Best Pogo Pin Connector China Manufacturer for Reliable Connection

Pogo Pin Connector is a core part for often connections, built-in springs, diverse designs, high custom. Brass gold plating for stable connections, charging, and signal transfer. Johoty provides solutions and on-demand production.

Features:

- High contact pressure, stable current transmission.

- Support multiple rows and pins for different uses.

- High durability, no looseness after long-term use.

- Flexible customization for diverse actual applications.

- Strong anti-vibration to ensure stable connection.

- Lean production, precise docking of each pogo pin.

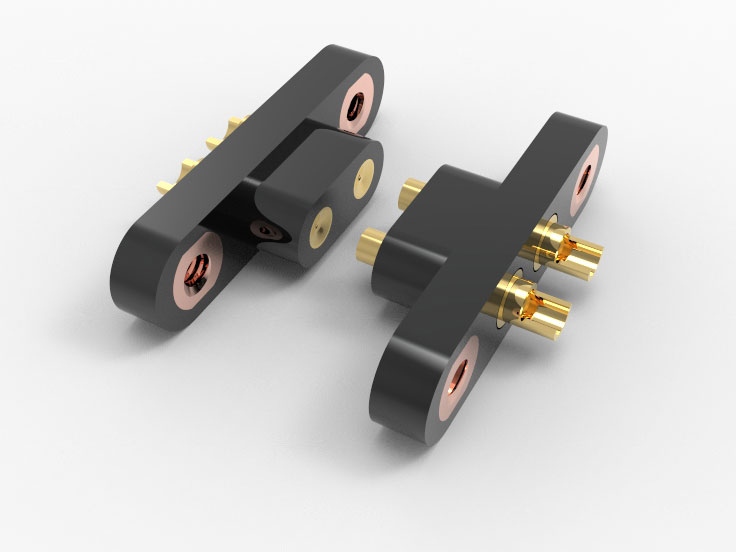

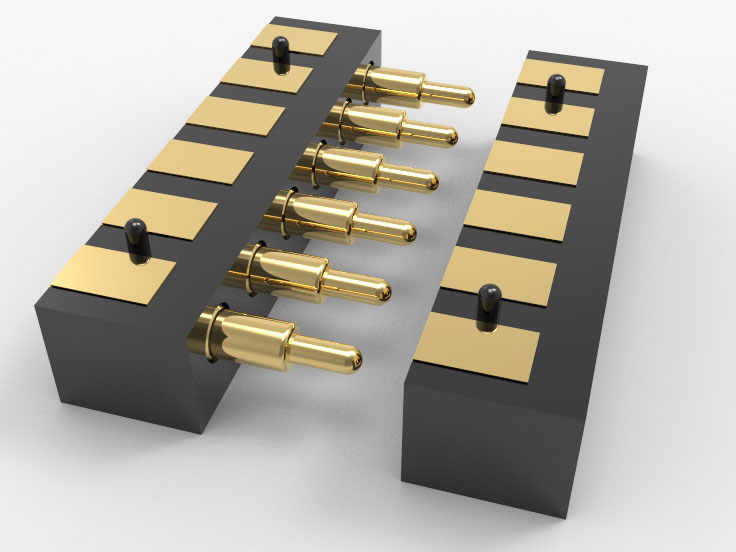

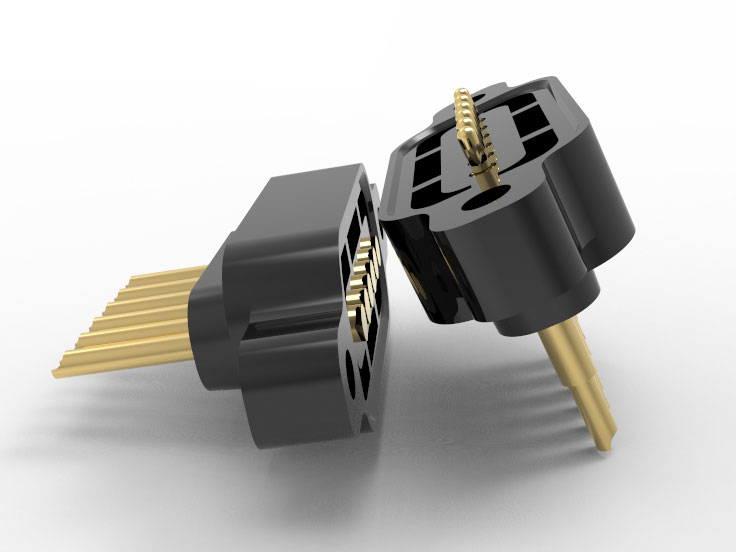

Pogo Pin Connector Series

Pogo pin connector has 2~598 pins, ≥1.0mm pitch or stroke. High elasticity and durability. Includes standard, miniature, high-frequency, high-power, and customizable shapes. It transmits signals, power, and precise connections. Materials include brass, phosphor copper, beryllium copper, tellurium copper, stainless steel, gold plating, palladium, silver, platinum, and high-temperature nylon. Common IP67 and N52 magnetic cables, supporting <500V voltage and <50A current. Compliant with ASTM, RoHS, REACH, etc

Specifications of Pogo Pin Connector:

| Parameter | Value and Description |

|---|---|

| Contact Resistance | ≤ 50 mΩ |

| Rated Current | Common 1A~5A per pogo pin, 3A~50A for power applications, custom |

| Maximum Working Voltage | 12V~60V (up to 250V for custom) |

| Insulation Resistance | ≥ 1,000 MΩ @typically tested at 500V DC |

| Signal Stability | ±5%~10% drift |

| EMI Resistance | Meets EN55032 Class B, Critical for high-speed data and RF signals |

| Spring Force | 5 gf~100N per pin, |

| Stroke Range | 0.10 mm~15.00 mm,70–80% of max travel |

| Cycle Life | ≥ 10,000~1,000,000 cycles, custom |

| Pogo Pin Material | Brass or Beryllium Copper, SUS, Tellurium Copper, custom |

| Plating | Gold plating (0.1~3.0 µm), composite coating, custom |

| Insertion Force | ≤ 300 gf, custom |

| Retention Force | ≥ 100 gf, custom |

| Operating Temperature | –40℃ to +105℃ (up to 125°C),custom |

| IP Rating (Sealing) | Up to IP67,IP68, O-rings and housing-level design |

| Vibration & Shock Resistance | IEC 60068-2-6 & IEC 60068-2-27,custom |

Structure of Pogo Pin Connector:

| Component | Description |

|---|---|

| Pogo Pin Array | A matrix of spring loaded pins designed to ensure consistent and low-resistance electrical contact under compressive force. Each pogo pin supports axial movement to accommodate tolerance stack-ups. |

| Plastic Housing | High-temperature-resistant thermoplastics (LCP or PPS) formed by precision injection molding. The housing ensures pogo pin alignment, dielectric insulation, and mechanical stability. |

| Plunger Tips | Movable top element of pogo pin, made of gold-plated hardened beryllium copper or SUS, ensuring long wear life, corrosion resistance, and low contact resistance. |

| Spring | Precision micro-coiled stainless or music wire spring offering controlled force range (typically 20–150g), enabling reliable electrical contact under varying compression. |

| Sealing(O-Ring,Gasket) | For IP-rated models, silicone or fluororubber rings are embedded to prevent dust, water, and flux intrusion. Essential in automotive, medical, or outdoor industrial use cases. |

| Mounting Bracket | Structural component defines connector placement. Often CNC-machined or stamped from stainless steel or brass. Provides mechanical fixation and EMI shielding in shielded variants. |

| Tail Pin | Termination interface between pogo pin and PCB or wire harness. Available as surface-mount leads, through-hole pins, or soldering cable, designed for automated or semi-automated assembly. |

| Conductive Sleeve | In high-frequency or high-current variants, a conductive tube (copper alloy) is used to enhance current-carrying capacity, thermal dissipation, or EMI shielding. |

| High-Frequency | Use of short barrel designs, low-inductance paths, controlled impedance layouts, and shielding sleeves to minimize signal loss and crosstalk in RF applications. |

| High-Current | Larger pin diameters, thicker spring coils, and enhanced barrel plating to carry 5–50A. Thermal mitigation through copper sleeves or heatsinks is common. |

| Waterproof (IP67/IP68) | Addition of multi-stage sealing systems, including O-rings at housing interface, potting materials around terminal exits, and hydrophobic venting membranes. |

| Long-Life Cycle | Enhanced plating thickness (up to 80 micro-inches of gold) and hardened wear surfaces for use in >1,000,000 compression cycles, with minimal resistance drift over time. |

