Cost Savings Begin with 0.01mm Precision Pogo Pins for Smoother Power Flow, Longer Uptime, Faster Installs. Discover How Smart Savings Scale

Everything is faster, more stable, and more cost-effective. Cost savings start with a connection accuracy of 0.01mm

Cost savings are never just numbers in financial statements, but hidden in every small detail of the project. One less minute for installation, 0.1 less ohms for testing, and one less risk for repair. What you see is smoother power transmission. What you feel is a more stable device running time. The key to achieving everything is often just a precision difference of 0.01mm. Johoty’s high-precision pogo pins are reconstructing the meaning of connections in a subtle yet quantifiable way.

If you are facing challenges such as product updates, testing station optimization, welding replacement, or even EMI control. So this article will provide you with a real and feasible solution that can verify returns. Cost savings are no longer the responsibility of financial personnel, but rather the millimeter-level decision at each engineering node.

0.01mm logic hidden in cost savings: How can precision connections save 30% of system costs?

Many people think that high precision means high price. But in the connectivity industry, this equation has long been broken. Johoty’s 0.01mm precision pogo pin or pogo pin connector does not result in a single component price increase, but rather a system-level cost reduction.

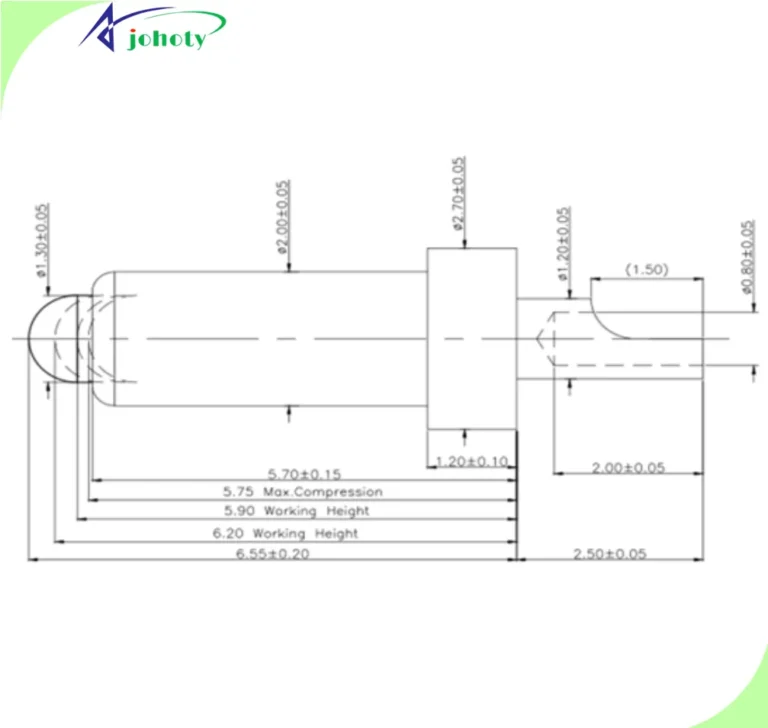

- The improvement in accuracy means that the pad size can be reduced, reducing the complexity of circuit winding for high-density circuit boards.

- Consistent performance of tolerance does not require repeated adjustment of test probe positions, saving fixture calibration time for automated assembly.

- In power transmission, accuracy ensures a constant contact area. Maintain the resistance below 0.05Ω to reduce heat loss significantly and effectively improve energy efficiency.

Pogo pins with a precision of 0.01mm showed a 29.7% reduction in contact resistance uplift rate over 36 months compared to conventional products. A comparative test showed that under the same design, the equipment failure rate decreased by 22%. The comprehensive cost savings for testing, repair, and station downtime exceed 30%. This is not a superficial comparison of unit prices, but a closed-loop optimization of the entire cost process from design to launch.

