Best 10 Pin Connector China Manufacturer Tight Spaces

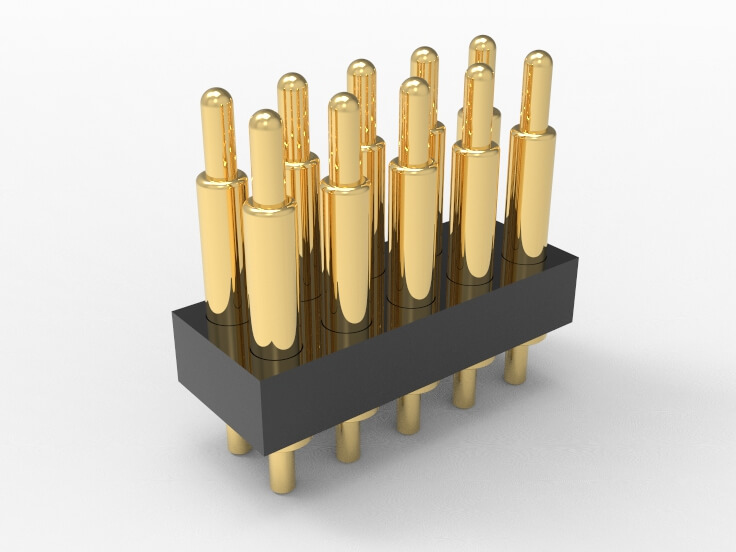

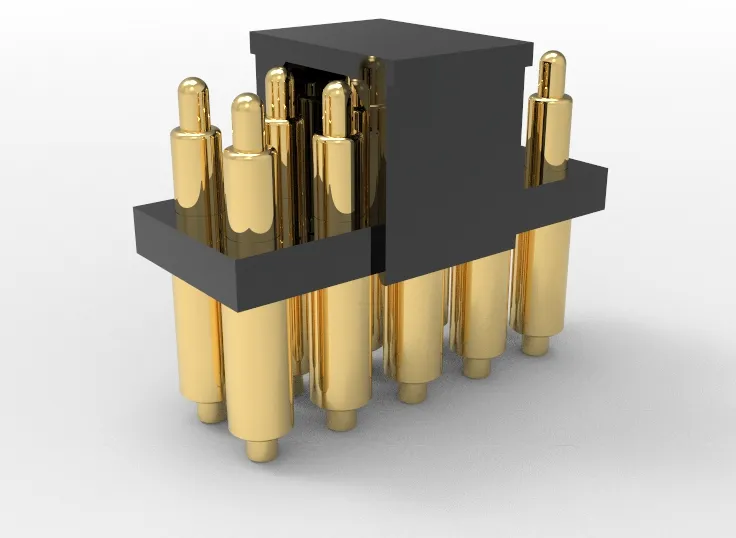

10 pin connector is made of brass, beryllium copper, gold-plated, stainless steel, provides high conductivity and high stability electrical, data, and signal connections. It is a high-density solution with pitch ≥1.00mm, ≥15mΩ, 10pcs pogo pins for single or double rows, male and female ends. It can achieve IP67 waterproof, 5Gbps or 5GHz under good anti-EMI. Johoty provides perfect customization of current, shape, pitch, stroke, etc.

Features:

- Limited space for multi-channel communication.

- High-durability springs increase stable lifespan.

- Stable transfer with high current, low impedance.

- High-speed, high-frequency, excellent stability.

- Gold-plating, composite coating, tolerant to oil, water.

- Waterproof, corrosion, and vibration resistant.

10 Pin Connector Series

10 pin connector series has 11 categories, clients often customize multiple functions in one connector to ensure optimal compatibility and performance:

High reliability: After 23 rigorous tests for temperature, humidity, mechanical shock, etc., it can withstand high stress under long-term working.

Automated Connection: Suitable for automated testing, programming, and assembly applications, it can quickly and reliably connect and disconnect, reducing manual intervention.

Single/double/three-row: Optimize space utilization, provide more connection options and stronger signal transfer.

Metalized contact: special alloys or metal materials that enhance wear & corrosion resistance for extremely high stability.

Seismic resistance: Seismic design that can maintain stable electrical connections in high vibrations, suitable for high vibration or sports equipment.

