Space Saving Starts With Custom Pogo Pins. Cut Board Clutter And Boost Reliability In Tight Designs. Engineer Smarter, Not Harder, Offer Now.

Introduction: Space Saving is A Design Revolution Starting from Custom Pogo Pins

Space saving is not just an engineering term for provincial and local areas. It often requires integration into the main control module of new energy vehicles or medical ECG signal detection terminals. A 0.10mm space redundancy can successfully deploy a heat dissipation unit or isolate a high-speed signal. This is not an exaggeration, but a reality in high-density PCB design.

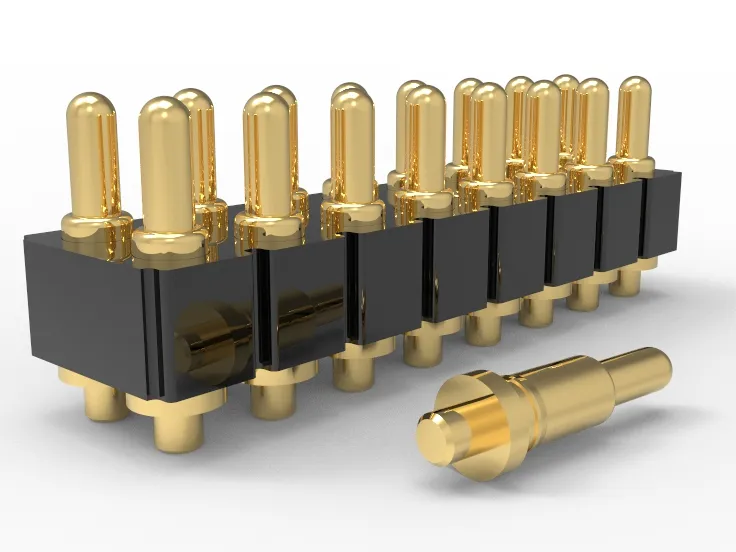

We are in an era where space is being compressed inch by inch. The integration of modules continues to improve, and connectors are no longer just connections. It must be a solution for system layout. Custom pogo pins often require a tolerance control of 0.01 millimeters. This changes the connection itself, redefines system stability, thermal control, and cost structure.

Johoty will delve into pogo pin disassembly with only a few cubic millimeters based on two types of cases: EV and ECG. How to achieve over 30% space saving and achieve a balance between high reliability and mass manufacturing. You will see real data and processes that can be perceived by engineers. And most importantly, how to find the lever for system optimization on a single pogo pin?

How can Space Saving become the starting point for electrical architecture reconstruction in EV control modules?

The layout challenge of the EV’s main control board has never been so sharp. To accommodate high-voltage control, drive module, communication interface, and sensor access. The size of each connector directly affects the heat dissipation path, EMI treatment, and EMC isolation layout.

Traditional pin connectors are extremely difficult to accommodate in small spaces. Usually, it is necessary to reserve 3-5 millimeters of space for plugging and unplugging operations. On a control unit that is only the size of a palm, this is equivalent to sacrificing an entire chip’s position.

