High-Temp Connectors 50A 250℃, Built for EV, Aerospace, and Harsh Environments. Trusted Reliability and High Performance. Custom Solution Now

Introduction: What are trustworthy high temp connectors?

High temperature connectors are commonly used in high stress EVs, aerospace, heavy industry, and extreme environmental equipment. Temperature is no longer a background parameter, but the determining factor that dominates all engineering reliability.

What you need is not just a connector. But it is a device that continuously carries 50A current at 250℃. A high-performance component that can maintain constant contact impedance and stable mechanical structure.

Johoty will provide you with in-depth analysis of high temp connectors customized for extreme environments. Meet your rigorous standards during the product design phase and address the risks and challenges you face in practical applications.

Why is 250℃ the threshold for high temp connectors, not the upper limit?

In EV electric drive, aviation electronics, and oil and gas electronic cabins, transient or sustained operating temperatures often exceed 200℃. The contact resistance of traditional connectors will significantly increase at high temperatures. Causing thermal runaway, local erosion, and even vehicle failure.

Is 250℃ just a tolerance threshold? and be not so. The 250℃ mentioned by Johoty is not the highest tolerable, but refers to a long-term working environment.

They need to undergo temperature resistance electrical testing in accordance with UL 1977 standards. Johoty’s high temp connectors can be powered continuously at 250℃ for 1,000 hours. The contact resistance only increased from the initial 10.8mΩ to 12.1mΩ. The current carrying capacity remained stable at 50A±3%. This means it can not hold on, but operates stably. This requires the support of 3 major designs.

The high reliability of high temp connectors stems from three major structural root cause designs

Breakthrough in material system:

