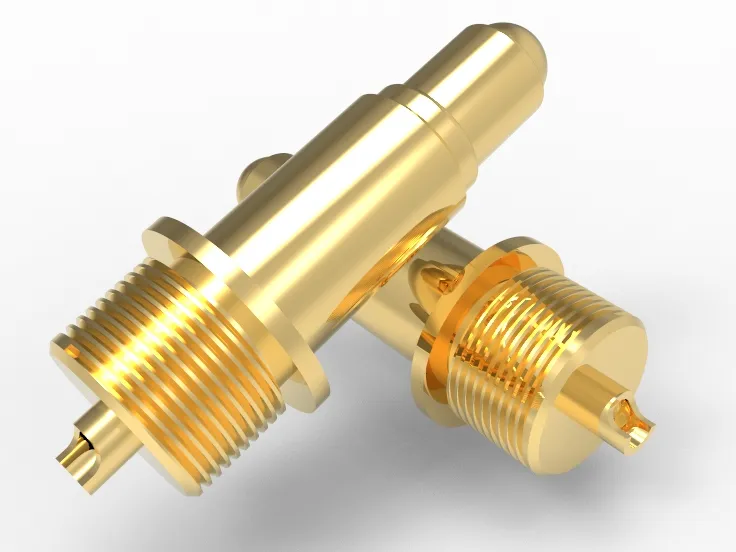

Best Threaded Pogo Pins China Manufacturer Stable Locking

Threaded pogo pins have sturdy threads that are stable and reliable for electrical connections under vibration or movement. High durability, excellent conductivity in harsh and high-end connection based on brass or beryllium copper gold plating. Johoty offers perfect customization.

Features:

- Stable thread, long-lasting, reliable connection.

- Anti-seismic & loosening for dynamic uses.

- Material options, durable, corrosion-resistant.

- High precision, excellent contact performance.

- Fit high frequency and low impedance conduction.

- High-temp resistance for extreme environments.

