Right angle connector 90° SMT Fits Compact PCB Perfectly with Stable Power Flow and Long Life Performance for Critical Use. Discover More Now

Introduction: Right angle connector in compact PCB space

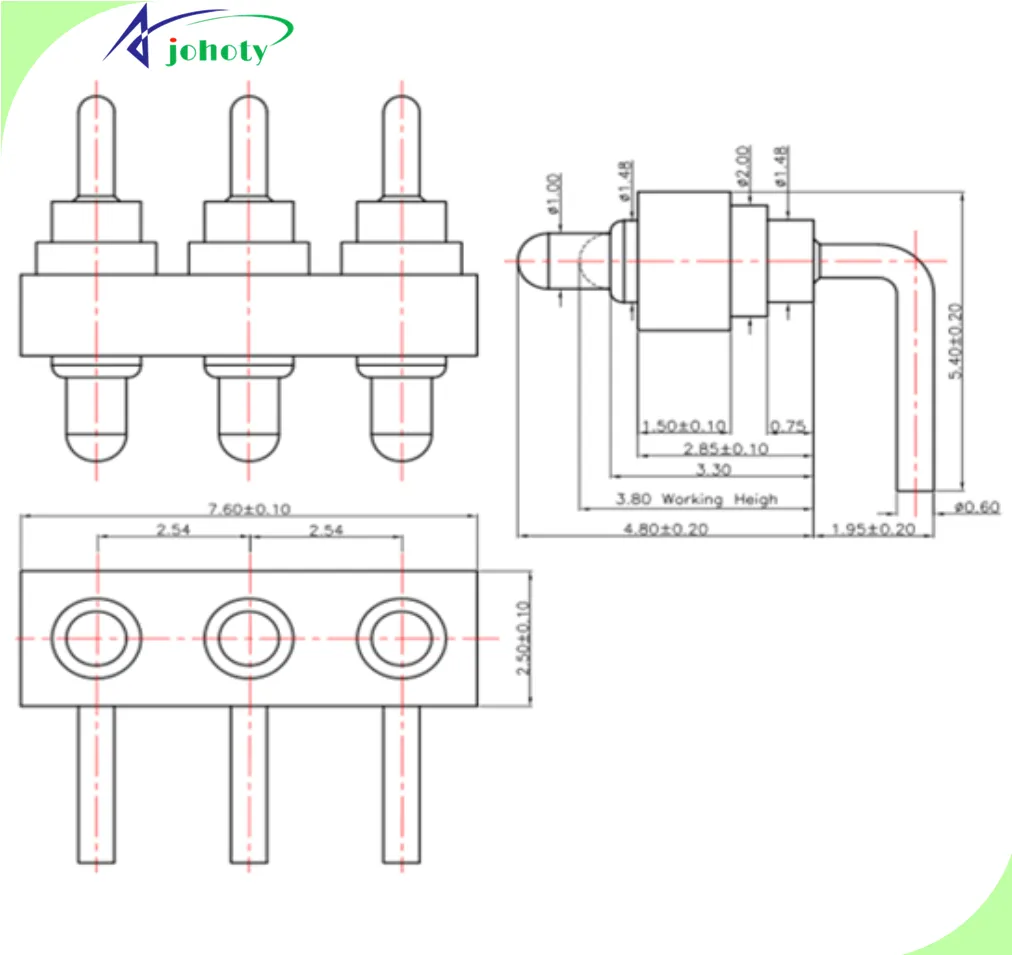

The right angle connector is a geometric 90° angled design. Many engineers contact Johoty for electronic system on stability and long-term operation. Most customers hope to achieve compact, lightweight, and high-performance PCBs. How to achieve stable current transmission in a limited space is a challenge that the customer’s R&D team must face directly. Johoty’s 90° SMT structure right angle connector is the key to resolving this contradiction.

