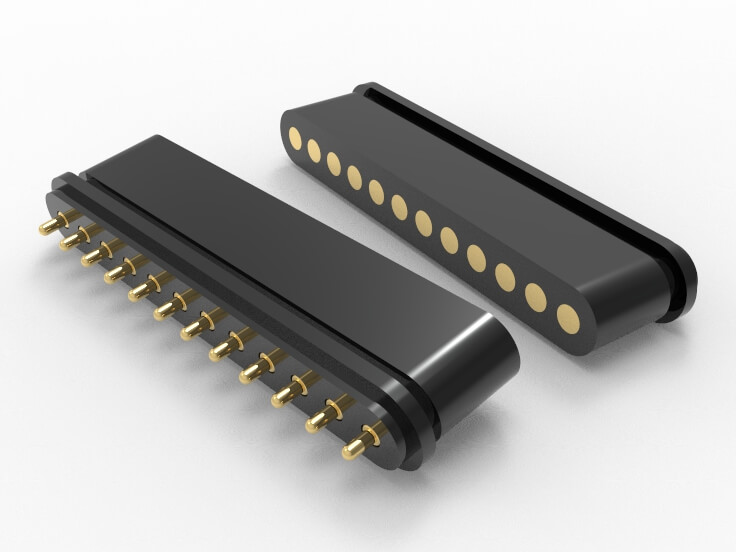

Best 12 Pin Connector China Manufacturer IP67

12 pin connector has 12 pogo pins with perfect consistency and low contact resistance. It adopts high-strength gold plating, corrosion & oxidation resistance, maintains excellent conductivity under high humidity and pollution. IP67 waterproof at 55℃ to +125℃, magnetic connection, shock and impact resistance. Compatible with high-speed data transfer, power management, and RF signals. Customize high-density board-to-board connections and adapt to customized interfaces. Johoty provides professional solutions.

Features:

- Ultra-high precision, micrometer level tolerance control.

- Ultra-long lifespan, with >10,0000 contacts without damage.

- Low impedance loss, efficient signal without attenuation.

- Wide temperature adaptation, stable in extreme environments.

- Anti-seismic and fall, dynamic connection without disconnection.

- Module design, suitable for various high-end applications.

12 Pin Connector Series

12 pin connector series is divided into 5 categories and is often customized based on various categories:

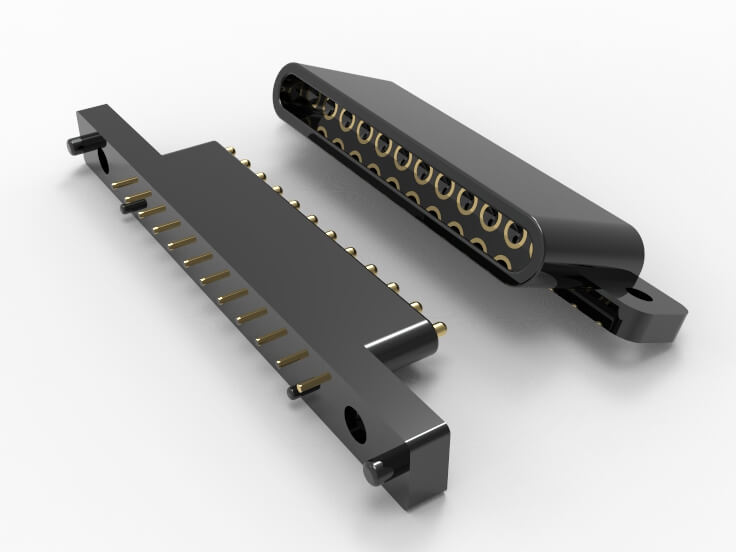

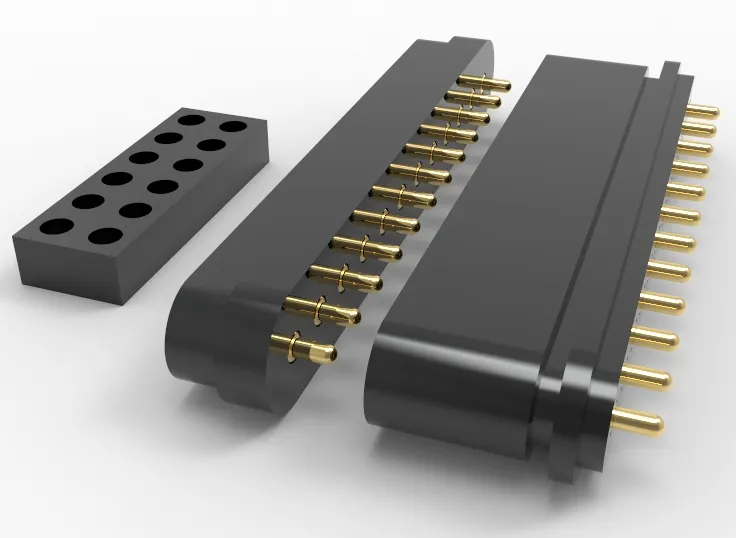

Connection method: SMT installation with high-density PCB design. High strength and high current through-hole connection. High-end replaceable modules, shock resistant and mechanically stable crimping type.

Electrical performance: Low impedance, high-speed signal & data transfer. High conductivity & high current transfer. Suitable for precision medicine with low electrical resistance.

Environmental adaptability: IP67/IP68 sealed structure, high shock resistance, high-temperature resistance.

Mechanical structure: Compact single-row structure, high contact density and signal integrity double/multiple rows. Quick replacement and high durability of pluggable modules. A self-locking mechanism with stable mechanical locking.

Special function: Magnetic connection for automatic alignment and improved connection efficiency. Blind insertion design with self-alignment, maintaining stable conductivity in rotating contact. High-speed mixed signal+power multifunctional.

Structure of 12 Pin Connector

| Component | Features |

|---|---|

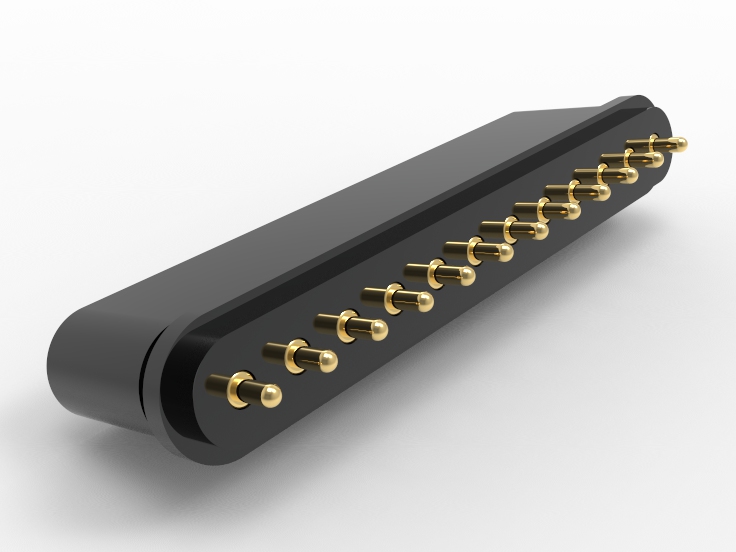

| Plunger | Gold-plated copper alloy material, with conductive contact terminals. Diameter 0.15mm~1.5mm, hardness ≥ 180HV, conductivity >75% IACS. Support stability for ≥ 10,000 contacts. |

| Barrel | Nickel-plated copper shell or stainless steel material, with a diameter of ≥0.50mm, used to limit the plunger travel trajectory and protect plunger. The coaxiality of the inner cavity is ≤±0.02mm. |

| Spring | SWP-B or SUS304 material, ensuring linear rebound force. Working pressure range is ≥5gf, the maximum compression stroke is 15.00mm, fatigue life is ≥ 10.000 cycles. |

| Housing | PPS/PA6T/PEEK and other engineering plastics serve insulation, guidance, and encapsulation functions. Hot deformation temperature ≥ 220℃, flame retardant grade UL94 V-0. Suitable for 12 12-channel array layout, with a minimum pitch of 1.00mm. |

