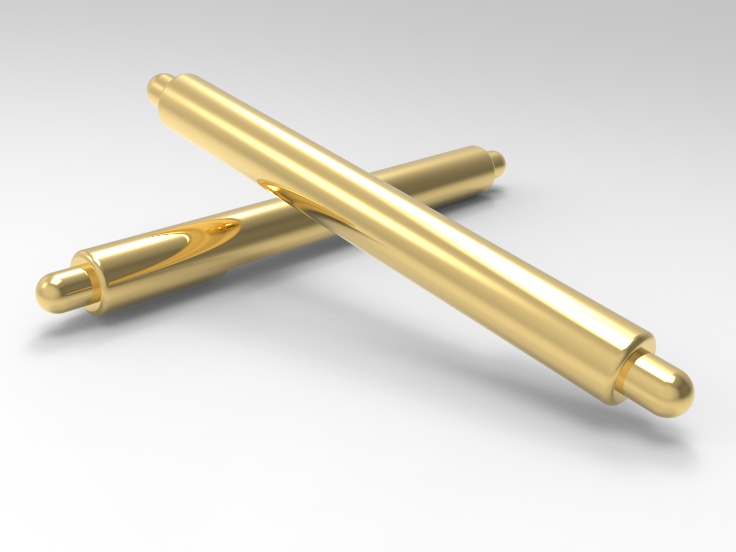

Best Double Ended Pogo Pin China Manufacturer High Efficiency

Double ended pogo pin is an electrical connection device with elastic plungers on both ends. Connecting plungers on both sides through 1~2 internal springs for bidirectional contact. Used for space-limited or module-to-module plug-in connections, mobile docking, power, and signal synchronization. Realize seamless connection between two subsystems. Used for B2B connections, module stacking, ATE fixtures, battery pack connections, medical interfaces, and magnetic docking structures.

Features:

- Low contact resistance, stable and reliable signals.

- High spring lifespan, with up to 200,000 life cycles.

- Dual pin contact design, bidirectional connection.

- Gold-plated finishing, corrosion, oxidation resistance.

- Supports high current carrying, up to 50A maximum.

- Customizable specs to meet various industry needs

Double Ended Pogo Pin Series

Double ended pogo pin, bidirectional design enables reliable connections between different circuit boards or devices. Plunger has flat heads, ball, pointed, grooved, claw, star, etc. Materials include copper alloy, stainless steel, gold plating, nickel, rhodium, palladium, platinum, ruthenium, etc. High frequency transfer, high current, miniature series used for high reliability connections, connection points in industrial automation, bidirectional charging in portable devices, PCB testing, chip testing. Processing tolerance ± 0.01mm, high elasticity and fatigue life of stainless steel and music steel springs. 1μm ~ 3μm coating to enhance wear resistance and oxidation resistance. Combining ISO9001, RoHS, REACH, ASTM, etc., Johoty provides highly competitive cost advantages and timely delivery.

Electrical and Mechanical Parameters of Double Ended Pogo Pin

| Parameter | Description |

|---|---|

| Rated Current | ≤ 3.0 A, ≤ 3.0 A, custom |

| Contact Resistance | ≤ 50 mΩ, custom |

| Insulation Resistance | ≥ 1000 MΩ @ 100V DC |

| Withstanding Voltage | 1000 V AC @ 1 min |

| Operating Voltage | ≤ 36 V DC, up to 550V, custom |

| Total Stroke | 0.10 mm – 4.00 mm, custom |

| Working Stroke | 60%–80% of total travel |

| Spring Force | Initial: 5 gf, Working: 5–300 gf, custom |

| Durability | ≥ 10,000 cycles, up to 200,000 cycles, custom |

| Plunger Diameter | ≥ 0.5 mm, custom |

| Barrel Diameter | ≥ 0.7 mm, custom |

| Coaxiality Tolerance | ≤ ±0.05 mm |

| Plunger Material | Copper Alloy |

| Spring Material | Stainless Steel / BeCu |

| Plating | Gold ≥ 10 μin over Ni ≥ 50 μin |

| Operating Temperature | –40°C to +125°C, custom |

| Storage Temperature | –55°C to +125°C |

| RoHS Compliance | Yes |

Key Designs of Double Ended Pogo Pin

| Key Design Variable | Classification | Description |

|---|---|---|

| Plunger Tip | Flat, Conical, Dome, Blade, Cup, Start, Custom | Clients often ask for it based on contact area, mechanical wear, and resistance stability |

| Plating Thickness | Gold: 1μ”, 10μ”, 20μ”, 30μ”, 50μ”, 80μ”, Custom | Best conductivity, corrosion resistance, operational lifespan, thicker plating, higher price. |

| Spring Material | SUS304, SUS316, BeCu, Spring Steel | Raw material determines fatigue life, electrical performance, and environmental durability, it is of top importance. |

| Spring Force | 20g, 50g, 100g, 300g, 500g, 1,000g, 3,000g, Custom | Defines contact reliability and mechanical engagement under compression. The right force enhances pogo pin durability. |