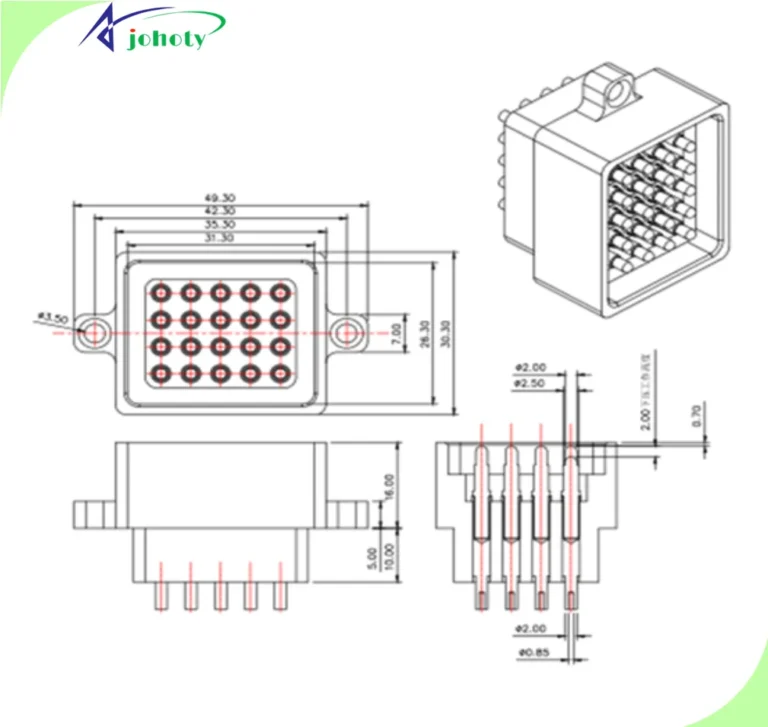

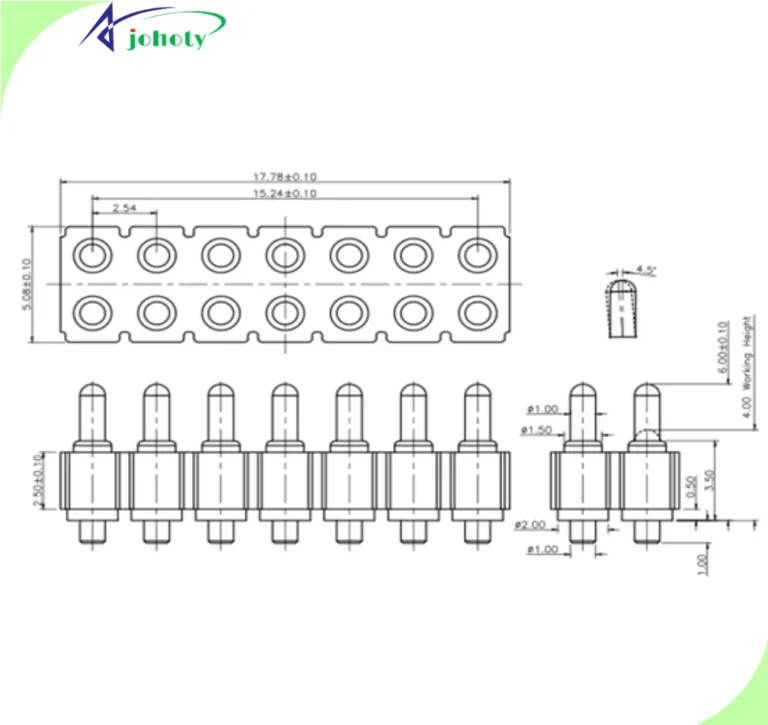

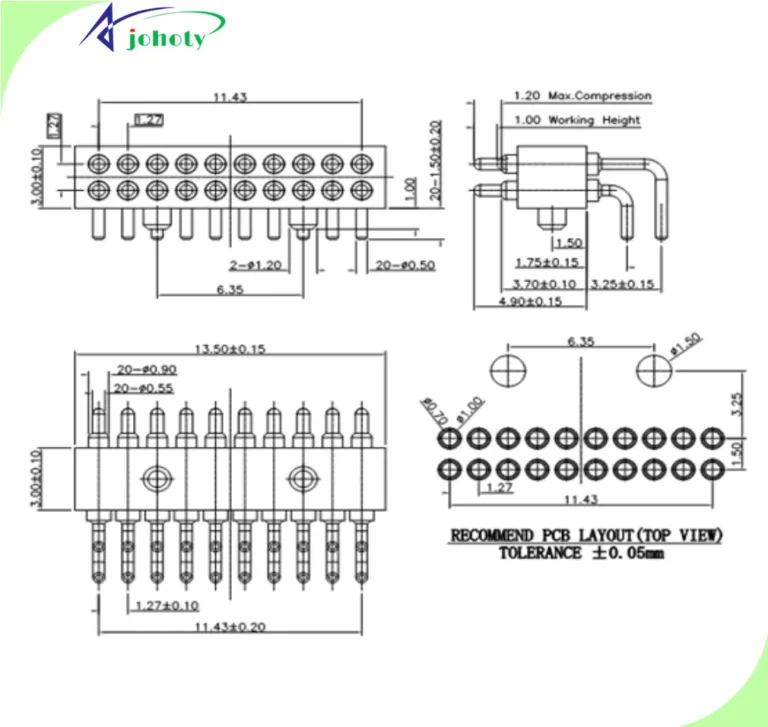

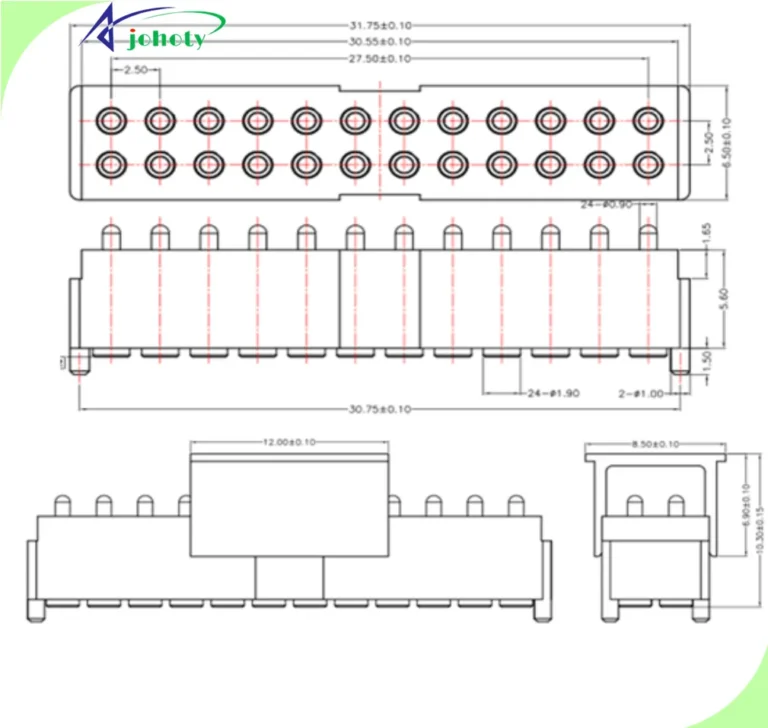

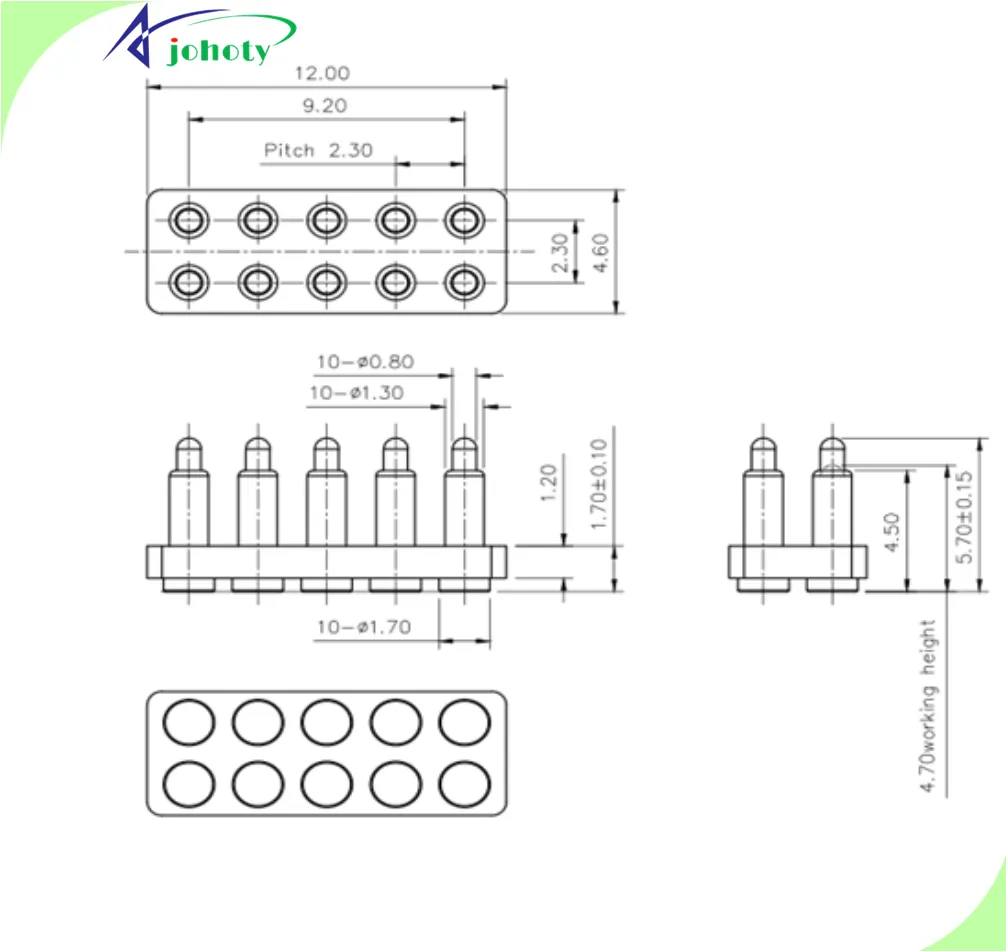

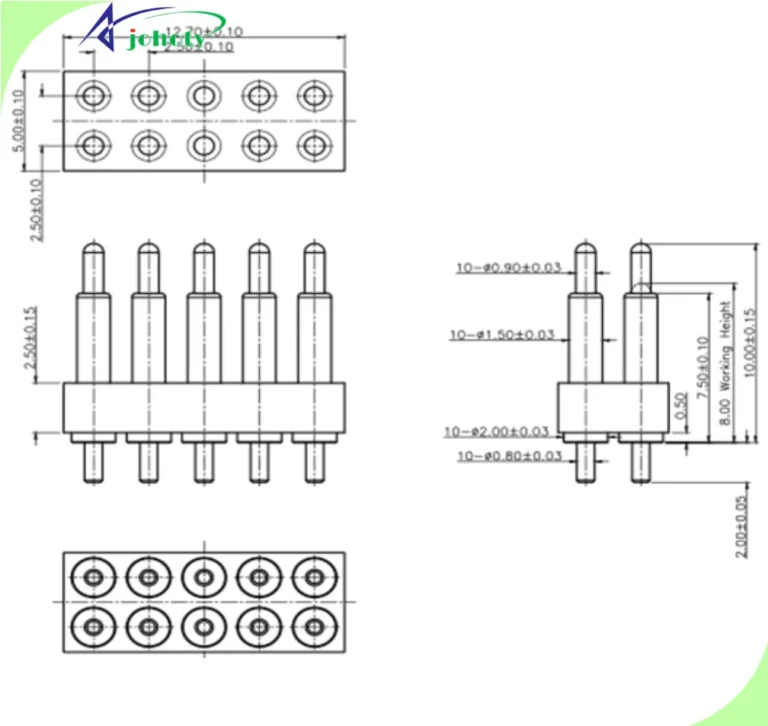

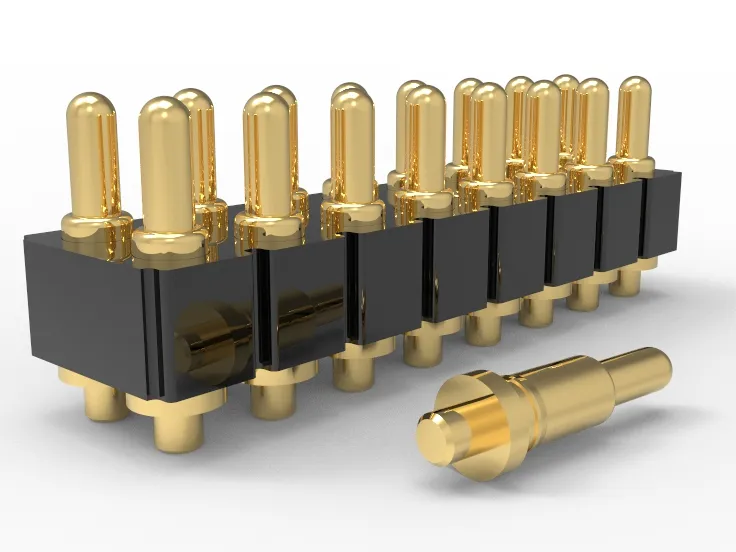

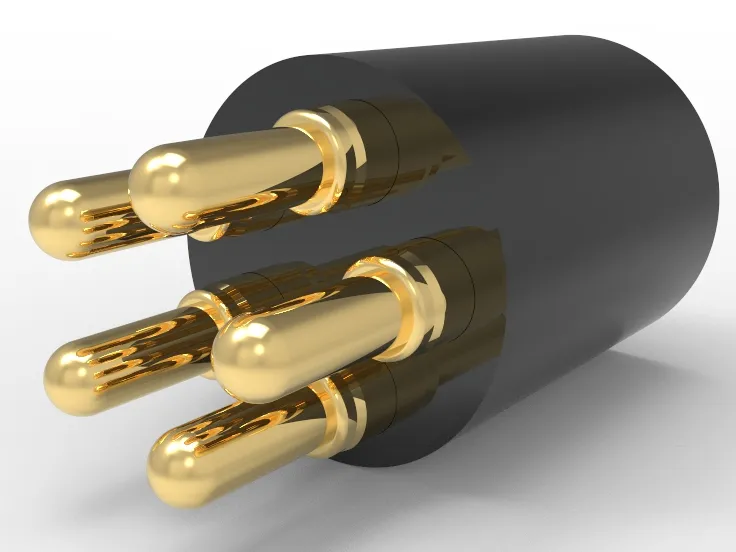

We use gold-plated palladium alloy elastic pogo pins coated with 5μm high-density pure gold. The bottom layer is a high thermal conductivity copper berry, with a thermal deformation point of up to 310℃.

Compared to nickel/tin plated connectors, the gold layer will not peel off due to oxidation in environments above 200℃. Electrical contact maintains close contact at the atomic level of the metal.

They can pass the ASTM B686 -55℃ to +250℃ repeated 500 thermal shock cycle tests. Our pogo pin connector still maintains a contact impedance of 10mΩ. On average, commercial connectors reach 20-30mΩ.

Mechanical structure stability design:

Each pogo pin adopts a dual section pre compression design, which can automatically adjust its elasticity during thermal expansion and contraction. Maintain a contact force of ≥50gf during high-temperature deformation.

At the same time, when the load lasts for 50A, the linear thermal expansion coefficient of the barrel matches the housing material. Avoid mechanical jamming caused by hot bumps.

