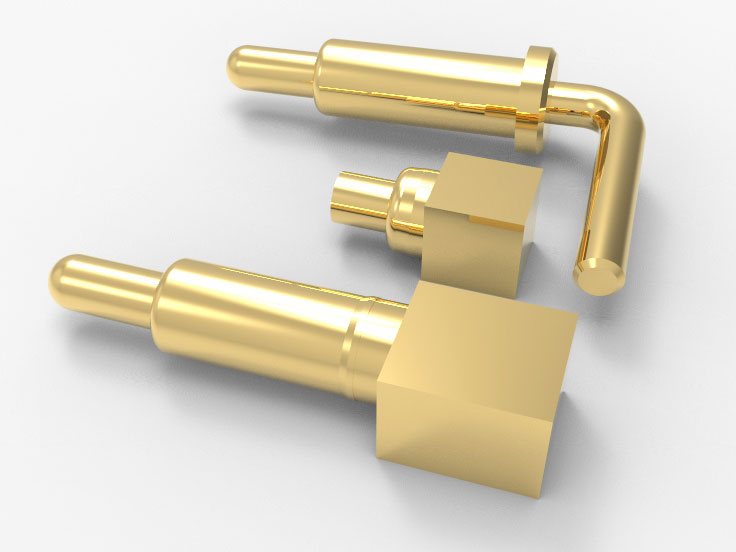

Best Right Angle Pogo Pin China Manufacturer Flexible Install

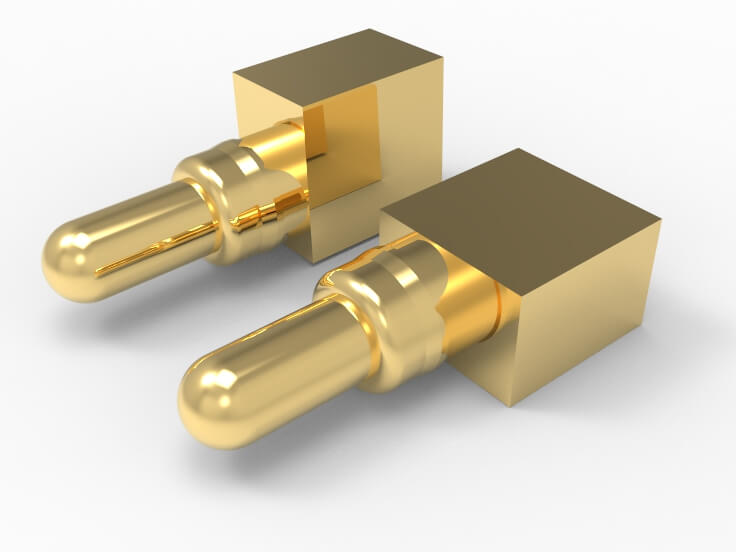

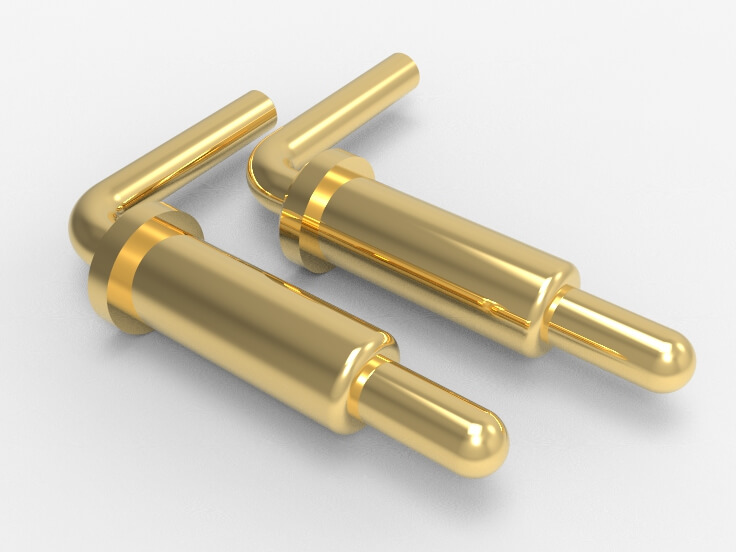

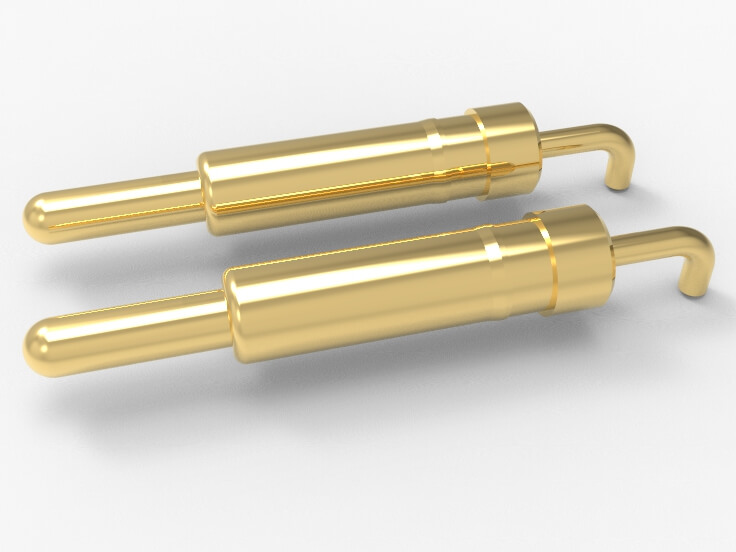

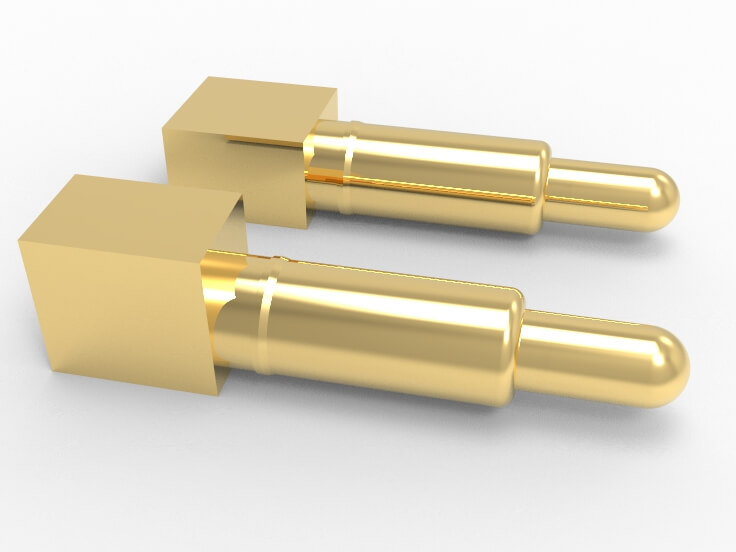

Right angle pogo pin is a connector installed parallel onto PCB by SMT. Suitable for PCB board layout with limited space. Space saving and easy installation. Resolve poor contact, welding failure, and insufficient lifespan. Johoty can flexibly customize.

Features:

- High conductivity and low contact resistance.

- Long lifespan, customized >200,000 times.

- Right-angle welding, suitable for narrow spaces.

- Adjustable spring force for various connections.

- Eco-friendly materials comply with RoHS, REACH.

- Flexible design, compatible with SMT processes.

Right Angle Pogo Pin Series

Right angle pogo pin, Miniature with smaller diameter and shorter stroke, standard series, larger diameter and larger stroke, high current series. Short, medium, and long stroke series. Low, medium, and high current series. Tail pin is a standard SMT surface mount design, reinforced right-angle with soldering points or mechanical fixing, tail pin is embedded at the edge of PCB. Gold-plating, silver, nickel, composite coating series. Flat head, pointed head, round head, cup head, star head series. Room temperature, high temperature, moisture-proof & anti-corrosion series. High-speed signal transfer, modular connection, magnetic series. Johoty’s customization fully meets your requirements.

