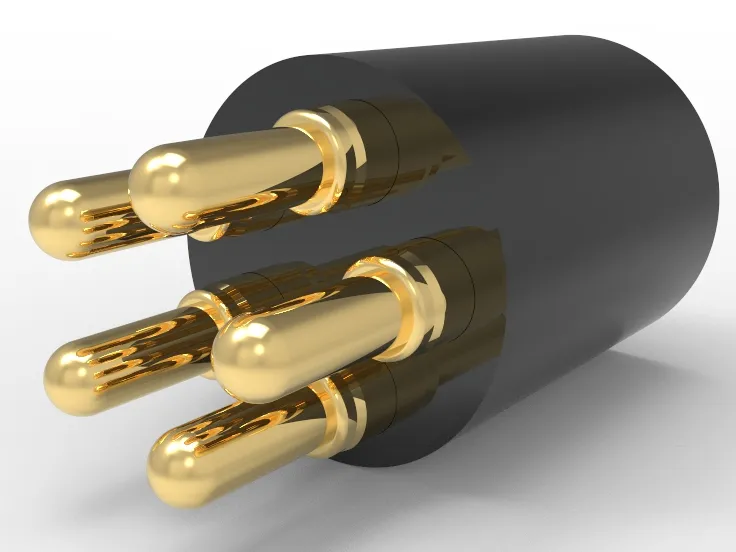

Waterproof Connector Ensures Tight Pogo Pin Seal, Withstands Storms And Vibration. Ideal For Outdoor Use In Harsh Weather. Get Durability!

Introduction: A complete shutdown caused by an outdoor system crash

Waterproof connector is often deployed in smart agriculture. But a smart control box located in a cornfield in North American agriculture suddenly shut down in heavy rain. After customer investigation, equipment itself has no any problems. The real fault comes from the corrosion of the connectors in the power supply module due to water ingress. Causing instantaneous power outage and remote communication interruption. In fact, Johoty knows that this is not uncommon in military communications, wind power systems, and edge computing nodes.

The connector may seem small, but it is actually the most fragile and important nerve endings in the entire system. How to achieve reliable sealing and connection stability in rainstorm, high-frequency vibration and salt spray corrosion? It also requires implementation without increasing complexity. The answer is: a waterproof connector with pogo pins.

Chronic diseases with poor contact: disadvantages of traditional shrapnel structures

Most traditional connectors use metal spring contacts, which provide good conductivity during initial contact. But it is highly prone to failure in the following environments:

- Rainwater infiltration leads to oxidation and increases contact resistance.

- High frequency vibration causes the shrapnel to loosen, resulting in intermittent power outages.

- Micro motion wear caused by thermal expansion and contraction ultimately leads to poor contact.

Up to 38.4% of electrical failures in outdoor equipment are caused by connectors. Nearly 70% of them are related to insufficient protection levels.

How does waterproof connector with pogo pins solve the above problems?