Threaded Pogo Pins Series

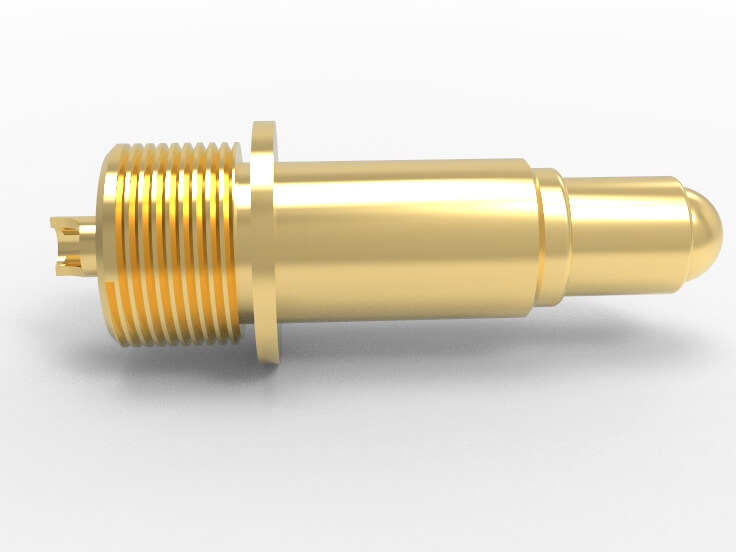

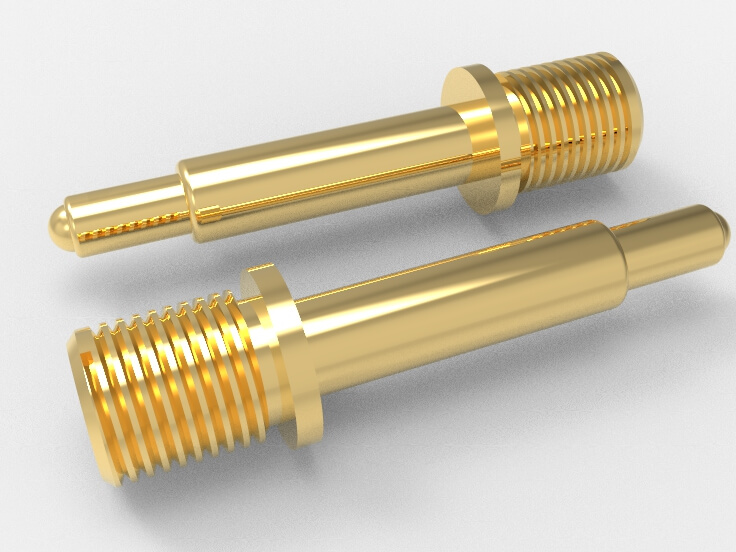

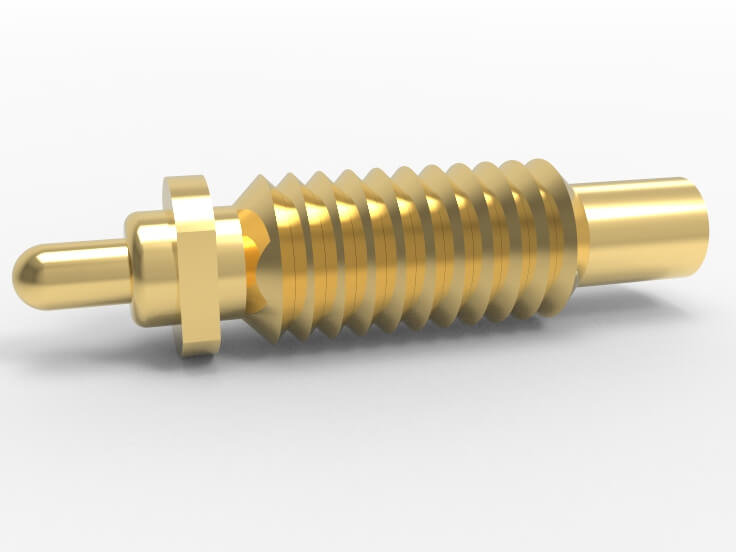

Design and Construction: fix the device slot with threads, avoid poor contact caused by vibration or insertion and extraction operations, suitable for high-frequency connection or unstable environments. The threaded part adopts precision cutting to ensure stability and durability, ensuring firm contact and insertion stability.

High-precision Spring: Made of high-quality piano steel, it effectively resists contact changes caused by vibration or mechanical loads.

Electrical Contact: low impedance, high conductivity. High Wear, Corrosion Resistant Materials: stainless steel or gold-plated copper, resistant to moisture, chemicals, and oxidation.

Adapt to Harsh Environments: -40°C~+125°C, vibration, high humidity, explosion-proof, waterproof, dustproof customized.

Specifications: Length 6.00~70.00mm, outer diameter M1.0~M12.0, voltage <500V, current <200A, flexible customization.

Specifications of Threaded Pogo Pins:

| Parameter | Description |

|---|---|

| Outer Diameter | ≥0.8 mm,≥M2.5, custom |

| Overall Length | 6.00–70.0 mm, custom |

| Stroke | ≥0.10 mm, custom |

| Rated Current | 0.10–50.0 A, custom |

| Contact Resistance | ≤ 50 mΩ, custom |

| Spring Force | ≥ 5gf, custom |

| Operating Temperature | -40–+125 °C |

| Mounting Type | Threaded / Screw-in |

| Thread Size | M2.5–M10, custom |

| Thread Pitch | 0.45–1.25 mm, custom |

| Thread Engagement Length | 2.25–15.00 mm |

| Installation Torque | 1.0–50 N·m |

| Vibration Resistance Rating | 10–20 G (10–2,000 Hz) |

| Plunger Material | Brass / BeCu / SUS |

| Plunger Plating | Gold 1–80 μin / Nickel 50–200 μin |

| Durability (Life Cycles) | 10,000–1,000,000 cycles |

Thread Position and Structure of Threaded Pogo Pin

| Thread Location | Structure Type | Description |

|---|---|---|

| Barrel Thread | Threaded Barrel | On the barrel to secure pogo pin to panel or module housing |