Installation Shape of Pogo Pin Connector:

| Installation Shape | Description |

|---|---|

| Vertical | Perpendicular to PCB, used in top-down mating. |

| Horizontal | Parallel to PCB, used for side-entry layouts. |

| Angled | Typically 30°–45° to avoid interference. |

| Through-hole | Strong retention for mechanically stressed designs. |

| SMT | SMT-compatible, suited for automated assembly. |

| Snap-in | Tool-less installation for modular builds. |

| Single Row | Linear layout, compact and simple. |

| Double Row | Higher density for multipoint contact. |

| Matrix Grid | Grid format for high I/O interfaces. |

| Custom | L-shape, circular, and custom layouts. |

| Mating | Spring tip mates with opposing pad. |

| Insertion | Engages inside mating hole/sleeve. |

| Sliding | Maintains contact during lateral motion. |

| Open | No sealing, for internal/non-critical use. |

| Sealed | O-ring/potting for IP-rated conditions. |

Pogo Pin Connector Applications:

Wearable ECG monitor: 2-pin spring loaded connector is used for quick connection between electrodes and data processing modules. Meet the requirements of high-frequency disconnection, corrosion resistance, and low contact impedance, ensuring data continuity and reliability during long-term wear.

5G outdoor micro base station maintenance interface: using a waterproof 7-pin pogo pin array as the debugging and firmware update interface, with IP67 level protection. Supports stable communication in environments ranging from -40℃ to 85℃, meeting the requirements of field maintenance scenarios.

PLC control module connected to IO terminal board: up to 12 pin high-density pogo pin structure can achieve parallel transmission of 24V power supply and signal. Support modular replacement and hot plugging to improve workstation wiring efficiency and system maintainability.

Drone flight control system: The high seismic pogo pin connector (14 pin) is used for reliable connection between the flight control board and the sensor module. Through 1,000G impact and 10,000 insertion and extraction tests, ensure stability under extreme working conditions.

Vehicle intelligent central control module testing fixture: 8pin customizable pogo pin group for bus protocol simulation and EEPROM writing testing, with contact resistance<50mΩ Effectively shorten the debugging time of the production line and improve the efficiency of automated production testing.

TWS earphone charging contact: 2Pin gold cap pogo pin is used to connect the charging case to the earphone, with a compact structure that supports a lifespan of >20,000 cycles. Cooperate with magnetic attraction structure to enhance user experience and reduce failure rate.

Smart Watch Multi functional Data Stand: 4-10 pins with different specifications of pogo pins to connect sensors, power supplies, and data channels, ensuring magnetic alignment accuracy ≤ 0.15mm. It realizes efficient operation of multi-protocol merging interfaces in limited space.

Outdoor portable energy storage power module interface: 8-pin high current pogo pin supports 10A instantaneous charging and adopts a gold-plated + stainless steel spring structure. Adapt to high and low temperature alternating environments ranging from -20℃ to 60℃, and enhance the stability of current transmission.

Wireless doorbell main and auxiliary unit connection base: using 4-pin moisture-proof pogo pin module to improve data synchronization and power supply reliability of the main and auxiliary units. Supports a lifespan of 50,000 cycles, making it easy to replace and maintain on a daily basis.

Laboratory multi-channel signal acquisition system: 20 pin arrangement for analog and digital signal split sampling, contact impedance <30mΩ Cooperate with EMI shielding enclosure to control interference sources and improve testing accuracy and repeatability.

BMS battery pack module testing fixture: 12 pin and 40 pin arrays are used for multi-channel voltage and temperature signal acquisition. The dynamic compensation structure of the spring needle ensures stable long-term contact pressure and effectively reduces the contact failure rate.

Modular Embedded Teaching Kit: Flexible selection of 5-pin standardized pogo pin interface to achieve fast module assembly and electrical connection. Enhance the module scalability and connectivity flexibility in experimental teaching.

Why Opt for Johoty's Pogo Pin Connector?

Johoty’s pogo pin connector provides you with high performance, high reliability, low contact resistance, high stability, long lifespan, fast response, diverse customized solutions, and high value. Johoty deserves your trust.

Modular System Compatibility of Pogo Pin Connector:

Multiple contact structures meet module customization:

Pogo pin supports structures such as vertical, right-angle, and dual-head configurations. Its contact height can extend from 1.0mm to 7.0mm. It is compatible with multi-layer module stacking designs. More than 70% of pluggable modules adopt non-vertical contact, pogo pin can improve their space utilization by >25%.