| Alignment Carrier | Precision injection molding positioning seat, used to maintain the linear distribution and insertion accuracy of 12 pins, with a position tolerance of ≤±0.05mm and a thermal expansion coefficient of less than 40ppm/℃. |

| Coating | Typical gold plating thickness: Au ≥ 0.5μm, bottom nickel layer ≥ 2μm. Contact impedance ≤50mΩ, with antioxidant and corrosion resistance (passed salt spray test for ≥ 48 hours). |

| Termination | SMT pads, DIP pins or cable crimping/soldering, support Max 50A/Pin, contact heat rise <30℃ (at 30A). |

| Spring Pocket | Precision turning forms grooves to ensure consistency between the axial force and compression stroke of the spring, with a groove depth difference of ≤± 0.03mm. |

| Base Support | Metal or high-strength plastic bracket, fixing the overall structure to the host or PCB, commonly made of LCP/PBT material, with impact strength >15kJ/m². |

Specifications of 12 Pin Connector

| Parameter | Description |

|---|---|

| Number of Contacts | Fixed at 12 channels, configurable for power/signal/ground |

| Current Rating per Pin | Standard 1A–3A. up to 5A via parallel configuration (thermal-limited), with a special design of 50A by Johoty. |

| Voltage Rating | Typically DC 12V–48V. up to 60V with proper insulation, 250V customized |

| Contact Resistance | ≤ 50 mΩ. typical 20–30 mΩ, custom |

| Mating Cycles | ≥ 10,000 mechanical/electrical stable cycles, up to 500,000, custom |

| Operating Temperature | -40℃ to +85℃. high-temp version up to 125℃, custom |

| Spring Force | ≥5gf per pogo pin. linear or progressive available, custom |

| Travel Range | Working stroke ≥0.10. max travel up to 15.00mm, custom |

| Pin Pitch | Supports ≥1.00mm, 1.27mm, 2.00mm, 2.50mm, 2.54mm, custom |

| Mounting Options | SMT, DIP, wire soldering, modular docking, magnetic, custom |

| Material Configuration | Plunger: Au-plated Cu alloy. Barrel: Brass/SS. Spring: steel/SUS. Housing: PPS/PA6T/PEEK, custom |

| Ingress Protection | Up to IP67 with proper sealing structure, custom |

| Thermal Rise | <30K rise under 3A continuous load at 25℃ ambient |

| EMI Control Option | Ground pins and optional shield housing for high-frequency signal integrity |

Applications of 12 Pin Connector

Automatic Test Equipment (ATE) Fixture Interface System: Used for high-speed signal and power switching in semiconductor and PCB automation testing. The 12 pin configuration enables parallel testing of multi-channel signals. Improve universality and contact reliability, with an average contact resistance of less than 50 milliohms.

Wearable medical device module connection: used for the separate connection of multi parameter acquisition modules such as heart rate, temperature, and blood oxygen with the main control board. Featuring small size and high-frequency wear resistance, it can withstand over 100,000 insertion and extraction cycles.

Connection structure between drone battery and flight control module: In high-speed current (>10A) and signal mixed transmission scenarios, the 12 pin detachable design optimizes wiring density. To ensure flight control safety, the impedance of the pogo pin connector is controlled within ± 15%.

Military grade data acquisition module (embedded system): meets the requirements of wide temperature operation from -55℃ to 125℃, with a seismic resistant structure suitable for high G-force environments (>50G). Adopting corrosion-resistant gold plating treatment to ensure high reliability connection.

In vehicle intelligent terminal (IVI system) module connection: applied to multi signal interfaces of system modules such as T-Box and HUD. Supports mixed protocols such as CAN, LVDS, GPIO, etc., with a plug and unplug lifespan of over 30,000 times. Avoid damage caused by repeated contact of traditional FPC.

Robot end effector and modular arm connection: The 12 pin interface is used to transmit control commands, power, and feedback signals. Implement hot swappable functionality for replacing modules such as claws/suction cups to improve system maintenance and deployment efficiency.