Optimization is not just about cost savings: lower contact resistance for less thermal collapse

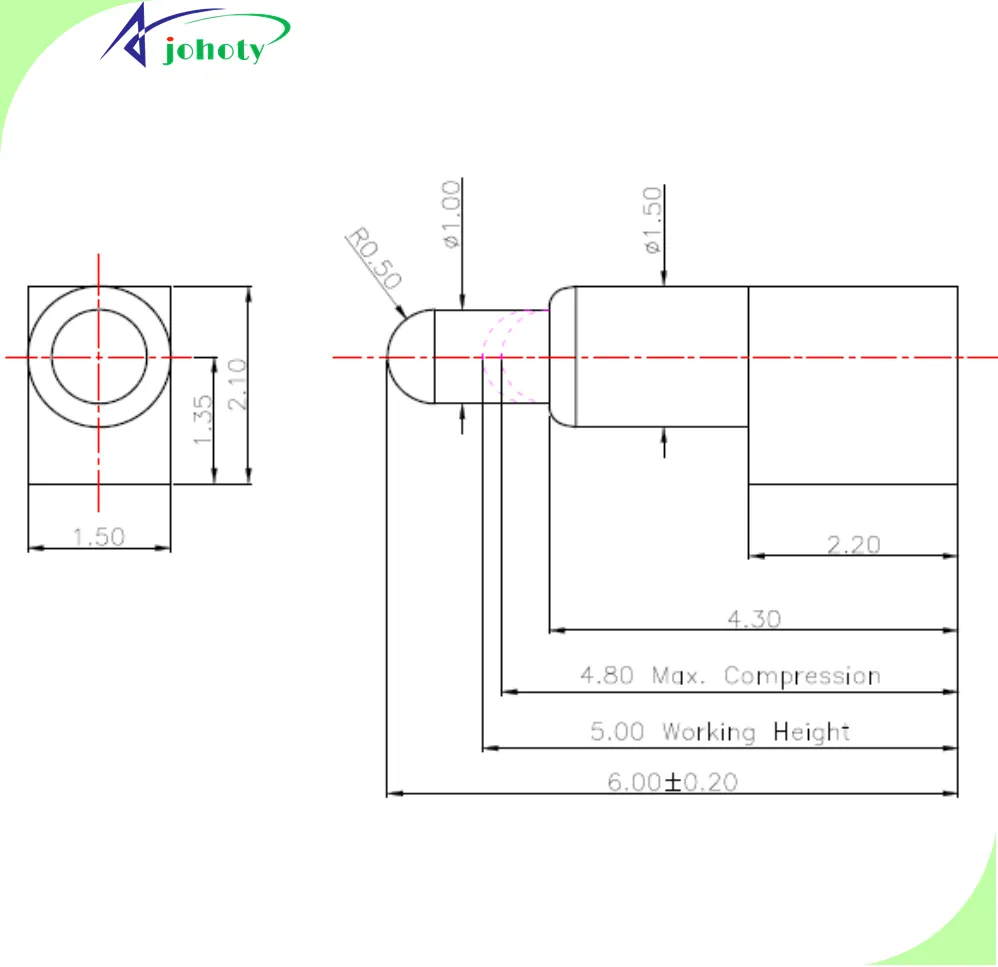

In many power applications, a very small temperature rise at a contact point can cause the entire system to overheat, reduce frequency, or crash. Even triggering protection interrupts in the main drive system of electric vehicles. Johoty’s 0.01mm pogo pin design adopts micrometer level spring preload control. Keep the contact surface pressure constant and continuous.The actual heatmap comparison data shows:

- After a continuous current of 2A/30 minutes, the surface temperature of the ordinary precision pogo pin rises to 41.5℃.

- Johoty precision pogo pins have a temperature rise of only 23.2 ℃ under the same conditions, resulting in a more uniform thermal distribution.

Heat is an invisible systemic poison. Reducing it is equivalent to extending the lifespan of your product and reducing the probability of sudden failures. These saved temperature differences are ultimately reflected in system maintenance costs and user satisfaction.