| Base Thread | Base-Mount Thread | Threaded screw is on bottom base for vertical installation to PCB or structural components by screwing |

| Head Thread | Nut-Lock Type | Pogo pin’s head or plunger, nut locks it from the top through a hole |

| Internal Thread | Internally Thread | Inside the barrel, female thread accommodate screws or specific structural components |

| Double Thread | Dual-End Thread | Head and bottom for complex fixed structures |

Customization of Threaded Pogo Pins

| Parameter | Description |

|---|---|

| Structural Type | Threaded, Press-fit, SMT, Wire-end, Custom |

| Overall Length | Customizable, 6.00 mm to 70.00 mm, Custom |

| Working Stroke | Adjustable, common range: ≥0.10 mm, Custom |

| Thread Size | M2, M2.5, M3, M4,M10, metric or UNC options, Custom |

| Tip Style | Flat, Dome, Sharp, Concave, Beveled, Star, Cup, Crown, Custom |

| Spring Force | Light (≈20gf), Medium (≈50gf), Heavy (≥100gf), tunable 5gf per electrical load |

| Rated Current | 1.0A to 50.0A, depending on pogo pin diameter, spring, and structure |

| Rated Voltage | Typically ≤ 48 V, adjustable ≤ 10kV based on application |

| Plunger Material | Beryllium Copper, Brass, Custom |

| Plating Options | Gold (5μ”, 10μ”, 30μ”, 80μ”), Nickel, Silver, Custom |

| Barrel Material | Brass, Stainless Steel, Alloy 42, Custom |

| Spring Material | SUS304, Music Wire SWP-B, High-temp Spring Steel, Custom |

| Mounting Type | Threaded, Adhesive-fixed, Press-fit into PCB, Custom |

| Operating Temperature | From -40℃ to +120℃ (extended options available), Custom |

| Cycle Life | 10,000 to 1,000,000 cycles (depends on structure), Custom |

| Coaxial Tolerance | Typically ≤ ±0.05 mm, Custom |

| Contact Resistance | ≤ 50 mΩ (typical 10–30 mΩ), Custom |

| Compliance | RoHS and REACH available upon request |

| Packaging Options | Tray, Tape & Reel, Bulk, Custom |

| Special Functions | Optional IP67, anti-solder design, high-frequency support, Custom |

Applications of Threaded Pogo Pins

ATE automatic testing equipment contact module: In the semiconductor ATE platform, threaded pogo pins are used for signal transmission and electrical testing node connection. Require stable contact impedance <30mΩ and mechanical life ≥50,000 times. Compatible with 0.65mm pitch BGA package testing and meets JESD22-B102 thermal shock standard.

Blind insertion interface for server and switch modules: In high-density data center equipment, threaded pogo pins are used for hot swappable structures. Supports 5A current load, with over 100,000 insertions and removals, and operates at a temperature range of 0-70℃. The contact structure complies with SFF-TA-1002 and SAS-4.0 connection standards, achieving backplane level fault maintenance.

High voltage battery module monitoring point interface: inside the EV power battery pack, used for voltage sampling and temperature signal extraction. Supports 1,000V insulation withstand voltage and meets the testing requirements of IEC 61010-1 and ISO 6469-1. The working current reaches 10A, maintaining a potential difference fluctuation of <10mV at the contact point.

RF signal debugging interface: used for transient RF path access in millimeter wave communication modules. Require S11<-15dB and insertion loss <0.1dB at a center frequency of 28GHz. Use SMP or GPO coaxial structure, and the needle body needs to be metal shielded to suppress crosstalk. Compliant with IEEE 802.11ad antenna testing specifications.

