Rapid Prototyping for Pogo Pin Connector Reduces Lead Time, Lowers Your Trial Costs, and Speeds Up Design Validation. Get Custom Samples Now.

Introduction: When the connector development cycle slows down the entire product line

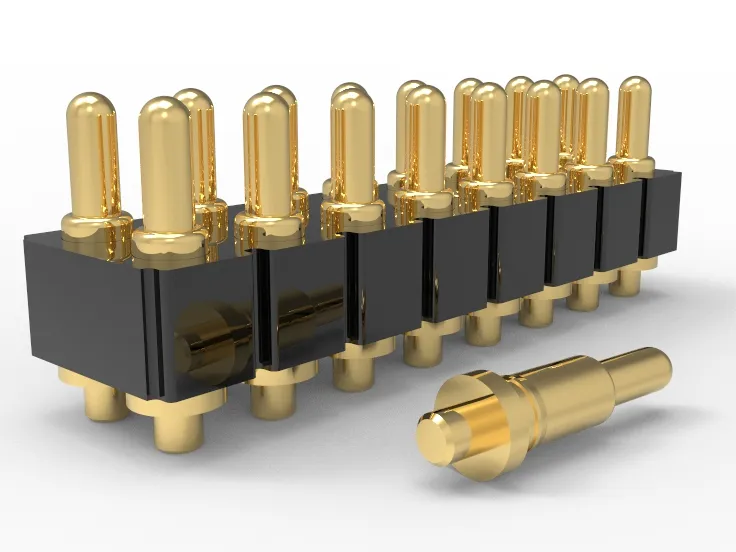

Rapid prototyping and product iteration speed are becoming more critical than ever before. They play crucial roles in European and American industries, healthcare, aerospace, and intelligent manufacturing. A technical decision may mean advancing the R&D progress by 3 months. It may also lead to a missed market for an entire quarter. Pogo pin connectors are commonly used for precision interfaces, which can be frequently plugged in and out, and are limited in space. But it can demonstrate significant and crucial advantages in rapid prototyping.

In the past, connector validation required a sample application and a 4-6 week lead time. The entire process involves initial testing that does not match, repeated iterations, engineering changes, and increased costs. For any engineer, it is a headache inducing procrastination system.

But now, this dilemma is being broken by Johoty’s rapid prototyping for pogo pin connector technology. It is not a buzzword, but a tool that completely reshapes the development process.

Johoty will show you: How to complete design validation in 1/4 of the time? Obtain iterative samples at one-third of the cost and solve engineering problems using engineering language. Collaborate with empirical data, real-life scenarios, and technology implementation to assist you in making decisions.

Why is the traditional pogo pin connector development process no longer able to meet existing needs?

Let’s first look at the traditional processing method of mold opening, CNC, contradiction between electroplating, assembly, and precision applications:

- In 2024, over 63% of pogo pin projects among European and American clients will undergo at least 2 rounds of iterative sampling.

- The average sample delivery time is between 26 and 35 days. Each non-conforming rework resulted in an average increase of $740 in indirect engineering costs.

- Customers often provide feedback that design validation is always slower than market validation, which is the main reason for slowing down the speed of new product launches.