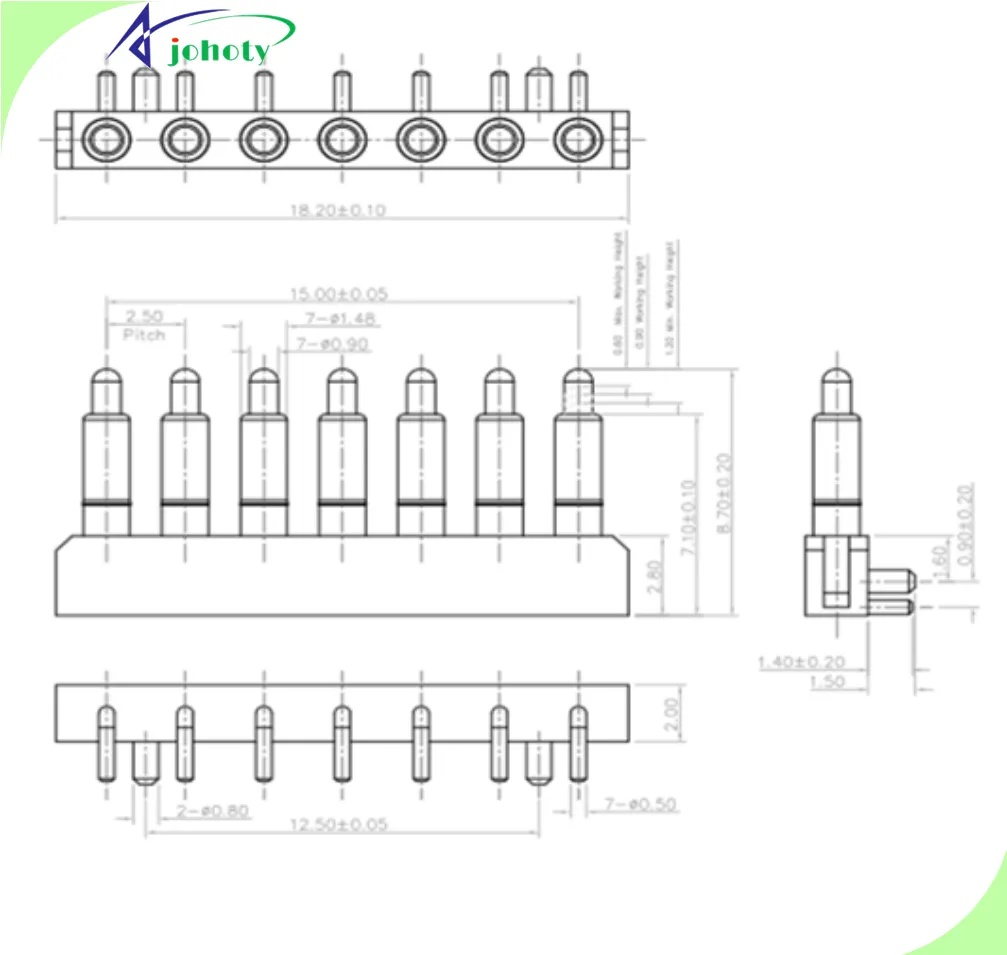

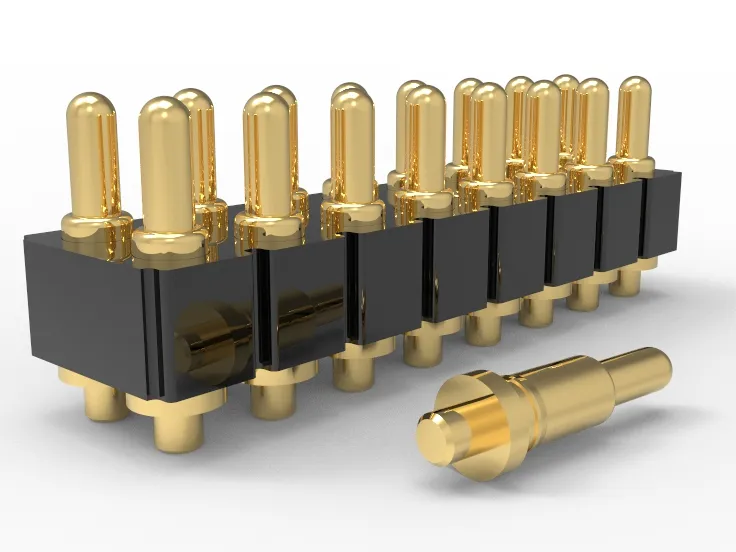

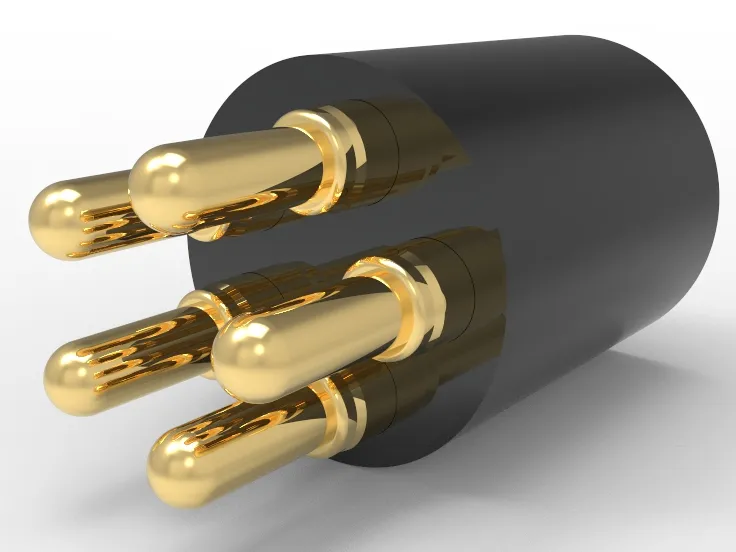

Johoty’s pogo pin achieves smooth current flow in a small size. Ensure the long-term lifespan of customer equipment systems in critical applications. It is commonly used for stability of high-speed signals and heat control in high current environments. Johoty can provide precise design and reliable craftsmanship for this pogo pin connector. For engineering applications that pursue extreme stability and high cost-effectiveness, it is worth your in-depth understanding.

