Best High Current Pogo Pins China Manufacturer Low Resistance

High current pogo pins have built-in or external springs to transmit <1,200A. Low contact resistance, long lifespan, and 7 installation methods. It uses gold-plated brass for high-power charging. Johoty offers flexible custom with safety and best price.

Features:

- Meet equipment stable current requirements.

- Low energy consumption, high-efficiency transfer.

- Less replacement, low maintenance, high reliability.

- Flexible design, and diverse installation methods.

- Stable and reliable operation in harsh environments.

- Customized solutions to meet specific usages.

High Current Pogo Pins Series

High current pogo pins handle currents from 3A to 1,200A, meeting diverse needs. They feature high conductivity and low resistance 1mΩ for long-lasting up to 500,000 cycles, 7 installation methods, Materials brass, beryllium/tellurium copper, stainless steel, gold-plated, platinum, or palladium. Used in charging and discharging, gigafactory, new energy, automobiles, and high-power. Johoty offers expert technical support, custom solutions, fast response, and safe delivery.

Electrical Parameters of High Current Pogo Pins:

| Parameter | Value |

|---|---|

| Maximum Current | 50A,special up to 1,200A,Custom |

| Contact Resistance | ≤ 50 mΩ, Custom |

| Current Carrying Capacity | Continue 50 A / Peak 80 A, |

| Contact Voltage Drop | ≤ 100 mV @ 10 A |

| Peak Instantaneous Current | 80 A |

| Max Operating Voltage | 250 V DC, special up to 10,000V, Custom |

| Electrical Life | ≥ 100,000 cycles, special up to 200,000 cycles, Custom |

| Pulse Current Endurance | 100 A @ 10 ms Pulse Width |

| Inductance | ≤ 1.2 µH |

| Capacitance | ≤ 1.0 pF |

| High Frequency Capability | ≤ 3 GHz |

| Thermoelectric Stability | ΔV ≤ 10 μV/°C |

| Temperature Rise | ≤ 30℃ |

Mechanical Parameters of High Current Pogo Pins:

| Parameter | Value |

|---|---|

| Overall Length | ≥ 4.00 mm, Custom |

| Compressed Length | ≥ 3.90 mm, Custom |

| Working Stroke | ≥ 0.10 mm, Custom |

| Maximum Stroke | ≤ 20.00 mm, Custom |

| Plunger Diameter | ≥ 0.20 mm, Custom |

| Barrel Outer Diameter | ≥ 0.48 mm, Custom |

| Mounting Hole Diameter | ≥ 0.50 mm, Custom |

| Spring Length | ≥ 2.00 mm, Custom |

| Spring Force | ≥ 5gf, proposed ≥ 20gf, Custom |

| Barrel Wall Thickness | ≥ 0.10 mm, proposed ≥ 0.15mm, Custom |

| Mounting Depth | ≥ 1.50 mm, Custom |

| Flange Diameter (if present) | ≥ 0.50 mm, Custom |

| Plunger Tip Shape/Dimension | ≥ 0.50 mm, Custom,≥ 20 kinds of shapes |

| Concentricity Tolerance | ≤ 0.05 mm, Custom |

| Perpendicularity Tolerance | ≤ 0.03 mm, Custom |

| Surface Roughness (Ra) | ≤ 0.8 µm, Custom |

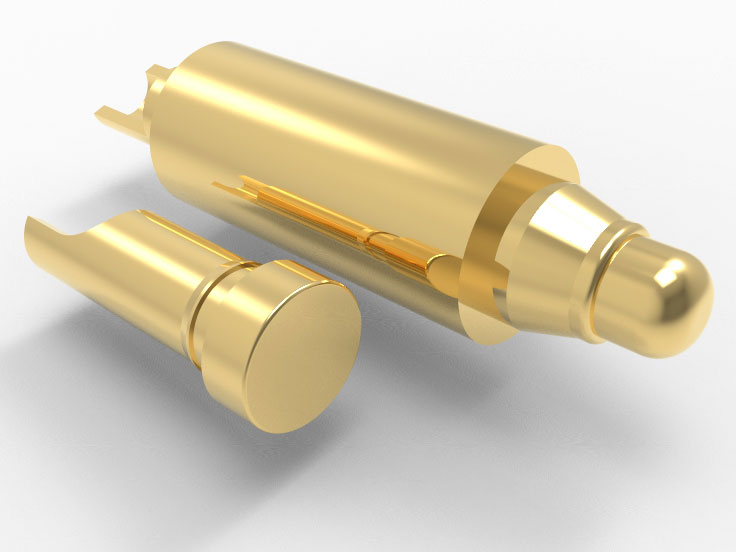

Special Structure of High Current Pogo Pins:

| Special Structure | Description |

|---|---|

| Dome Tip | Radius ≥ 0.50 mm, Custom |

| Cone Tip | Cone angle 45°–90° |

| Cup Tip | Depth 0.50–1.50 mm |

| Cross Slot Tip | Groove depth 0.20–0.80 mm |

| Gold-Plated Tip | Thickness 0.50–5.00 µm Au |

| Rotating Head | Free rotation ±360° |

| Locking Mechanism | Mechanical snap fit |

| Angled Mount | Tilt angle 15°–45° |

| Dual Spring | Independent upper/lower spring |

| Internal Travel Stop | Travel limit accuracy ±0.1 mm |

| Anti-Rotation Guide Slot | Slot width 0.20–0.50 mm |

| Flanged Barrel | Flange diameter 0.50–6.00 mm |

| Flat Head | Face width 0.50–2.00 mm |

| Leaf Spring | Non-helical elastic component |

| Twin Pin | Parallel connection of double contact points |

| Insulation Sleeve | Material PEEK/PPS |

Applications of High Current Pogo Pins

Electric vehicle battery management system (BMS): The BMS module is used to connect the battery monitoring board with the main control unit, and supports instantaneous pulse current transmission of 30A or more. Equipped with a self elastic structure to ensure reliable contact during thermal expansion and contraction processes. Widely deployed in power platforms: Tesla and Rivian to improve the efficiency of battery module detection and maintenance.

Autonomous driving sensor fusion system: integrated into the LIDAR/millimeter wave radar main control unit, with dual channel connection for power and data. Carrying a current of 15-25A to ensure low latency synchronous power supply for the system. Meet the interface requirements of ISO 26262 functional safety level.

High speed train traction control system: used for pluggable connections between onboard control units and power modules. Meet the EN 50155 anti vibration standard and rated continuous current requirements of 20~50A. Designed to ensure convenient maintenance, commonly used in traction inverters from manufacturers, Siemens and Bombardier.

Rail transit signal system: used for maintainable connections between internal high current modules such as signal control cabinets and emergency power supply units. Equipped with anti arc design and a current carrying range of 20-40A. Compatible with IEC 61375 series interface specifications to ensure high availability of vehicle ground communication systems.

Medical imaging equipment module connection: Implement current supply and signal connection between the detection unit and the main control chassis in MRI or CT scanning equipment. It is necessary to support stable conduction in strong magnetic interference environments. A typical example is a low resistance spring needle with a contact consistency error of less than 2%, above 15A.

5G base station power module interconnection: used for power and RF signal connection between PA module and motherboard in high-frequency 5G NR base stations. Carrying power of 10-20A, with both frequency stability and thermal management capability. Commonly used in communication devices such as Huawei, Nokia, Ericsson, etc.

Data center bus and power system: used for connecting high-density rack PDU to blade server power input. Must meet UL1977 standards, with a typical current of 40A@48V DC is deployed in the low-voltage distribution systems of data centers at Meta, Amazon, and Google.

Server hot swappable power module: supports high-frequency hot plugging between power supply module (PSU) and motherboard, with a typical current carrying capacity of up to 25A@60V DC. Contact resistance less than 10mΩ, commonly found in redundant power supply systems in high-density server architectures.

Industrial robot drive control module: used for high reliability connection between servo drive controller and actuator joint motor. It has an IP67 protection level, can withstand continuous vibration and oil mist environments, and typically requires a current of 15-30A. It ensures the stability of multi axis synchronous control signals and power transfer.