Micro: Small in size, suitable for highly integrated and miniaturized designs, limited in space, and requiring high-performance devices.

High current: Capable of carrying large currents, with strong heat resistance and electrical stability, suitable for power or high load applications.

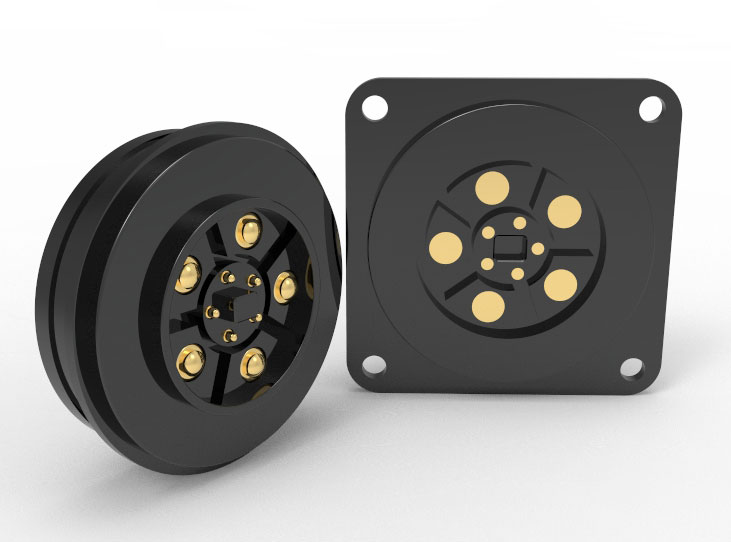

Waterproof: IP67, IP68 waterproof, Used outdoors or in industrial environments.

High frequency: low resistance, low parasitic capacitance, and higher signal integrity, suitable for high-speed data transfer.

High density: Provides more connection points within a limited space. Suitable for compact space and complex signals.

Magnetic: N52 strong magnet with automatic male and female alignment, providing a great user experience.

Specifications of 10 Pin Connector

| Parameter | Value |

|---|---|

| Pin Number | 10 pins |

| Rated Current | 1.0 A ~ 50.0 A per pin, custom |

| Contact Resistance | ≤ 50 mΩ per pin, custom |

| Insulation resistance | ≥ 1000 MΩ @ 100 V DC |

| Withstanding voltage | 100 V AC ~ 250 V AC @ 60 Hz, 1 min |

| Working voltage | ≤ 48 V DC, ≤ 250V, custom |

| Working temperature range | -40℃ ~ +85℃,-55℃ ~ +125℃,custom |

| Life Cycles | ≥ 10,000 cycles, ≤200,000 cycles, custom |

| Pitch | ≥ 1.00 mm, custom |

| Size(Length, Weight, Height) | ≥ 12.00 mm x 2.50 mm x 4.20 mm, custom |

| Stroke | ≥ 0.10 mm, custom |

| Spring Force | ≥ 5 gf @ working stroke, custom |

| Plunger Tip | ≥ 0.60 mm, custom |

| Installation | Solder-Cup, SMT, DIP, Right-Angle, Double-Ended, custom |

| Pogo Pin Materials | Copper alloy, gold-plating, custom |

| Housing Materials | LCP, PPS, Peek, Metal, custom |

Shape and Arrangement of 10 Pin Connector

| Structure | Description |

|---|---|

| Plunger Tip Type | Dome, Flat Tip, Cone Tip, Chamfered Tip, Ball, Sharp, Hollow Cup, Cross, Double Step, Star, Custom Shaped Tip, custom |

| Arrangement Types | Single Row (Straight), Dual Row (Parallel), Dual Row (Staggered), Matrix Grid (e.g., 2×5), Right-Angle (90°), Bent Pin (Custom Angle), Circular Layout, Square Closed Loop, Center Symmetry Layout, Vertical Through-Board. |

Applications of 10 Pin Connector

Medical equipment: Double row sinking plate structure, suitable for high-density signal transmission. Reliable contact, commonly found in surgical navigation systems and portable monitors. Has a >10,000 cycles lifespan and prevents accidental insertion.