Cost savings for higher workstation throughput: Test station beats increase by more than an order of magnitude

If your testing bench is still at the stage of traditional needle positioning, you may not have realized the true impact of connection accuracy on the beat. A Johoty customer workstation test data shows:

- The original plan tested 58 products per minute.

- After replacing high-precision pogo pins, the number has been increased to 74, with a 27.6% increase.

- The overall testing yield has increased by 3.3%, and the demand for manual intervention has decreased by over 60%.

The optimization of rhythm brings not only a single efficiency improvement. But rather the overall compression of production line layout, testing costs, and manpower allocation. These cost savings are far more direct than imagined.

Cost savings are also consistent: batch stability determines engineering confidence

A precision of 0.01mm is not occasionally achieved. But every factory pogo pin or pogo pin connector maintains consistent performance output. Johoty conducts 23 tests on each pogo pin before leaving the factory, including:

- Insertion/extraction force ±5gf control.

- Contact resistance with a floating range of ± 0.01Ω.

- The spring rebound life is over 10,000-100,000 times.

This set of testing ensures high performance of customers’ high-end instruments, aviation/satellites, and electric vehicles. The same expected response can be obtained on any batch of items. And this consistency is the foundation for R&D decisions, batch production switching, and project delivery to be completed on schedule. What is saved is not just materials, but the time, confidence, and resource allocation costs of the entire project team.

How structural micro innovation accelerates installation and brings hidden cost savings

In the traditional pogo pin installation, there are 3 most common issues:

- Poor oxidation of PCB pads leads to unstable contact.

- The testing fixture is repeatedly adjusted, which is time-consuming and labor-intensive.

- Elastic interference and contact misjudgment are prone to occur in multi-pin arrays.

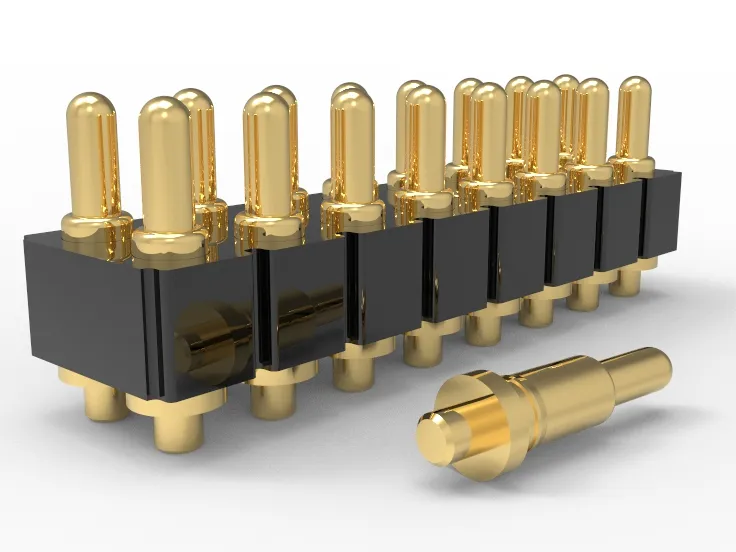

Johoty has designed to address the above issues:

- A quick positioning structure that does not require welding.

- Double joint anti slip design enhances stability and fixation.

- Elastic partition structure to avoid array interference.

In 100,000 plug and unplug tests, the misjudgment rate decreased by 84% and the average installation time decreased by 41%. You don’t need to train operators extra for accuracy, nor do you need to sacrifice stability for efficiency. The savings it brings are the real returns reflected every hour on your production line.

From design-in to mass production: cost savings throughout entire product lifecycle

Many costs are not based on how much is bought, but on whether it can be quickly used. Johoty supports a complete design collaboration path:

Quick sample response: Delivery of validation samples within 3-14 days.

Customized structural adaptation: supports multiple pin combinations, directional flow guidance, and structural fine-tuning.

