High Current Connector Deliver Zero Power Loss, Safe Fast Charging, and Reliable Clean Energy. Discover The Future Of EV Power. Learn More.

Introduction: The Significance of High Current Connector and Zero Power Loss

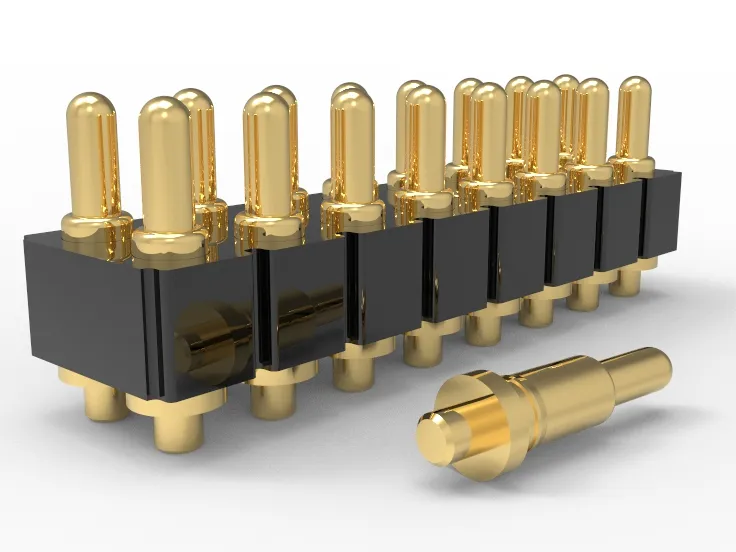

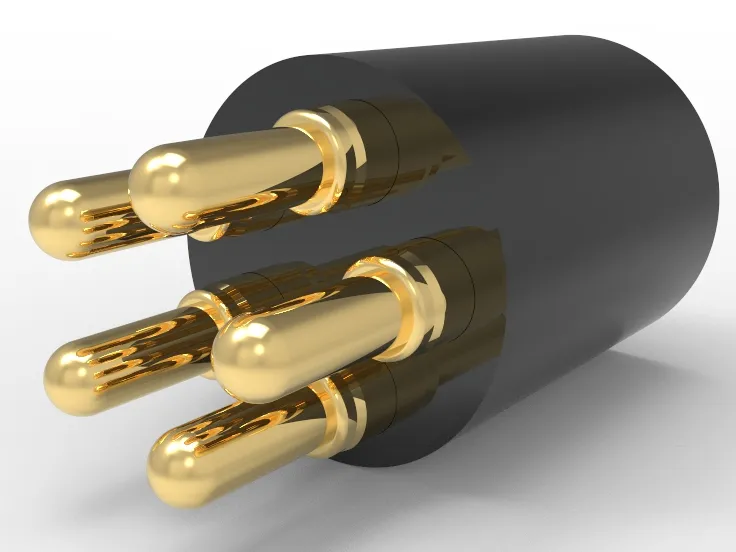

High current connector is commonly used in electric vehicles, battery systems, and clean energy systems. The utilization rate of each kilowatt hour of electricity is related to the cost and sustainability of customers. Johoty has been striving to reduce or avoid the potential loss of one thousandth of the current in the transmission process. Because accumulating over the lifespan of the entire vehicle or running thousands of charging stations can result in astonishing energy waste. The vast majority of customers only value Johoty’s high current connector based on high-precision pogo pins. Contact Johoty to order various solutions: 25A, 60A, 100A, 200A, 300A, 500A, 600A, 800A, etc.

Johoty’s high current connector often has a contact surface of ± 0.02mm and an extremely low resistance of 0.50m Ω. The current flowing through them has almost zero loss during transmission, making fast charging and high-power output both safe and efficient. For engineers and procurement experts, this is an iteration of connectors. They are also a structural change that can reduce energy consumption by 20% in the future electric mobility system.

High current connector: from contact resistance to system energy efficiency

The loss of traditional connection methods under high current mainly comes from contact resistance. According to the electrical formula P=I²R, we need to pay attention to contact resistance in high current environments. Even an additional resistor of 0.1mΩ can generate 25W of heat at a current of 500A. The significant heating and shortened lifespan of charging guns or battery modules during long-term operation.

Johoty’s high current connector with pogo pin structure can control the contact resistance at 0.2mΩ, which is more than 80% lower than traditional pins. This level of precision improvement reduces the energy loss of an electric vehicle during fast charging to a negligible level. The charging time of the entire vehicle is reduced by 15%, and the battery life is extended by more than 10%. This invisible loss control is the decisive factor that many engineers crave for system reliability.