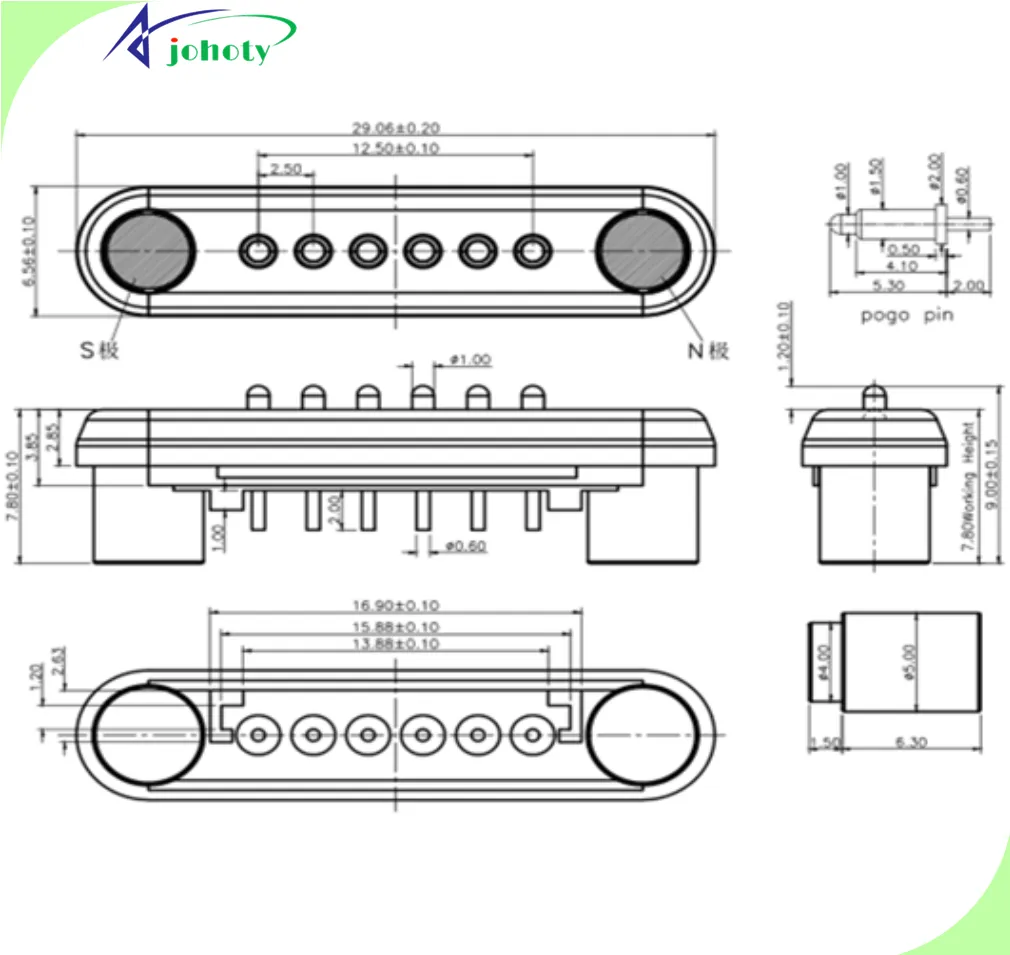

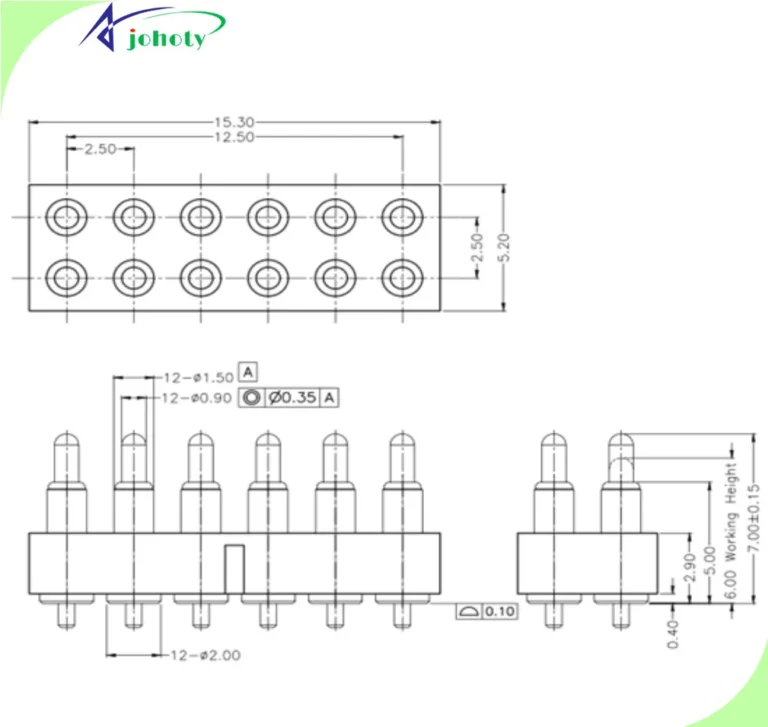

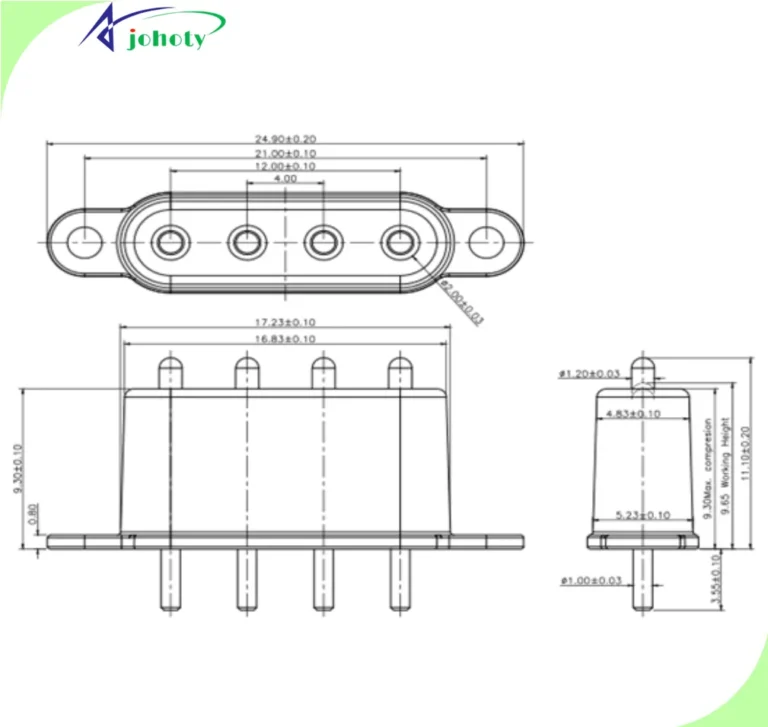

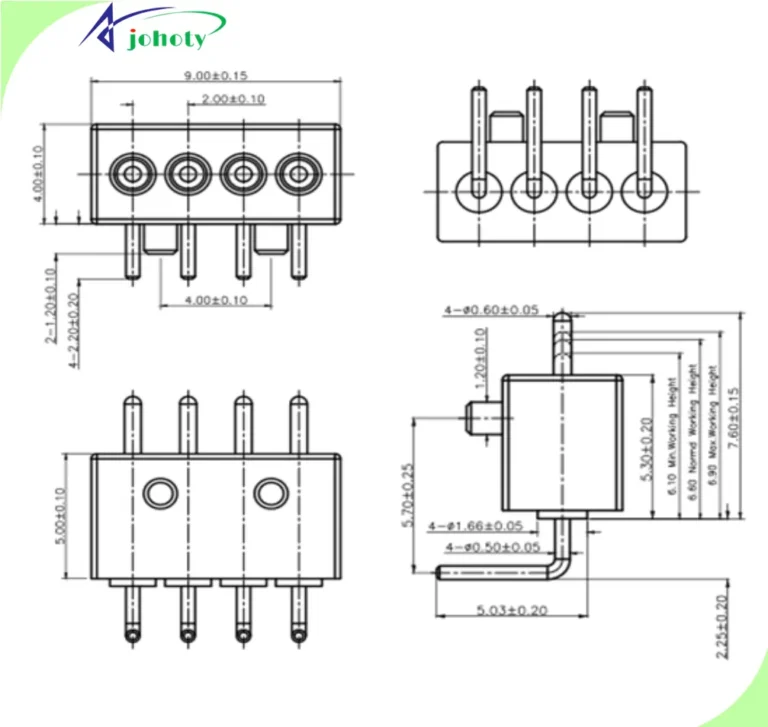

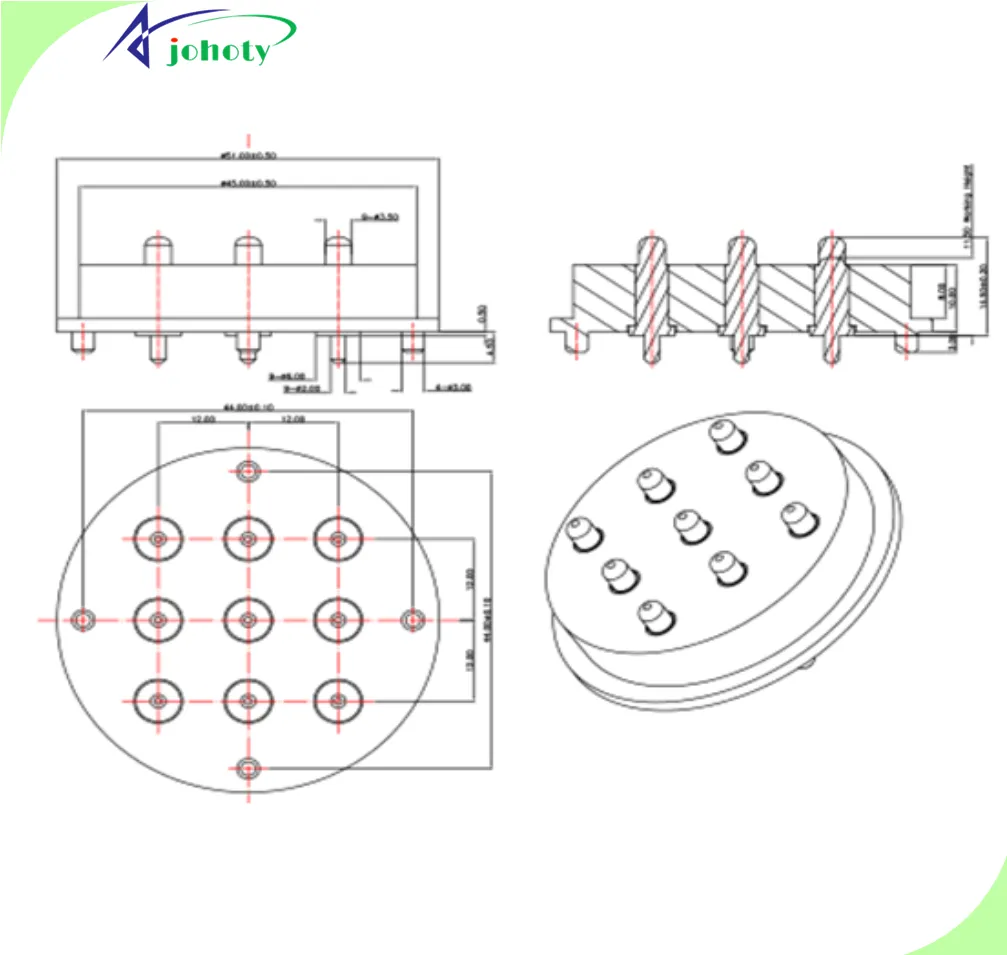

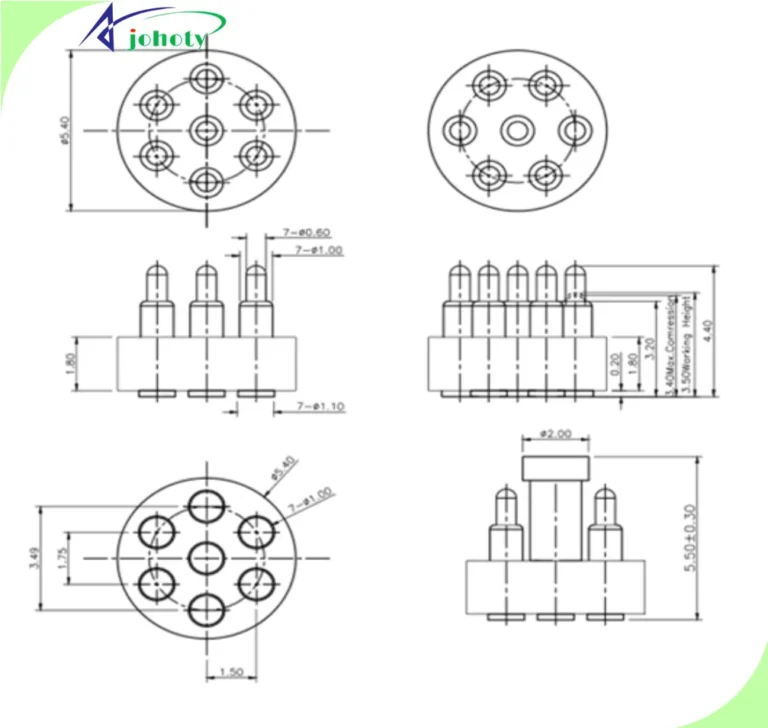