Space advantage of right angle connector in compact PCB design

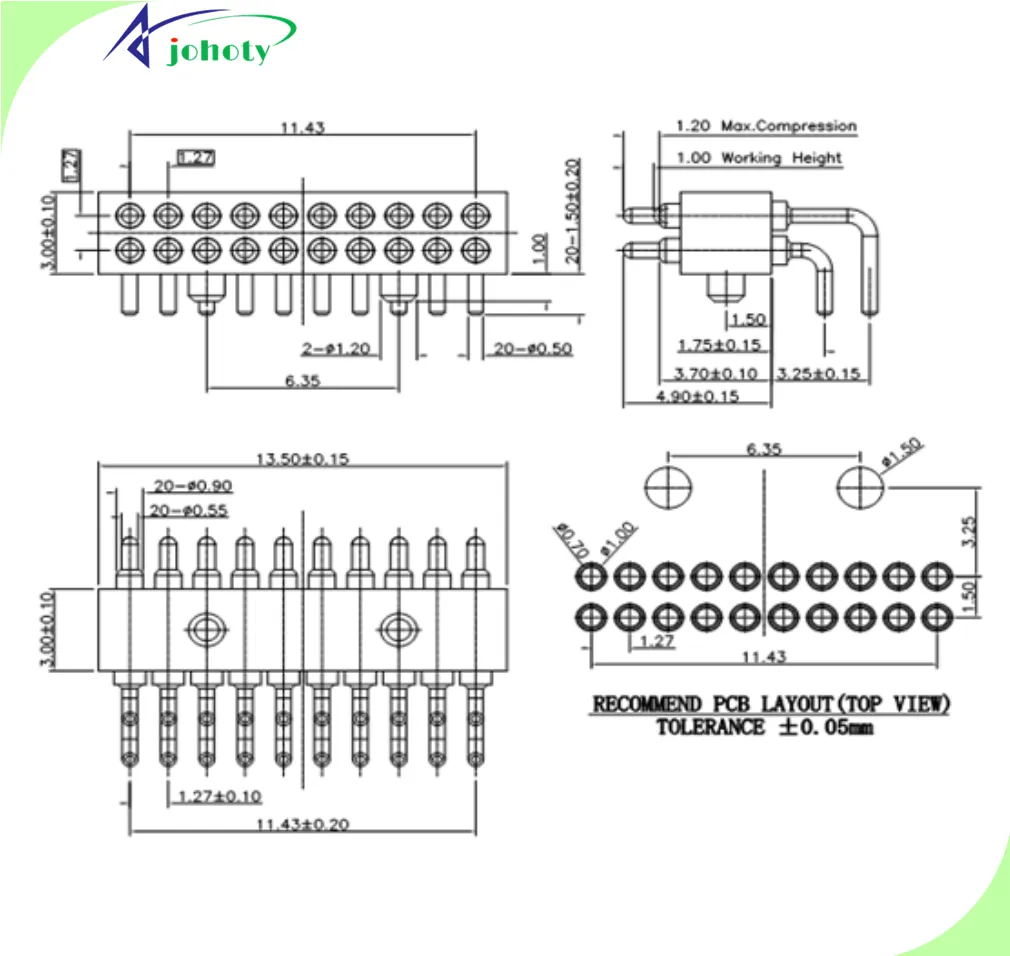

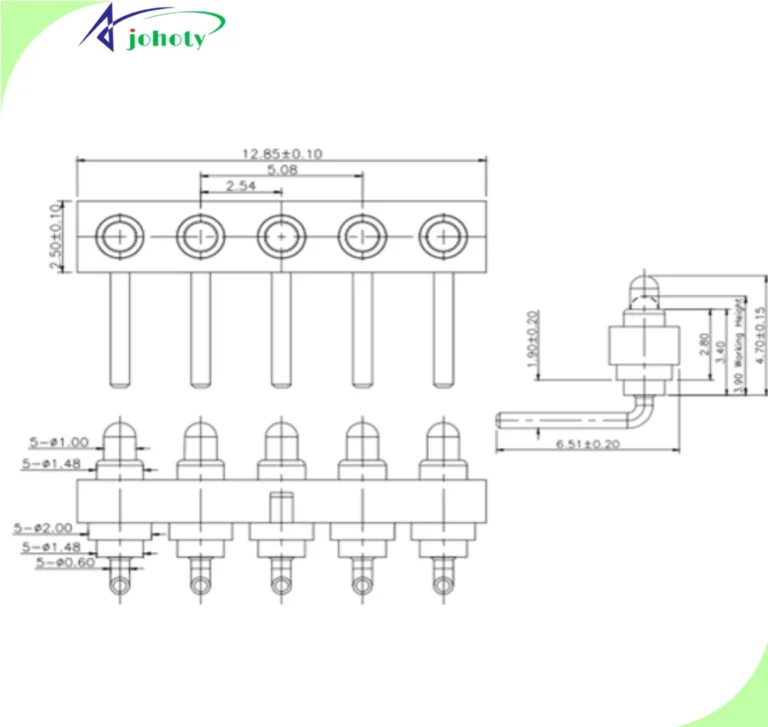

As circuit boards become smaller and the number of components continues to increase, space becomes the primary contradiction. The 90° structure of the right angle connector can shift from vertical to horizontal layout without the need for additional space expansion. The compact PCB using 90° SMT connector saves an average of 22% in overall wiring