Satellite and Aerospace Electronic Systems: Used in modular power management and attitude control systems, carrying high current (30A+) and multi band control signals. Meets MIL-STD-202G seismic standards and is compatible with aerospace grade redundancy design requirements. Used for rapid ground debugging and replacement.

Intelligent manufacturing equipment IO module: Fast plug-in connection from industrial field PLC to IO module, supporting continuous 20A load in 24/7 operating environment. The plug-in life can reach over 5,0000 times, suitable for high-end automation systems such as Schneider, Rockwell, Omron, etc.

Wearable military electronic equipment interface: forms a stable power supply path between the tactical backpack power module and the wearable terminal. The current range is 10-20A, with IP68 protection and salt spray corrosion resistance. Applied to NATO standard military communication and navigation modules.

Why Choose Johoty's High Current Pogo Pins?

Choose Johoty’s high current pogo pins to enjoy a long lifespan, stable electrical performance, and fast connection. High-demand applications, high efficiency and reliability. Enhance your product performance as well as market competitiveness. Choose Johoty now to create huge value for you!

Current Transfer in Electric Vehicle Charging System

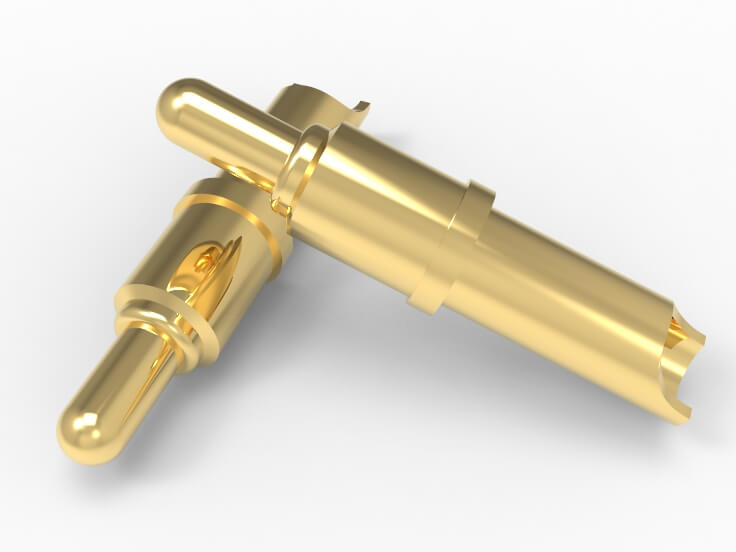

Plunger Material and coating:

BeCu, SK4, 316L, or tungsten steel are commonly used. Beryllium copper has a conductivity of approximately 22% IACS and high tensile strength >1100 MPa, making it suitable for high-frequency plug-in connections. SK4 has higher hardness and wear resistance, making it more advantageous in mechanical impact resistance and high load applications, but its conductivity is slightly inferior. The material selection depends on the current carrying capacity, mechanical fatigue life, and terminal contact pressure.

Gold plating is the most common choice, with a thickness range of 5-30μin. It can achieve stable low contact resistance <50 mΩ and has excellent oxidation resistance. Rhodium (Rh) or ruthenium (Ru) plating is commonly used in high-end wear-resistant designs, with a Vickers hardness of up to 700-1000 HV. It effectively extends lifespan and supports signal and power interfaces.

Spring material and coating:

The spring is made of piano steel wire SWP-B or SUS304, SUS631. SWP-B has high elastic modulus and long fatigue life, suitable for high-frequency compression/release conditions. If corrosion resistance and durability need to be improved, hardened SUS631 stainless steel is the preferred choice. Its yield strength can reach 1250 MPa, suitable for use in high humidity and high salt spray.

To improve corrosion resistance, some springs are treated with electrophoretic coating or inorganic rust proof film. Extend the lifespan of pogo pins and stabilize compression force. Suitable for equipment with electrical interfaces exposed to air or corrosive gases for a long time. It is recommended to verify reliability through the 48 hour salt spray test according to ASTM B117 standard.

