Best Pogo Pins China Manufacturer in a stable connectivity

Pogo pins are core parts used for high-frequency connections, with built-in springs, diverse designs, and high custom to ensure stable contact force and long-term reliable performance. Often designed with gold-plated brass. Used for high-end connectivity and signal transmission. Johoty offers complete custom.

Features:

- High-precision designs for various applications.

- Spring structure ensures stable contact.

- Flexible customization to meet different needs.

- Excellent electrical conductivity and stability.

- High load-bearing capacity for heavy loads.

- Strong corrosion resistance for harsh environments.

Pogo Pins Series

Pogo pins have 9 customizable types: Through Hole, SMT, High Current, Double End, Solder Cup, Right Angle, Threaded, IC Test Probe, ICT/FCT/ATE Test Probe. 3 types of functions: charging, data transmission, and test connection. Materials and processes include brass, beryllium copper, phosphor copper, tellurium copper, stainless steel, gold plating, silver plating, palladium plating, platinum plating, etc. Divided into standard type, high-precision type, customized type, non-magnetic, special function and shape. The spring force ranges from 15gf to 100N, with durability exceeding 10,000 to 200,000 cycles. They are high reliability, miniaturization, compliance with ISO, RoHS, REACH, ASTM, etc

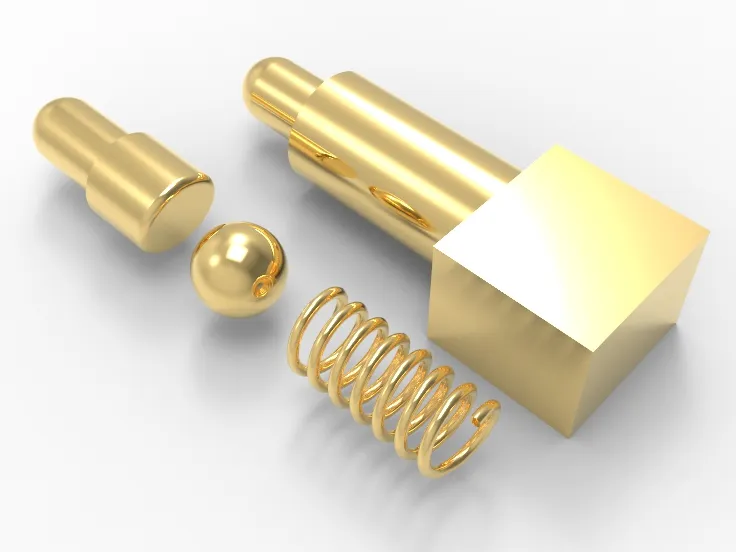

Principle and Structure of Pogo Pins:

| Component | Principle |

|---|---|

| Spring | Stores and releases energy between plunger and housing, maintaining stable contact under uneven surfaces or vibration. |

| Plunger | Axially slides under force to drive the contact tip engagement, completing signal transmission. |

| Barrel | Precisely locates internal components and distributes mechanical load to the mounting structure. |

| Contact Tip | Establishes electrical contact with DUT, using spring preload for low-resistance connection and signal integrity. |

| Insulating Sleeve | Surround plunger and contact tip to prevent short circuits between different potentials and isolate housing from conductive path. |

| Base | Secures the probe assembly to the test fixture or PCB and bears external mounting loads. |

Specifications of Pogo Pins:

| Parameter | Specifications |

|---|---|

| Length | 1.39 – 100.00 mm, custom |

| Stroke | 0.10–15.00 mm, custom |

| Spring Force | 5 gf–100N, custom |

| Plunger Diameter | 0.15–15.00 mm, custom |

| Barrel Diameter | 0.48–20.00 mm, custom |

| Contact Resistance | 15 mΩ-200 mΩ, custom |

| Continuous Current | 0.1–50 A, custom |

| Rated Voltage | 0.1 – 10,000V, custom |

| Durability | 10,000–200,000 cycles, custom |

| Operating Temperature | –40 ℃ – +125 ℃,custom |

| Plunger Material | Beryllium Copper (BeCu), Brass, Tellurium Copper, custom |

| Barrel Material | Brass |

| Spring Material | Phosphor Bronze, BeCu, Stainless Steel |

| Plating | Nickel 5–10 µm / Gold 0.1–2.0 µm, composite coating (e.g. For acid-base solution: Copper 80~120u” + Copper zinc tin 80~120u”, Silver 80~120u” + Gold 2u” + palladium 4u” + gold 2u” + Platinum 15u”), custom |

Pogo Pins Applications

PCB automation testing: Johoty's spring loaded test probes can achieve a contact reliability rate of 99.9%. In PCB automation testing, we help customers improve testing efficiency by 30% and achieve a cycle life of 500,000 times.