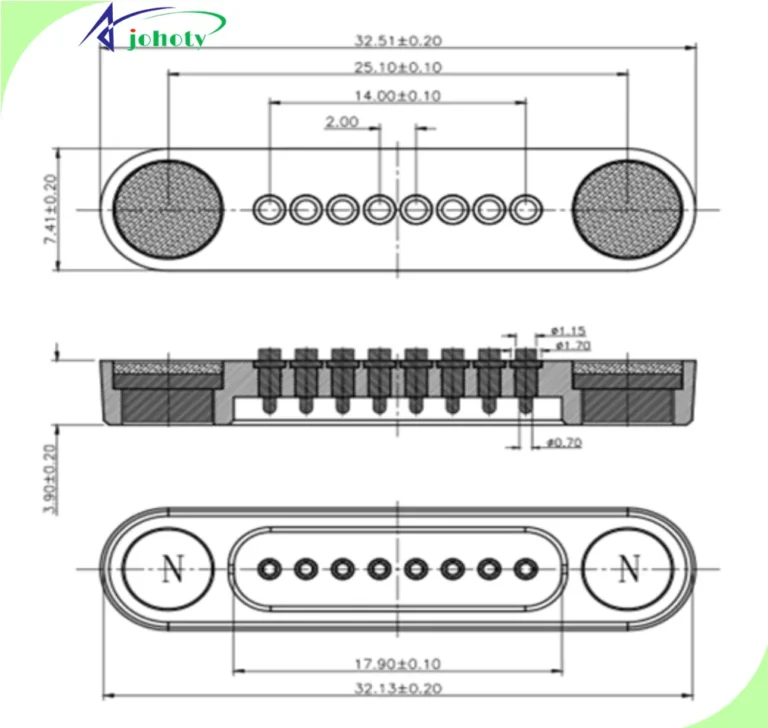

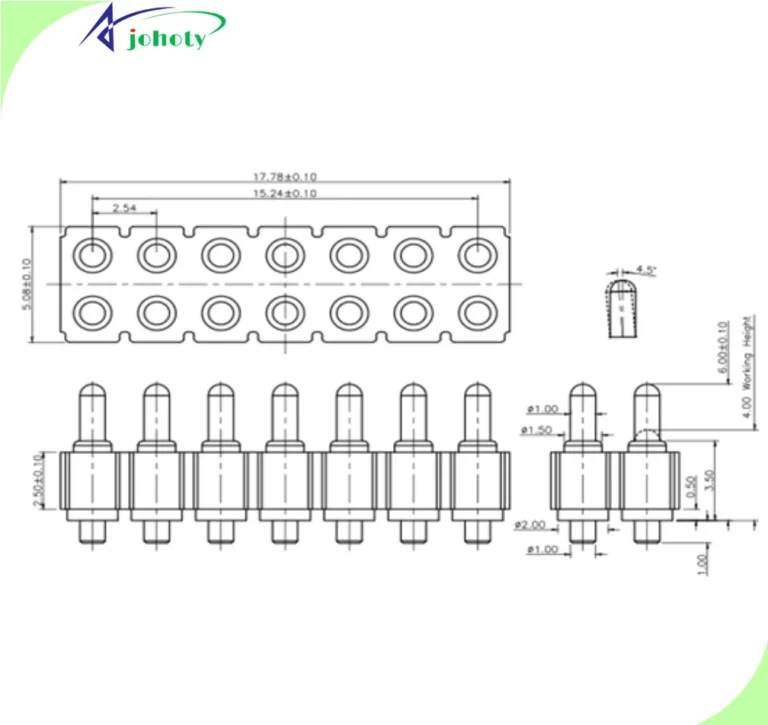

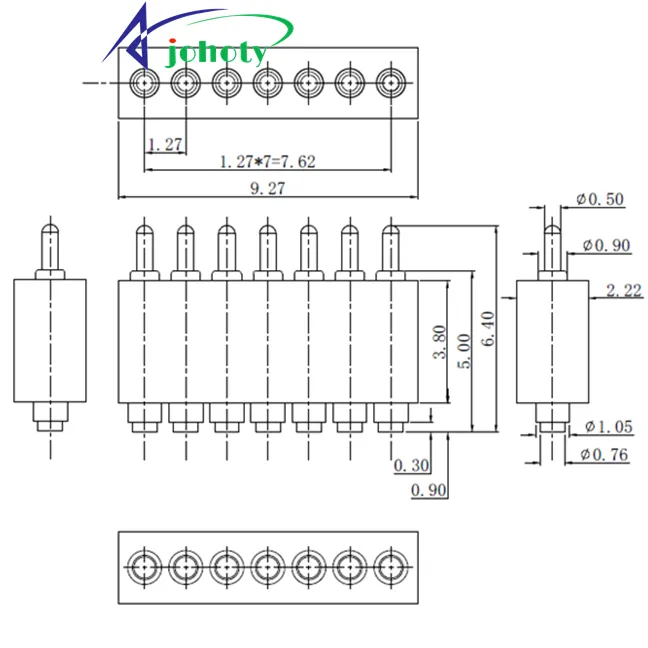

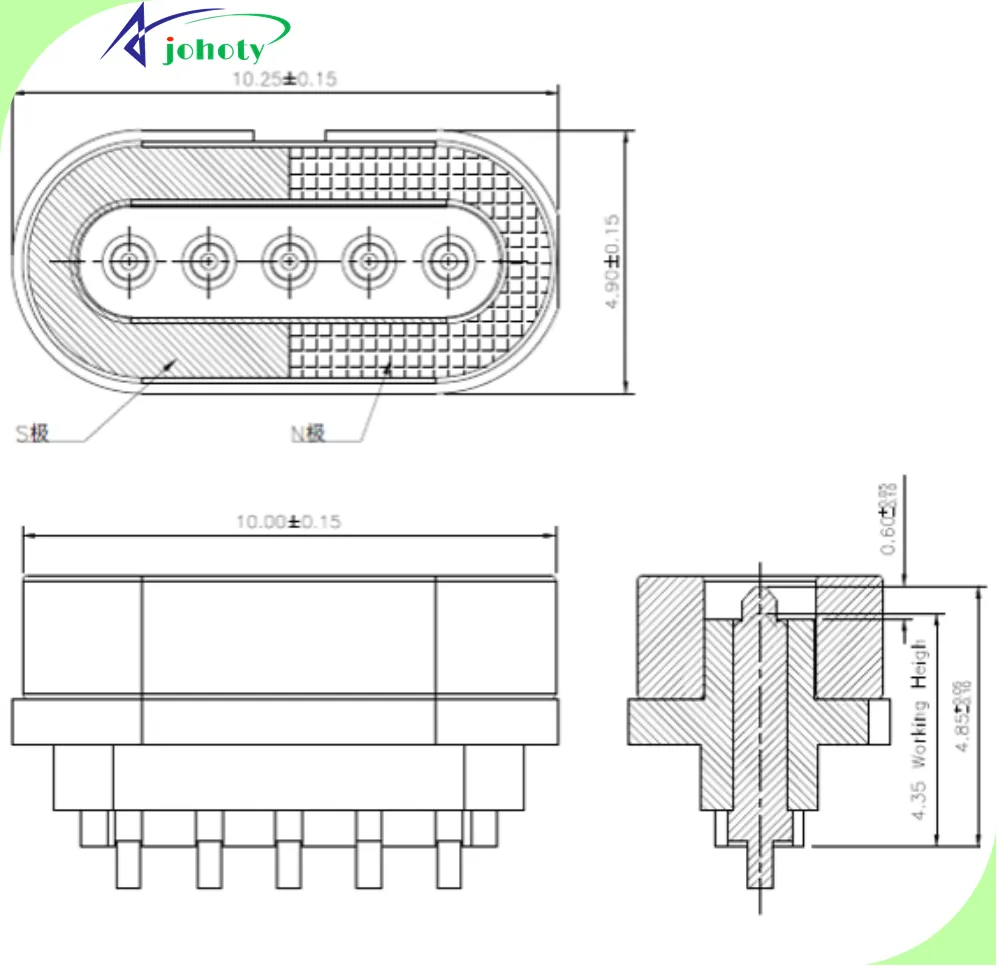

Pogo pin connectors are often used for:

- Medical terminal with mixed current signal transmission, intelligent wearable.

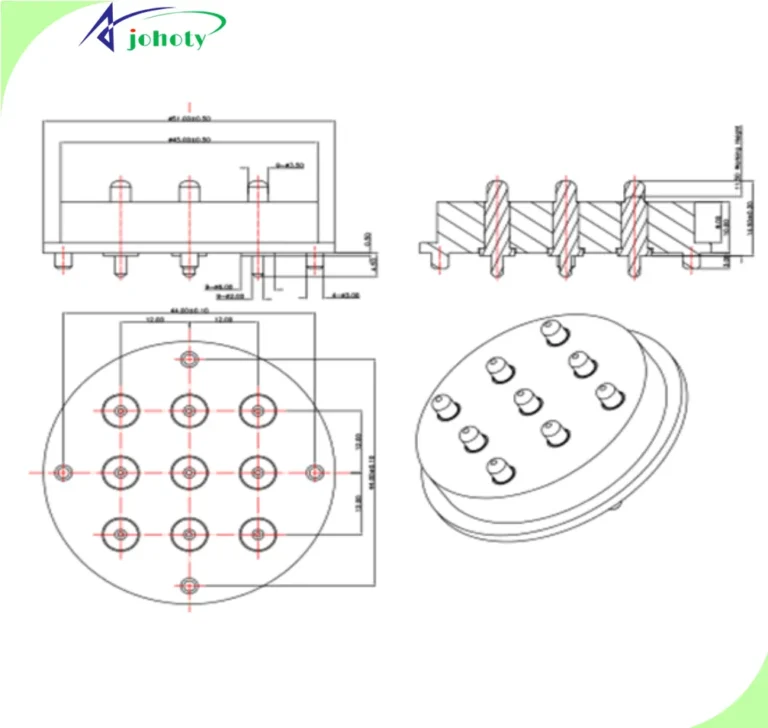

- High density assembly, micro space layout of drone interface, vehicle mounted radar module.

