Best 5 Pin Connector China Manufacturer High Conductivity

5 pin connector provides up to 200,000 connections based on gold-plated pogo pins and ≤50mΩ. It is anti-vibration and low wear for high-speed signal and power. It supports space optimization and adaptive tolerance for industrial use. Johoty offers perfect solutions based on our expertise.

Features:

- Durable, with a lifespan of at least 10,000 cycles.

- Low contact impedance, stable signal transfer.

- Adaptive alignment, compensation up to ±0.2mm.

- Seismic and impact resistant to harsh environments.

- Optional waterproof, supporting IP67/IP68 levels.

- Compact design, optimized space for high integration.

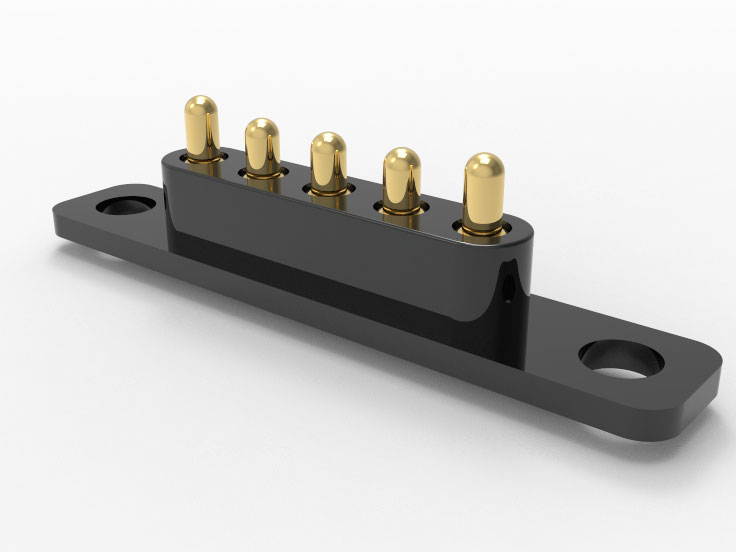

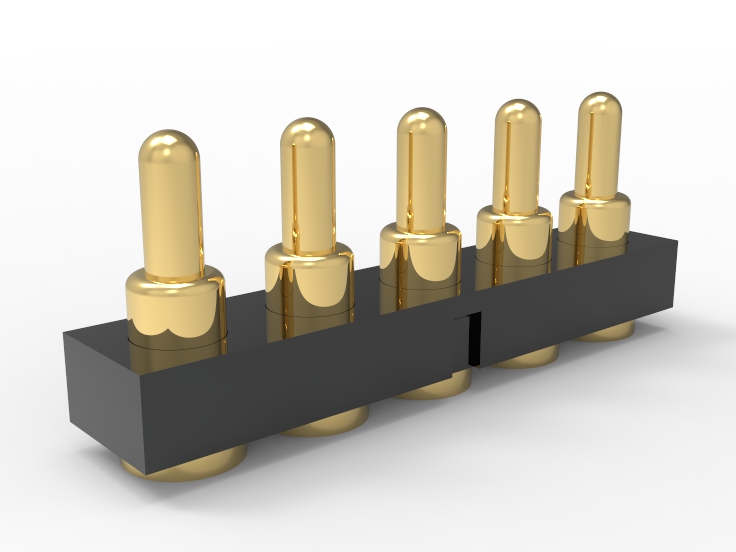

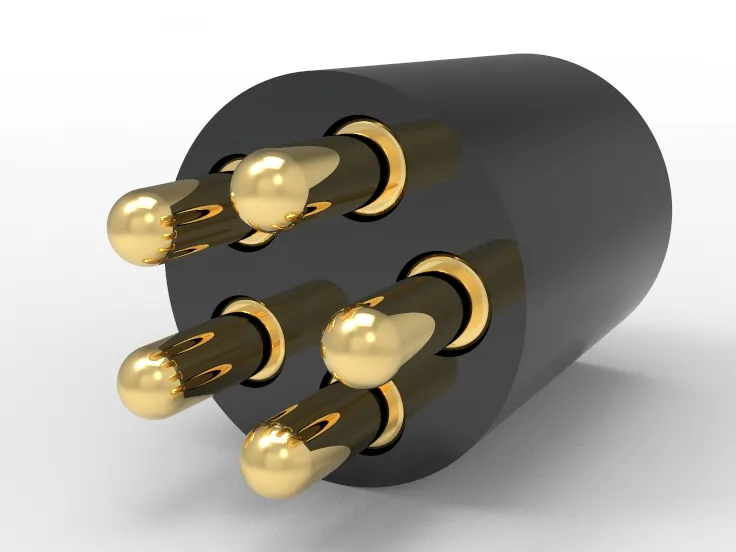

5 Pin Connector Series

5 pin connector maintains stable contact pressure through a spring, achieving stable electrical transfer. Its parameters include spring life cycles, spring force, stroke, pitch, Working temperature, rated voltage/current, contact resistance, insulation resistance, withstand voltage. Raw material includes brass, BeCu, SUS/AISI, SUS304/316, SWP, Au, Pt, Pd, Ni, Rh, 1~50μin, LCP, PA66, PBT, etc. Connection methods: board to board, wire to board, wire to wire, magnetic connection. Customization: Pitch, stroke, spring force, rating voltage/current/resistance, costing thickness, magnetic or non-magnetic, etc. R&D supports 3D models of stp, igs, prototype samples, reliability tests of life cycles, salt spray, mechanical performance. Quality inspection of contact resistance, insulation resistance, withstand voltage, plug-in life, spring fatigue testing, salt spray tests, high and low-temperature testing, vibration tests. Certificates: RoHS, REACH, ISO 9001/13485, IATF16969, ASTM.

Structure Categories of 5 Pin Connector

| Categories | Classification |

|---|---|

| Structural Type | Monolithic Pin, Split Pin, Adjustable Spring Force, Coaxial Multi-Spring, Micro Probe |

| Mounting Method | SMT Surface Mount, DIP Through-Hole, Solder-Cup Cable, Right Angle Mount, Double-End Connection, Threaded Nut Fixing, Snap-Fit Press-In, Magnetic Alignment |

| Tail-End Pin Layout | Single Row Inline, Dual Row Symmetrical, L-Shaped Bent, Circular Coaxial, Custom Asymmetric |

| Mating Socket Design | Board-to-Board Spring Contact, Vertical Board-to-Wire, Probe Insertion Type, Guide-Slot Alignment, Conductive Crimped Shell |

Specifications of 5 Pin Connector

| Parameter | Specification |

|---|---|

| Number of Pins | 5 pins |

| Rated Current | ≥1.0A, up to 50.0A (per pin), custom |

