Best 6 Pin Connector China Manufacturer High Performance

Features:

- High-precision contact ensures signal transfer.

- High-quality materials, wear, corrosion-resistant.

- Fine pitch, compact design, saving space.

- Strong elastic support, stable contact force.

- Resistant to multiple contacts, long service life.

- Low resistance, high power, and signal efficiency.

6 Pin Connector Series

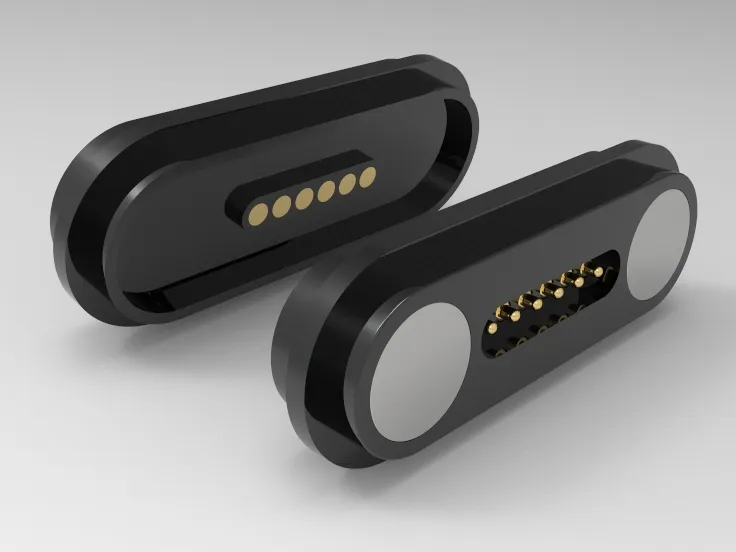

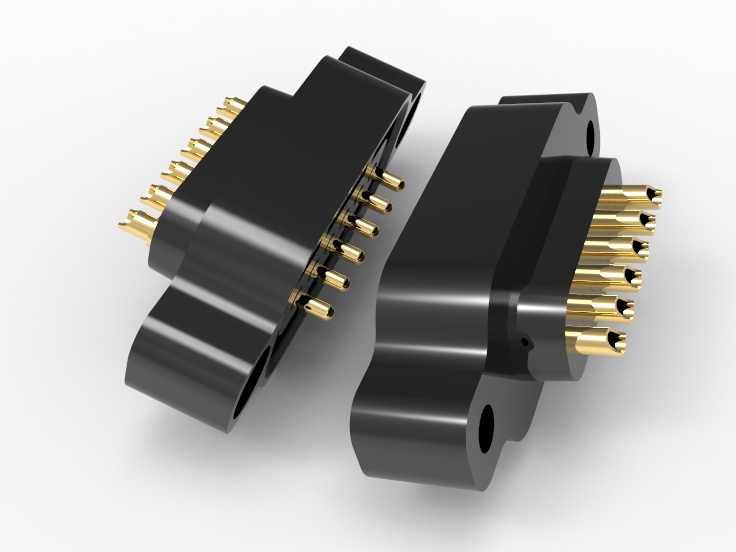

6 pin connector series, male and female with IP67, magnetic IP67 waterproof. 10 types:

- Standard for electrical signal and power transfer.

- High-frequency type with low signal attenuation and high bandwidth.

- High power transfer, ≥ 10A high current, a high current type that reduces heat loss and contact resistance.

- Compliant with IP67, IP68 waterproof type that uses special sealing rings and waterproof coatings to prevent water and dust from entering.

- Work normally at temperatures up to +150 °C or even +250 °C, with consideration given to high-temperature resistance, thermal expansion and thermal shock.

- Miniature 6 pin connector for portable devices, smart wearables, and mobile terminals with limited space.

- Multifunctional model that integrates power supply and data transfer, compatible with different signal types.

- Precision models for high-end applications that require high contact stability as well as low contact resistance.