Communication base station: equipped with positioning columns, suitable for outdoor high-frequency plugging and anti-vibration environments. Support 5G RF module connection, signal stability verified through -40~+85℃ aging test.

Industrial automation: suitable for PLC modules and servo drives, ensuring data transmission integrity. Adopting a floating structure to solve the problem of poor contact under equipment vibration.

New energy vehicles: fixed with shrapnel and nuts, compatible with BMS modules. High temperature resistance up to 125℃, meeting the AEC-Q200 standard for automotive specifications.

Drones/Robots: Spring loaded pins with floating structure, suitable for high-frequency battery and module replacement. >20,000 insertion and extraction cycles, impact resistance ≥50G.

Consumer electronics: using a simple straight through structure, suitable for micro devices such as smart watches and AR glasses. The minimum distance between PIN pins can reach 0.4mm.

Smart Home: Dustproof sliding pogo pins, suitable for wall switch control modules and other scenarios. Designed with IP5X rating, suitable for complex home environments.

Military equipment: Metal shell shielding structure, strong resistance to electromagnetic interference. Reliability has passed MIL-STD-202G testing and is compatible with portable command terminals.

Aerospace: High locking force structure connects flight control and attitude sensing module, with a pressure resistance of up to 500V. Suitable for extreme vibration and temperature change scenarios.

High end instruments and meters: Multi PIN coplanar sinking plate, realizing partitioned transmission of multiple electrical signals and analog signals. Accuracy <± 0.1mm, suitable for spectrometers.

Semiconductor equipment: anti-static conductive structure, used for connecting wafer test sockets. Electrostatic discharge withstand >15kV, repeatability error <2%.

Research experiment platform: Modular magnetic attraction structure, suitable for rapid experimental iteration. Connection stability verification CV value <1%, widely used in universities/laboratories.

Why Johoty's 10 pin Connector As Solutions?

Choosing Johoty’s 10 pin connector, with its innovative pogo-pin design and high-precision manufacturing, solves complex design problems. We ensure excellent stability and durability, provide flexible delivery cycles and cost advantages. Johoty helps customers improve product performance and reduces overall procurement costs.

Competitive Edge of 10 Pin Connector

Technical advantages

Johoty adopts precision five axis CNC machining and high elasticity beryllium copper material. The lifespan of the spring needle exceeds 100 000 insertions, with a contact resistance as low as 20mΩ. The signal integrity and high-frequency performance can meet the high-speed transmission requirements of 5Gbps. Significant advantages have been demonstrated in the field of automated testing and wearable devices, in compliance with the IEC61076 standard.

Cost-benefit analysis

Johoty vertically integrates the manufacturing chain to control unit costs. On the basis of maintaining high-precision processes, we help customers achieve a 15% -30% reduction in unit costs. At the same time, the delivery cycle has been shortened to within 2 weeks, significantly reducing the customer’s Total Cost of Ownership (TCO). Significantly better than top brands in the industry.

Innovative design features

The 10 pin arrangement adopts an equally spaced symmetrical layout, supporting a maximum current carrying capacity of 50A per pin. Modular packaging design facilitates customer customization and maintenance. Patent locking structure and foolproof positioning design effectively prevent accidental insertion. Improve assembly yield by over 98%, significantly reduce misplacement rate, and enhance assembly efficiency.

Brand and market reputation

Johoty has a customer repurchase rate of 87% on B2B platforms in Europe and America. For three consecutive years, we have been providing Pogo Pin solutions to OEM customers in the fields of medical equipment and industrial automation. It has also been highly recognized and recommended by guests from Germany, France, Italy, Switzerland, Türkiye, South Korea and the United States. We have also received many inquiries and assistance from customers recommended by us.

Customization Process of 10 Pin Connector

Signing NDA and Project Archive Establishment: Sign an NDA at the initial stage of the project to clarify the scope of IP protection. Establish independent engineering files for clients to ensure zero risk of leakage of R&D data and business information.

Requirement research and application environment assessment: Confirm core parameters: rated current/voltage, contact resistance, lifespan, elasticity and stroke, working environment temperature. IP Rating, mating interface structure, Plating, Accurately restore the customer’s real working conditions.