The safety and speed advantages of high current connector in fast charging

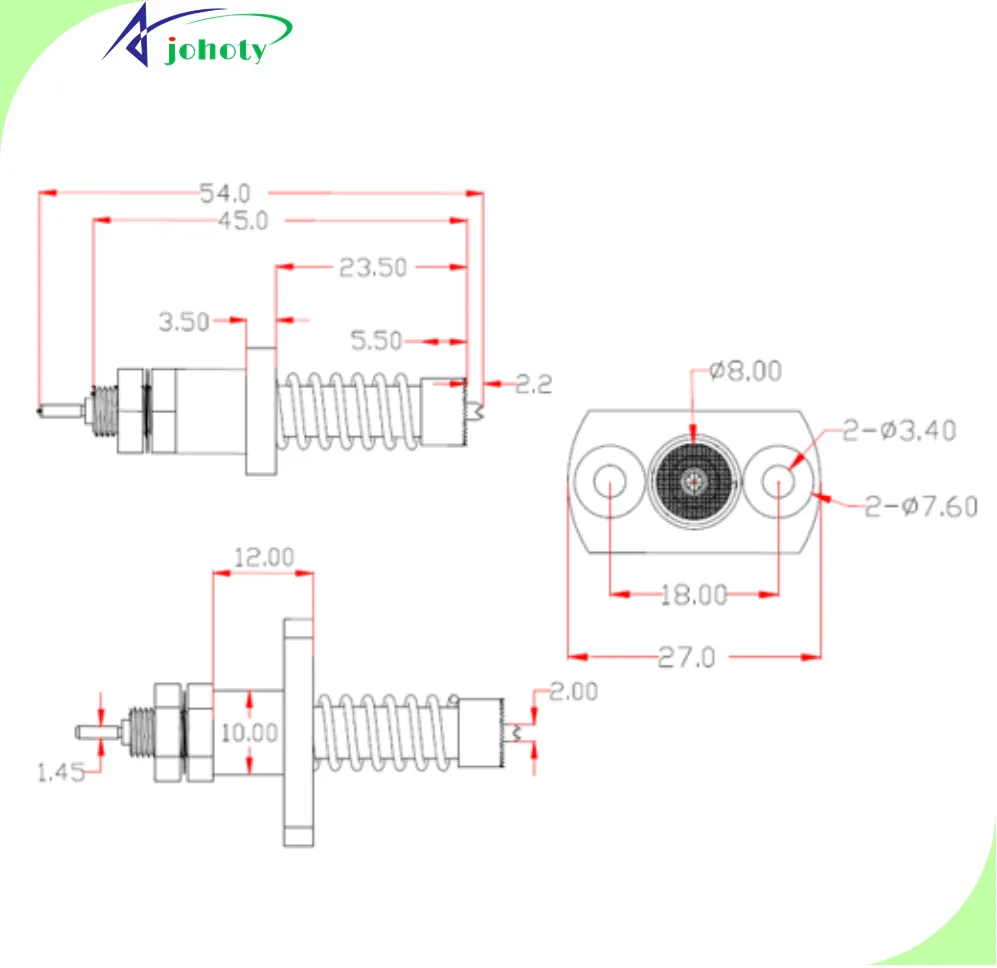

EV fast charging is essentially an instantaneous input of high current, and the challenge lies in heat accumulation and material stress. If the connector cannot guarantee sufficient compression force and surface stability, arcing, local erosion, and even safety accidents may occur. High current connector is based on Johoty’s pogo pins. Their elastic barrel ensures that the plunger maintains a stable pressure distribution throughout microseismicity and temperature differences.

After 1,000 insertions and removals, the contact resistance increased by less than 2%. This zero drift characteristic ensures that the vehicle remains safe and reliable even after 10 minutes of 80% fast charging. Will not trigger overheating protection due to contact failure, avoiding interruption of user experience. Meanwhile, this brings you smaller heat dissipation design redundancy and a lighter overall structure.

Compatibility between high current connector and clean energy systems

Johoty also has some high-end customers from wind power, photovoltaic, and energy storage systems. They share that electricity enters the energy storage battery through a DC busbar and is then fed into the grid through an inverter. The loss of each connector will be multiplied, resulting in a decrease in efficiency from the power generation side to the load side.

The guests also tried using Johoty’s high current connector for 10 out of 10 at the beginning. The end-to-end efficiency of the system has been found to increase from 92% to 96%. A 100MW photovoltaic power station can deliver 40GWh electricity to state power grid annually. This is equivalent to 40,000 households’ annual electricity consumption.

This is like the same bucket of water, which used to only pour out 90%, but now it can pour out 9.6%. For customers, this difference is directly reflected in the competitiveness of power generation revenue and carbon emission indicators. Customers also gradually trusted the performance of Johoty’s high current connector after a long period of testing and validation.