- Double-sided plug-in type with simultaneous insertion and removal from both sides.

- Specific dimensions, materials, functions, lifespan, current and voltage, interface shape, installation method, customized for special environments. Compliant with RoHS, REACH, ASTM, etc.

Core Structure of 6 Pin Connector

| Struecture | Description |

|---|---|

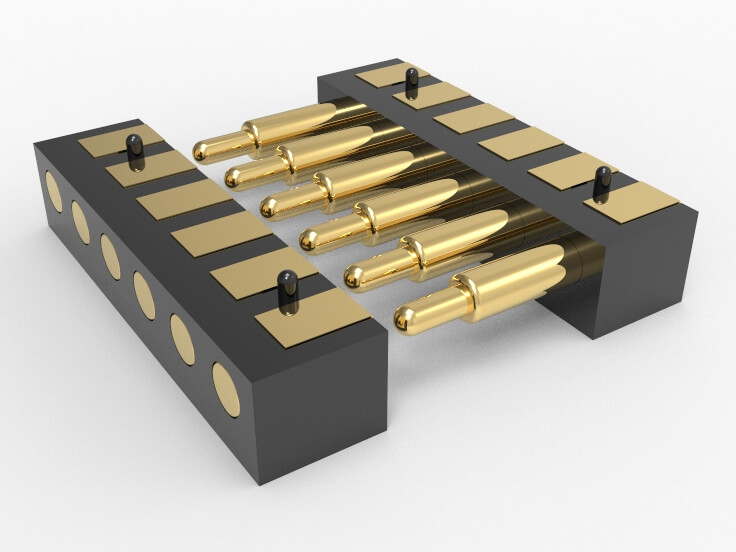

| Pogo Pin Assembly | Composed of a plunger, housing, barrel, and spring, it achieves controllable contact force and high-frequency insertion and extraction performance |

| Pin Configuration | Standard 6-pin, can be arranged in various ways, such as linear, matrix, circular, etc. to adapt to wiring and structural requirements |

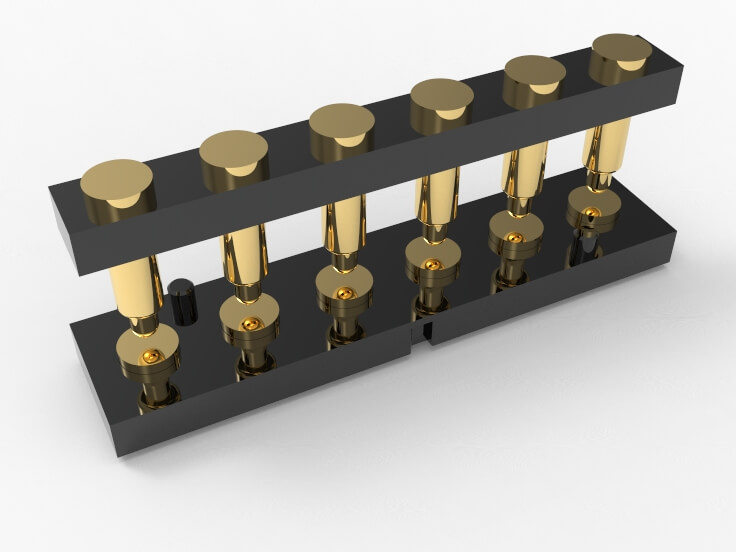

| Mounting Structure | Including various forms such as SMD surface mount, DIP direct insertion, solder-cup, right-angle, screw locking, etc |

| Connection Method | Support board to board, line to board, board to fixture and other methods to meet various system integration requirements |

| Contact Head Type | Various plunger tips: ball head, flat head, pointed tip, crown, cup, start, etc., adapt to different docking surfaces and contact requirements |

| Stroke Design | Spring stroke range is usually ≥ 0.10 mm, used to absorb structural tolerances and achieve reliable docking |

| Conductive Pathway | Independent conductive design, supporting high-frequency signal, power and ground separation wiring |

| Housing/Insulation | Provide directional, limiting, foolproof, and anti-misplacement functions, and some models support EMI shielding structures |