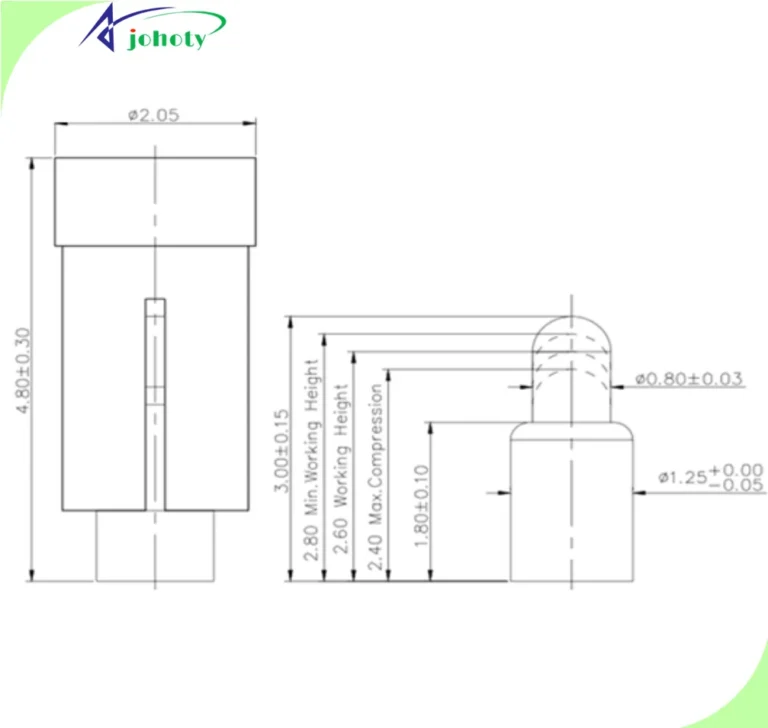

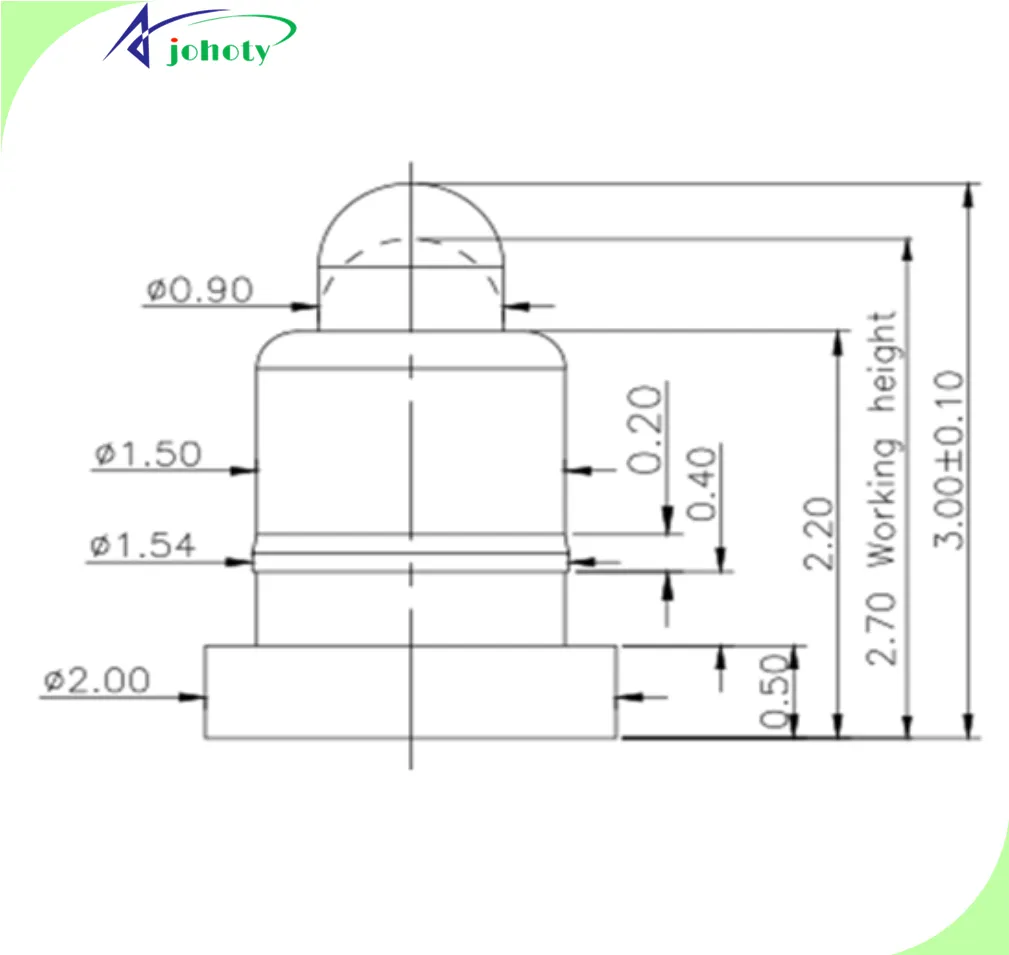

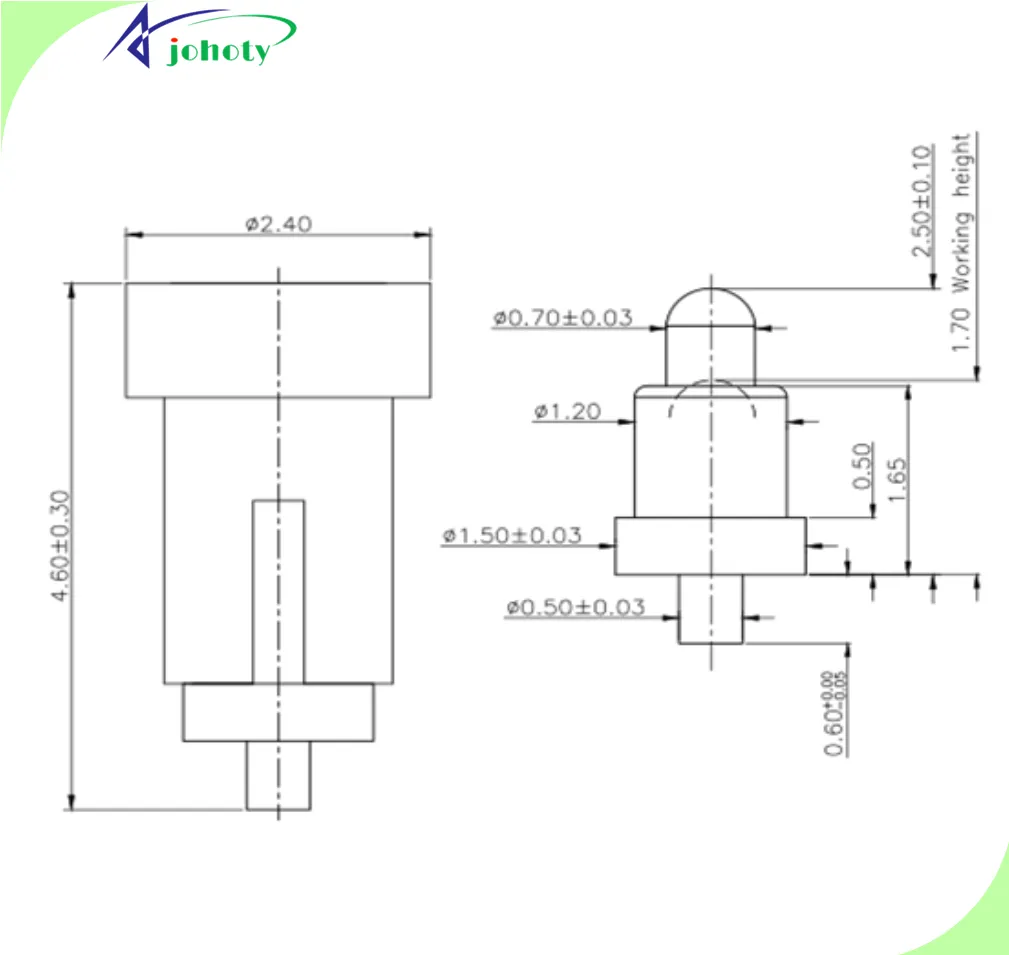

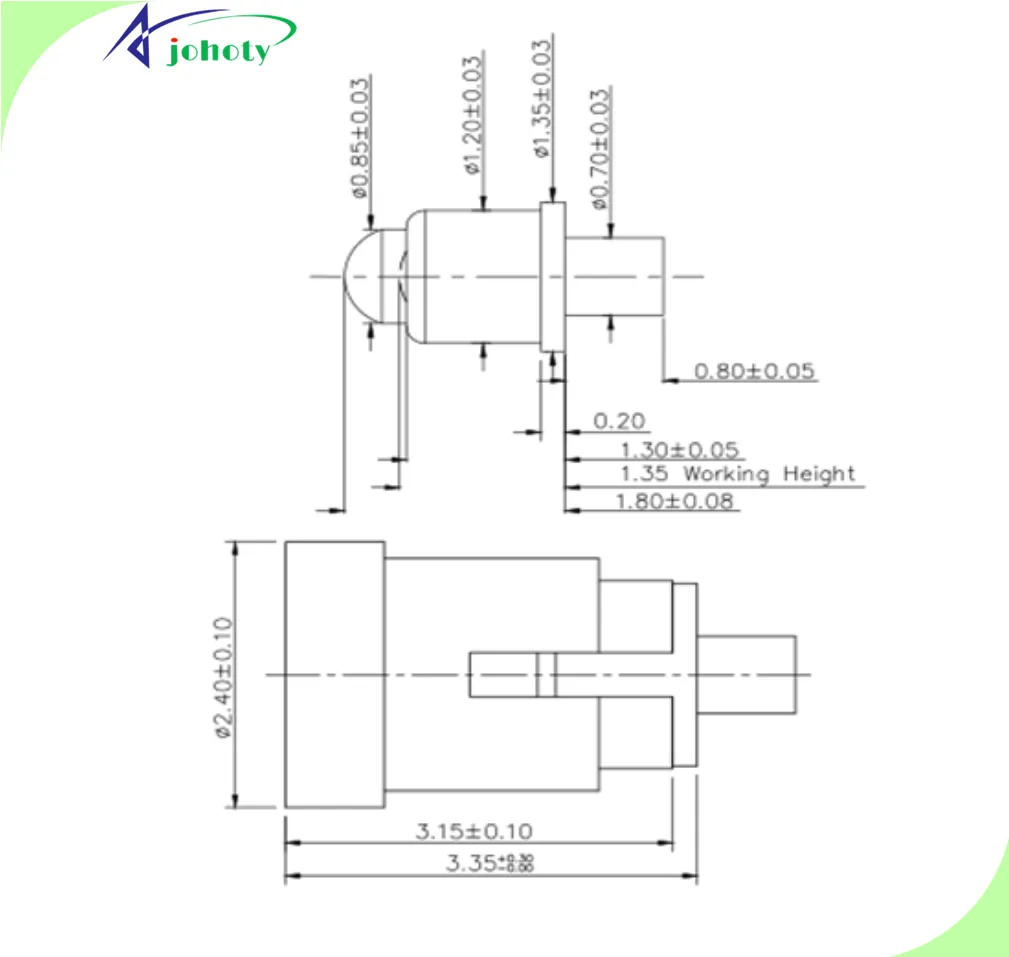

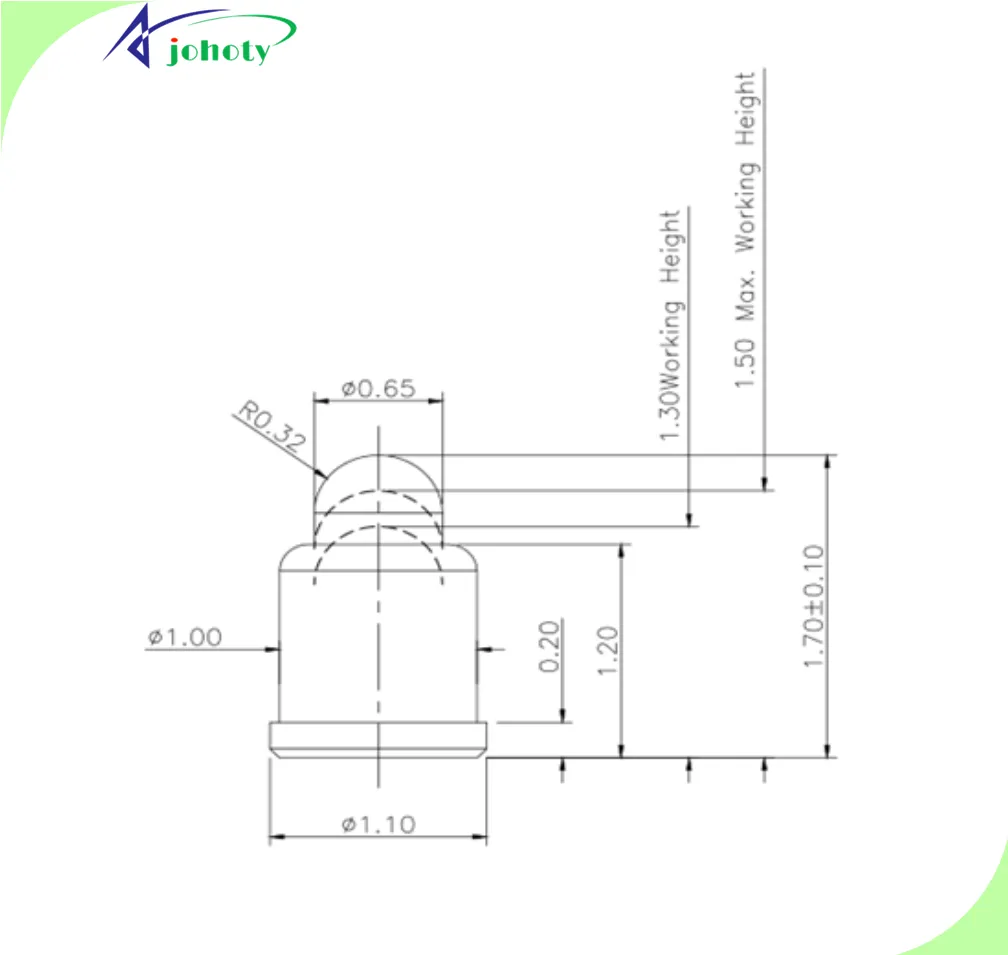

The contact structure of the customized pogo pin adopts a no insertion and extraction force scheme, combined with hidden vertical pressing. Reliable connection can be achieved with only 1.5mm vertical space, saving over 33% of space. In addition, Johoty achieves high