Components and Performance of Double Ended Pogo Pin

| Structure | Description |

|---|---|

| mechanical structure | Double ended pogo pin with independent elastic contact at both ends to avoid signal interference. |

| material selection | High elasticity alloy steel, gold-plated plunger tips, excellent corrosion resistance and conductivity. |

| Electrical performance | Contact resistance below 50 milliohms, stable signal and high-frequency performance. |

| mechanical life | Lifespan exceeds 50,000 cycles, with long-term repeated connections. |

| structure size | Pogo pin length can be customized, with a diameter accuracy of ± 0.01mm, suitable for PCB and module interfaces. |

| spring design | Spiral spring, constant elasticity and vibration resistance, stable contact. |

| Contact surface treatment | Polish the plunger tip surface to reduce friction and wear. |

| Insulation section | High temperature wear-resistant plastic insulation housing, avoid electrical leaks and short circuits. |

| Application scope | Used for testing fixtures, connectors, PCB testing, and module docking, etc. |

| Thermal performance | The working temperature ranges from -40℃ to+125℃. |

| Compatible with standards | Compliant with IPC and JEDEC |

| Installation method | Support manual pressing and automated insertion |

Applications of Double Ended Pogo Pin

ATE automated testing system: used for connecting high-speed signals and power channels, supporting ≥10 times of plugging and unplugging. Contact resistance<50mΩ, compatible with PCIe 5.0/USB4 testing platform.

Battery module BMS connection port: realizes signal acquisition between PACKs and is compatible with sensing current channels below 1A. Meets the module replaceability design in ISO 26262.

In vitro diagnostic equipment module structure: meets the medical safety requirements of IEC 60601-1. Support low-voltage communication access under non welding conditions, with contact pressure<0.5N.

Radar TR component signal bridging: applied to high-frequency interconnection between multi-layer PCBs, working temperature range -55 °C to+125 °C. Meets MIL-STD-202 vibration standard.

Industrial vision system sensor connection: used for short distance connection between Sensor ISP. Supports 10Gbps signal, impedance control of 50 Ω, connection error <0.2mm.

Electric vehicle VCU module experimental platform: adapted to LIN/CAN bus testing structure, with plug-in stability>50,000 times. Support the deployment of simulated load injection channels.

Aerospace grade board bridging structure: commonly used for hot swappable interfaces within CubeSat structures, with a single pin supporting 1A current. Gold plating layer ≥ 5μin, compatible with NASA GEVS standards.

Laboratory automatic sorting device: used for quick connection between rotating platforms and fixtures. Supporting corrosive environments, the surface coating has passed ASTM B571 testing.

Server module testing station: used for DIMM/SSD simulation plug-in system, single contact supports instantaneous 10A current. Hot swappable lifespan >100k, resistance stability ± 10%.

PD fast charging test fixture interface: supports 3-5A current load. Compatible with USB-C PD3.1 full-featured interface testing structure, with electrical response delay <1 μ s.

Modular collaborative robot structure: connects joint drive and signal control modules, supports ± 0.3mm axial offset, and has stable insertion and extraction force. Commonly used in IP65 environments.

Millimeter wave communication module test bench: used for 24-60GHz signal channel connection, S11 reflection coefficient<-15dB. Suitable for RF probe platform path isolation structure.

Why Johoty's Double Ended Pogo Pin?

Johoty’s double ended pogo pin has excellent quality and precise design, achieves stable current conduction and reliable connections. Satisfy various complex circuits and provide customers with efficient and stable solutions. Johoty helps customers reduce production costs and create higher value.

Structural Differences of Double Ended Pogo Pin

Symmetrical type (equal length plunger + central spring)

The left and right plungers are of equal length, with a single spring at the center and symmetrical stroke. Typical spring compression force: 100gf ± 20% @ working stroke 1.5mm, total stroke 3.0mm, conductive resistance<50mΩ. Suitable for high-speed signals that require bidirectional equal contact force.

Asymmetric type (short stroke + long stroke)

One end of the plunger is short and has a small stroke, while the other end is long and has a large stroke, with the spring arranged eccentrically. Johoty’s double ended pogo pin is suitable for a fixed connection on one end and a floating structure on the other end. The short stroke end is usually 0.8mm, and the long stroke end can reach 2.5mm, both of which can be customized with compression consistency better than ± 5%.

Equal length plunger + double spring

The plungers are of equal length but equipped with independent springs to avoid center interference. Two independent spring frames, Johoty can achieve IP67 between the two ends of the plunger. The stroke consistency is better than ±3%, and the spring force can be designed to match the load separately. Pogo pins can significantly improve fatigue resistance and are recommended for products with over 50,000 cycles.

Plunger diameter and stroke reduction + internal and external dual guidance

Plunger diameter is uneven and the stroke difference is designed. The internal dual guide column achieves high positioning accuracy. Typical applications include micrometer level connections or optoelectronic collaborative structures. Travel difference ±0.05mm, resistance fluctuation <10mΩ, suitable for BGA socket docking, etc. Customer feedback shows that this design often effectively solves problems.