- ATE fixtures for frequent insertion and extraction testing, mass production testing stands.

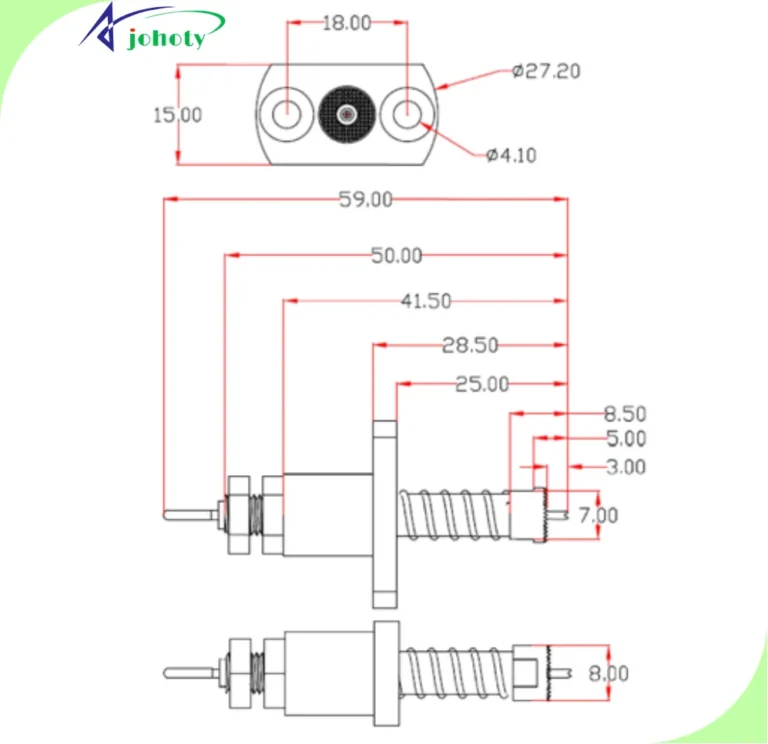

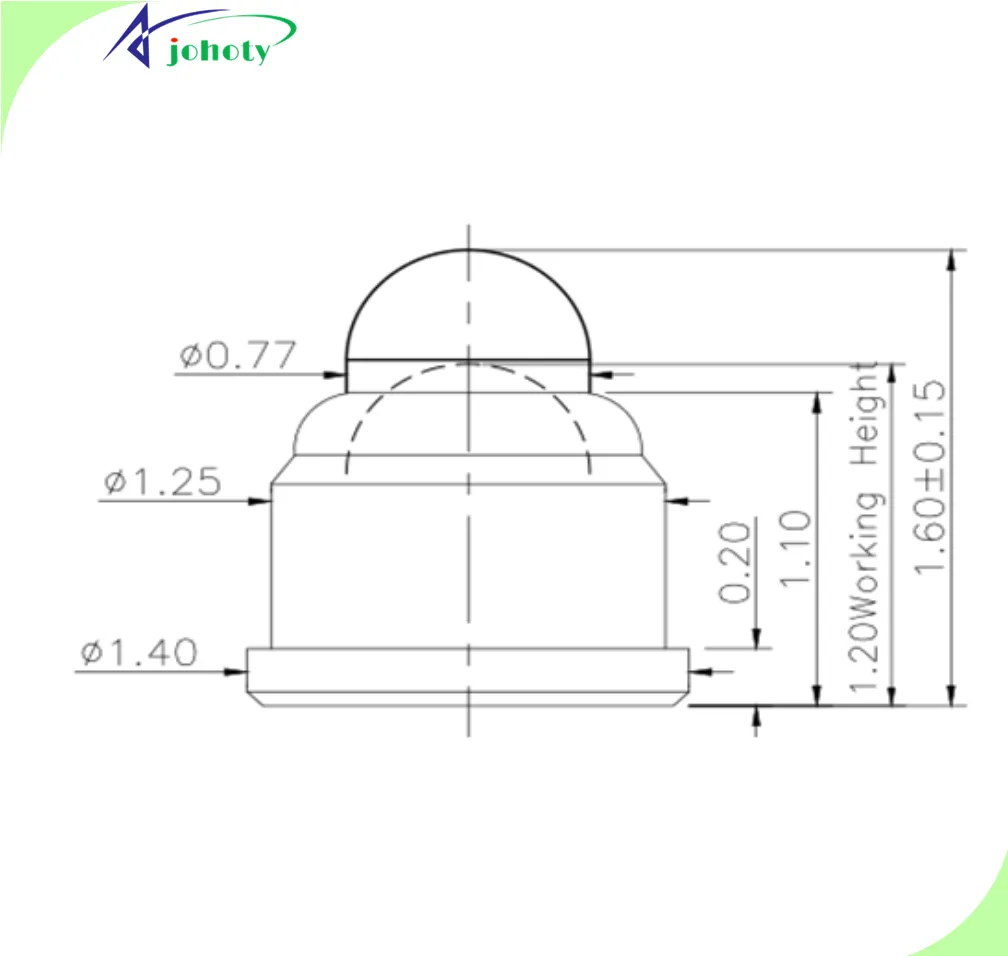

- These applications impose extremely strict customization requirements on the size, crimping strength, and resistance stability of pogo pins. Any tolerance that does not reach 0.05mm will result in intermittent contact failure of the circuit system.

You may not be able to rely on existing sample libraries or official products, and must customize them quickly. However, traditional craftsmanship has obvious natural defects in this rapid step.

Rapid prototyping for Pogo Pin Connector: What is true rapid prototyping?

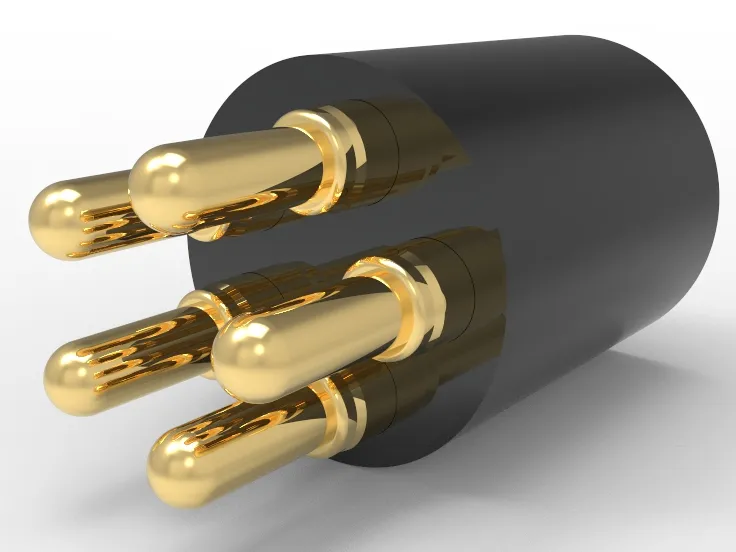

True rapid prototyping is not about easy production or fast 3D printing. A set of engineering level small batch customized processing procedures with consistency similar to mass production processes. Capable of high-precision tolerance control and able to output fully testable functional samples within 2 weeks. In the pogo pin connector industry, it is more like:

The rapid prototyping strategy adopted by Johoty covers the following key dimensions:

- Material consistency: Gold plating thickness equivalent to the mass-produced version (e.g. 0.1μm~5μm), spring wire hardness (≥600MPa).

- Structural restoration degree: Adopting adjustable multi-stage CNC prefabricated components to meet the compression displacement requirements below 1mm in microstructures.

- Multi scheme parallel verification: Allow 2-3 pin shapes and travel combinations to be provided at once for customers to compare.

A German testing equipment manufacturer once requested an interface module with a 5A high current, 2 signal pins, 10mΩ impedance, and 1.00mm spacing. Traditional processing requires the use of 3 different molds, costing nearly 5,000 euros.

And through Johoty’s rapid prototyping platform. Ultimately, 18 days were saved and 3,500 euros were saved in engineering costs.

- Complete process simulation and DFM correction within 3 days of design submission.

- On the 14th day, the first batch of samples (3 sets of structural schemes in total) were sent out.