Barrel material and coating:

Generally, brass HBi59 or phosphor bronze is popular. Brass has a high thermal conductivity of approximately 109 W/m·K and good machinability, making it suitable for high current carrying designs. Phospho bronze performs better in terms of elastic recovery and corrosion inhibition. It can use in humid, seawater, or corrosive environments for long time. In actual selection, it is necessary to balance the performance of thermal, electrical, and mechanical aspects.

Usually, Ni is used as the base, followed by gold or silver plating. Nickel plating provides structural strength and corrosion protection. Optimize the stability of the contact interface with the gold plating layer. For high current pogo pins>10A, thick layer tin plating is preferred to enhance weldability and reduce contact thermal resistance. The coating thickness is controlled within the range of 80-150 μin, which meets the requirements of industrial welding processes.

Tail pin material and coating:

C3604 brass or phosphor bronze materials are commonly used, which have good weldability and strength. In stress testing, it is required that the pull-out force of the solder joint exceed 1.5kg to ensure the reliability of the solder joint in wave soldering or reflow soldering. Thermal conductivity and wetting of matching pads are key evaluation indicators.

The surface is usually gold-plated, and the thickness is often the same as that of the needle tube. Can have good compatibility with solder and prevent the formation of oxide film. High end pogo pins adopt a nickel plated bottom layer before gold plating to enhance the strength and shielding performance of solder joints. Suitable for high-speed signal transmission or high current parallel transfer environments.

Installation of High Current Pogo PIns

SMT mounting type of high current pogo pins:

Suitable for highly automated PCBA production lines, fixed to the PCB surface through reflow soldering. The pad design must comply with the IPC-A-610 standard to ensure welding stability and low impedance of electrical connections. Recommended for medium to high-density modular connections with current demand ≤10A.

Through Hole Vertical Mount of high current pogo pins:

The Pogo Pin pin passes through the PCB and is fixed by wave soldering. Provide excellent mechanical strength and stable conductivity. Suitable for repeated plugging and high vibration environments. The pull-out force of the pin can reach over 20N, and the resistance to plugging and unplugging can reach 100,000 times.

Right Angle Through Hole of high current pogo pins:

Suitable for designs with limited space and lateral connections, the needle body is perpendicular to the PCB at a 90 ° angle. Welding should control the amount of tin to prevent shadow effects and ensure the integrity of the current path. Commonly used for side plug connections between communication equipment and rack mounted modules.

Threaded fixed type of high current pogo pins:

The base is threaded and fixed to metal/plastic components through a screw structure. Paired with copper pillars or heat dissipation components, the structure is sturdy and has thermal stability under high current (>30A). Recommend using M2 or M2.5 standard threads for global replacement.

Snap Fit Mount of high current pogo pins:

Plastic buckles or metal spring clips are directly inserted into the product shell without the need for welding. Pay attention to the temperature resistance of the buckle structure, PA66 material can withstand temperatures up to 125 ° C. It prevents loosening caused by long-term thermal expansion and contraction.

Press Fit of high current pogo pins:

Press into PCB or metal base to avoid welding stress and thermal effects, suitable for high reliability connections. Used in industrial computing platforms, the residual stress of crimping should be controlled within 70% of the material yield strength.

Modular assembly type of high current pogo pins:

The probe is encapsulated in a standard module housing, which can be quickly replaced and maintained, and is used for high-end automatic testing systems. Select modules with positioning and guiding structures to improve insertion and extraction accuracy and contact consistency. The error should be controlled within ± 0.05mm or even ± 0.02mm.

Inlaid injection molding of high current pogo pins:

Embedding Pogo Pin into plastic structure during injection molding process provides strong overall protection and durability. Used in industrial or medical environments that require water proof connectors. Ensure probe sealing and mechanical integrity, up to IP67, IP68 water proof.

Magnetic-assisted type of high current pogo pins:

Combining magnetic positioning to improve contact accuracy and automatic alignment capability. Used for device docking scenarios where visual positioning is not possible. The magnetic force is usually controlled within the range of 10-30mT to ensure stable adsorption without hindering mechanical rebound and contact stroke.