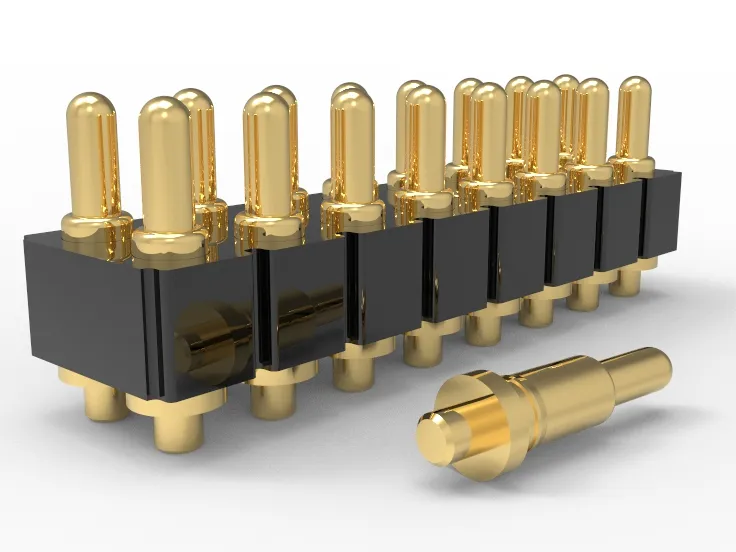

The key lies in the adaptive mechanical advantage of pogo pins. Pogo pins are metal probes with built-in springs that can maintain stable contact pressure during crimping. This structure can maintain a constant contact force even under long-term mechanical disturbances. Compared with the shrapnel structure, the contact surface of pogo pin has smaller wear dead corners and is more fatigue resistant.