Parallel verification of numerical models: Provide STEP/IGES modeling for direct import into CAD/PADS processes.

Batch switching standardization: one-stop structural module, compatible with multiple fixture platforms.

You no longer need to iteratively design a connector or delay project milestones due to customization. Cost savings are not just a decrease in price, but also a compression of time and standardization of processes in various aspects of the product.

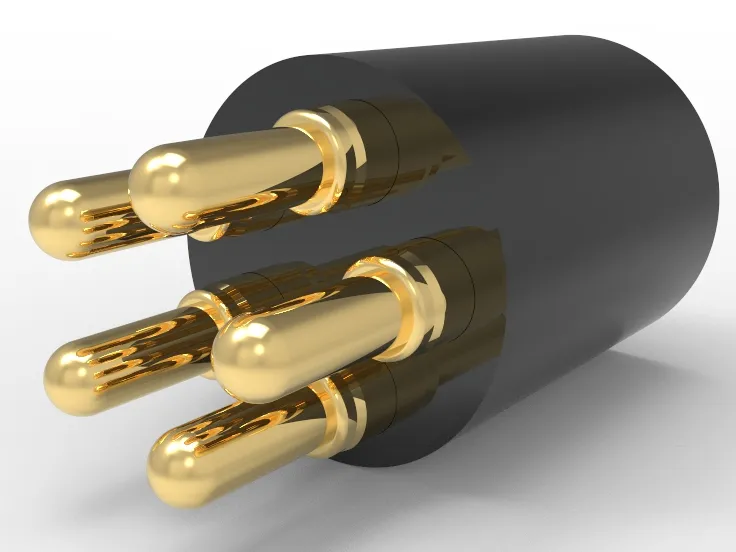

Accuracy is not about stacking materials, but the long-term strategy behind cost savings

Many connector companies emphasize the thickness of the gold plating layer, spring strength, and types of electroplating in their marketing. But what truly achieves system cost optimization is the system engineering strategy behind Johoty’s accuracy.

We never blindly stack parameters. But based on the actual application load, mechanical stress, assembly method, and thermal expansion environment of each connection point, matching level optimization is carried out. What you get is not more expensive pogo pins or pogo pin connectors, but a more suitable solution.

As commented by a French client of Johoty, the decrease from 0.05Ω to 0.02Ω was not for promotional purposes. But it’s because we need to maintain a stable load on the entire control board. And this directly determines whether our wind tunnel testing can pass or not. This is the fundamental way to save costs, avoid failures, and improve one-time success rates.

Cost savings are not just about connectivity: it means you stay ahead in the industry competition

You require faster connection, less heat generation, more stable testing, and more efficient installation. This is not just a small craftsmanship detail, but a strategic barrier that widens the gap in the long run. And Johoty’s pogo pin connection solution transforms these invisible differences into visible advantages for customers.

We do not provide parameter stacked products, nor do we pursue vague concepts of cost-effectiveness. We focus on one thing: achieving the most consistent mechanical electrical synergy performance at extreme sizes. Help you achieve visual, quantifiable, and reusable optimization in connection costs.

Cost savings: Let Johoty assist you in achieving project goals

Cost savings ultimately result from the designer’s judgment. It is a deployment by the engineering manager and a trust from the procurement department. And the beginning of all of this may just be one communication.

Johoty currently supports clients from multiple industries including aerospace, automotive, new energy, healthcare, and measurement equipment. Obtain long-term sustainable cost returns in customized connectivity solutions. We will provide you with real engineering solutions based on your specific product structure, electrical environment, and installation requirements.

Click to contact us and immediately get an optimization design proposal based on your actual needs. Before the next product iteration or testing layout, save your system space, power consumption, and labor costs with precision in advance. Connection is no small matter, 0.01mm can change everything. Johoty only provide reliable precision connections and bring you cost savings.

+86 13590816656

+86 13590816656 +86 13590816656

+86 13590816656