reliability requirements in EV environments through the following optimizations:

- Contact resistance is controlled within 15 milliohms to ensure transient stability of 300A pulse current.

- The spring has a lifespan of over 100,000 compression cycles and is designed to withstand signal wear during repeated charging and discharging of EVs.

- 360° gold-plated anti-oxidation shielding structure, with corrosion and vibration resistance levels tested according to ISO 16750-3.

All of this is not for the sake of being smaller, but for a more stable, cooler, and more flexible rearrangement of the main control architecture. Space saving become the trigger point for architecture optimization, rather than passive adaptation.

How to achieve true Space Saving for ECG signal acquisition devices through customized design?

The update pace of ECG collection terminals is faster than we imagined. From portable wristbands to multi lead collectors, they all revolve around one goal: smaller, lighter, and more accurate.

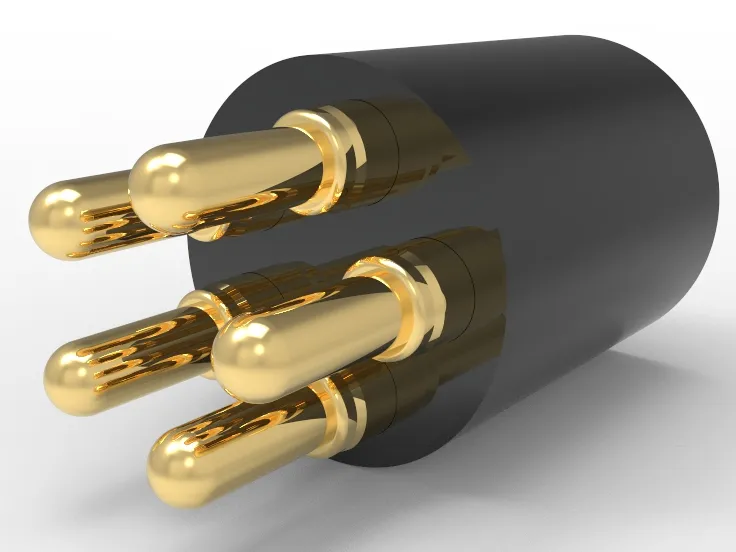

Traditional pin connectors form a ribbon like arrangement in ECGs with 10 or more conductors. Not only does it occupy valuable space at the edge of the PCB, but it also causes signal crosstalk and EMC issues. The distance between conductors is greater than 2.50mm. ECG signals often experience baseline drift during transmission due to unstable contact or long paths.