Semiconductor packaging testing: In semiconductor packaging testing, Johoty's spring test probes have precise contact pressure. It can support silicon wafer alignment accuracy of 10 μm and has a cycle life of over 300,000 times.

Electronic assembly testing: Yes, electronic assembly testing, SMT pogo pins have a contact resistance of less than 20mΩ. This is their strength, ensuring a 98% pass rate and reducing single positioning time by 20%.

Communication equipment verification: In the verification of communication base station modules, the RF pogo pin has a stable transmission rate of 10 Gbps, with over 200,000 plug and unplug cycles and an error rate below 10 ⁻¹ ².

Automotive electronic system testing: High current pogo pins are used in automotive ECU testing, with a temperature resistance of -40 to+125℃. They can withstand a pressure of 50 N and reduce testing cycles by 25%.

Medical equipment testing: Threatened pogo pins use biocompatible coatings to ensure zero contamination in medical monitoring instrument testing. Its cyclic contact frequency exceeds 400,000 times, reducing maintenance costs by 15%.

Wearable device charging: In wearable devices, the right angle pogo pin charging contact current can reach 2 A. The contact resistance is less than 30 m Ω, and it supports 10,000 insertions and removals without damage.

Industrial robot connections: Industrial connectors support a load of 10 kg and are resistant to vibration frequencies up to 500 Hz. In robot end effectors, they can extend maintenance intervals by 20%.

Aerospace interface: In the aerospace electronic module interface, the aircraft connector based on pogo pin is subjected to a 1000 g impact test. The working temperature range is -55 to+85℃, ensuring 99.5% signal integrity.

SMT production line testing: The testing time for pogo pins has been reduced from 5 seconds to 3 seconds, resulting in a 25% increase in production capacity and a failure rate of less than 0.2%. It can significantly improve the coverage and efficiency of SMT welding machine closure testing.

PCB life cycle: Spring loaded pins can support 800,000 reciprocating contacts, ensuring high efficiency in PCB life cycle testing. The increase in contact resistance is less than 10%, and the stability reaches 100%.

IoT module debugging: In IoT module debugging, pogo pins enable fast plugging and unplugging. The average single debugging time is only 4 seconds, with a 50% increase in debugging efficiency and support for 50,000 cycles.

Why Johoty's Pogo Pins for your success?

Johoty’s pogo pins, you will enjoy excellent quality, exceptional stability, fast response, customized solutions, and unparalleled high value. Johoty is a trustworthy partner.

Materials and Durability of Pogo Pins

Plunger Tip Material:

Beryllium copper alloy (BeCu) core with selective gold plating (≥1 µm Au) over nickel underlayer. contact resistance ≤50 mΩ initially. retains <10 mΩ drift over life, oxidation-resistant.

Spring Wire Material

Phosphor bronze spring wire, temper-rolled to H63–H70 hardness. maintains consistent force (10–30 cN) across full stroke. Fatigue life >100,000 cycles without cold-flow.

Barrel Material

Stainless steel barrel (grade SS304/SS316L). wall thickness 0.15–0.30 mm. hardness ~180 HV, corrosion resistance per ASTM B117 salt spray ≥96 h. dimensional tolerance ±0.02 mm.

Durability & Life Cycles

Rated for ≥10,000 mating cycles at 1A, contact resistance drift <10 mΩ. spring force retention change <5% post-test. operates –40 °C to +125 °C, storage humidity ≤95% RH.

Installation and Usage Precautions of Pogo Pins:

- You’d better keep spring loaded pin aligned coaxially with the socket to avoid lateral forces.

- Plug forces must be within the rated range to avoid affecting reliability.

- The torque of threaded pogo pins should not exceed the recommended value to prevent excessive stress.

- Clean plunger tip surface with a lint-free cotton swab or isopropanol to ensure it is dust-free.