Self-locking fixture type of high current pogo pins:

Fix the probe with an adjustable locking fixture for temporary wiring during the R&D and testing phases. This structure facilitates quick replacement and position adjustment. The contact impedance of the fixture should be controlled below 20mΩ to ensure the accuracy and repeatability of data acquisition.

Thermal Performance and Temperature Rise of High Current Pogo Pins

Location of heat source of high current pogo pins:

The main heat source of the high current Pogo Pin is located in the contact area between the needle body and the spring. Due to the concentration of current and high contact resistance, significant Joule heating is generated at this location. Under continuous current above 10A, the temperature rise in this area can exceed 45°C. Accurate modeling and heat flow path control are required.

Typical thermal resistance structure of high current pogo pins:

The thermal resistance path of Pogo Pin mainly includes: contact thermal resistance, axial thermal conductivity impedance of the pin body, thermal conductivity of the welding area, and environmental convection heat dissipation. The overall thermal resistance is approximately 10-20°C/W, depending on the structure and material. The upper limit of temperature rise per unit power is determined.

Johoty’s thermal rise control design:

Johoty adopts a multi-point gold-plated contact design to reduce local contact thermal resistance. At the same time, high thermal conductivity copper alloy with a thermal conductivity of over 300 W/m·K is selected as the material for the needle body. Design an efficient heat conduction path inside the shell to achieve stable performance output with a thermal resistance of less than 8 °C/W.

Relationship between current density and temperature rise:

Johoty conducted an experiment to test a 1.5mm diameter Pogo Pin at a current of 20A. The temperature rise at the contact area is about 30°C, which is about 17% lower than the market average for products of the same specifications. The temperature rise control mainly benefits from the optimization of internal heat flow distribution and the design of stress compensation structures.

Thermal fatigue reliability testing:

Our high current pogo pins have undergone 1,500 cycles of 10A on-off testing. Contact resistance variance is <10%, and the temperature rise fluctuation is controlled within ± 3°C. The thermal fatigue failure mode is mainly related to stress accumulation in contact with the shrapnel. Effective suppression has been achieved through material tempering and surface treatment.

FAQ

What is the Maximum Current of Johoty’s High Current Pogo pins?

Johoty’s high current pogo pins are designed to support a maximum current of 1200A. By using beryllium copper gold plating and precision CNC machining, we ensure that each Pogo Pin operates continuously at 120 ℃ for 4 hours with a temperature rise not exceeding 25 ℃. They have long-term reliable electrical connectivity to meet high load current transmission.

How Long is the Lifespan of High Current Pogo Pins?

Johoty’s high current pogo pins have undergone strict testing for current and spring force, lifespan is up to 500,000 cycles. We use wear-resistant materials, gold plating, and optimized contact surfaces. It can minimize wear and ensure excellent electrical performance and long-term stability.

How to Ensure Electrical Stability of High Current Pogo Pins?

Johoty conducted rigorous resistance, conductivity, and anti-interference tests for each high current pogo pin. Through these tests, we ensure that the electrical connection is stable and will not cause electrical faults due to overheating, vibration, or external factors, thereby providing high-quality current transfer.

What is Material Selection for High Current Pogo Pins?

Our high current pogo pins are gold-plated beryllium copper or stainless steel, which can withstand high current loads and reduce heat generation. The coating uses corrosion-resistant gold and palladium, which can resist moisture and oxidation, and is stable and reliable. Meanwhile, our materials comply with RoHS, REACH too.

How can High Current Pogo Pins Solve the Challenges in High Temperatures?

For high temperature, we have used thermal diffusion technology in the design, which can effectively dissipate heat and avoid the decrease in current carrying capacity. We also use high-temperature resistant insulation materials to ensure stable operation in large temperature fluctuations.

How to Customize High Current Pogo Pins?

Johoty can provide personalized customization and design suitable high current pogo pins based on customer needs. We can provide customized solutions in terms of size, shape, impedance, material, and current to ensure each pogo pin fully meets your requirements.

+86 13590816656

+86 13590816656 +86 13590816656

+86 13590816656