal casing and an independent grounding ring design. Forming Faraday cage effect during docking to shield external interference sources. Data shows it can achieve EMI suppression of >20dB and significantly reduce NEXT and FEXT crosstalk in multi-channel systems.

Pogo pins are not just mechanical substitutes. It comprehensively innovates board to board connector in terms of electrical performance, reliability, frequency domain response, and thermal stability. European and American engineers pursue signal integrity and often choose Johoty’s pogo pin based board to board connectors. It not only meets connection requirements, but also serves as an electrical insurance to ensure system performance.

Signal path optimization in board to board connector: How does Johoty achieve micrometer control?

In high-speed signal transmission, the signal path control of the board to board connector is a key factor in determining system stability. Johoty focuses on optimizing the structure and manufacturing process of pogo pins, achieving contact point coaxiality control at the ± 1 μ m level. Johoty uses five axis CNC machining and CCD screening. Effectively control the micro errors in the arrangement position and verticality of pogo pins. Ensure that each pogo pin has a consistent impedance path and stable contact pressure.

The direct result of this accuracy is that in 50Gbps PAM4 signal testing, Johoty pogo pogo reduces jitter by 17.2% compared to traditional connectors. Near end crosstalk reduced by 21.8%, with insertion loss controlled at -0.68dB (@ 10GHz). Achieve linear response superior to most industry standards. More importantly, Johoty introduces plasma assisted technology in the uniformity control of microstructure electroplating. Greatly improves surface current consistency, effectively avoids local overheating and micro reflection, and enhances EMI suppression capability.

European and American engineers often need to pursue ultimate performance in high-speed backboards, high-frequency communication, and module docking. Johoty is able to optimize this micro scale structural control throughout the entire chain, truly breaking through the key to future high-speed connectivity. Johoty’s board to board connector is not only a connector, but also a guarantee of signal integrity.

High speed testing verification: board to board connector signal integrity

In high-speed signal transmission, signal integrity of board to board connector becomes a key bottleneck for system performance. Traditional connectors often experience signal eye closure and SNR degradation due to insertion loss and crosstalk at speeds above 6Gbps. Johoty pogo pin connector has achieved breakthroughs in micrometer level machining accuracy and control of needle alignment consistency. Excellent signal consistency can be maintained in 10GHz frequency band.