area compared to the direct insertion solution. This brings about a reduction in volume and minimizes bending losses in the current path.

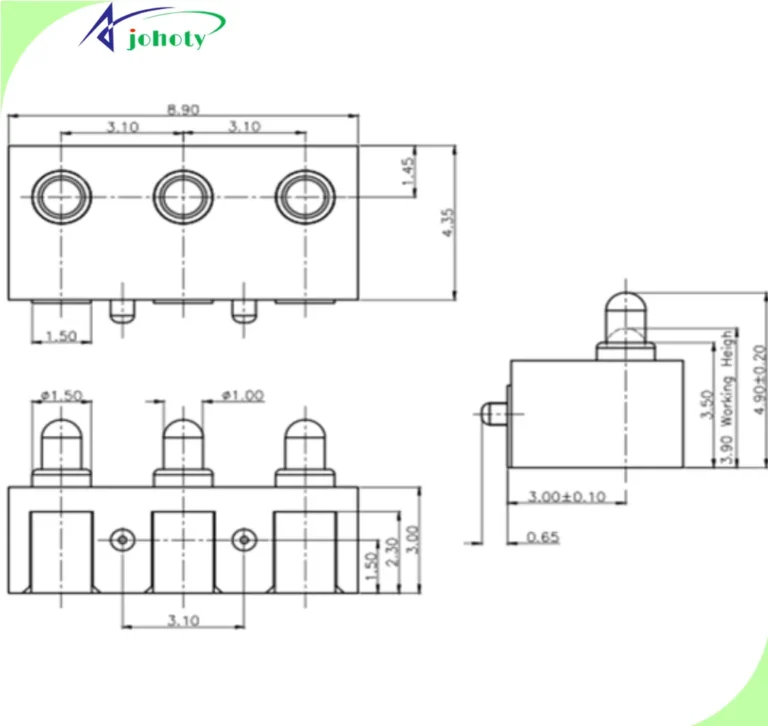

Many engineers in medical systems, robotics, and aviation systems purchase Johoty’s right angle connector. They provided feedback that this space saving can help maintain more reasonable heat dissipation channels within the system. Thus achieving more stable temperature performance in high-power applications.