- Wear a grounding wristband or anti-static gloves to protect against static electricity during operation and maintenance.

- Working temperature -40℃ to+125℃, avoid vibration or impact.

- Long-term storage in a dry environment with a relative humidity of 20% -60%.

- According to the drawing definition, the cycle life should be ≥ 10,000 times to replace the expired pogo pin.

Quality, Reliability, and Benefits of Pogo Pins:

- ISO 9001: Consistent quality,

- RoHS Compliance: No toxic substances,

- REACH: Chemical safety compliance,

- Mating Cycle Test (≥ 10,000 cycles): Lifecycle durability,

- Vibration & Shock Testing (per MIL-STD-202): Vibration resilience,

- Thermal Shock Testing (–40℃ to +85℃, 10 cycles): Thermal tolerance Salt,

- Spray Corrosion Test (ASTM B117, >48h): Corrosion resistance,

- Contact Resistance Measurement (≤ 200 mΩ): Low contact resistance,

- Current Carrying Capacity Test (per IEC 60512): Stable current capacity,

- Damp Heat Test (85℃/85 %RH, 96h): Humidity & heat resilience.

Selection Help and Descriptions of Pogo Pins:

- Application: Select by circuit power & signal type

- Current rating: rating above peak operating current

- Voltage rating: ≥20% safety margin above system voltage

- Mating cycles: ≥10,000 or ≥50,000 cycles

- Spring force: balance contact stability and load

- Stroke: 0.10–15.00 mm for mating tolerance

- Contact resistance: Contact resistance: ≤20 mΩ nominal (≤25 mΩ actual)

- Operating temp: –40℃ to +85℃ (–55℃ + 125℃ opt.)

- Material & plating: high-spring alloy pin with gold/nickel plating

- Mounting style: through-hole, SMD, solder-cup, double-end, high-current, right angle, threaded pogo pins per PCB process

- Package type: single-row, dual-row, matrix, or custom pitch

- Sealing/IP rating: optional seals or high IP rating for dust/water protection

Support and Customization of Pogo Pins:

- Technical consultation: rapid response to clients’ application inquiries

- EDA library support: provision of CAD,3D model

- Failure analysis: delivery of root-cause reports

- Test support: PCB debugging and validation plan guidance

- Compatibility validation: assistance with system compatibility

- Design review: schematic and layout reviews

- Custom dimensions: Pogo pin length, diameter, stroke, force, contact resistance, life cycles,

- Surface finishing: options include gold, nickel, palladium, platinum, rhodium, ruthenium, etc.

- Custom packaging: ESD- and moisture-proof solutions

FAQ

What are Pogo Pins?

Pogo pins are electronic components used to connect PCBA boards and other devices. They have brass or stainless steel plunger tips that can be inserted and securely connected. They have music steel springs that provide stable electrical contact. Commonly used in electronic cigarettes, mobile phones, computers, smart SOS, and automotive electronic products. Spring loaded pin can easily achieve quick docking.

What is Purpose of Pogo Pins?

Pogo pins are used for electrical connections to ensure stable transmission of power or signal between devices. They are used in assembly or testing processes. Engineers often use them for prototype testing. Pogo pin also connects batteries and circuits. Due to its simplicity and reliability, pogo pins are very important in rapid prototyping.

How to Choose Pogo Pins?

When choosing pogo pins, please consider length, stroke, diameter, contact force, current, waterproofing, etc. Choose appropriate current according to different devices. Testing frequency and contact requirements also need to be considered. Confirm the required operating temperatures. Ensure compatibility with the device through these parameters.

What Industries Are Pogo Pins Suitable For?

Pogo pins are suitable for consumer electronics, communication devices, automobiles, and medical equipment. They can provide high-precision connections. Suitable for require frequent connections. They are always used in the prototype stage, engineering validation, design validation, and small-scale production stage, and are a powerful guarantee for mass production. Due to its durability, pogo pins can work in different environments.

What is Work Principle of Pogo Pins?

Pogo pins achieve electrical contact through the pressure inside the spring. When metal plunger tip comes into contact with target, spring provides an appropriate pressure. Plunger tip remain stable and not easily loose. Due to spring force, pogo pins can adapt to different connection distances. This spring loaded pin ensures reliability during long-term use.

+86 13590816656

+86 13590816656 +86 13590816656

+86 13590816656