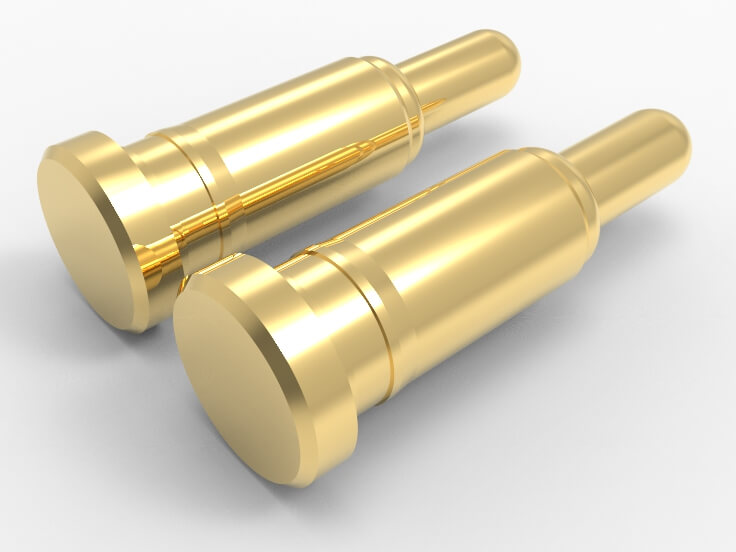

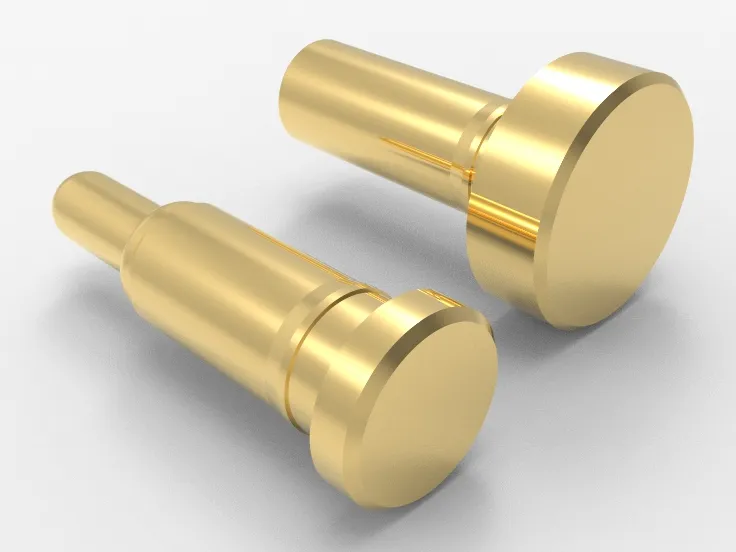

Best SMT Pogo Pins China Manufacturer Automatic Installation

SMT pogo pins are precision connectors for surface mount, spring-pressed and electrical connections. Brass plunger and barrel, built-in spring, transmit high-frequency signals, connect test interfaces and modules. High compression force, automated assembly, strong durability for small, high-density consumer electronics, medical equipment, etc. Johoty offers perfect customization.

Features:

- Surface mount, used for SMT assembly.

- Resistant to use, high durability, long lifespan.

- Diversified sizes, customized specifications.

- Good electrical feature, stable signal transfer.

- Compact structure, saving circuit board space.

Antioxidant, corrosion resistance, reliability.

SMT Pogo Pins Series

SMT pogo pins, Plunger shapes: round or dome tip for flexible contacts and smaller contact areas. Flat tip for low voltage, high current, and high power. Pointed tip for high-density circuit boards, small solder pads, or small connections. Pyramid tip for multi-point contact, increasing contact area and evenly distributing pressure. Chamfered tip is used for smooth contact and to avoid sharp contact. Ball tip for high current and high power. Elliptical tip is used to increase contact area without increasing excessive contact pressure. Multiple star tips are used for high-density contact. Materials: Brass, stainless steel 304, 316, tellurium copper, beryllium copper. Plating: gold, silver, nickel, palladium, platinum, rhodium, ruthenium, composite electroplating.