Right angle connector and current stability: from micro contact to macro lifetime

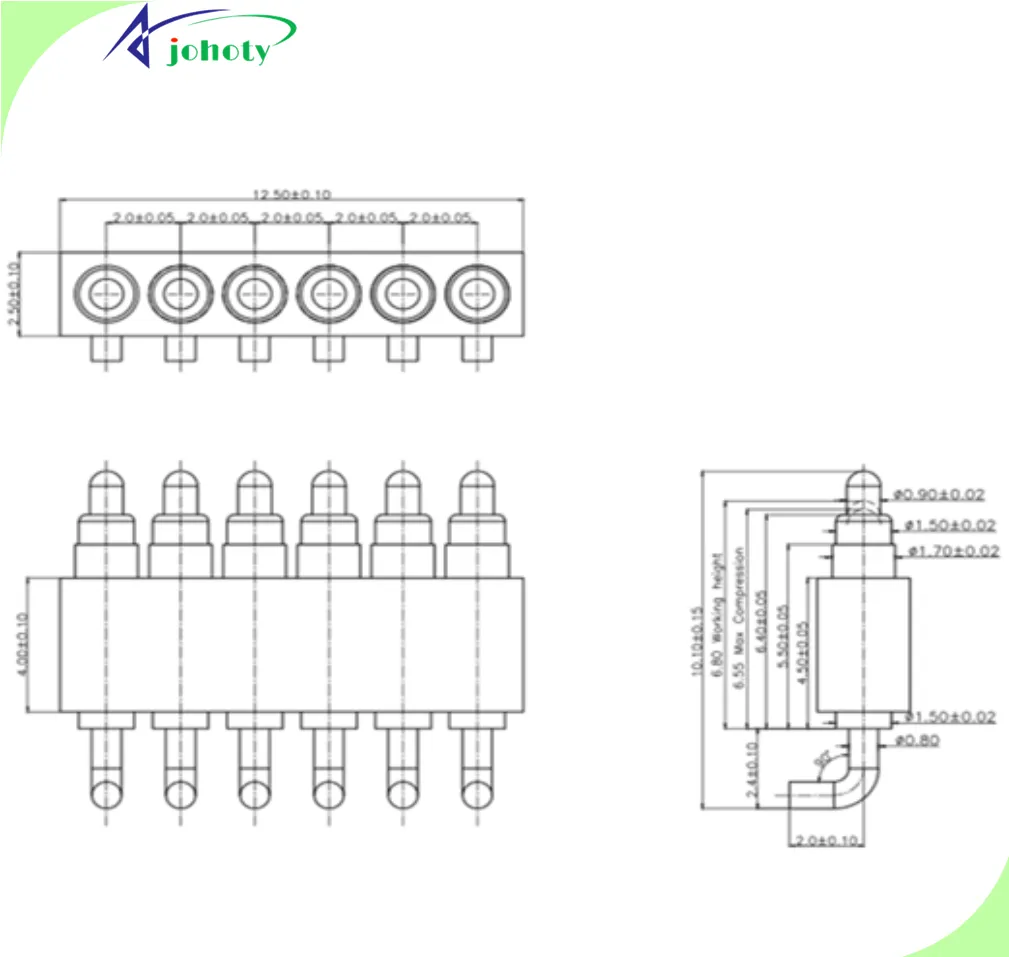

The transmission of current in a conductor is not an ideal straight line. It is often affected by contact resistance, material microstructure, and interface oxidation. During the design of the right angle connector, the contact resistance is controlled within 10mΩ by increasing the thickness of the gold plating layer on the contact surface.

A PCB with a rated current of 5a will reduce the contact resistance from 20mΩ to 10mΩ, and the power loss will be reduced by 0.25w. Although the value may seem small, on densely arranged circuit boards, the overall temperature rise can be reduced by an average of 3.8℃. Lower temperatures directly extend the lifespan of the device. Ensure that the connector remains stable even after over 100,000 cycles of insertion.