Specifications of Right Angle Pogo Pin:

| Parameter | Description |

|---|---|

| Overall Length | ≥ 3.00 mm, Custom |

| Barrel Diameter | ≥ 0.50 mm, Custom |

| Mounting Hole Size | ≥ 0.50 mm, Custom |

| Working Stroke | ≥ 0.10 mm, Custom |

| Full Stroke | ≥ 0.20 mm, Custom |

| Spring Force | ≥ 15gf at WorkStroke, Custom |

| Rated Current | 0.1–5.0A, special ≤50A,Custom |

| Contact Resistance | ≤50mΩ, Custom |

| Operating Temperature | -40℃–+125℃ |

| Plating Thickness | 1–80μin, Custom |

| Plunger Material | BeCu / SUS / Brass |

| Spring Material | SUS304 / SWP-B |

| Mounting Type | SMT / DIP / Press-fit, Custom |

| Plunger Travel Direction | Horizontal |

| Tail Pin Angle Range | 85°–95° |

Installation and Soldering of Right Angle Pogo Pin:

| Categories | Specifications |

|---|---|

| SMT (Surface Mount) | No drilling, surface mount, Customized shape |

| Through-Hole (THT) | ≥φ0.5mm, custom |

| Wire Solder | 26AWG–20AWG,custom |

| Pad Solder | Pad width: ≥0.50mm, custom |

| Custom Press-fit | Hole diameter: ≥φ0.30mm,custom |

| Single-side Right Angle Mount | Angle: 90° |

| Dual-side Right Angle Mount | Dual 90° symmetry |

| Vertical Adapter Mount | 90° pin-to-board adapter |

| Bent Tail Solder | Bend length: ≥1.5mm, custom |

| Rotated Side Solder | Custom angle: 15°–90° |

Applications of Right Angle Pogo Pin

Lateral elastic connection of wearable devices: ultra-thin smart rings, health patches, etc., with right angle pogo pins that can be placed at the edges. Lateral triggered contact, supporting packaging height design of<4mm. And verified with IEC 60529 IP67 protection level.

Smart glasses power and data connection: The right angle structure allows for docking of the circuit board along the temple direction. Meet the requirement of parallel transmission of data and power supply under the condition of controlling the thickness of the whole machine within <10mm. Verify the reliability of the connection through a 48 hour salt spray test.

Chip level Burn in Test Fixture: An extremely compact fixture structure used for conducting Burn in tests on bare chips or packaged devices at high temperatures. The right angle pogo pin meets the low loss connection requirements of<2.5mm pin height and <12GHz high frequency.

Modular portable device internal signal connection: Right angle pogo pin is used for side board to board connection. Supports ≤ 0.05Ω contact resistance and >10,000 insertion and extraction cycles. Realize module signal docking in narrow spaces below 10mm in portable medical instruments and industrial testing terminals.

High integration medical endoscopic system probe connection: Due to the limited volume of the endoscopic module, the right angle structure is used for horizontal elastic connection between the probe and the processing module. Suitable for pipes with a diameter <6mm, in compliance with testing requirements of ISO 10993 biocompatibility.

Lateral connection between multi-layer stacked PCBs: In RF communication modules and image processing systems, right angle pogo pins achieve 90 ° horizontal connection between PCBs. To save vertical height, it is compatible with 6-10 layer high density boards and supports a continuous current of 1-3A per contact.

Compact space interface for in car central control system: Due to structural compression, the in car entertainment and diagnostic modules require horizontal lateral docking. The right angle pogo pin can be embedded at the edge of the central control module PCB. Maintain reliable signal connections in structures with a thickness of<6mm, in compliance with AEC-Q200 testing specifications.