Specifications of 6 Pin Connector

| Parameter | Value |

|---|---|

| Pin Pitch | 1.00 mm, 1.27 mm, 2.00 mm, 2.54 mm, custom |

| Connector size (LxWxH) | ≥ 7.50 mm, ≥ 2.30 mm, ≥ 2.40 mm, depends on stroke and design |

| Pin Diameter | ≥φ0.50 mm (based on current, stroke/current,etc),custom |

| Spring Stroke | Effective stroke ≥ 0.10 mm, custom |

| Mounting Height | ≥ 2.40 mm for SMT configuration, custom |

| Plating Thickness | Gold 10 μin ~ 50 μin over Nickel ≥50 μin, custom |

| Contact Resistance | ≤ 50 mΩ, custom |

| Insulation Resistance | ≥ 500 MΩ @ 500 VDC |

| Dielectric Withstanding | ≥ 1000 V AC (1 minute) |

| Rated Current | 1.0 A ~ 50.0 A per pin, custom |

| Rated Voltage | ≤ 550V DC, custom |

| Mating Durability | ≥ 10,000 cycles, custom up to 100,000 |

| Housing Shape | Shaped, Round, Rectangular, L-shaped, Custom |

| Housing Material | PPS, LCP,HTN, PBT, PEEK, custom |

| Spring Material | SUS304, SUS316, SWP-B, BeCu, custom |

| PCB Mount Type | Right Angle, Double-Ended, SMT, DIP, Solder-Up, Screw Mount, Custom |

| IP Rating | IP67 or IP68, Custom |

| Plating Options | Gold 0.5μm – 3μm over Ni base, custom |

| Life Cycles | ≥ 10,000 cycles, up to 300,000, custom |

| Operating Temperature | -40℃ ~ +85℃, -50℃ ~ +125℃, custom |

| Salt Spray Resistance | ≥ 48 hours, custom |

| Special Features | Anti-misplug features, Alignment posts, shielding EMI, custom |

Applications of 6 Pin Connector

Automated Test System (ATE): A signal testing fixture used for high-frequency plugging. The 6Pin structure can achieve synchronous power supply, ground wire, and multi-channel signal sampling. Supports >10,000 insertions and removals, typically used in PCBA functional testing platforms.

Medical wearable device interface: suitable for charging and data synchronization interfaces at the bottom of miniaturized devices. Compliant with ISO 10993 biocompatibility requirements, capable of long-term stable contact in surface environments ranging from -10°C to+50°C.

Industrial robot end module: In the EOAT (End of Arm Tooling) module, it is used for quick signal/power docking of fixture module replacement. Supports ± 0.2mm alignment tolerance and a stroke of 1.5mm to ensure floating contact tolerance.

Aviation cable debugging interface: provides ground debugging channels for avionics equipment. Adapt to MIL-STD-810G vibration and temperature and humidity specification requirements. Avoid structural damage to traditional rigid interfaces during testing.

Electric tool battery docking terminal: As a quick plug and unplug power supply interface, it can carry 2A continuous current and has a design life of 30,000 cycles. Suitable for electrical docking between battery packs and handle modules in high-intensity industrial operations.

Smart watch base connector: used as a magnetic interface between the charging base and the host. Adopting a circular arrangement of 6-pin structure, with a stroke of 0.8mm and a contact impedance of <40mΩ. Verified through 1,000 insertions and removals after a 1-meter drop.

New energy on-board diagnostic interface: installed inside the vehicle harness or electronic control box, providing testing and programming interfaces for workshop debugging personnel. Meets the ISO 16750 automotive environmental electrical testing standard, with a 96-hours salt spray resistance.