Satellite communication equipment ground testing platform: replaces SMA/SMB plugging in high-density RF and power control interfaces. Avoid wear and tear issues, with a durability of over 500,000 cycles. Meet the high-frequency testing requirements on the ground.

Industrial grade portable measuring instruments (multi-sensor collaboration): applied in portable devices such as power detection and environmental monitoring. The 12 pin connector combines multi-channel analog signals with digital control cables. It meets the IEC 61000-4 standard on anti-interference performance.

Medical imaging diagnostic table module plug-in system: 12 pin structure isolates different voltage areas. Used for hot swappable connections of probes or interface boards in large equipment such as X-rays and ultrasound. Meets the IEC 60601 safety standard.

Modular interface structure of electric vehicle BMS: used for synchronous connection of signals and power between BMS submodules and the main control board. Realize synchronous sampling of temperature, voltage, current and other channels, supporting continuous current >5A.

Embedded controller plug-in system for rail transit: transmits status and control signals in train control and passenger information systems. 12 pin connector simplifies cable layout and has EN 50155 standard seismic and electromagnetic interference capabilities.

Micro wind tunnel sensing testing system: used for connecting high-speed sensor modules in aerodynamic experimental platforms. 12-pin can achieve multi-dimensional data synchronization acquisition, with signal response time <1ms, suitable for transient testing.

Why Johoty's 12 pin Connector For Projects?

Johoty’s 12 pin connector, specially designed for engineers to solve complex application problems. Excellent signal transfer stability and durability, supporting high-end technology requirements. Improve equipment performance, long-term reliability, and efficient operation. Johoty is trustworthy.

Why Select Johoty's 12 Pin Connector?

Unit life cost control and performance improvement

Johoty adopts a CNC modular platform to unify the standard components of needle tubes/springs. The material reuse rate is greater than 85%, reducing manufacturing losses. The plug-in life reaches 30,000 times (test current 1A, working stroke 0.5mm). Far higher than the typical industry standard of 10,000 times, with the optimal unit life cost.

Process Consistency Assurance and Quality Control

Implement SPC full process monitoring for 12 key processes (needle tube outer diameter ± 2μm, electroplating thickness error ± 1μin). The assembly CTQ index meets the requirement of 3σ. The average monthly yield rate remains above 99.2%. The consistency of parts meets the delivery requirements for medical equipment and military modules.

Traceable data delivery and process chain transparency

Johoty provides full batch raw material, elasticity/resistance testing, salt spray/thermal cycling aging curve, and needle coating thickness chart data. All delivery records are bound with unique barcodes and support ERP level integration. Meet the traceability requirements of UL, FDA, CE and other regulations for European and American customers.

Stable delivery capability and risk buffer

We have dual production lines in Dongguan and Shenzhen, with dual backup of core molds and raw materials. The inventory guarantee period for regular model raw materials is greater than 45 days. Under abnormal warning, activate the emergency delivery channel and replace 50K level orders within 7 days. Meet the zero supply demand in aviation, automation, and military scenarios.

Design and Configuration of 12 Pin Connector

Electrical characteristics: Balanced design of current load and contact resistance

It is recommended to control the contact resistance below 50mΩ within the rated current range of 1.0~2.0A/pin to avoid signal degradation caused by voltage drop. Use gold-plated needles with a thickness of ≥10μin to ensure low contact impedance and high reliability. Adapt to the conventional logic levels of 3.3V/5V systems.

Housing material selection: equal emphasis on temperature resistance and mechanical strength

Choose LCP or PBT +30%GF material, with a hot deformation temperature of ≥230℃. Meet the requirements of SMT/Reflow process to avoid thermal instability after assembly. The dimensional stability of the connector structure will be very high.

Contact head material and electroplating layer design

The recommended needle material is BeCu or brass, which has excellent elasticity and conductivity. The recommended thickness of electroplated gold is 10-30μin to meet the requirements of stable transmission of low voltage signals and corrosion resistance. Cooperate with nickel plating to enhance adhesion.