Suggestions for Assembly and Structural Integration of Double Ended Pogo Pin

Design Suggestions of plug-in board structure

Suggest reserving coaxial positioning holes on both sides of PCB or structural components. The aperture tolerance is controlled within ± 0.03mm to ensure axial consistency of pogo pins. Avoid eccentric insertion and removal that may cause lateral cutting of plunger body. Recommend a maximum offset tolerance of ≤0.1mm to reduce the risk of mechanical fatigue.

Module slide rail connection scheme

The sliding rail connection component needs to be designed with a wedge-shaped surface with a guide angle of 5°~15° to limit the displacement in the shear direction. Avoid lateral shear stress on the plunger during sliding. POM or PI materials can effectively reduce friction and extend lifespan to over 50,000 cycles.

Key points of mother seat structure design

It is recommended to use flexible PCB or floating contact module. It can eliminate parallelism error between upper and lower boards or shells, which is ≤±0.2mm. This can improve contact redundancy and reduce the risk of single point contact failure. The typical elastic compensation stroke is set to 0.5~1.0mm.

Power supply lead out structure configuration

Both ends can use crimping or sliding contact to draw current. Recommend copper alloy barrel + gold plating finishing to reduce contact resistance (<30mΩ). Supports continuous current of 3.0~5.0A. It is recommended to control surface roughness Ra <0.8 μm in sliding contact area.

Reliability evaluation and standard adaptation of Double Ended Pogo Pin

Mechanical life test:

Based on IEC 60512-9-1, Johoty will conduct ≥50,000 insertion and extraction cycle tests. We require a plug and unplug rate of 1 time per second and maintain contact resistance fluctuations within ±20%. QE will check that the plunger is not deformed and the surface coating is not peeled off after testing, ensuring long-term stable operation.

Contact resistance assessment:

Measure the contact resistance value before and after testing. It is required that the stable value of a single plunger be controlled below 30mΩ, with a fluctuation range of<10m Ω. Based on IEC 60512-2-1, the 4-wire method will be used for measurement to eliminate lead errors. I always ensure the accuracy of evaluation data and engineering reproducibility.

Environmental adaptability:

Generally, cyclic testing, high humidity (95% RH, 48h), and salt spray testing (48h, 5% NaCl) are conducted at temperatures ranging from -40℃ to+85℃. It is used to evaluate contact performance and surface integrity, with a resistance growth rate of <15% after salt spray. We check if it meets the IP67 and IP68 sealing requirements. Strictly follow MIL-STD-202 standard.

Verification of electrical load-bearing performance

The current carrying capacity of a conventional double ended pogo pin is 3A, and the voltage insulation level is ≥ 500V. According to the UL 1977 standard, the temperature rise during a 10 minute constant current load test is<30℃. Actually, 30℃ is the upper limit, and we design and control most temperature rises to be less than 20℃. In this way, the barrel + gold-plated contact surface can support stable high-frequency electrical signal or power current transmission.

FAQ

What devices are suitable for Johoty’s double ended pogo pin?

Suitable for smart devices, industrial equipment, communication equipment, etc. Double ended pogo pin is flexible on designs and meets various applications. Small in size, suitable for compact spaces. High conductivity ensures stable connection. Strong durability and support for long-term use.

What is operating temperatures of double ended pogo pin?

Supports extreme temperatures with a wide range of -55 ℃~155 ℃, and can be customized to achieve+250℃. Suitable for high and low temperatures. Double ended pogo pin is resistant to high temperatures without deformation and does not fail at low temperatures. Ensure stable performance and suitability for industrial applications. Meet strict environmental requirements.

How long can spring life of double ended pogo pin?

Long lifespan, Johoty can design up to 200,000 life cycles, it fits high-frequency connection. Good elasticity and long-term stability. The double ended pogo pin is wear-resistant and suitable for frequent connection. Structural design optimization to enhance service life. Meet long-term reliability requirements.

Does double ended pogo pin support customization?

Johoty supports customization according to needs. Flexible design to meet special requirements. Double ended pogo pin material is optional to optimize performance. Multiple specification options, suitable for different applications. Provide professional design advice to enhance product applicability.

What are dual head design advantages?

Double ended pogo pin bidirectional connection, flexible and reliable. Space saving and suitable for compact structures. Improve assembly efficiency and reduce design difficulty. Stable performance, suitable for use in multiple scenarios. Enhance device compatibility and support multifunctional applications.

How to ensure double ended pogo pin stability?

Optimized contact surface for stronger conductivity. Elastic design, adaptable to different pressures. The double ended pogo pin is vibration resistant and suitable for mobile devices. Stable performance, not easy to loosen. The structure is sturdy and can maintain connection for a long time.

What are sizes of Johoty’s double ended pogo pin?

Johoty offers multiple size options to meet different device requirements. Double ended pogo pin hold microstructures, saving space. Standard sizes are easy to quickly select. Special sizes can be customized to meet personalized needs.

What is double ended pogo pin current?

It always supports high current and bring clients’ reliable performance. Low resistance, reducing energy loss. The double ended pogo pin has high conductivity and reduces heat generation. Easily achieve 50A, and you can also find our 800A high current pogo pins. Suitable for high-power devices, improving circuit performance. Meet different current requirements.

+86 13590816656

+86 13590816656 +86 13590816656

+86 13590816656