Removable sensor array connection structure: In intelligent manufacturing equipment, the sensor array is quickly connected to the main control board using threaded pogo pins. Support insertion and extraction alignment tolerance of ± 0.2mm, suitable for impact loads of 30g or more. The transmission signal speed can reach up to 480Mbps, used for high-speed acquisition modules such as optoelectronics and displacement.

Rail transit safety control motherboard connection: used in the rail transit vehicle control unit to achieve safety redundancy logic board connection. Require contact reliability >99.99%, long-term operating temperature -40℃ to +85℃. Compliant with EN 50155 electrical and mechanical reliability standards, with a salt spray resistance rating of ≥720 hours.

Medical portable device electrode module interface: used for replaceable electrode signal access in in vitro diagnostic instruments. Must meet the requirements of ISO 13485, and the biological contact metal part must comply with ISO 10993-5 cytotoxicity testing. Supports weak current collection within 1A, with a contact pressure of 50-150gf.

Industrial camera module quick contact structure: used in visual inspection systems for temporary connection of camera module or LED fill light unit power supply and synchronization signal. The design requires support for signal transmission of over 5 million pixels. ESD level >15kV air discharge, connection error <0.1mm, can be easily achieved.

Wearable terminal magnetic charging interface: commonly used threaded pogo pins such as smart bracelets and TWS earphones serve as magnetic power and data connection contacts. Design current <2A, contact life ≥10,000 times. The port supports IP67 waterproof packaging, with a typical size of <1.5mm diameter.

Robot joint data bus pluggable structure: In collaborative robot joint modules, threaded pogo pins are used for CAN or RS485 temporary interfaces. Contact impedance <20m Ω, supporting plug-in angle deviation ± 5°. They can ensure signal stability during high-frequency movements of the robotic arm.

Unmanned system power control module connector: PCBA module connection in unmanned aerial vehicle and electric logistics vehicle systems, required to support wide voltage input of 12-48V. The needle body is resistant to vibration of 5-200Hz without contact interruption, and the function does not degrade after 1000 thermal cycles. Adapt to MIL-STD-202 testing framework.

The interface between the tested board and the needle bed in the mass production testing fixture: Threaded pogo pins are widely used as electrical circuits in electronic manufacturing testing fixtures. Require low impedance below 0.1Ω and needle body elasticity attenuation rate <5% (after 10,000 insertions and removals). Compliant with IPC-A-9701 fatigue testing standards, used for ICT, FCT, Hi pot and other stages.

Why Johoty's Threaded Pogo Pins As Priority?

Johoty’s threaded pogo pins are 99.9% reliable with exceptional conductivity, boost efficiency by 20% for over 100 companies. Fast global delivery means no delays for your project. Choose Johoty as a trustworthy partner!

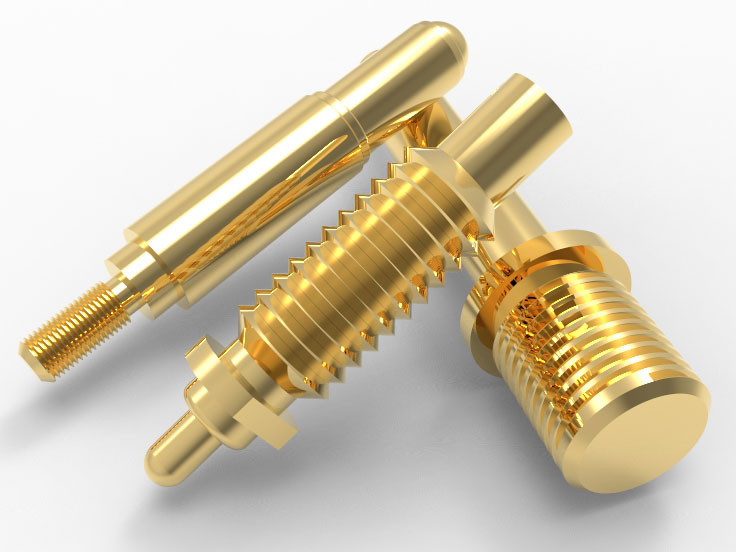

Function of Threaded Pogo Pins

Plunger

Acts as contact tip with 20 shapes, providing electrical connection to mating surfaces of client’s device. Typically made of hard gold-plated alloy for low contact resistance ≤ 50 mΩ) and strong wear resistance.

