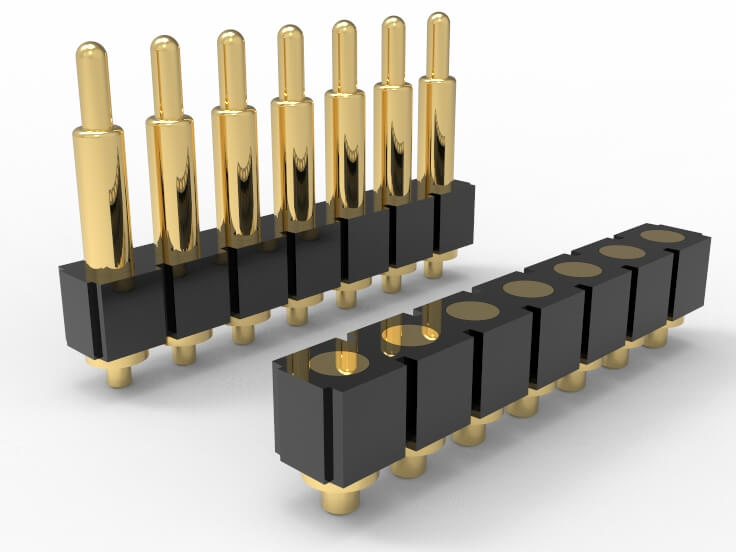

Best Through Hole Pogo Pins China Manufacturer Easy Install

Through hole pogo pins are spring loaded pins to solder PCB through holes, provide stable electrical and mechanical connections for high-density, reliability, frequent applications. Brass, beryllium copper with gold and nickel plating. Johoty customs diverse sizes, pitches, forces, currents, etc.

Features:

- Accurate conductivity, stable electrical performance.

- Through-hole PCB installation, strong stress resistance.

- High life cycles of 200,000 times of contact or more.

- Fit high temperature, humidity, corrosive environments.

- Flexible custom, multiple specs, diverse applications.

- Low resistance lossless transfer reduces power loss.

Through Hole Pogo Pins Series

Through hole pogo pins come in over 5,000 styles including standard, high current, micro, long stroke, and customized. Distinguished by diameter, stroke, contact force, installation pitch or depth, lifespan, rated current or voltage, contact resistance, plunger or barrel or spring material, coating material, high and low temperature, anti-oxidation and anti-corrosion salt spray time, bulk or T&R packaging, sample, small batch or bulk. Superior electrical performance, anti-vibration & corrosion-resistant designs, fit high-frequency insertion and removal, and through-hole design for easy welding and fixation. Johoty’s spring loaded pin is widely used in portable monitoring and detection devices, vehicle electronic modules, battery connections, testing instruments, automation equipment, base stations, antenna modules, mobile phones, tablets, headphones charging or signal transmission, and high reliability connection devices.

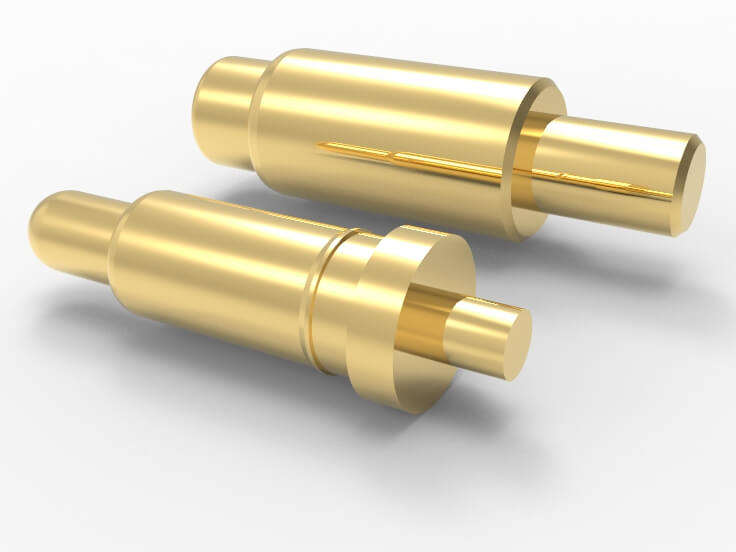

Basic Structure of Through Hole Pogo Pins:

| Structural | Functional Description |

|---|---|

| Plunger Tip (Contact) | Conducts current, contacts mating surface |

| Spring | Provides compressive force to maintain stable contact pressure |

| Barrel | Protects pin body, maintains coaxiality |

| Guide Rod | Ensures linear pin movement, prevents tilt |

| Tail Pin | Fixes through hole pogo pins in PCB through-hole location |

| Stroke | Allows compression to accommodate assembly tolerance |

| Contact Plating | Prevents corrosion, improves conductivity |

| Mounting Structure | Supports soldering or mechanical fixation |

Specifications of Through Hole Pogo Pins:

| Parameter | Range |

|---|---|

| Overall Length | ≥ 1.39 mm, Custom |

| Mounting Hole Diameter | ≥ 0.50 mm, Custom |

| Working Stroke | ≥ 0.10 mm, Custom |

| Spring Force | ≥ 15 gf, special ≥5gf,Custom |

| Plunger Diameter | ≥ 0.30 mm, Custom |

| Barrel Diameter | ≥ 0.50 mm, Custom |

| Plunger Tip Style | Flat, Round, Dome, Conical, Concave, Cup, Crown, Star, Ball, Custom |

| Material | Brass, Beryllium Copper, Stainless Steel, Custom |

| Plating | Gold, Nickel, Silver, Palladium, Rhodium, Hard Gold, Palladium, Ruthenium, Composite coating, Custom |

| Contact Resistance | 15mΩ~200mΩ, Custom |

| Rated Current | 0.1A – 50.0A, Custom |

| Peak Current | ≤ 100A (depending on model) |

| Rated Voltage | ≤ 40VDC,up to 10KV DC, Custom |

| Spring Force | ≥5gf, proposed ≥20gf, Custom |

| Durability (Life Cycle) | ≥ 10,000 cycles, special up to 500,000 cycles, Custom |

| Operating Temperature | From -40℃ to +85℃,or -55℃ to +125℃, Custom |

Installation and Soldering of Through Hole Pogo Pins

| Installation & Soldering | Description |

|---|---|

| Vertical Through-Hole Mount | Pogo pin inserted into PCB hole vertically for wave soldering (single/double side) |

| Wave Solder Compatible | Compatible with standard wave solder process. solder paste 0.15–0.25 mm; halogen-free flux preferred |

| Manual Soldering Supported | Suitable for prototypes or low-volume. <260℃ iron tip, <3 seconds contact time |

| Dual-Side Pad Plating Compatible | Requires copper-plated via walls for robust dual-side mechanical bonding |

| Recommended Hole Size Tolerance | ±0.05 mm tolerance; typical diameter 1.0–1.6 mm depending on pogo pin design |

| Pad Surface Finish Compatibility | Supports HASL, ENIG, OSP, etc. for low contact resistance |

| Auto-Insertion System Compatible | Compatible with auto-insertion lines for pogo pin straightness and dimensional consistency |

Applications of Through Hole Pogo Pins

Wearable medical device pulse/temperature acquisition unit: used as a signal output pin in medical grade continuous monitoring devices. The barrel material is often made of gold-plated beryllium copper, with biocompatibility up to ISO 10993. Stable signal sampling under low voltage conditions.

High end robotic arm end tool quick change system: used for connecting power and control signals in the tool quick change module of the intelligent manufacturing line end effector. Supporting automated insertion and closing, with a cycle durability of over 300,000 times.

Test interface for electric vehicle BMS system: used as a voltage sampling and protection board adjustment point in the development and maintenance of power BMS. It has high insulation and constant contact impedance, and is often used in conjunction with high-voltage DC testing platforms.

5G RF module reliability testing interface: used for automated detection of 5Gmm Wave RF front-end modules. Supports high-frequency signal transmission over 6GHz. The through-hole design reduces board level resonance and improves signal integrity.

Industrial grade PLC terminal crimping inspection system: applied in PLC manufacturing for terminal crimping strength and continuity testing. Mechanical devices adapted to high repetitive contact. The rebound force of the probe is precisely controlled within the range of ± 15gf.

High reliability ATE testing fixture system: used as a probe interface for ATE to achieve high-frequency and high cycle electrical connections. Test platform stability and repeatability, with a typical lifespan of up to 500,000 insertions and removals.

Low temperature electrical interface in quantum computing platform: suitable for signal extraction in quantum bit control systems. Working in extremely low temperature environments, the through-hole structure enhances contact stability. Adapt to low heat noise and weak current requirements.

New energy photovoltaic inverter maintenance port: used for DC side testing interface, to achieve real-time detection of MPPT working status. Supports high current <50A, and the structure is often packaged in outdoor IP65 modules.

Redundant module connection for rail transit signal control cabinet: used for hot swappable connection of functional modules in CBTC control cabinet. Through hole welding enhances mechanical stability and supports high reliability redundant switching. The MTBF design standard exceeds 10,000 hours.