| Contact Resistance | ≤ 50 mΩ |

| Insulation Resistance | ≥ 1000 MΩ (@100V DC) |

| Dielectric Withstanding Voltage | ≤ 250V AC for 1 min |

| Rated Voltage | ≤ 550V DC, custom |

| Pin Diameter (Barrel Dia.) | ≥ 0.5mm, custom |

| Pitch | ≥ 1.00mm, common 1.27mm, 2.50mm, 2.54mm, custom |

| Housing Material | PPS, LCP, PBT, PEEK, custom |

| Spring Material | SUS304, SUS316, BeCu, SWP-B, custom |

| Plating Options | Gold plating (0.5μm – 3μm) over Ni base, custom |

| Operating Temperature | From -40℃ to +85℃, -40℃ to +85℃,custom |

| Storage Temperature | -55°C to +100°C |

| Durability (Mating Cycles) | ≥ 10,000 cycles, up to 500,000, custom |

| Spring Stroke | Working: ≥ 0.3mm, custom |

| Insertion Force | 20gf – 100gf (per pin) |

| Retention Force | ≥ 0.2N (overall) |

| Vibration Test | 10~55Hz, amplitude 0.75mm, 2 hrs per XYZ axis |

| Shock Test | 490 m/s², 11ms, 3 times per XYZ axis |

| Housing Shape | Round, Rectangular, L-shaped, Custom |

| PCB Mount Type | SMT, DIP, Right Angle, Double-Ended, Solder-Up, Screw Mount, Custom |

| IP Rating | Up to IP67 or IP68 (depending on design), Custom |

| Special Features | Alignment posts, Anti-misplug features, Shielding EMI, custom |

Applications of 5 Pin Connector

TWS earphones and charging case: Due to limited volume, SMT surface mount installation is required. Typical current <0.5A, lifespan >10,000 cycles, preferred low elasticity flat head design. Ensure stability in light pressure contact and high-frequency insertion and extraction.

Smart Watch: Thickness<10mm, horizontal contact required, working current ≤1A, preferred flat shape and high-density layout. Supports LCP packaging and small pitch (1.0mm) wiring.

Wearable health devices: Require sweat resistance, corrosion resistance, and contact resistance <30mΩ. Use BeCu gold-plated spring pins, support IP67 structure and anti-oxidation design.

Mobile phone expansion module: requires fast plugging and unplugging, frequent interfaces, and typical plugging and unplugging times >20,000 Requires a total stroke of 1.2mm, response force <70gf, and supports magnetic connection.

Medical handheld devices: high contact reliability requirements, insulation resistance >1,000MΩ. Commonly used for patient monitoring and data transmission, compatible with shielding structures and anti-EMI design.

Drone/aerial module: Seismic performance is critical, requiring vibration testing at 10~55Hz with a holding force greater than 0.2N. It is compatible with high-temperature resistant PPS structural shells and SUS316 spring materials.