Electrical connection of the curved surface inside the unmanned aerial vehicle casing: The internal space of the consumer grade unmanned aerial vehicle casing is complex. The right angle structure can adapt to the non perpendicular connection requirements between the side wall and the electronic control board. The insertion and extraction force is controlled within the range of 0.5-1.2N, effectively avoiding the problem of traditional wire bonding occupying structural space.

Removable battery pack structure interface: Lithium battery modules with limited space require quick connection/disconnection. The right angle pogo pin can be embedded into the side wall of the battery case. Realize stable current output for structures with a height of less than 8mm, with a duration of 3A and a pulse current of up to 5A.

Embedded industrial control module DIN rail docking: The IO expansion module inside the industrial control device is packaged in a standard DIN rail and requires parallel plug-in connection. The right angle pogo pin completes a modular connection scheme with a shell thickness of<15mm and is compatible with 10G signal frequency bands.

Alternative structure for connectors on the inner side of satellite cabin: The compact structure of microsatellites often uses right angle pogo pins instead of standard connectors. Lateral connection of two closely attached PCBs, achieving power/signal parallel connection at a structural height <12mm. It can meet the low emission gas requirements for aerospace applications.

Head mounted equipment rail sliding interface: In MR/VR equipment, module side sliding assembly often requires a right angle spring pin to dock with the rail interface. Realize dynamic electrical connections in parallel motion, and the anti-vibration test meets the 2Grms random vibration specification.

Why Choose Johoty's Right Angle Pogo Pin?

Johoty’s right angle pogo pin has excellent conductivity, high durability, and superior spatial adaptability. Johoty ensures high reliability through precision design and strict quality control, provides customers with stable and long-lasting solutions. Can help you significantly enhance product value and competitiveness.

Materials and Finishing of Right Angle Pogo Pin

Plunger material: Beryllium copper (BeCu)

Beryllium copper has excellent mechanical strength, with a tensile strength of up to 1,100 MPa, and good conductivity, about 22% IACS. Beryllium copper is often the preferred material for high reliability pogo pins. High elastic modulus, capable of maintaining stable deformation in 10 million compression cycles. It has strong adaptability for high-frequency and high-density connections.

Contact surface treatment: gold plating (Au plating)

A hard gold coating with a thickness of 0.1μm~1.27μm is commonly used, effectively reducing the contact resistance to 10~20mΩ Gold plating provides excellent corrosion resistance and can withstand harsh environments with salt spray for ≥96 hours. The hardness of the gold layer is usually 130-200 HV, which is suitable for frequent insertion and removal wear requirements.

Spring material: Stainless steel SUS304/SUS631 (17-7PH)

After 17-7PH heat treatment, the tensile strength reaches over 1,200 MPa and the fatigue life is over 1 million cycles. Springs are often made of martensitic precipitation hardened stainless steel. Has corrosion resistance and high stability, exhibiting superior mechanical consistency in high temperature and high humidity environments.

Barrel material and surface: brass plated with nickel and then gold-plated

The barrel is made of high-precision HBi59 brass, and the outer layer is electroplated with 3-5 μm nickel to enhance hardness and oxidation resistance. The resistivity of the nickel layer is about 7 μΩ· cm, which helps to improve the overall shielding effectiveness. The outermost layer is coated with 0.1-3 μm gold, or with palladium, platinum, rhodium, ruthenium, etc. Ensure that long-term contact interfaces do not fail due to oxidation and comply with industrial grade electrical interface specifications.

Reliability Test of Right Angle Pogo Pin

Electrical performance stability test:

Measure using the 4-wire method and apply power for 100,000 cycles at a rated current of 3A. The contact resistance is always maintained within 30mΩ, with a deviation of no more than ±5%. The voltage ripple during testing is below 10mV, which complies with the IEC 60512-2-1 standard. Ensure signal integrity and low-power transmission capability during long-term use.