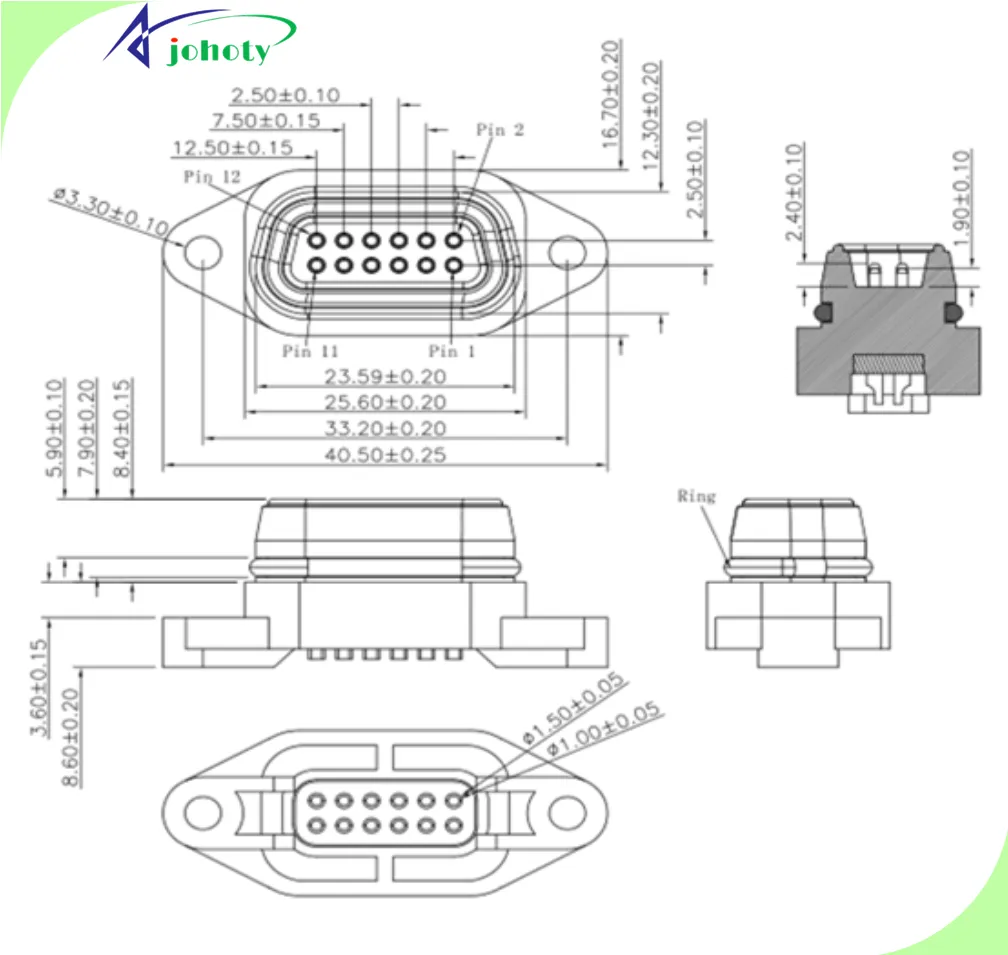

By combining with the following packaging design, pogo pins can build a waterproof connector for high-level protection systems:

- O-ring waterproof ring+dustproof cover: achieving IP67/IP68 level sealing.

- Press in or threaded fixing method: prevents vibration and detachment.

- Fluororubber sealing material: oil resistant, temperature resistant, salt spray resistant.

Many clients have verified that Johoty’s waterproof connector showed no surface oxidation during 48 hour salt spray test. After 500 hours of wet heat cycling, the increase in contact resistance should not exceed 2mΩ.

Key Challenges of waterproof connector in Outdoor Environments

Vertical rainfall, risk of transverse storm intrusion:

In open structures such as wind towers, lamp posts, and communication base stations, rainwater may strike equipment from multiple angles. Traditional connectors only seal from the top, while water proof connectors can achieve all-round wrapped sealing. Pogo pins themselves do not need to be exposed, improving overall IP level stability.