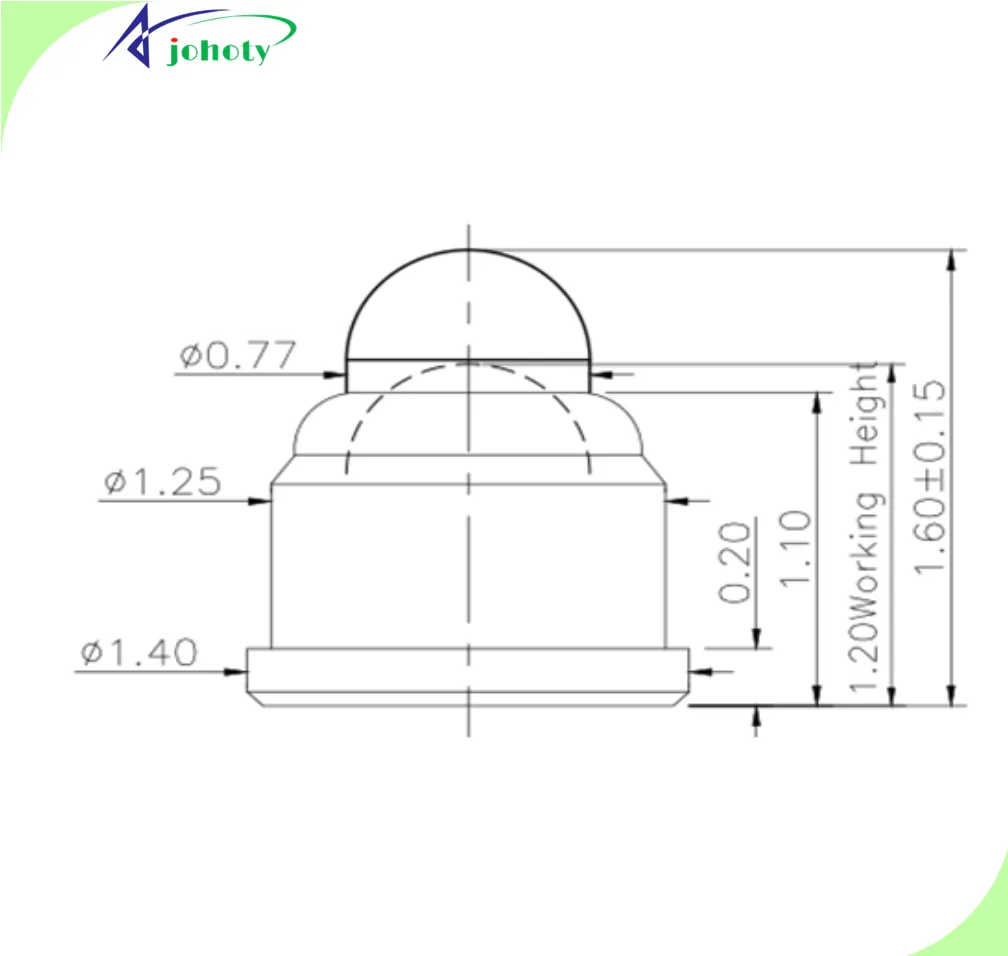

The custom pogo pin provided by Johoty has a dual-point contact structure. Compress the single path to a width of 1.20mm, saving 42% of the layout space. Simultaneously customize and design independent shielding shells, with each signal independently grounded, greatly reducing high-frequency crosstalk. In real testing:

- Baseline fluctuation of ECG decreased by 27.6%.

- Overall thickness of the equipment has been reduced from 15mm to 8.4mm.

- Pogo pin modules have passed a 5-year long life electrical performance acceleration test without any contact degradation.

All of this is built on genuine custom manufacturing capabilities. Each pogo pin is the optimal structure for the number of leads, signal type, and device form.

Space saving can be converted into cost savings

Space saving not only reduces the size of terminal devices, but also brings a series of manufacturing advantages. An EV module has been compressed from a thickness of 14.00mm to 9.80mm. The original design using CNC aluminum shell has been changed to an injection molded composite shell. The cost of a single shell has decreased by 18.2%.

By using the vertical pressing process of pogo pins, traditional connector soldering processes are avoided. The entire PCBA testing and assembly time has been reduced by 32 seconds per piece, equivalent to assembling an additional 108 devices per hour.

You don’t need to compress the BOM or use cheap components, just choose a customized solution for the connection method. There is a measurable positive feedback on the efficiency and cost structure of the entire production line. The engineer’s time, production pace, and quality inspection repair rate are all indirect spatial economic dividends.