Waterproof handheld terminal interface: encapsulated in an IP67 rated housing, with Pogo Pin design on the exposed front end of the connector. Realize non insertable waterproof docking, suitable for outdoor work type PDAs or measuring devices.

Military portable communication system connection module: applied to module docking units such as field radios and command terminals. Meets MIL-DTL-38999 structural dimension standard. The insertion and extraction force should be controlled between 50-80gf, and the impact resistance should be greater than 500m/s².

Embedded debugging interface: used for online burning or debugging of high-speed MCU, SoC and other core boards. 6-pin wiring supports JTAG/SWD standard signals, with a frequency of up to 10MHz, and is compatible with a minimum spacing of 1.27mm.

3C consumer magnetic data cable connection port: magnetic earphones, learning machines, etc., used to provide fast charging and data channels. A typical 6-pin configuration is V+/GND/USB D+/D -/ID/CLK, with a contact life that meets 15,000 tests.

Communication base station signal transfer test port: used for RF and control signal testing during on-site maintenance. The 6-pin design includes a redundant RF grounding structure with a contact impedance of less than 30m Ω. It meets the signal integrity requirements below 3GHz.

Why Johoty's 6 pin Connector As Solution?

Johoty’s 6 pin connector can give you excellent quality, flexible customization services, and competitive prices. We promise to provide customers with rapid response and on-time delivery with extremely high precision and reliability. Customers can improve product performance, reduce costs, and maintain sustained competitiveness.

Installation of 6 Pin Connector

Contact form

Adopting a multi-point spring pin contact structure. The single needle stroke range is generally 0.3mm to 1.5mm, with a gold plating layer thickness of 5 μ in or more. Effectively reduce contact resistance to the range of 10-50mΩ. Its axial floating ability adapts to small assembly deviations and improves reliability under multiple insertions and removals. The lifespan test can reach over 100,000 times.

Electric path

The single Pogo Pin path has low inductance (<5nH) and low resistance characteristics. Can support up to 5A continuous current or instantaneous 10A current path, with long-term stable contact impedance. The EMC interference minimization design can adapt to high-speed signal transmission. It has been widely used in transition interface scenarios for DDR4, USB 3.1, and customized high-speed channels.

Installation method

The common installation methods are SMT surface mount, through hole, solder up, and right angle. SMT type is more suitable for automated assembly The mounting accuracy can be controlled within ± 0.05mm, suitable for modern high-density PCB designs. The perforated panel provides stronger mechanical strength and is suitable for industrial applications under harsh working conditions such as high vibration and high temperature.

Connection method

The typical docking form is vertical crimping and lateral sliding, and the matching docking seat is mostly a customized structure. The docking tolerance design is controlled within ± 0.05mm. Insertion force <1.5N/Pin, pull-out force >0.5N/Pin, high-frequency insertion and stable contact. Some high-end applications have added anti misplacement positioning design and guidance structure to improve docking consistency.

Selecting 6 Pin Connector Based on Requirements

Current load requirements: For battery connections, motor control, etc., it is recommended to use a high elasticity gold-plated 6 pin connector with a rated current of ≥3A. Ensure that the contact resistance remains <50mΩ even under a compression stroke of 0.5mm, to meet the high current transmission requirements.

Anti vibration capability: Use a 6 pin connector with lateral positioning structure in automotive electronics and aerospace testing. It can pass the MIL-STD-202 standard vibration test, effectively reducing the risk of contact breakage.

Plug and unplug lifespan requirement: Industrial automation production line testing fixtures, using pogo pin components with a lifespan level of ≥100,000 cycles. Adopting stainless steel springs and hard gold-plated structure, it can maintain low resistance contact.

Corrosion resistance: In medical or marine application environments, select a structure with a gold plating thickness of ≥ 5μin and a shell packaging with an IP67 or higher rating. Effectively resist corrosion in high humidity and high salt spray environments.