Military aviation cable connection module: used in military avionics platforms for fast signal interconnection in high vibration environments. Adapt to MIL-STD connector requirements, with impact resistance and corrosion resistance. In terms of data transmission integrity, through hole pogo pins have a strong advantage.

Satellite attitude control system sensor connection: used to connect MEMS sensor modules inside the attitude control system. Provide micro-current transfer paths and enhance PCB soldering stability through through-hole structures. Meet the working temperature range of -55℃ to 125℃, with a small size and a minimum height of 1.39mm.

Aircraft engine condition monitoring device: used for high-frequency connection of monitoring points for parameters such as temperature and current of turbine engines. Meet the DO-160 standard to ensure high reliability of system maintenance ports during flight.

Why Johoty's Through Hole Pogo Pins?

Our through hole pogo pins last 10,000 ~200,000 cycles or more, with precision within 0.01mm and a 99.9% quality rate. Efficient production and quick delivery ensure smooth project progress, Contact Johoty now!

Raw Materials and Finishing of Through Hole Pogo Pins

Plunger

The commonly used materials are SK4 high carbon steel or copper alloy HBi59, which have both hardness and conductivity. The surface is mostly coated with gold Au ≥ 3μin, up to 80μin to improve contact stability and prevent oxidation, with a resistance to over 100,000 insertions and removals. Composite coatings are also commonly used to prevent oxidation and improve durability.

Barrel

Using brass as the main material because of its high mechanical strength and easy CNC machining. The surface is usually nickel plated with Ni ≥ 50μin to prevent corrosion, and then overlaid with a gold layer of Au ≥ 3μin. Another function of nickel plating is to prevent the detachment of the gold plating layer. Meet engineers’ requirements of high-frequency contact and low impedance electrical performance, and enhance wear resistance.

Spring

The preferred material is stainless steel SUS304 or piano steel wire SWP-B, which balances elastic fatigue life and oxygen resistance. The surface is plated with gold, silver, and nickel to improve conductivity and prevent long-term oxidation. The lifespan can reach 500,000 cycles, and the design lifespan can reach 1,000,000 cycles.

Tail Pin

The design is often combined with barrel, using brass HBi59 or phosphor bronze C5191. Has good weldability and conductivity. Like barrel, the surface is gold-plated, and within budget constraints, tin plating with Sn ≥100μin is also possible. Optimize welding wetting and ensure welding consistency, suitable for THR and wave soldering processes.

High Reliability Verification of Through Hole Pogo Pins

Insertion and extraction lifespan test: Conduct ≥10,000 compression tests using an automatic insertion and extraction cycle machine. Verify structure durability and contact consistency to effectively evaluate long-term mechanical reliability.

Contact resistance test: Measure contact resistance at 1A, with a requirement of ≤ 50 mΩ. Confirm electrical path stability and micro contact surface quality according to MIL-STD-202 Method 307.

Salt spray corrosion test: Conduct a 96 hour salt spray test under ASTM B117 to inspect corrosion resistance of surface coating. Pogo pins can work stably for 3-5 years under slightly protected conditions. Mainly verify the reliability in high humidity or marine environments.

High/low temperature cycling test: Temperature range -40°C to + 85°C, cycle 50 times. Verify the impact of metal thermal expansion differences on assembly stress and contact performance.

Constant temperature and humidity test: Maintain 85°C /85%RH for 168 hours continuously. Evaluate electrical and mechanical performance stability of spring pogo pins in high temperature/humidity environments.

Drop impact test: Drop freely from a height of 1 meter 10 times to test the mechanical impact tolerance that pogo pins may encounter during transportation and assembly.

Temperature rise test: Under rated current 3A/5A/10A for 1 hour, the monitored temperature rise shall not exceed 30°C. Evaluate current carrying capacity and thermal conductivity design rationality according to UL 1977 standards.

Vibration test: 10Hz-500Hz, 1.5mm displacement, 5g acceleration, lasting for 2 hours. It’s to evaluate anti-vibration performance of pogo pin structure in working condition.

Welding reliability testing: Perform peak soldering or reflow soldering thermal shock testing, up to 260°C. Verify tail pin mechanical structural stability and pad adhesion performance under high-temperature soldering processes.

Electroplating adhesion test: Use tape peeling or friction and wear test to evaluate gold coating adhesion. Ensure that pogo pins will not peel off during long-term use based on ASTM D3359.