Structure and Use of SMT Pogo Pins:

| Classification | Description |

|---|---|

| SMT Type | Surface-mountable with solder pad/ball base for reflow soldering in mass SMT production. |

| Straight Type | Simple vertical pin structure. Common stroke range: 0.3–1.5 mm. Typical spring force: 50–150 gf. |

| Right Angle Type | Designed for 90° side contact. Lateral spring configuration is ideal for tight horizontal layouts. |

| Multi-stage Type | Multi-contact segments enable layered or sequential conduction. Applied in battery packs/modules. |

| High Current Type | Supports 5A~50A continuous current. low-resistance spring of BeCu with larger diameter ≥1.2mm. |

| High Frequency Type | Operates above 6 GHz. Designed with impedance control. Ideal for RF or antenna testing interfaces. |

Specifications of SMT Pogo Pins:

| Specifications | Value |

|---|---|

| Barrel Diameter | ≥0.50 mm, Custom |

| Plunger Diameter | ≥0.15 mm, Custom |

| Total Length | ≥1.60 mm, Custom |

| Working Stroke | ≥0.10 mm, Custom |

| Contact Force | ≥5 gf, Custom |

| Rated Current | 0.1 A – 50.0 A, Custom |

| Rated Voltage | ≥1V, up to 10.000VDC, Custom |

| Contact Resistance | ≤ 50 mΩ, Custom |

| Terminal Type | Flat Tail / SMT Mount |

| Durability (Cycles) | ≥ 10,000 cycles, up to 500,000 times, Custom |

| Operating Temperature | -40°C ~ +105°C |

| Material (Barrel/Spring/Plunger) | Copper Alloy / SUS / BeCu or Steel |

| Surface Finish | Gold (Au) , Nickel (Ni),Silver(Ag), Palladium(Pd), Platinum(Pt), Rhodium(Rh), Ruthenium(Ru). Composite Coating, Custom. |

| Mounting Type | SMT Surface Mount |

Applications of SMT Pogo Pins

Smart wearable connector: suitable for modular connection of watches, bracelets, etc. It is recommended to use a cap shaped plunger with a 0.4mm stroke for the structure. Support reliable charging and signal synchronization in small sizes.

Medical portable device interface: This interface requires a size of <2.5mm and a corrosion-resistant surface treatment (Ni+Au). Pogo pins are used as battery interfaces for micro devices such as blood glucose meters and electrocardiographs. Avoid long-term exposure to human sweat for corrosion.

TWS earphone charging case: SMT pogo pins are commonly used for earphone holder charging pins. Need to achieve a elasticity of ≥0.3N and a lifespan of ≥5,000 cycles. Customers often request a dome shaped plunger cap with a dust cover. Can avoid the accumulation of ear debris impurities causing poor contact.

Connection of drone battery shrapnel: The drone structure needs to support 3A continuous current and anti vibration locking structure. SMT pogo pins are used for pluggable connections between batteries and motherboard modules. It can also adapt well to instantaneous impacts in complex flight postures.

Vehicle mounted central control and instrument module: ECU connection and testing points, requiring a temperature resistance of ≥125℃. Adopting a side sticker + double spring double stroke structure to address vehicle grade vibration and thermal expansion issues.

Server/router high-speed interface: Hot swappable module communication interface commonly used SMT pogo pins. Must meet >5Gbps signal integrity, low impedance gold-plated design and grounding sheath Support EMI suppression.

Industrial automation module connection: used as a module connection interface for PLC or I/O modules, adopting a multi pin parallel structure. Equipped with a stop limit design, supporting mechanical fatigue resistance>100,000 times of insertion and extraction.

Quick disconnect battery holder for electric tools: SMT pogo pins are often required for battery connections of electric screwdrivers and shears. They require an instantaneous current of ≥10A, and copper alloy high current core + corrosion-resistant hard gold plating is a good solution.

Consumer electronics magnetic interface: Customers who design tablets and magnetic charging modules often contact Johoty to customize SMT pogo pins. We mostly recommend magnetic positioning structure + SMT terminals, combined with high elasticity gold-plated pogo pins. Customers can achieve perfect charging and data reliability.

Chip programming burner: used for chip pin contact in IC programming fixtures. High density layout is required to support a pitch of ≥0.5mm and a lifespan of ≥ 100K times. Requires low contact resistance and supports precise alignment.

5G communication RF module testing: applied to the RF channel testing port, it needs to meet the requirements of <0.1dB insertion loss and 50Ω characteristic impedance matching. The plunger with coaxial shielding design ensures stable transmission of high-frequency signals.

Automated testing fixture: used for SMT pogo pins in ATE testing fixtures, supporting high-speed mass production testing. Contact life ≥50,000 times, precise elasticity. Signal integrity and low contact resistance of<50mΩ.