Stable electrical parameters, verified authoritative test:

Typical spring loaded connector support 1A~5A continuous current, contact resistance<50mΩ. Resistance change rate is <10% after 100,000 cycles of life testing. Under high temperature and humidity conditions (85 ℃/85% RH), performance remains stable for over 500 hours. It meets the requirements of automotive and industrial grades.

Standardized vehicle interfaces for automated assembly:

Support tape packaging, SMT mounting or press fit processes, and adapt to automated surface mounting and modular pre assembly processes. European and American customers often use standard pogo pins instead of traditional solder pin connections. The assembly efficiency has increased by 34%, and the assembly failure rate has decreased to 0.8%.

Compatible with mainstream protocol modules for system integration:

Pogo pin connector is compatible with standard modules such as USB, I2C, SPI, UART, etc. The signal integrity has passed TDR and S parameter tests, and data jitter is controlled within 10ps. 90% of medical and industrial control module manufacturers use pogo pin for hot swappable interfaces of functional modules.

Structural Life Analysis of Pogo Pin Connector

Spring life cycle test:

Core component of pogo pin is a high elasticity precision spring, which undergoes lifespan testing according to IEC standards. Under 100,000 compression cycles, contact resistance change is ≤20mΩ, connection is stable for a long time. Testing environment includes -40℃~85℃ and vibration interference to verify fatigue resistance under extreme working conditions.

Stability analysis of contact impedance:

Measure the contact impedance at a working current of 1A using the four wire method. At an initial value of 30mΩ, it remains within 50mΩ after repeated loading for 100,000 times. The contact surface is coated with a gold/nickel composite layer, effectively reducing the risk of oxidation. Maintain conductivity reliability and adapt to high-speed data signal transmission.

Structural fatigue fracture simulation:

Using finite element simulation to analyze the stress concentration area of pogo pin structure. Under the condition of a design compression ratio of 60%, the wall thickness of the needle tube and the preload force of the spring are both within safe limits. 70% of the maximum stress yield limit of the spring, to avoid metal fatigue and plastic deformation from a design perspective.

Insertion and removal wear and corrosion stress testing:

Evaluate the antioxidant performance of the connection surface through wet heat corrosion, 96 hours, and 5% NaCl salt spray test. After 10,000 cycles, the wear degree of the coating is ≤10%. Scanning Electron Microscope analysis shows that coating structural integrity is excellent. Multi frequency plug-in application can prove the performance of Johoty’s pogo pin connector.

Customize Structure and Function of Pogo Pin Connector

Structural design flexibility: Multiple mechanical configurations for complex embedded applications.

Pogo pins often consist of 3 parts: barrel, spring, and plunger. It can be designed as single headed pogo pin, double heads, floating, multi-point parallel arrangement, or matrix distribution. Suitable for complex working conditions such as high-density connections, dynamic crimping, and curved contacts. The typical stroke is 0.3-1.2mm, supporting customized base installation height and spring travel tolerance. It is suitable for space-limited structures integration and high-frequency plugging.

Materials and Electroplating Process: Ensure mechanical lifespan and electrical stability.

The commonly used barrel materials are brass, beryllium copper, nickel plated steel, and stainless steel. Cooperate with gold, silver, or nickel palladium alloys to control contact resistance <50mΩ and surface oxidation. Springs are mostly made of stainless steel or alloy steel, with a high fatigue life, typically exceeding 100,000 cycles. Different electroplating combinations provide a compromise solution for performance such as corrosion resistance, conductivity, and frictional impedance. It often operates in high humidity or dusty industrial environments.

Electrical performance customization: compatible with high current and high-speed signals.

Pogo pin connector often supports currents from 0.5A to 5A, depending on the design of barrel diameter and contact area. When used for USB-C, charging dock or power module,spring force and plunger shape can be adjusted to reduce voltage drop. For RF and high-speed data channels, coaxial shielding or differential arrangement can be used. This can effectively control crosstalk and signal integrity. Support dedicated connections for impedance control and low contact resistance.

Process support and mass customization: rapid prototyping and high consistency.

We can provide a one-stop customization from 3D model, rapid sample production to mass production. Tolerance control is usually better than ± 0.02mm to ensure the reliability of large-scale connections. Support customized plunger tip shapes, including spherical, blade, flat, claw, cup, star, pointed. Tail welding methods include SMT, DIP, solder cup, etc., working life targets, and contact force settings. Pogo pin number and arrangement support automated assembly, and are used for wearable devices, automotive electronics, and medical probes.