Reliability and lifespan of high current connector

Engineers know that any technology related to high-power transmission requires reliability verification. The high current connector based on Johoty’s pogo pins showed a resistance change of less than 5% after 100000 uses. However, traditional connectors have shown significant degradation after 30000 cycles. After long-term tracking by Johoty’s customers, it was found that the lifespan of electric vehicles can cover a lifespan of over 8 years.

Meanwhile, Johoty’s high current connector can operate in cycles ranging from -40℃ to 125℃. Their contact performance remains stable and no thermal fatigue failure has occurred. This cross temperature reliability allows it to operate stably in extremely cold Northern Europe or high-temperature Middle East regions.

Many of Johoty’s customers require the production of EV or battery charging products for use in countries with different temperatures and humidity levels. Our high current connector can reduce the need for complex adaptation due to regional climate differences. Johoty can greatly reduce the development cost of global deployment of vehicles for customers.

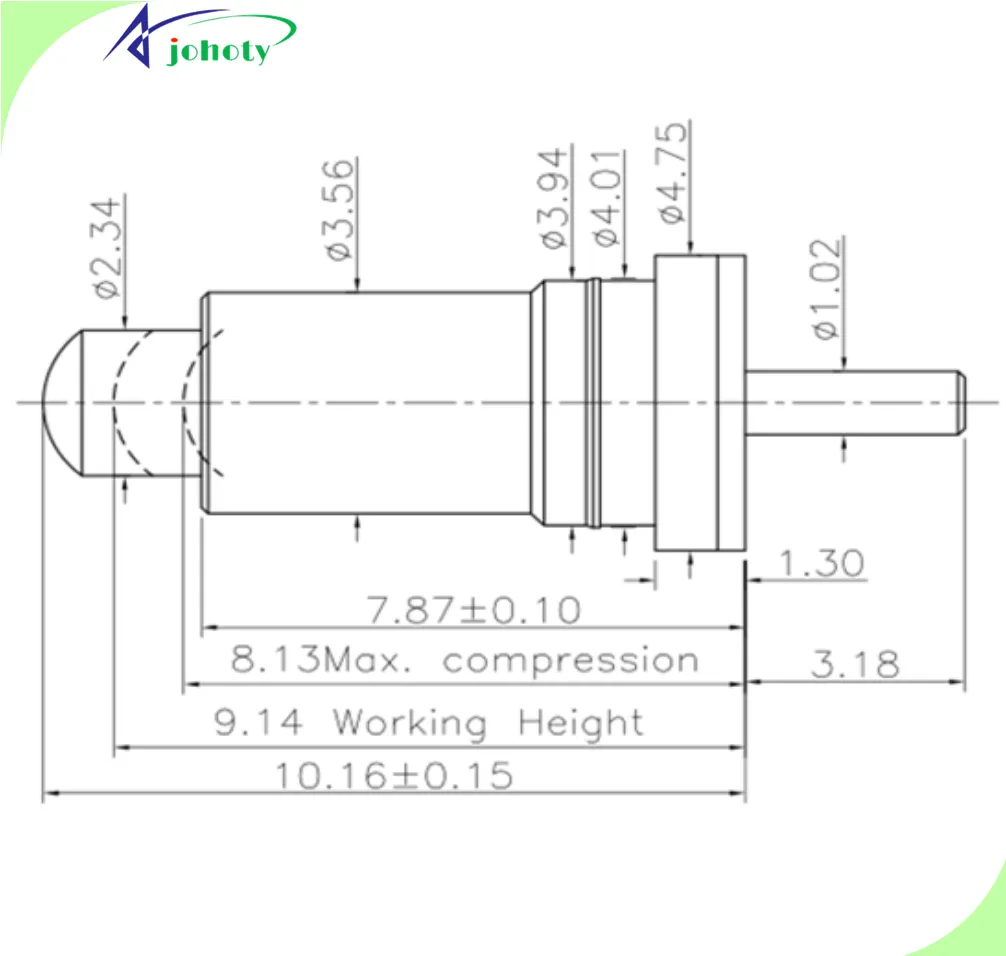

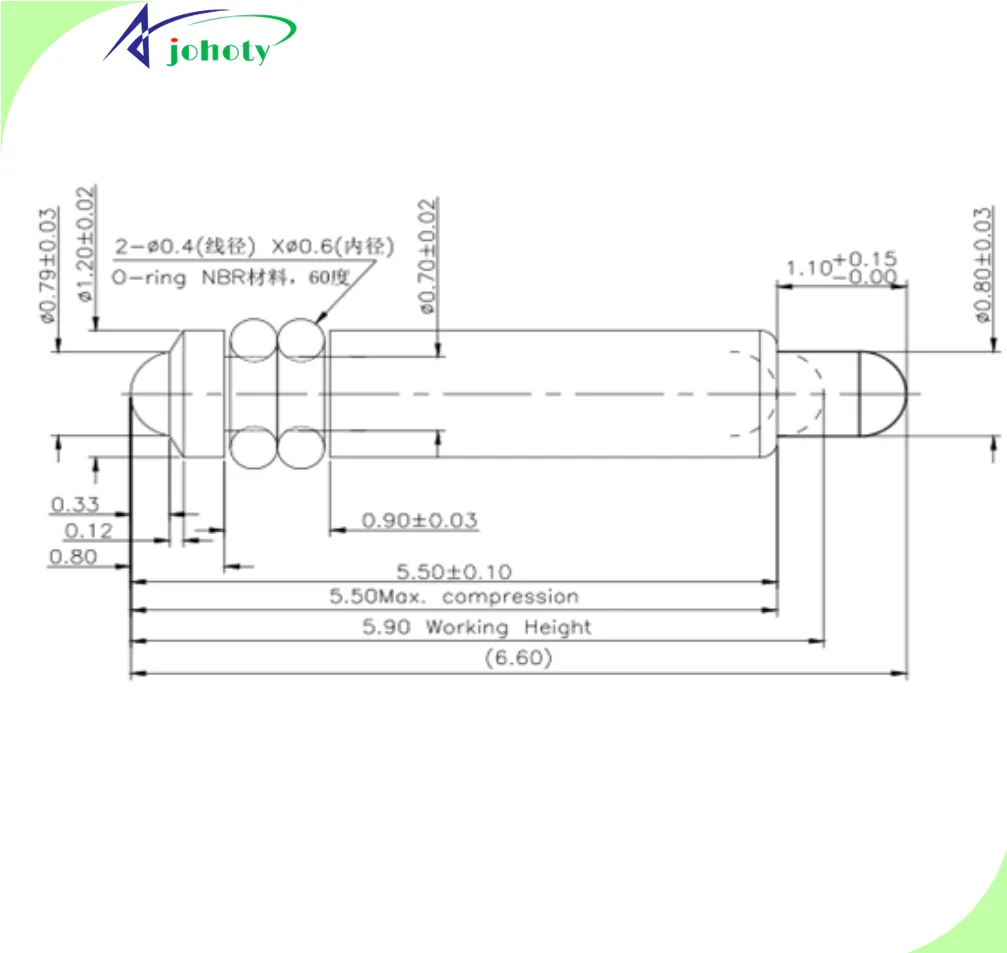

Structural details and design logic of high current connector

The pogo pin serves as the core structure, and the spring is made of high elasticity alloy material. Continuous operation at 120℃ for two years without plastic deformation or embrittlement. The external coating adopts thick gold electroplating, and the contact surface maintains low impedance in humid and salt spray environments. This design logic is similar to the plug of electric kettles in our daily lives: frequent plugging and unplugging can always provide stable power, but the latter needs to withstand hundreds of amperes of impact.