Space Saving in Engineering Design is not an extreme challenge, but a multiple-choice question

Many designers often make difficult choices between standard connectors and customizable connections when initially designing connector layouts. Choosing standardization means fast design speed and low risk. But in the end, it may be forced to remake the board due to issues such as space overload and signal attenuation.

Choosing custom pogo pins does not mean giving up universality. Johoty’s solution is to provide highly customized layout packaging based on standard modular structures, such as:

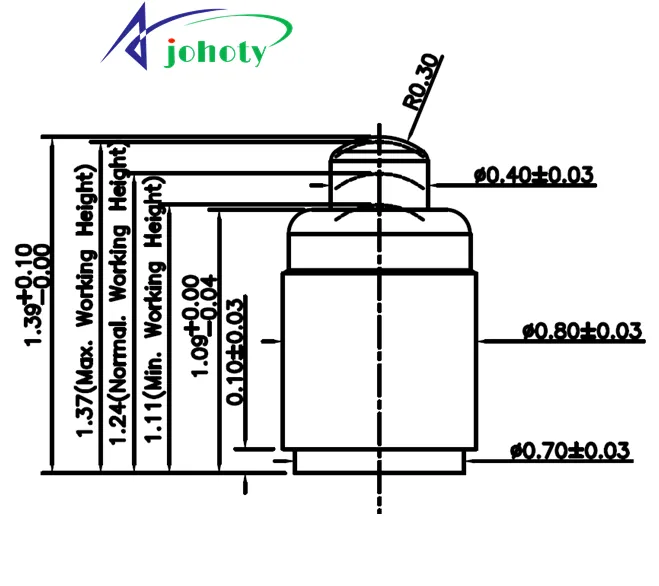

- Plumger tip can vary within 0.3-1.5mm.

- Adjust spring force flexibly based on contact pressure requirements.

- Contact point material can be flexibly selected from CuBe to alloy NiFe.

You can combine the electrical and structural parameters you need like building blocks without having to pay a high price for non-standard products. The essence of space saving is the degree of freedom in system reconstruction.

Not smaller, more reasonable: How do space saving bring about system level thermal management optimization?

One of the biggest challenges of compact layout is concentrated heat generation. Traditional pin connectors often cause interruptions in the heat dissipation path due to the gap between the plug structure and the housing. Connectors often become thermal bottlenecks near electric vehicle controllers or medical terminal chips.