Layout of grounding and signal line distribution structure

To avoid crosstalk, the 12 pin connector is configured with 4 GND and the signal is isolated from the power supply. Adopting a structure of symmetrical differential + signal ground signal. It can significantly reduce crosstalk (>-30dB) and improve EMI immunity.

Design of PCB end pads and selection of fixing methods

The recommended SMD pad diameter is 0.80-2.00mm, with additional positioning posts or metal shell fixing holes. Prevent fatigue cracking of solder joints caused by shear forces during the insertion and removal process. The spacing between solder pads must meet the minimum tolerance of ± 0.05mm in PCB manufacturing.

Protection level and sealing treatment

If used for industrial or medical equipment, it is recommended to design to achieve an IP67 rating. The shell is equipped with a sealed silicone ring, and the needle seat is filled with epoxy resin. Ensure that dust and liquids cannot penetrate into the electrical contact area to improve reliability.

Electrical matching and impedance control (high-speed applications)

If used for high-speed data transmission (such as USB 3.0, LVDS), the connector impedance must be controlled within the range of<50 ± 10m Ω. Suggest using differential pair structure and simulating to verify reflection loss (S11<-15dB).

Assessment of adaptability to working environment temperature, humidity, and temperature drift

Adapt to the industrial temperature range of -40°C to+85°C, ensuring material CTE matching and avoiding virtual soldering under thermal cycling. 96 hours of high humidity aging experiment at 85°C/85% RH must be completed. Verify the performance retention of the 12 pin connector in extreme environments.

Hot swappable performance and arc suppression measures

If the application involves live plugging and unplugging, a combination of pre grounded pins (long pins) and delayed energized pins should be designed. Reserve a 3-5ms empty window to avoid arc discharge. Increasing the thickness of the gold layer to 30 μ in or above can further suppress electrical corrosion.

Reliability Test of 12 Pin Connector

Part-I:

Contact Resistance Test: Initial value ≤ 50 mΩ, tested according to IEC 60512-2, loaded with 1A current. The change value after 100 insertions and removals shall not exceed 20%.

Insulation Resistance Test: Measure the resistance between pins and between pins and the housing at 500V DC, with a requirement of ≥1,000 MΩ, in accordance with IEC 60512-3.

Dielectric Withstanding Voltage Test: 1,000V AC applied for 1 minute, no breakdown or arc, leakage current ≤2mA, according to IEC 60512-4.

Mating Cycles: Simulate actual usage scenarios, plug and unplug ≥10,000 times, and increase contact resistance ≤20%. Standard reference EIA-364-09.

Insertion/Withdrawal Force Test: Single pin insertion force of 3-10N, withdrawal force ≥1.5N, verify the rationality of mechanical matching according to EIA-364-13.

Normal Force Test: When compressed to the working stroke, each pin maintains a force of ≥0.5N, with a recommended range of 0.6~1.0N, to ensure contact stability.

Operating Temperature Range: Long term operation should be stable between -40℃ and+85℃, meeting vehicle regulations and industrial grade requirements.

Thermal Cycling Test: Cycle 100 times between -40℃ and+85℃ for 30 minutes each time to verify the effect of thermal expansion and contraction fatigue according to IEC 60068-2-14.

Temperature & Humidity Bias Test: Under 85℃/90%RH conditions for 96 hours, load 1A current to confirm that the material and properties have not deteriorated.

Salt spray corrosion test: according to ASTM B117, 35℃, 5% NaCl solution spray for 48 hours, there is no red rust, and the contact performance does not decline.

Random Vibration Test: According to MIL-STD-202 Method 214, 5~500Hz, 7.56Grms, 15 minutes in each 3-axis direction, without contact failure.

Part-II:

Mechanical Shock Test: 50G, 11ms half sine shock, 3 times in each direction, with no structural damage or electrical abnormalities observed after testing.

Spring Fatigue Test: Cycle ≥100,000 times under compression of 0.3-0.6mm, with an elastic recovery rate ≥90%, to verify the lifespan of the spring leaf.