Spring

Provides force to maintain consistent contact pressure. Typical force range ≥20gf, custom force ≥5gf. Working stroke ≥0.10 mm, mechanical durability ≥ 10,000 cycles), up to 1M cycles.

Barrel

Supports and guides the plunger and spring, maintaining structural integrity. Made of brass with gold/nickel plating for corrosion resistance and conductivity.

Threaded Screw

Provides mounting and fixation by male or female thread. Typically its position is on barrel inside or outside. Threaded design ensures secure and detachable installation. Common standard thread sizes M2.0–M10.0; length customized per mounting requirements.

Installation Design and Precautions of Threaded Pogo Pins

Thread pre-tightening force control: During installation, the torque should be controlled between 0.5-0.8Nm to avoid spring deformation or material cracking caused by over-tightening. Suggest using torque tools for operation to improve consistency.

Anti-vibration and anti-loosening structure: Anti-loosening glue or locking nuts should be added in high-vibration environments. Through MIL-STD-810G testing, the threads remain tight and the contact is reliable during long-term operation. The M2.5 screw can withstand vibration for ≥5,000 cycles without loosening under the action of 0.4N.m.

Through hole tolerance matching: It is recommended to install a hole diameter of thread outer diameter +0.05mm. Coaxial errors exceeding 0.10mm will significantly increase the risk of probe side loading, resulting in travel jamming or poor contact. Complies with ISO 2768-f to prevent contact instability and mechanical stress concentration caused by eccentric installation.

Current and thermal effect control: Insufficient rebound force can lead to unstable electrical contact, while excessive rebound force will increase wear or fatigue of the mating structure. It is recommended to conduct thermal simulation when using current exceeding 5A. Ensure that the interface temperature rise is below 30℃ to prevent local overheating from causing structural failure or resistance drift.

Coating wear and impedance monitoring: Thread repeated assembly ≤10 times, using ≥0.5μm nickel gold coating to prevent contact resistance from increasing. It is recommended to conduct regular low-voltage testing to maintain impedance<50mΩ.

Reliability Test of Threaded Pogo Pins:

Mechanical life cycle test:

Perform ≥10,000 insertion and extraction cycles on threaded pogo pins to evaluate their mechanical durability. Observe the changes in insertion and extraction force and the trend curve of contact resistance to monitor contact wear. The structural continuity and fatigue life performance meet the requirements of long-period connection applications.

Contact resistance stability test:

The initial contact resistance should be ≤50mΩ, and the change after 100 insertions and removals should not exceed ± 20%. Continuously monitor resistance stability through the four wire method. Reflecting the consistency of coating uniformity and spring pressure retention performance in dynamic connections.

Stability test in constant humid and hot environment:

Keep the pogo pin at 40℃ and 95%RH humidity for 96 hours. Test its electrical performance and mechanical integrity. Observe structural abnormalities caused by coating corrosion, spring fatigue, and insulation material moisture absorption and expansion.

Salt spray corrosion test:

According to ASTM B117, the threaded pogo pins were exposed to a 5% NaCl salt spray environment for 96 hours. Test corrosion resistance of pogo pin surface coating. Conduct contact resistance measurement and surface SEM inspection after testing. To evaluate the quality of metal oxidation treatment and long-term electrical performance retention.

Vibration and impact test:

Perform sine vibration testing at 10-500Hz and 30g acceleration impact testing. This simulates the physical impacts encountered in transportation, assembly, and terminal applications. Monitor whether the contact instantaneous frequency is less than 1μs to ensure signal continuity.