- The customer completed the testing feedback and finalized the batch plan before the 19th day.

Technical advantage: not only fast, but also significantly improved verifiability

Many customers misunderstand rapid prototyping as a temporary product, which is a technical misunderstanding. In Johoty’s experience, the value of rapid prototyping lies in its performance under realistic simulated production scenarios.

Electrical consistency: The thickness of the gold plating layer for rapid prototyping is controlled within ±1mΩ for resistance fluctuations. It can simulate real current heating, signal interference, etc. The Johoty sample electrical testing report can be provided in real-time, with a testing accuracy of ±0.05mΩ.

Mechanical reliability: Johoty provides compression strength and fatigue life for each pogo pin. Simulate the performance degradation trend after 10,000 insertions and provide chart analysis. These indicators are not provided by most suppliers during the prototype phase.

Assembly verification capability: using housing that matches the customer’s actual structural diagram. The sample can be used for complete assembly structure verification. Expose structural interference or poor crimping in advance for industrial design teams.

Value presentation of rapid prototyping in the eyes of customers

R&D Director: We are not trying and wrong, but locking in risks in advance. Rapid prototyping enables risk mitigation throughout the entire project lifecycle and enables design revisions to be completed within controllable costs. It is the core means for R&D management to control the failure rate.

Engineering Manager: The sampling cycle has been reduced from 36 days to 14 days, which is one-third faster than the entire design cycle. A shorter verification cycle allows for more testing iterations to be conducted. Accumulate more data to ensure smooth project review.

Purchasing Manager: The sample cost has been reduced to 30% of the original, but we have achieved more than three times the market response efficiency. The controllable cost of small batch prototypes makes early-stage project exploration bolder and commercial risks lower. Rapid prototyping is beneficial for promoting the implementation of new series.

Comparison with traditional sample methods in terms of cost and time:

| Indicators | Traditional | Rapid Prototyping | Improvement |

|---|---|---|---|

| Initial sampling cycle | 25~30 days | 10~14 days | Shorten 65~75% |

| Average sample cost (per set) | 175~258 USD | 54~97USD | Reduce 60~70% |

| Process consistency | Medium requires resampling | High, suitable for electrical/structural/fatigue verification | Increase by 2 times |

| Proportion of successful entry into mass production | 68% | 93%(Johoty Customersample) | +25% |

This is not a fuzzy estimation. It is a horizontal analysis based on 164 European and American projects served by Johoty in 2024. Data can be traced, and decisions are based on reason and evidence.

Feedback from real customers

American communication module companies:

Goal: Design a pogo pin connector that is resistant to high vibrations, operates at temperatures of -40~125℃, and can be plugged 20,000 times continuously. The requirement is for on-site module hot plugging.

Challenge: No ready-made products available. The ordinary sample still cannot pass the low-temperature aging test after 2 rounds.

Rapid prototyping solution: Johoty offers 3 types of spring wire/structure combinations for 14 day sampling. The customer’s laboratory passed the thermal shock test once.

Feedback: You are the first manufacturer to pass our three temperature cycle test on the sample.

University medical research equipment teams in the UK:

Goal: Develop a wearable EEG signal acquisition device interface that balances signal stability and lightweight.

Problem: The existing connectors cause interference peaks, affecting data sampling.

Solution: Rapid prototyping optimizes the shielding cover material and pogo pin layout. Send samples within 14 days and complete three rounds of iterations within 20 days.

Result: The data error decreased by 42%, and the scientific research report was successfully published.

Conclusion: Design validation is no longer a gambling game of investing first and then correcting

If design is an art, then validation is a rational competition. Rapid prototyping for pogo pin connectors is not just a technical term. It is a reshaping of the pre decision-making ability of the entire engineering chain.

Everyone is pursuing zero waste and zero delay. Many customers will demand time and cost savings from rapid prototyping. Ultimately helping customers improve the speed of new product launches, project winning rates, and customer trust.

If you are facing the following situation: design versions often undergo repeated rework during the testing phase. The sample delivery time cannot meet the requirements for synchronous launch of new projects. Need low-cost trial and error multiple solutions but do not want to use the mold budget. So now it’s the right time to learn about Johoty’s rapid prototyping solution on pogo pins or pogo pin connector.

+86 13590816656

+86 13590816656 +86 13590816656

+86 13590816656