Thermal Resistance Test: The temperature rise under full load current does not exceed 30℃, and the thermocouple method is used to monitor the temperature response of a single pin.

Plating Thickness Testing: Au or Ni layer ≥ 3μin, with a conventional control range of 10-50μin and a thickness error of ≤±10%, according to ASTM B487.

Adhesion Test of Electroplating Layer: Verify that the electroplating layer does not peel off through tape peeling or scraping test, in accordance with ASTM D3359 standard.

Fretting Corrosion Test: Simulate micro vibration environment (5-10μm range), 1,000,000 cycles, to test the oxidation and wear stability of the contact area.

Signal Stability Under Motion Test: After applying continuous lateral micro vibrations, test signal integrity (frequency domain reflection loss ≤–20dB) for high-speed data scene verification.

EMC Shielding Test: In frequency range of 50MHz~3GHz, test EMI leakage around pogo pin design, requiring a shielding efficiency of ≥-60dB.

Pin Alignment Accuracy Test: After repeated connection 1,000 times, single pin offset is <±0.05mm to ensure the accuracy of connector end docking.

Coplanarity: Height error of pin top is controlled within ±0.03mm, meeting the requirements of automated bonding and crimping.

Flame retardancy test: The plastic shell material meets UL94 V-0 grade, with a self-extinguishing combustion time of ≤10 seconds and no dripping phenomenon.

RoHS/REACH Material Compliance Verification: All materials should pass RoHS and REACH SVHC testing and be free of restricted substances: lead, cadmium, and ortho benzene.

FAQ

How does 12 pin connector perform in high temperatures?

This 12 pin connector performs very stably in high temperatures. Made of high-quality gold-plated brass, each pogo pin can always withstand high temperatures and avoid poor contact. This pogo pin connector is suitable for high temperature and extreme environments, and is suitable for use in automation equipment, automotive electronics, and more. It is very helpful for equipment that needs to work in harsh. Its high temperature resistance ensures long-term stable signal transfer, this can effectively avoid equipment failures caused by overheating.

What are special advantages of using 12 pin connector?

The 12 pin connector provides higher signal transfer density. For complex applications, it can support more signal pathways simultaneously, saving space while improving efficiency. 12 pin design makes the connector more compact, it can flexibly and effectively meet high-density connections. In limited space, its high-performance performance is even better. In addition, 12 independent pogo pins can achieve precise control of more signals, meet complex systems, and overally improve system’s performance.

Can 12 pin connector maintain stable connection during dynamic motion?

Yes, Johoty’s 12 pin connector can fit devices in dynamic motion. Due to its elastic pogo pins, it can maintain stable electrical contact in frequent connection and vibrations. This design is very suitable for dynamic motion robots, drones, etc. Devices’ continuous vibration or movement of ensures accurate signal transfer through contact pressure and stability of our pogo pin connector. It greatly improves equipments’ reliability.

What is 12 pin connector’s lifespan?

The lifespan of standard 12 pin connector is >10000 times, and, Johoty can specially design it to support 200,000 operations. Its unique spring loaded pin and high-quality materials ensure consistency with each contact, avoiding wear on contact points. It is commonly used in high-precision equipment that requires frequent replacement and connection. Meanwhile, high durability of pogo pin connector greatly reduces maintenance frequency and costs. In unmanned aerial vehicles and automated production lines, it can significantly ensure long-term stability.

How to ensure 12 pin connector doesn’t interfere with other signals in high-density design?

In high-density design, 12 pin connector adopts precise electromagnetic shielding technology. Each pogo pin can independently transmit signals to avoid mutual interference. In addition, the pogo pin connector has a compact structure that can effectively reduce crosstalk between signals. This ensures the independence of each signal path. When multiple signal channels are working simultaneously, Johoty’s spring loaded connector can still ensure clear and stable signals. It is suitable for high-density, high-frequency precision equipment, ensuring their efficient operation.

+86 13590816656

+86 13590816656 +86 13590816656

+86 13590816656