Design a cost-effective right angle connector

High cost-effectiveness means reducing costs and balancing performance and cost. Johoty’s customers often demand high quality while also demanding the best price. I believe you, like most customers, hope to solve problems while also demanding good quality and affordable prices. The 90° SMT process of the right angle connector can reduce the complexity of the mechanical structure and lower the welding pressure in the assembly process. Compared to traditional direct insertion, its production cycle is shortened by about 15%, and the defect rate of solder joints has decreased by 32%.

This is the improvement of production line efficiency and the reduction of maintenance and rework risks. Johoty’s customers have provided feedback that stable electrical performance can indeed reduce system downtime during long-term operation. The operational costs of hope have also been indirectly saved. For customers’ high-frequency and high-maintenance equipment, MTBF can be extended from one month to 2-3 months. Overall, Johoty’s right angle connector meets both high-quality requirements and budget expectations.

Signal integrity of the right angle connector

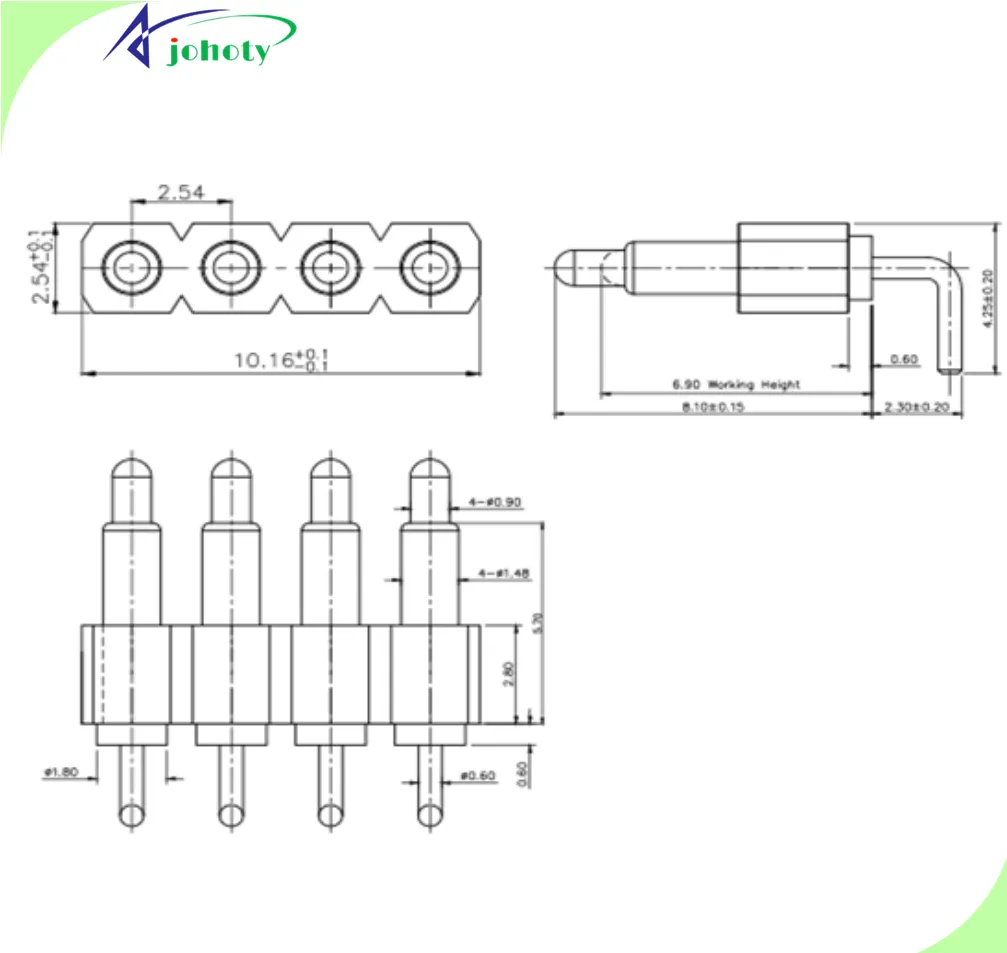

Impedance matching is an issue that customers cannot bypass in the high-frequency signals of Johoty’s client devices. Our right angle connector controls the length of the pogo pin and the geometric parameters of the corner transition zone. We can control the impedance deviation within ± 5% and achieve a contact impedance of 15mΩ or even 10mΩ. Our Norwegian client has customized a 4.00mm right angle connector. In the customer’s RF circuit, the signal return loss is reduced by 7dB in the 2.4GHz frequency band.