Why Choose Johoty's SMT Pogo Pins?

Johoty’s SMT pogo pins give you high quality, customization, fast delivery, and cost advantages. Help you reduce production costs and accelerate market launch. Johoty is your reliable partner.

Manufacturing and Raw Materials of SMT Pogo Pins

High precision plunger material: tungsten steel alloy (hard alloy).

Tungsten steel alloy (YG15 or K10) has extremely high wear resistance and hardness (>HRA89), and is commonly used for continuous high-frequency crimping. The bending strength exceeds 1500MPa and the deformation resistance is superior to traditional stainless steel materials. Can maintain a processing tolerance of the plunger within 1 μ m, compatible with high-speed SMT testing fixtures and automated probe modules, suitable for ≥10 ⁶ crimping cycles.

High ductility barrel material: SUS304L/SUS316L precision stainless steel.

Barrel is made of austenitic stainless steel SUS304L or SUS316L. It has a ductility rate of over 40% based on excellent corrosion resistance and high toughness. The wall thickness control can reach ±0.005mm, and the coaxiality of the inner hole is ≤0.01mm, suitable for fitting with micro spring cavities. Suitable for miniaturized products with a diameter of <0.25mm, supporting high-density array design (1.00mm pitch).

Precision spring material: Japanese piano steel wire SWP-B/German imported SUS304WPB.

Adopting Japanese JIS standard SWP-B piano steel wire or German stainless spring wire SUS304WPB, it has high fatigue life (≥ 5 × 10 ⁶ times) and excellent rebound performance. The commonly used wire diameter range for springs is between Φ 0.05-0.10mm, with a load error controlled within ± 5%. After processing, residual stress is released through aging treatment to ensure long-term consistent compression characteristics.

Electrical contact coating: gold palladium alloy/gold cobalt alloy/three-layer electroplating structure.

Use gold palladium alloy (hard gold, ≥ 0.5μm) or gold cobalt alloy coating. The contact resistance can be stabilized at ≤ 50mΩ, suitable for microcurrent/signal scenarios. The bottom layer is coated with nickel (≥ 2μm) to prevent gold diffusion. Some high-end models adopt a 3-layer structure (gold/palladium + nickel + copper) to improve corrosion resistance and multiple insertion and extraction performance. The lifespan of the coating has been certified through IEC 60512-5-2 testing.

FMEA and CAs of SMT Pogo Pins

Poor contact: Due to lateral force, insufficient elasticity, plunger oxidation, or coating wear, the signal is discontinuous. Preventive design includes high elasticity beryllium copper, optimization of plunger structure, and surface gold plating of ≥3μin. Design a ball plunger tip to reduce contact resistance and extend lifespan.

Barrel deformation: Long term lateral loads or assembly errors can cause barrel to bend or lose its roundness, affecting its travel and guidance. Limit lateral offset tolerance and add limit structures. Choose barrel design with higher wall thickness to avoid it.

Plunger failure: Plunger experiences jamming during long-term repeated use. This is often related to the wear of internal friction pairs and pollutants accumulation. Use dry lubricated MoS₂ and enclosed structure to prevent dust or flux from entering. Of course, SMT pogo pins also require a clean usage environment, which can greatly extend their lifespan.

Spring fatigue fracture: In high-frequency/high stroke, spring fractures due to cyclic stress exceeding material fatigue limit. Johoty often uses high elastic SUS304/631, with a design compression ratio of <30%, to avoid over pressure assembly.

Pad virtual soldering: Bottom metal pin of SMT pogo pins has unstable contact with PCB pad. Due to floating solder pads, insufficient solder, or thermal stress. Johoty suggests using large-sized circular solder pads, matching high Tg PCB materials, and optimizing reflow soldering curve.

Barrel corrosion: In high-humidity and high-salt environments, barrel or spring metal oxidizes and corrodes, leading to performance degradation. Nickel palladium alloy packaging and double-layer sealing structure are helpful. Conduct a salt spray test for ≥48 hours as a verification method. Pogo pins can be made of high-quality stainless steel for long-term use in seawater. Design 6-7 layer composite electroplating for medical or chemical acid-base liquid working environments.

Reliability Test of SMT Pogo Pins

High cycle life test: Perform continuous compression ≥10,000 times at a frequency of 2Hz under a stroke of 1.27mm. The change in contact resistance shall not exceed 20mΩ, and the decrease in elasticity shall not exceed 15%.