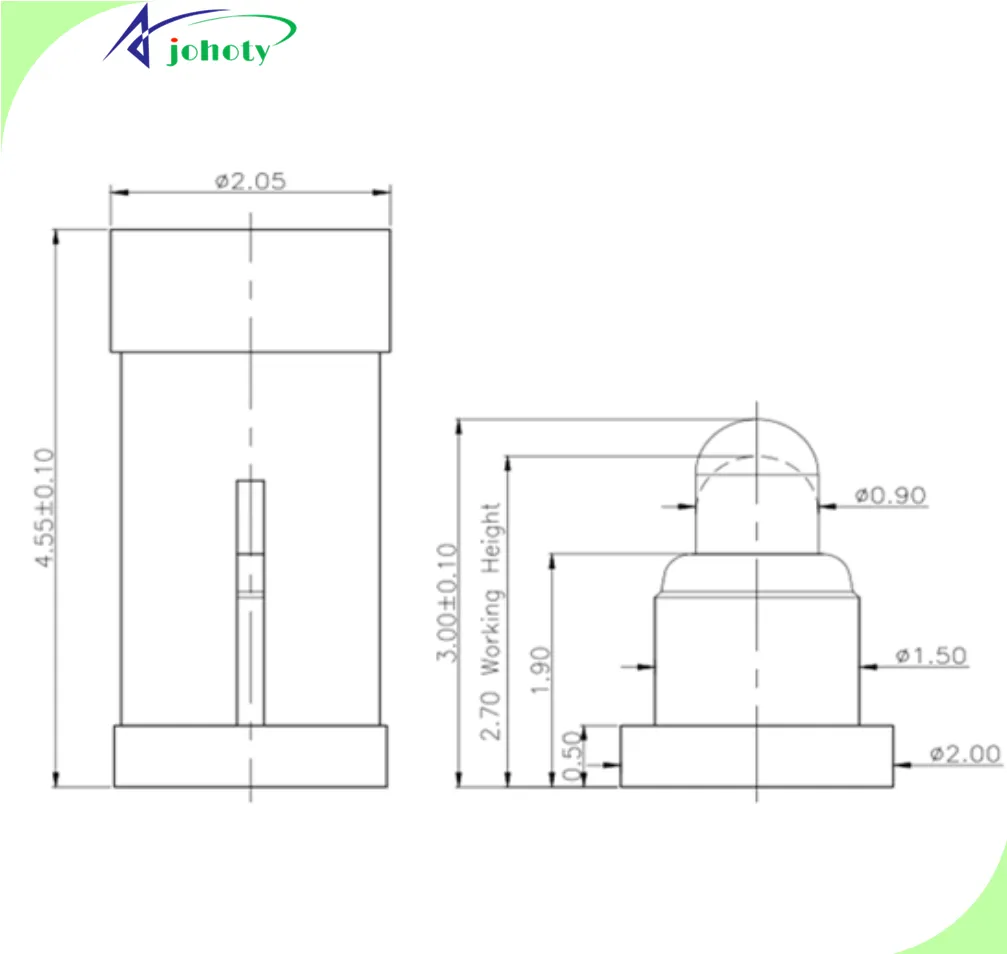

Johoty’s pogo pin adopts a high thermal conductivity contact structure plated with gold or Ni/Pd alloy. Combined with the copper tin plated conductive chassis of the spring base, the thermal resistance of the connection point is controlled below 4.7℃/W. Under the same current, heat is more easily transferred to the casing or radiator rather than accumulating at the contact point.

In the car MCU module of British customers, pogo pins replace traditional needle arranging. The thermal peak of the core chip decreased from 78.5℃ to 70.2℃ and maintained a thermal stability of ±1.2℃. This greatly improves the lifespan of the chip and system stability. In other words, space saving is not a stacking game, but a reconstruction of the heat dissipation flow field.

Consistency between vibration resistance and lifespan of Space Saving

In EV and ECG applications, vibration testing is not just a process. It determines whether the connector is disconnected during driving and whether the signal is lost in the hospital ambulance.

Johoty adopts a symmetrical bidirectional spring loading structure, and the vibration frequency of pogo pin is as high as 200Hz. Under the condition of displacement amplitude ±0.50mm, the contact resistance change is still less than 3 milliohms. It can effectively alleviate micro motion wear and maintain stable contact performance even after 100,000 presses.

In addition, the controllable process of coating thickness and optimization of substrate material ratio. Johoty pogo pin showed no corrosion during extreme humid heat (60℃, 90% RH) testing. Continuous operation for 1,000 hours without performance degradation.

So, these space saving solutions are not just small. They promote system evolution through a three-dimensional integration of reliability, thermal management, and electromagnetic control.

True value of Space Saving lies in giving you control over the system’s initiative

A truly experienced engineer knows that the most expensive thing is not the materials. But it was reworked later in the project due to insufficient space, crashed due to thermal runaway, and distorted data due to unstable connections.

Starting from a customized pogo pin, space saving gives active design rights. It is the initiative to grasp the rhythm of system evolution from the beginning of design.

You no longer need to sacrifice performance to accommodate size, nor do you need to delay the launch time and wait for adjustments. You can choose the right connection strategy from day one to free up space. Give the system more redundancy and imagination.

Space Saving is not the endpoint, but the starting point for establishing contact: Contact Johoty immediately

Space saving is an engineering philosophy that is a way for you to find breakthroughs in the limits of a system. Behind every millimeter of compression, Johoty has contributed >50,000 experiments and iterations. But this should not only belong to a few top companies.

Johoty can entrust this ability to you. We understand all your requirements for accuracy, cycle time, cost, and testability. We also believe that your system can be more efficient, compact, and reliable. Contact us now. Let space saving start from your next PCB.

+86 13590816656

+86 13590816656 +86 13590816656

+86 13590816656