Assembly Method and Application Environment Support of Pogo Pin Connector

SMT automated assembly compatibility:

Pogo pin connector can support SMT automatic assembly. Bottom terminal can be customized with L-shaped and Gulf wing shapes to meet SMT identification and soldering requirements. Base material and dimensional tolerance control accuracy is better than ± 0.02mm, suitable for solder paste printing and AOI inspection. Pogo pin material is gold-plated and nickel plated, with contact impedance as low as 15mΩ. It is beneficial for stability and batch consistency of subsequent reflow soldering.

Reflow Profile:

Connector material has been selected and verified, pogo pin uses high-temperature PA9T or LCP insulated housing. Its melting point is above 290℃, meeting lead-free reflow soldering curve of JEDEC J-STD-020D (260℃, duration of 10s). Internal spring material is stainless steel 304 or beta titanium, which is stable and deformation-free after heat treatment. After 8 reflow soldering simulation tests, insulation impedance remained >1,000MΩ and contact resistance fluctuated by <5%.

Waterproof and dustproof rating (IP54~IP68):

Pogo pin connector has IP54~IP68 through silicone sealing rings, separated shell, and O-rings. Soaking underwater for 48 hours, exposure to dust for 72 hours, function is normal and contact resistance remains unchanged. It fits outdoor equipment, medical instruments, military terminals, etc. with high environmental packaging requirements, complies with IEC 60529.

Vibration, drop, torque testing and structural design:

Pogo pin connector passes vibration test of 10~2,000Hz, 3-axis direction, and 5-hour per axis according to IEC 60068-2. Free fall to 1.5 meters, with one test on each of six sides and a static torque of 5Nm for 60 seconds. To cope with stress, pogo pin adopts multi-point support positioning. Barrel adopts anti fatigue design, housing is equipped with cushioned shoulders, and spring life exceeds 30,0000 times. The structural finite element simulation shows that the deformation after impact is controlled within 0.05mm.

FAQ:

How Long Can Pogo Pin Connector Last?

The pogo pin connector lifespan can reach 50,000 dockings, depending on the material and design. The high-quality electroplating layers can enhance wear resistance. Proper use can reduce wear and tear. Design that adapts to harsh environments allows for a longer lifespan. Regular cleaning can prevent poor contact.

How Much Current Can a Pogo Pin Connector Withstand?

The high-end pogo pin connector can carry 0.1A~50A, depending on the diameter and material of the pogo pins. Optimize contact resistance to reduce current loss. High-temp resistant materials ensure long-term stable operation. Suitable for high-power of automobiles and industrial equipment. Different models meet various current requirements.

Will Pogo Pin Connector Have Poor Contact?

As long as the design is reasonable, the contact reliability of the spring needle is very high. The gold plating layer reduces the impact of oxidation. The elastic structure provides stable contact pressure. Dustproof design can prevent dirt interference. Products that meet strict tolerance requirements have better contact performance.

Is Pogo Pin Connector Waterproof?

Many models support IP67 or even higher protection levels. The sealing structure can prevent liquid from entering. The material has strong corrosion resistance. Suitable for outdoor and humid environments. The waterproof for reliability through rigorous testing.

What is Pogo Pin Connector Size?

The diameter of pogo pin connector can be > 0.4mm. Suitable for micro devices, wearable devices. Precision design supports 2~598 pin layout. Small size does not affect current and signal transmission performance. Provide more design space for compact electronic devices.

What Devices Are Pogo Pin Connector for?

Used in consumer electronics, smart robots, automotive electronics, medical equipment, smart SOS, industrial automation, etc. Capable of withstanding different temperatures and humidity. Support high-speed data transfer and stable power supply. Can custom specs based on needs. Meet device performance across multiple industries.

How to Maintain Pogo Pin Connector?

Regular cleaning of plunger tips can maintain stable performance. Avoid violent plugging and unplugging to extend the service life. Check the spring pressure to ensure good contact. Add protective cover for harsh environments. Ensure equipment meets the product design parameters.

Why is Pogo Pin Connector Better?

It is more durable than traditional connectors and suitable for often connection. Compact design suitable for modern device needs. Spring force enhances reliability. Supports high-speed transmission and high current. High flexibility, suitable for various complex environments.

+86 13590816656

+86 13590816656 +86 13590816656

+86 13590816656