During testing, the customer found that Johoty’s high current connector can achieve stable conduction within 2ms. They can avoid arc damage at the moment of contact. This millisecond level response capability is the implicit cornerstone that supports the safety of high-frequency fast charging for customers.

Many customers are concerned not about the cost of individual connectors, but about the overall economy of the system. A public charging network in a city can increase the efficiency of each charging station by 3% due to differences in losses. With a scale of 1,000 piles, 5 million kilowatt hours of electricity waste can be reduced annually. Calculated based on the average electricity price, this is equivalent to saving over $500,000 in operating costs. The value of this scale is far more convincing than the cost difference of a single component. In other words, the significance of high current connector is not about single point breakthroughs. But it is about promoting a leap in overall energy efficiency. This is exactly the system-level bonus that Johoty’s clients are most concerned about.

Conclusion: High current connector lead the future

The value of custom connectors lies in enabling complex systems to achieve the most efficient energy transfer in the simplest way possible. Based on Johoty’s pogo pins, high current connector can help you achieve zero power loss. Help you enter a new stage of reliable and scalable fast charging and clean energy utilization.

Johoty also has many customers who like to pursue performance limits. Of course, you can exchange lower system redundancy for higher energy efficiency and longer product lifespan. Your future electric transportation and energy system will have a more solid underlying guarantee due to these seemingly small connection details.

If you would like to learn more about how to apply Johoty’s high current connector in your system, please contact Johoty immediately. You can get all the in-depth analysis about zero-loss power connections as soon as possible.

+86 13590816656

+86 13590816656 +86 13590816656

+86 13590816656