Mechanical life and elastic fatigue testing:

Johoty conducted continuous compression and tensile fatigue tests on the right angle pogo pin using an automatic loading system. After 100,000 cycles, the elasticity attenuation does not exceed 10%, and the spring stroke maintains a recovery rate of over 95%. As the mechanical engineer of the Taiwanese customer said, my equipment is broken, but your pogo pins are still intact. All parts have no cracks or structural failures, meeting the lifespan requirements in MIL-STD-1344A.

High and low temperature cycling and wet heat testing:

Many American customers require pogo pins to operate continuously at 125℃. Perform 100 cycles of alternating cold and hot temperatures in an environment ranging from -40℃ to +125℃, each lasting for 1 hour. The change in contact resistance after testing is less than 8%. American guests accept this impedance change value because of the strong destructive nature of high temperatures. Simultaneously perform 168 hours of wet and hot storage at 95% humidity and 60℃. The metal components have not undergone oxidation or corrosion, and the surface coating has not peeled off, meeting the requirements of IEC 60068-2-30.

Salt spray and corrosion resistance assessment:

Most USA clients ask uss if right angle pogo pin pass ASTM B117? Of course, Johoty designed pogo pins based on this standard. The sample was placed in a 5% NaCl concentration salt spray box for continuous testing for 96 hours. The gold plated area of Pogo pin has no black spots or corrosion spots, and its corrosion resistance level reaches level 9 (out of 10). Adapt to the long-term reliability requirements of interfaces in harsh industrial environments.

FAQ

What is right angle pogo pin?

The right angle pogo pin is a spring loaded pin used to connect circuits. It is mounted on the surface of parallel PCBs and is suitable for compact spaces. Used for electronic products, communication devices, etc. Design can reduce installation space and increase connection stability. These devices can be used on multiple connection points to improve system reliability.

Why choose right angle pogo pin?

Right angle installation saves space for small devices. Right angle design can better adapt to circuit boards. It can reduce assembly complexity. Simplified engineers’ operations in confined spaces. The connection is more stable and reduces looseness.

What is difference between right angle installation and traditional installation?

Right angle installation doesn’t require direct contact and is more suitable for limited spaces. Traditional installation requires vertical connections, which takes up a lot of space. The right angle design provides more flexible wirings. Right angle installation can avoid interference from circuit. Installation process is simple, right angle pogo pin can save time and costs.

What are applications of right angle pogo pin?

Applied to smartphones, computers, and wearable devices. Johoty’s right angle pogo pin is suitable for very small devices, smart devices, and high-density circuit boards. It can quickly replace modules and enhance device functionality. Also it is used for testing fixtures and connecting ports. Right angle pogo pin can provide stable electrical performance and long-lasting contact force.

Can right angle pogo pin improve signal stability?

The spring pressure is evenly distributed and its contact is stable. Reduce poor contact and improve signal exchange. Avoiding looseness and interference during installation. Ensure connection quality through high-precision manufacturing. Right angle design can avoid damage caused by vibration.

How to choose right angle pogo pin?

When choosing, please check circuit board size and connection requirements. Ensure spring pressure is moderate to ensure stable connection. Confirm if current carrying of pogo pin is sufficient. Consider working temperature to ensure long-term stability. Check pogo pin lifespan and durability.

What is lifespan of right angle pogo pin?

Right angle pogo pin lifespan is related to connection number, standard lifespan is 10,000 cycles. Through special design, Johoty can provide a lifespan of up to 200,000 or even 300,000 cycles. Reasonable usage can extend pogo pin lifespan, including temperature, humidity, and pressure. Durable materials and precision manufacturing can increase its service life. It is better avoid frequent excessive use.

What should be noted when installing right angle pogo pin?

You’d better to ensure precise installation and avoid contact errors. Don’t apply excessive pressure during installation. Appropriate tools can ensure accurate installation. It is important to avoid contact with metal materials to reduce short circuits. And, flat surface can ensure a stable connection.

+86 13590816656

+86 13590816656 +86 13590816656

+86 13590816656