Johoty’s water proof connector soaked in water at a depth of 1 meter for 30 minutes showed no abnormalities in connection or disconnection.

Pogo pins anti-shake head, connection loosening caused by severe vibrations in drones/transport equipment

Risk of connector misalignment is extremely high during high-speed driving or flight. Traditional connectors are prone to loosening during periodic pulling and pulling due to their position being maintained by insertion and extraction friction. Pogo pins rely on axial spring pressure and mechanical limit to maintain contact surface adhesion during crimping. Even if the device vibrates in a 9G environment, the water proof connector still does not detach.

Johoty prototype was installed on a high-speed rotary wing unmanned aerial vehicle and underwent 50 takeoff and landing cycles. The connection status is stable without signal interruption, contact resistance deviation is <0.3mΩ.

Wide compatibility: from smart manhole covers to medical or aviation terminals

The encapsulation form of waterproof connector with pogo pins supports multiple forms:

- Panel type waterproof joint: embedded in the front panel of the intelligent control box.

- Cable side compression joint: used for drag chain mobile cable connection.

- Magnetic automatic docking: used for wearable or temporary docking terminals.

Suitable for power transmission, signal synchronization, data transmission, low resistance ≤50mΩ. Medium current 0.5~50A per pin, high cycle life >100,000, etc.

Verifiable waterproof connector protection: reassuring from a data perspective

| Test Project | Test Condition | Results |

|---|---|---|

| Salt spray test | 48 hours @35℃/5% NaCl | No rust, intact shell |

| Underwater test | immersion in 1 meter for 30 minutes | Contact resistance<initial value+2mΩ |

| Vibration test | 9G, XYZ three-axis each 30 minutes | without detachment of joints, stable connection |

| Hot cycle | -30℃~+85℃, 100 cycles | With no deformation of the shell and intact sealing |

| Insertion and extraction lifespan | Once per minute, 100,000 cycles | No abnormal abrasion on the contact surface |

What do engineers think of Johoty’s waterproof connector?

A military contractor equipment maintenance manager in USA: We have completely replaced the shipborne radar power module with a waterproof connector with pogo pins. The signal packet loss rate during sea cruising has decreased from 3 times per week to 0 times.

CTO, an edge computing equipment company in Germany: The challenge when the edge AI module is deployed in the northeast field is the low temperature of -20℃ and the moisture refreezing every night. We evaluated multiple structures and ultimately chose Johoty’s waterproof connector with pogo pins. They are only one vendor without any problems in the night frost and morning dew.

Is waterproof connector worth adopting in large quantities over the long term?

Taking a typical edge device module with an annual procurement of 50,000 sets as an example:

- The average annual replacement rate of traditional connectors is 12.6%, and the average replacement cost (including labor) is $8.4 per set.

- The average annual replacement rate after using a waterproof connector with pogo pins is <1.2%, and the replacement cost is<1.3 US dollars per set.

Over the course of one year, the cost savings from replacement alone exceeded 300,000 US dollars. Reduced maintenance time by 72%, indirectly saving deployment team manpower costs.

Many technical leaders may question the cost when they first hear about it, but after considering the following points, the decision maker’s judgment usually changes:

- The cost of whole machine maintenance caused by each connector detachment can reach several hundred dollars.

- The possibility of misjudgment/data loss caused by signal failure is incalculable.

- When replacing, the system needs to be disassembled, shut down, and restarted for verification.

- For every 1% increase in stability, the overall cost risk of the project is reduced by over 3%.

From a TCO perspective, a waterproof connector isn’t expensive, but rather trade structure for stability and reliability for budget space.

Conclusion: Visible reliability of waterproof connector

Waterproof connector with pogo pins is not just a theoretical concept, it is a systematic response to the connectivity requirements in complex environments. It is commonly used in aircraft, maritime communication, intelligent outdoor terminals, and military mobile nodes. Replace repetitive after-sales repairs with structural physical safety.

Johoty does not make any false promises. We only use data, testing, and scenario applications to provide real answers. Do you want to know if waterproof connector can adapt to the structure of your device? Do you want to personally measure how low the contact impedance is after vibration? Contact Johoty’s CFT team immediately to obtain sample testing and complete specifications of Johoty waterproof connector with pogo pins. Don’t regret not changing the structure until the next rainstorm. Now is the starting point for your stable connection.

+86 13590816656

+86 13590816656 +86 13590816656

+86 13590816656