Vehicle mounted central control/sensing interface: resistant to temperatures ranging from -40°C to+85°C, requiring resistance to vibration and high-frequency insertion and removal. Typical use of SMT clamp type and side PIN structure, supporting CAN and other signal connections.

Industrial automation fixtures: high current applications, single pin carrying capacity ≥3A, multi pin synchronous contact and mechanical alignment mechanism. Support DIP fixation and shell reinforcement structure.

Smart home panel/touch screen: It needs to be installed and connected to the wiring/module, typically with a 1.0mm needle pitch flat head spring needle. Support SMT process and assembly tolerance compensation.

Electric tool charging dock: requires high mechanical strength and durability. Typical lifespan ≥30,000 times, insertion force >100gf, contact surface requires a gold plating layer ≥1μm.

Laboratory testing probe module: requires accuracy and repeatability, with contact resistance fluctuations<10%. Needle length tolerance <±0.05mm, it is recommended to use a linear needle set with a guide shell.

Modular battery pack connection: It needs to support hot swapping, current ≥2A, and is typically a board to board structure. Equipped with self elastic positioning design, supporting 2.54mm large pitch and dual spring contact.

Why Johoty's 5 pin Connector As Solutions?

Johoty’s 5 pin connector has lower contact resistance, stronger shock resistance, and optimized space utilization. Our customized services can fully meet customer needs, enhance product compatibility and service life. By choosing Johoty, you can obtain high-performance, high-stability connection solutions, which can help product innovation, enhance market competitiveness.

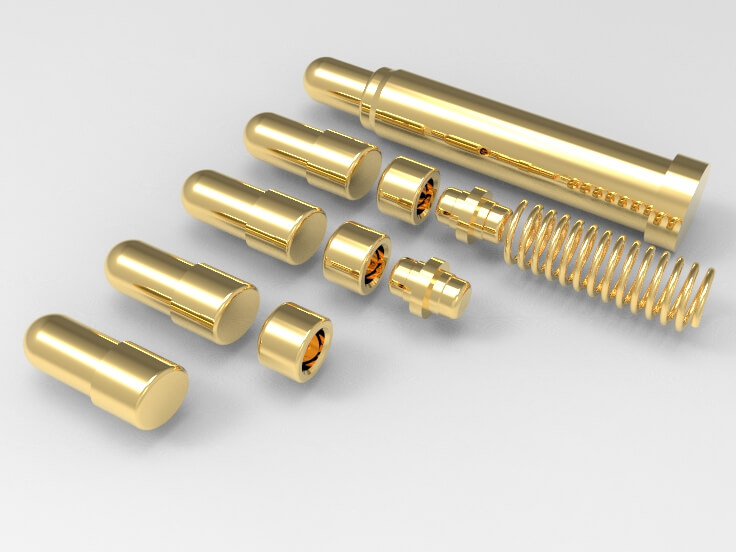

Raw Materials of 5 Pin Connector

Plunger

HBi59 brass that complies with JIS H3250 standard is selected, which has excellent machinability and a conductivity of 28% IACS. Can ensure the insertion and extraction life and signal integrity, suitable for precision machining of micro structural components. Using neutral electrolytic nickel plating with a thickness of >2μm as the bottom layer to improve corrosion resistance and solder barrier ability. The surface gold plating thickness is controlled between 0.1 μm and 0.3 μm, with stable contact and contact resistance <50mΩ.

Barrel

C5191 phosphor bronze that meets ASTM B103 standard. Good elasticity and wear resistance as the main material of the needle tube, with a conductivity of 15-20% IACS. Suitable for stable conduction during high-speed connection actions. The conventional process involves a 3μm nickel plating base, followed by gold or silver plating depending on the application. Gold plating provides high reliability and low contact impedance, while silver plating has the best conductivity. Satisfy SMT soldering, through-hole soldering, wire bonding, or crimping.

Spring

Adopting SUS304-WPB piano steel wire that complies with JIS G4314, it has good elastic fatigue life. The tensile strength can reach over 1,500 MPa, and there will be no performance degradation after more than 10,000 compressions. Generally maintain a natural state to avoid elasticity attenuation caused by electroplating. High humidity environment can prevent oxidation without changing mechanical performance parameters.

Housing

Using UL94 V-0 grade PA46 modified material, with a temperature resistance of up to 250°C, suitable for SMT reflow soldering process. The material has high dimensional stability and insulation performance, suitable for high-frequency and high-density packaging. To improve structural strength and thermal stability, 30% -40% glass fiber reinforcement is often added. The tensile strength reaches over 130 MPa, with low dielectric constant characteristics to avoid signal crosstalk.

Customization of 5 Pin Connector

Customization range and tolerance for length and outer diameter: Pogo pin length can be customized according to the assembly depth, with a standard range of ≥0.50mm. The tolerance is controlled within ±0.05mm, suitable for different shell structures and laminated plate thicknesses.