Customer feedback: The signal is less reflected during transmission and has higher fidelity. Reduce image jitter in video signal transmission and lower the bit error rate in the data link. The equipment can work stably under high temp. and pressure conditions.

The value of combining the right angle connector with the pogo pin connector

Johoty’s pogo pins are suitable for dynamic contact and high-frequency testing. The right angle connector is responsible for fixed connections and long-term current transmission. They often complement each other in applications. Our Brazilian medical equipment company has customized a 7-pin right angle connector. 7 tail pins are soldered to 7 through holes on the PCB. Then, the plunger and tube are parallel to the PCB and connected to the 1.27mm female end of the pitch.

After repeated module replacements, the customer’s medical equipment maintained stable power supply and maintenance efficiency increased by 41%. The customer system remains efficient and reliable at all stages from R&D prototype to mass production. Fully meet the space constraints and system stability of clients.

Long term performance of the right angle connector

Data centers, electric vehicles, and aerospace systems have extremely high stability requirements for connectors. The application cases of the right angle connector 90° SMT in these industries show that its average lifespan exceeds 12 years. In the EV BMS, it helps achieve high current up to 50A per pin and low loss transmission. In the server motherboard, it maintains data stability under 24-hour continuous operation.

More importantly, the heat resistance of this pogo pin connector is very good. It can maintain a contact resistance of no more than 15mΩ within the temperature range of -40℃ to 125℃. This performance is incomparable to traditional direct insertion solutions.

Additionally, when current passes through the connection point, Joule heating is inevitably generated. Pogo pins of the right angle connector have been optimized for heat flow distribution through R&D simulations. When passing through a current of 3a, the temperature rise of the pins is only 12.5℃. Under the same conditions, you can see 18.7℃ for its temperature rise. The reduced temperature rise not only ensures electrical stability, but also slows down the aging rate of plastic insulators. In an accelerated aging test, this design extended the lifespan of the insulation layer by nearly 1.5 times.

The reliability and high-voltage adaptability of the right angle connector

The introduction of SMT technology enables pogo pin connectors to better integrate with PCBs during reflow soldering. The pogo pin of the right angle connector can be precisely matched with the solder pad. During the welding process, the tin solution can be evenly covered to avoid virtual soldering or cold soldering. The X-ray inspection showed that the qualified solder joint rate reached 99.3%. This high yield almost does not require rework during mass production. Johoty is fully capable of improving the delivery efficiency of the entire project for customers through the right angle connector.

In addition, insulation design in high-voltage environments is another core indicator of connectors. The right angle connector introduces reinforced ribs and insulation slots in its structure, increasing the creepage distance by 18%. At 1,000V, Johoty’s pogo pin connector has no breakdown and a leakage current of less than 0.1mA. This provides safety redundancy for critical industry applications. In the medical imaging equipment of customers, the stable pressure resistance directly determines whether the imaging system can maintain safe operation for a long time.

Conclusions: Right angle connector from connecting to the future, contact Johoty immediately

With the popularity of 5G and electric mobility, Johoty’s customers often demand higher frequencies and currents in connectors. Many customers need to combine the right angle connector with pogo pins. Johoty is required to implement a scalable system architecture through modular thinking. We believe right angle connector will account for 28% of the compact PCB connectivity market. For the customer’s R&D team, we can help you achieve shorter development cycles and lower validation costs.

The right angle connector is not just a 90° angle, it is the cornerstone of stable operation in high-performance systems. Achieve the space savings, stable current, optimized heat dissipation, and long lifespan you require in compact PCB design. This has been verified by over 20 clients of Johoty. Combined with Johoty’s pogo pins, the right angle connector can provide complete support for complex engineering applications. If you wish to achieve higher reliability and cost-effectiveness in future projects, please contact Johoty immediately. Let precise and reliable right angle connectors bring long-term stability and security to your system.

+86 13590816656

+86 13590816656 +86 13590816656

+86 13590816656