Function Categories of Through Hole Pogo Pins

Signal transmission type: mainly used for high-speed or low-speed data communication. To ensure signal integrity and anti-interference ability, it is commonly used for PCB testing and board to board connections. Signal integrity indicators are commonly used to evaluate their performance.

Power transmission type: designed for medium to high current transmission, with a current generally between 1A and 50A. The plunger tip has low contact impedance and is used for module power supply and battery contact.

High frequency signal type: working frequency range can usually reach GHz level for 5G and RFID. Low VSWR and good impedance matching are required. Customers often request to design pogo pin connector and attach importance to insulation materials and inner pin structures.

Micro precision type: barrel diameter ≤0.3mm, used for space extreme scenarios such as smart wearable devices and endoscopic systems. The manufacturing accuracy tolerance is controlled within ±5μm, emphasizing the capability of micro machining technology.

High temperature resistant type: can withstand environments of ≥200℃, commonly used in reflow soldering or internal environments of automotive engine compartments. When making pogo pin connector, housing material is mostly LCP or PEEK, and has been verified by UL 746B.

Corrosion resistant type: The barrel is electroplated with nickel gold or rhodium gold for high humidity/salt spray. Applied to marine, medical, etc. Meets the salt spray test for over 1,000 hours according to ASTM B117.

Self-cleaning type: plunger tip has friction or rotation function to remove oxides or pollutants during each contact. Long term contact reliability for high-frequency connections.

High lifespan type: plug-in life is >50,000 cycles, up to 500,000 cycles. Built in guiding structure reduces wear for long-term testing equipment or automated testing heads on production lines. The test life is based on MIL-STD-202.

FAQ

What is Work Principle for Through Hole Pogo Pins?

Through hole pogo pins utilize springs to provide a stable electrical connection and automatically rebound upon insertion to maintain contact. Good conductivity is formed between the metal plunger and the contact surface. Strong contact force, easy insertion and removal, reduces wear, suitable for high-frequency connections. High precision design ensures long-term reliability.

What are Applications of Through Hole Pogo Pins?

Widely used in mobile phones, healthcare, smart wrists, SOS, cars, robots, etc. Ensure stable charging and data transfer in smart devices. Provide precise electrical connections in medical equipment. Ensure smooth data transfer in SOS, robots, automotive electronics. In industrial robots, various sensors and control systems are connected.

How to Choose Through Hole Pogo Pins?

When choosing, consider pogo pin pitch, stroke, contact force, size, current, and durability. Fit application environment and meet electrical performance. Choose high durability models based on use frequencyof connected devices. Ensure high temp resistance, anti-interference, and adaptability to different requirements. Choose the best metal materials to optimize conductivity in material selection.

What Materials Fit Through Hole Pogo Pins?

Stainless steel, brass, beryllium copper, tellurium copper, gold-plated, silver, palladium, platinum, etc. Copper material has good conductivity for efficient transfer. Stainless steel has corrosion resistance for harsh environments. Gold-plated surface increases oxidation resistance and prolongs lifespan. Select different materials based on different needs, optimize performance and cost. The material determines conductivity and durability.

What is Installation Method for Through Hole Pogo Pins?

Usually installed through welding or insertion. The welding method is simple, highly reliable, and suitable for small-scale production. Plug in installation facilitates quick replacement for large-scale automation. Ensure pogo pin direction is correct during installation to avoid poor contact. After installation, it is necessary to confirm pogo pins are well connected to contact points.

How Much Current can Through Hole Pogo Pins Withstand?

The current carrying of spring loaded pin depends on their size and material. Common models can carry currents from 100mA to >10 amps. Select spring loaded pogo pins with appropriate current based on actual requirements to avoid unnecessary overload. High power equipment requires large pogo pins. Reasonable selection can ensure long-term stable operation.

What is lifespan of Through Hole Pogo Pins?

The service life depends on insertion number and working environment. High quality through hole pogo pins can support 10,000 insertions and removals, while Johoty can design up to 200,000 or even 300,000 insertions. Environmental humidity and temperature can also affect pogo pin lifespan. Good designed through hole pogo pins have wear and corrosion-resistance. Regular inspection and cleanliness can extend ervice life.

What is Temperature of Through Hole Pogo Pins?

Temperature range for through hole pogo pins is -40°C to +85°C. Some special designs can support -55°C to +125°C. Different materials and structural designs have an impact on temperature adaptability. Select high temp resistant materials to fit high-temperature environments. Excessive temperature may lead to poor contact or damage.

+86 13590816656

+86 13590816656 +86 13590816656

+86 13590816656