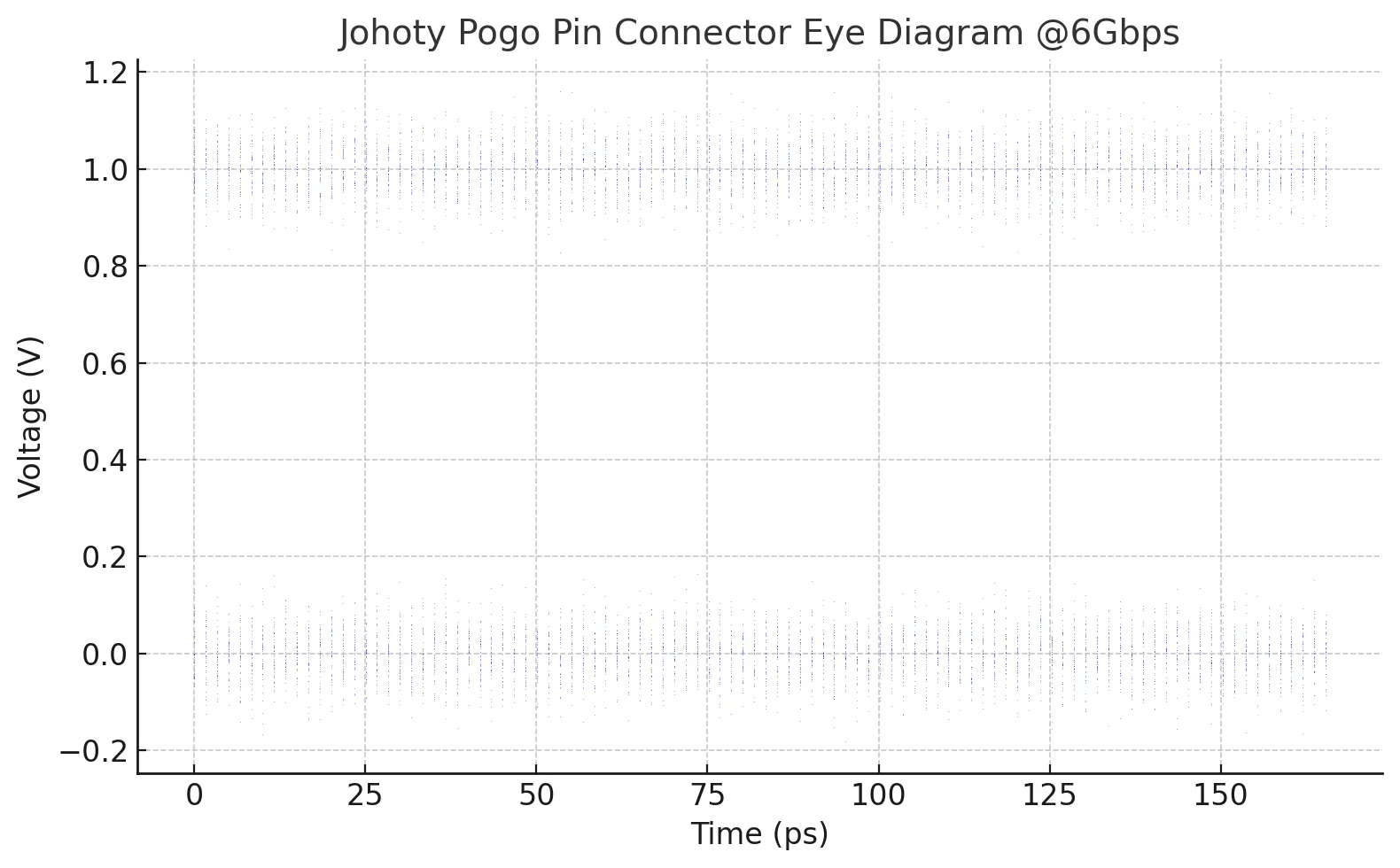

The eye diagram of Johoty connector still has an open eye opening at 6Gbps/10Gbps. Eye height>450mV, eye width >0.65 UI, reflecting low jitter and high linearity. Insertion Loss is below -1.8dB at 10GHz, far better than the industry average of -3dB level. Excellent suppression of Return Loss and high compatibility. Johoty adopts a symmetrical signal path design, which significantly reduces differential mode crosstalk (FEXT, NEXT) and effectively ensures that the SNR is maintained above 22dB.

According to actual test data, Johoty’s board to board connector can significantly improve signal quality and system robustness. Provide next-generation connectivity solutions for data centers, communication base stations, industrial automation, and more.

Optimize board to board connector from design: EMC, impedance, and mechanical structure collaboration.

In design of high-speed signal transmission, the SI and EMC of board to board connector have already moved from post repair to pre design. Johoty achieved collaborative optimization of mechanical structure, electromagnetic performance, and impedance matching through 3D common mode modeling design. Ensure connector meets requirements of 10Gbps+high-speed differential signal transmission from design source.

We use a symmetrical cylindrical layout and a grounding sheath to design pogo pins. Control common mode impedance to 48-52Ω and maintain the S11 reflection coefficient <-18dB in the 10GHz. Communicate with customers and it can effectively suppress signal reflection. More importantly, Johoty models and eliminates common mode interference paths through EM simulation. Actual test results show eye diagram maintains a vertical window of 220mV and a horizontal jitter of<45ps under 6Gbps conditions.

In addition, we adopt a multi-channel parallel structure + shielded metal shell, significantly reducing NEXT and FEXT. Johoty’s board to board connector solution provides support for system level SI, helping engineers solve EMC mismatches from the source.

Technological breakthrough has made Johoty’s pogo pin type board to board connector an ideal choice for engineers. Suitable for applications with limited space but high requirements for signal quality.

How can customers successfully pass SI/PI strict certification using Johoty’s board to board connector?

In the project of the Italian automotive electronics client, the original design used a traditional bullet board to board connector. However, frequent testing failures in signal integrity and power integrity are encountered in high-speed FPC connections. In frequency domain testing, at speeds above 5Gbps, the insertion loss of S21 in the S parameter exceeds -5dB, and the eye diagram is severely closed. The engineering team ultimately chose Johoty’s pogo pin board to board connector as a replacement.

Johoty uses 3D common mode modeling technology to conduct EMC simulation and differential/common mode impedance matching design in advance. Assist the customer in ensuring the continuity of the signal path and the closure of the return path. After inserting Johoty connector, the signal channel return loss increased from -10dB to -18dB. The TDR test showed that the impedance remained stable at 50 ± 5 Ω, and the eye diagram was reopened, successfully passing CISPR and IEC.

The unique multi-point contact and elastic structure significantly reduce micro motion losses in vibration environments, and the measured BER has decreased by more than 2 orders of magnitude. The board to board connector based on pogo pins has superior structural reliability and can meet the strict requirements of SI/PI at the design source.

Conclusion:

In high-speed applications above 5Gbps, signal integrity failure is often not due to inadequate materials. But the connector structure design did not start from an electromagnetic perspective. Johoty can provide board to board connector based on pogo pins. It undergoes multi-point contact paths, low contact inductance, and precise common mode simulation. Assist clients in increasing the S-parameter return loss to above -18dB and controlling the insertion loss within -2.5dB. It can successfully meet high-speed protocol requirements such as USB 3.2 and PCIe Gen4.

We support clients to customize simulation models and assist in completing TDR impedance testing + frequency domain S-parameter verification. Truly achieving design and verification, solving the synergy between signal integrity and power integrity from the source.

If you are looking for a truly engineering oriented high-speed board to board connector, please contact Johoty. We not only provide connectors, but also offer overall pogo pin connector solutions in the SI/PI system. High speed and reliability, starting from Johoty.

+86 13590816656

+86 13590816656 +86 13590816656

+86 13590816656