Airtight packaging and pollution protection:

The deposition of tiny particles in aerospace or EV high voltage has a fatal impact on the performance of connectors. Johoty’s high temp connectors feature a fully enclosed ceramic ring and epoxy protective packaging. This design ensures long-term corrosion resistance and particle blockage.

In the IEC 60512 salt spray corrosion test, there were no corrosion spots on the contact surface of the pogo pin. The signal integrity can also be maintained at over 99%.

High temp connectors are not just carriers in EV systems

In EVs, temperature not only causes material fatigue problems, but also a system level chain reaction. For example, the inverter controller operates at a temperature of 160-200℃. Once the connector experiences slight contact looseness, it is highly likely to cause resonance signal interference, local thermal breakdown, etc. Ultimately, it leads to a decrease in electric drive efficiency and even a complete vehicle power outage.

Johoty’s high temp connectors are equipped with an internal spring positioning system. It can achieve dynamic compensation tolerance within 0.10mm and high frequency signal integrity above 10GHz. Perfectly compatible with industrial buses such as CAN, LIN, Ethernet, etc. It is also suitable for EV onboard chargers, high-temperature e-drives, and regenerative braking of braking energy

Vibration + high temperature + low-pressure oxygen in aerospace

Aerospace connectors face multiple pressure accumulations:

- The risk of breakdown in high-altitude and low-pressure environments.

- The engine area is exposed to temperatures above 240℃ for a long time.

- Continuous g-value vibration stress during flight.

Johoty’s high temp connectors can pass the vibration, thermal shock, and insulation withstand voltage tests in MIL-STD. In the simulation satellite level platform, it can pass the 3KV insulation withstand voltage test under low voltage oxygen. Johoty’s high temp connectors still show no signs of breakdown and are suitable for:

- Satellite attitude control motor drive.

- Redundant channels for flight control computing units.

- Turbine monitoring high-frequency signal output.

Customize Aerospace Connectors from Design Parameters to Terminal Testing

Many of Johoty’s clients come from European and American OEMs and aerospace first tier suppliers. The requirements they proposed are not standard products, but rather:

- Compatible with specific PCB apertures within 0.38mm.

- It needs to support resistance not increasing after 10,000 consecutive insertions and removals.

- Ensure 360° mating stability after bonding with thermal conductive adhesive.

Johoty has expertise in structural design, material selection, temperature rise simulation, and electrical modeling. The complete capability chain up to the final finalization testing. We develop ANSYS thermal simulation, SolidWorks mechanical modeling, and CST signal integrity simulation throughout the entire process. Shorten the design cycle by at least 30%.

Long-term reliability of high temp connectors at high temperatures

The following are our measured key data under 250℃(50A load):

| Items | Original | 100 hours | 500 hours | 1,000 hours |

|---|---|---|---|---|

| Contact Resistance(mΩ) | 8.2 | 8.4 | 8.8 | 9.1 |

| Current Resistance(A) | 50.0 | 49.9 | 49.8 | 49.8 |

| Surface Oxidation Spots | No | No | minimal | minimal |

| Elastic Recovery Rate(%) | 100 | 99.7 | 98.9 | 98.4 |

| Probability of frame loss in vibration signals(%) | <0.001 | <0.001 | <0.005 | <0.005 |

Why are high temp connectors bottleneck patch for entire system?

Engineers know that system failure is never the weakest component, but the interface point that is most easily overlooked. Each connector holds the same position as the last nail in the entire vehicle, machine, and architecture. In extreme environments, a connector with unstable contact can cause the entire system to crash.

Johoty does not pursue mass production standardization, but truly helps every customer. Provide customers with the most suitable, stable, and adaptable high tem connectors or connection solutions for the future.

Conclusion: High temp connectors are not just about today’s pogo pin connectors, but also about tomorrow’s trust

We believe that connectors are not just devices that connect circuits, but also an extension of the engineer’s will. Engineers often face high temperatures, strong earthquakes, and complex electromagnetic interference. What they need most is a trustworthy partner who won’t drop the chain in critical moments. This is existence significance of Johoty high temp connectors.

If you are seeking customizable high temp connectors or a long-term stable connection solution. It’s for your EV platform, aerospace products, or extreme operating equipment. Welcome to contact Johoty’s CFT team. We are willing to break down the last barrier between design and performance for you.

+86 13590816656

+86 13590816656 +86 13590816656

+86 13590816656