Confirmation of electrical performance parameters and pin definition configuration: Define the current, voltage, and signal type carried by each pin based on customer system requirements. Refer to IEC 60512 standard to ensure the integrity of multi loop signals.

Structural dimension definition and PIN layout design: Customize the pin layout (rows/spacing) based on the customer’s mechanical structure diagram or STEP file. Accuracy control is ≤±0.02mm, compatible with automatic assembly.

Selection of spring needle type and mechanical performance: Choose customized spring needles (≥50k cycles) based on insertion frequency and service life. Elasticity of 1.0~2.5N, with a fatigue test failure rate of <0.05%.

Definition of material and thickness of contact surface coating: Gold plating, nickel plating, composite coating and other schemes are selected, and the recommended gold thickness is ≥0.5μm. Ensure resistance doesn’t exceed ±10% of initial value after 5,000 insertions.

Housing material and docking structure design: High temperature resistant LCP/PEEK (HDT≥260℃) make the housing. Support buckle/screw/welding fixation to ensure the stability of the mechanism.

PCB interface and soldering compatibility design: Confirm the SMT/pin process requirements and design PCB pads that comply with IPC-A-610 Class II standards. Support seamless matching from SMT to THT processes.

Prototype sampling and rapid engineering verification: Deliver functional prototypes within 14 days. Complete plug and unplug life, contact resistance, PIN rebound, and corrosion resistance tests. Attached is a complete engineering verification report.

Small batch trial production and customer feedback on actual installation: Provide 50-500 sets of small batch trial production to support customer on-site evaluation. Collect assembly adaptability, electrical performance, and feedback data from end customers.

Formal mass production and implementation of quality control system: Implement IQC/OQC full process quality inspection, with test reports and traceability codes attached for each batch. Maintain a yield rate of ≥99.8% and support customer annual frames and supply agreements.

Lifecycle management and engineering support for continuous supply: Establish ERP material codes and retain drawing and BOM data for more than 10 years. Support EOL notifications, alternative recommendations, and secondary technical development.

FAQ

What is signal transfer speed of 10 pin connector?

Johoty’s 10 pin connector is designed specifically for high-speed signal transfer and is useful for 5Gbps video signal transfer. It uses low impedance materials to ensure minimal signal attenuation and supports high-frequency data transfer. Our pogo pin connector precision structure can reduce crosstalk and signal reflection. It can work stably in high-speed digital communication, RF applications, and even high-speed data buses. This ensures data integrity and is suitable for designs that require high bandwidth.

Will pogo pins of 10 pin connector deform due to prolonged use?

Pogo pins are made of high-strength copper alloy and plated with gold. And, the springs are also subjected to special heat treatment. The 10 pin connector ensures long-term use and maintains good elasticity and resilience. After multiple insertions, pogo pins can still maintain precise position and aren’t easily bent or lose elasticity. This pogo pin connector can effectively avoid poor contact and ensure stable operation.

Is installation method of 10 pin connector complicated?

Provide SMD patch or THT through-hole soldering, it can easily integrate into various PCB designs. SMD is suitable for automated production to improve assembly efficiency, while THT is suitable for applications with high mechanical strength. The 10 pin connector is designed to be compact and supports automated mounting, reducing the difficulty of manual operation. By improving production yield, Johoty’s 10 pin connector can meet large-scale manufacturing.

What is maximum current 10 pin connector can withstand?

Normally, each pogo pin pin can individually withstand 3A current, and overall current can be expanded according to design requirements. So, when designing 10 pin connector, Johoty can support high-power applications. Low contact resistance design can reduce electrical energy loss and ensure long-term stable power supply. In high-power charging, industrial control, or battery connection, our pogo pin connector can operate reliably without overheating or damage.

What is operating temperatures of 10 pin connector?

Can operate stably in extreme temperatures from -40°C to+85°C. 10 pin connector is suitable for industrial equipment, automotive electronics, and outdoor communication that require high and low temperature resistance. The material of this pogo pin connector has undergone strict screening and wong’t experience performance degradation due to temperature changes. It can still work stably in cold, high temperature, damp heat, or sudden temperature changes.

+86 13590816656

+86 13590816656 +86 13590816656

+86 13590816656