Space limitations: For wearable devices or micro sensing modules, low back Pogo connector with a spacing of ≤1.27mm and a total height of ≤3mm. To meet the needs of board layout in confined spaces.

Temperature adaptation range: Use a material system with a temperature range of -40℃ to +125℃ in the engine compartment of automobiles or high-temperature environments in factories. The spring is made of CuBe or SS316 to ensure thermal stability.

Electrical signal integrity: A 6-pin connector with coaxial structure shielding used for high-speed data or analog signal transmission. Insertion loss less than 0.5dB (@ 1GHz) can reduce crosstalk and EMI.

Mechanical fixation method: In high-frequency testing or robot end applications, a 6 pin module with self-locking structure or positioning hole position is selected to help quickly match the fixture docking, improve assembly efficiency and stability.

Maintainability and replacement cycle: Modular structural design is used in situations where testing equipment maintenance is frequent. The 6 pin connector is fixed with a buckle or thread for quick on-site replacement, with <5minutes average maintenance time.

Cost-sensitive requests: In large-scale testing fixtures or civilian equipment, copper core + thin gold-plated (0.3 μin) economical 6 pin connector. Ensure basic performance while controlling unit price <1.00 USD (batch size of 3K or more).

FAQ

Why is 6 pin connector more popular than traditional plug-in connector?

Longer service life, stable and reliable connection, adaptable to harsh environments, compact size for integration, and low maintenance costs. Engineers prefer 6 pin connectors because their elastic structure reduces wear and ensures stable signals with low contact resistance. It is not easy to disconnect during vibration, with good dust and water resistance, and can adapt to high-density PCB layouts. The space saving design makes this pogo pin connector the preferred choice for precision equipment.

What is 6 pin connector working principle?

The spring pushes the plug tip, providing constant pressure to ensure stable contact, unobstructed signal flow, and efficient current transfer. The plunger tip tightly adheres to the contact surface under the action of the spring, ensuring stable conductivity. Not affected by external forces, the spring pre tension maintains contact and reduces resistance fluctuations. The signal quality of the 6 pin connector doesn’t get worse yet after prolonged use.

Why is 6 pin design more common than 4-pin or 8-pin?

Reasonable signal and power distribution, compact structure to meet most needs. The 6 pin connector can balance cost and performance, with better stability than 4-pin and lower complexity than 8-pin. 6 pogo pins can simultaneously transmit power and signals, suitable for multiple applications, it is just right. It can avoid unnecessary pins increasing costs while ensuring conflict free data and power transfer, making it a common standard.

How does 6 pin connector prevent current overload?

Control spring pressure, select appropriate electroplating layer, optimize contact area, ensure good heat dissipation, and avoid overcurrent damage. Excessive contact resistance can cause heating, therefore precise control of spring pressure is required to stabilize the contact. Reasonable selection of coating can reduce losses, increase contact area, and reduce resistance. The heat dissipation design ensures that there is no temperature rise when high current passes through, ensuring the stable operation of 6 pin connector.

What will affect life cycles of 6 pin connector?

Spring fatigue, contact surface oxidation, external force damage, temperature and humidity changes, and high current load. After prolonged use, the spring may lose its elasticity, and the metal surface exposed to air will oxidize and affect conductivity. Excessive external force may cause deformation of plunger tip, and extreme temperature and humidity may accelerate the aging of 6 pin connector. High current loads can cause overheating and also reduce the lifespan of 6 pin connector.

Why is gold generally used for plating or coating of 6 pin connector?

Gold is resistant to oxidation, has good conductivity, strong corrosion resistance, low friction loss, and maintains long-term stable connection. Compared to other metals, gold is not easily oxidized, has low signal transfer loss, and can withstand harsh environments. The service life far exceeds that of nickel or silver plating, and high-frequency contact will not affect contact performance due to wear. The 6 pin connector with gold-plated pogo pins is the best choice for high-precision connectors.

+86 13590816656

+86 13590816656 +86 13590816656

+86 13590816656