Thermal shock test:

Perform 100 thermal shock cycles on pogo pins between -40℃ and+85℃. Observe the changes in contact properties of materials after thermal expansion and contraction. Verify the consistency of interface connections between multiple metallic materials and the risk of low-temperature stress cracking.

Current carrying capacity test:

Continuously apply rated current of 3A or 5A and monitor the temperature rise for 1 hour, with a limit not exceeding 30K. Measure the resistance drift as an indirect indicator of the integrity of the conductive path.

Material composition analysis:

EDX and ICP-OES were used for elemental analysis of pogo pin spring and housing materials. Confirm compliance with RoHS/REACH restriction standards and avoid prohibited elements such as lead and cadmium. Simultaneously ensuring material stability and long-term environmental reliability.

Plating thickness consistency test:

Non destructive testing of Ni/Au plating thickness. Require Au layer ≥ 0.1μm, Ni layer ≥ 3.5μm, and uniformity error ≤±10%. Verify its wear resistance and contact resistance stability under long-term use.

Compression rebound performance test:

Test the rebound rate of the spring after being compressed to its maximum stroke. Require a recovery distance of ≥90% of the original and no permanent deformation. Using laser displacement sensors for sampling ensures that the mechanical recovery ability after multiple loading meets the conditions for repeated use.

FAQ

What are Threaded Pogo Pins?

Threaded pogo pins are spring loaded pins with threads used for electrical connections and fixation. They enhance connection firmness through threaded design, making them suitable for precise installation and repeated connections. They are commonly used in electronic signals or power, charging interfaces, module connections, etc., and have both conductive and fixed functions.

What is Purpose of Threaded Pogo Pins?

Used for electronic devices, module docking, and fast charging interfaces. Its threaded design ensures firm fixation and avoids loosening or instability caused by vibration. In addition, they can effectively improve contact stability, ensure data transfer and smooth current, and support multiple installations.

Does Threaded Pogo Pins Support Customization?

Johoty provides perfece customization including size, spring force, thread specifications, and contact materials. We can fine tune specs based on acctual needs to ensure precise matching of applications. Customized services provide higher efficiency and cost-effectiveness, adapting to industrial and commercial needs.

What Working Principle Do Threaded Pogo Pins Have?

Apply pressure through internal springs to ensure a stable connection with the target contact surface. The threaded part is used to lock pogo pin to prevent detachment or misalignment. The contact part is made of conductive brass or stainless steel to ensure stable current. The spring structure supports more than 10,000 compression uses, extending its service life.

What are Specs of Threaded Pogo Pins?

The specifications include the length, diameter, sroke, thread type, rated current/voltage, and spring force. The length is usually 6-70 mm, and diameter is 0.8-2.0 ms. Thread types can be customized, available in M1-M12. The spring force from 20g to 500g, supporting diverse needs.

Is Installation of Threaded Pogo Pins Complicated?

Easy to install, supports manual and automatic tool operation. Quick installation and reduced operation time through thread design. No additional fixation after installation to maintain stability. Modular design adapts to multiple devices and reduces debug complexity. Flexible and efficient installation.

What Materials are Threaded Pogo Pins?

Contact plunger tip is brass, stainless steel, or composite materials. Its threaded structure is suitable for materials of different hardness, ensuring a tight connection. Conductive parts are gold plating and silver plating to improve contact reliability. Spring design can adapt to small deformations of various materials.

What is lifespan of Threaded Pogo Pins?

The typical lifespan is between 10,000-200,000 cycles of compression, depending on the usage environment and material selection. High quality stainless steel and gold-plated surfaces can improve lifespan. The spring strength maintains long-term stability and supports high-frequency use. Anti corrosion design extends lifespan.

+86 13590816656

+86 13590816656 +86 13590816656

+86 13590816656