Contact resistance stability test: Load 0.5A DC current at working stroke and record 100 pressure contact resistance fluctuations. The standard deviation is in ± 10% of initial value.

Temperature and humidity double 85 reliability tests: Continuous 168 hours in an environment of 85℃ and 85% RH, to test coating integrity and elasticity retention rate. The coating and elasticity determine wear resistance and contact stability of pogo pins. The requirement is that the increase in contact resistance should <25% of original value.

Salt spray corrosion resistance test: Continuous 96 hours in a 5% NaCl atomization environment. Barrel surface shouldn’t have visible corrosion points, the coating shouldn’t have bubbles or peeling, and contact resistance deviation should be < ± 20%.

Plunger lateral load stability test: cyclic loading of 1N force value within ± 0.2mm lateral offset range. Ball design can completely solve the impact of lateral force. Test whether the barrel is stuck, with a maximum friction force not exceeding 0.3N and no permanent deformation of plunger tip.

High and low temperature impact test: -40℃ to +85℃, conversion time <1 minute, after 100 cycles to test structural integrity and functional retention. All welding parts have no cracks, and the electrical performance indicators remain within an error of ± 10%.

FAQ

Can SMT pogo pins withstand extreme temperatures?

Johoty considers temperature range when designing SMT pogo pins, which can work stably at high temperatures of 150°C or low temperatures of -55°C. Their contact points are plated-gold beryllium copper and different special materials. This can minimize the affection from temperature differences. It can usually work normally in -40°C to +125°C. The electronic device reliability is very important. It is suitable for harsh environments.

Can SMT pogo pins adapt to circuit boards of different thicknesses?

The contact pin length and elasticity of SMT pogo pins can adapt to circuit boards of different thicknesses. They will automatically adjust the pressure according to circuit board thickness during contact process. Even if changing circuit board thickness, the contact points can always remain stable. Adapting to multiple specifications enhances design flexibility. Reserve suitable installation space during design.

Why do SMT pogo pins have different plunger shapes?

SMT pogo pins have various plunger tip shapes, star, spherical, cup, cylindrical, and conical. Different contact methods can optimize contact quality according to actual usages. The spherical design is suitable for frequent connection, and has good durability. Cylindrical shape is suitable for stable connection and reduces contact impedance. Cone contact can increase pressure and adapt to more equipment.

Will SMT pogo pins be affected by vibration?

SMT pogo pins have strong anti vibration. Due to spring design and contact points, the vibration impact can be effectively reduced. Even if strong vibrations are generated during device operation, they can still maintain a stable connection. Spring to compress or stretch helps absorb vibrations. Suitable for high vibrative automobiles and aviation.

How to avoid contact point wear of SMT pogo pins?

The key to avoiding contact point wear is to use right designs and appropriate materials. Contact points are usually made of high wear-resistant gold-plated copper beryllium copper. Reducing frequent excessive contact can extend its lifespan. By precisely controlling the contact pressure, unnecessary friction can be reduced. It can effectively extend lifespan by regular inspection and routine preventive maintenance.

How can SMT pogo pins improve connection stability?

SMT pogo pins ensure stable electrical contact with each connection by designing pressure and spring contact method. The spring force can be adjusted according to usage needs to ensure that it doeen’t loosen for long time. Fully consider contact resistance during design to reduce poor contact risks. Good contact stability helps improve equipment operation efficiency. Suitable for high stability.

Can SMT pogo pins work in humid environments?

Johoty’s SMT pogo pins are specially designed to maintain good performance effectively in humid environments. The contact points are usually coated with anti-corrosion layer to prevent erosion by water vapor and oxides. The spring and conductive parts aren’t easily damaged by moisture. Johoty once designed waterproof magnetic connectors for EMS systems, with a female end that reaches IP67 and 6-layer composite electroplating, which can resist solvent corrosion and can be cleaned in washing machines. For some devices that require waterproof, special protective measures will be taken during design. Ensure long-term stable work.

Can SMT pogo pins be used in high-frequency applications?

SMT pogo pins perform excellently in high-frequency. Its contact design effectively reduces signal loss and ensures stable transfer of current and signals. By optimizing the shape and material of the contact points, high-frequency interference can be reduced. Its structure can withstand high-frequency currents and signals. Suitable for high-frequency communication and wireless devices.

+86 13590816656

+86 13590816656 +86 13590816656

+86 13590816656