Spring force adjustment: The working force range can be customized from 5gf to 100N. Based on the usage environment and contact reliability requirements, commonly used applications select 70gf ± 15gf to ensure stable contact.

Life cycle optimization: The lifespan can be designed as needed for 10K to 500K cycles. The key component material is made of BeCu alloy and subjected to metal fatigue analysis to verify its stability performance under high-frequency insertion and extraction.

Rated current support range: A single pin can carry a continuous current of 0.1A to 50A, and the contact heat rise is controlled within 30℃ through AWG6-28 cables and a maximum of 200 μin gold layer verification.

Contact resistance parameter control: Contact resistance ≤ 50mΩ (typical value <30mΩ), tested by four wire method and compared with different electroplating schemes. Improve transmission consistency under micro voltage.

Alien design for space limited environments: supports L-shaped, U-shaped, patch type and other alien structures to achieve horizontal lead out or vertical low height connection. Suitable for wearable, laptop, and small medical devices.

Non standard arrangement support: In addition to conventional linear arrangement, it supports various custom arrangement methods such as arc, matrix, symmetrical and asymmetrical. Adapt to irregular contact surfaces or rotating module docking requirements.

Positioning anti misoperation mother seat structure: designed with irregular hole positions, directional key slots, and magnetic suction assisted alignment. Reduce assembly error rate, commonly used in automated assembly and error prevention scenarios.

Compatibility of magnetic docking module: Supports embedded magnets or external magnetic structures, with pull-out force controlled within the range of 10gf~1000gf. Enhance user experience while maintaining electrical contact stability.

Impedance control scheme for high-frequency signals: using coaxial shielding structure or board end impedance matching design. Ensure that the signal reflection loss is <-20dB and insertion loss is <0.5dB within frequency of 500MHz to 3GHz.

Material selection for high corrosion environments: Supports electroplating solutions such as gold plating, palladium nickel alloy plating, ENIG, etc. Conduct a 48 hour salt spray test according to the IEC 60068 standard to ensure long-term stability.

Customization of insulation and protection levels: According to application requirements, insulation withstand voltage ≥500V and IP67/IP68 sealing structures can be provided. Meet the requirements of industrial automation, outdoor equipment, or medical enclosed environments.

High temperature resistance and thermal cycling: The working temperature range can reach -40℃ to+125℃, and the material structure is ensured to have no delamination or deformation through thermal shock testing (-40/+125℃, 1000 cycles).

Matching of welding and assembly methods: Three installation end options are provided: SMT, DIP, and crimping, which can be combined with customer PCBA process selection to ensure consistency between mechanical strength and electrical performance.

Optional plastic materials for the mother seat: High temperature and high-strength plastics such as LCP and PA9T can withstand reflow soldering temperatures of ≥ 260℃, with low CTE, suitable for high-density assembly environments.

FAQ

What is the working principle of 5 pin connector?

Pogo pins utilize spring force to achieve reliable contact and ensure good electrical connections. This spring in spring loaded pin can ensure stable and durable connections. Due to its spring force, the 5 pin connector can flexibly adapt plunger tip to different contact surfaces. The contact between pogo pins and 5 pin connector won’t disturbe signal transfer. It is commonly found in high-precision electronic products.

Why choose 5 pin connector?

The 5 pin connector can provide multi-point electrical connections for complex circuits. It can save space and is more compact than traditional connectors. The layout of 5 pogo pins makes signal distribution more uniform. This pogo pin connector adapts to various devices, enhances design flexibility, and has high and more stable performance.

How durable is the 5 pin connector?

Pogo pin, due to its spring, can withstand frequent connection for a long time, and automatically adjust to avoid poor contact. The 5 pin connector has excellent durability for high-frequency use. This pogo pin connector can reduce wear and tear, although it has limitations, it is still suitable for most electronic products and high-precision designs.

Can 5 pin connector ensure signal high stability?

The spring of pogo pin can maintain stable contact pressure and ensure smooth signals. Precise contact points can reduce signal interference. The good pressure distribution of 5 pin connector reduces oxidation. Its structure is very simple and not difficult to keep its cleanliness. Johoty’s pogo pin connector is designed with targeted consideration on how to effectively prevent electrical noise.

What is difference between 5 pin connector and a traditional plug?

Compared to traditional plug, 5 pin connector is more adaptable to small spaces and automatically adjust for more stable connections. Compared to conventional connectors, pogo pin connector has a more efficient number of connections, and Johoty can designa lifespan of up to 200,000. This spring loaded connector has flexible applications, can meet complex circuits. It has small size, simpler design, and fits compact devices.

+86 13590816656

+86 13590816656 +86 13590816656

+86 13590816656