Best 7 Pin Connector China Manufacturer High Performance

7 pin connector provides contact pressure through built-in spring to ensure stable electrical connection. Customize male and female terminals in rows 1, 2, and 3, compatible with magnetic, waterproof, and EMI. Applications of high-density and high-precision. SUS, brass, Becu, gold plating, or composite coating to avoid oxidation and corrosion. Johtoy offers highly reliable and compact solutions for you.

Features:

- High-precision docking ensures stable signal transfer.

- Resistant to frequent connections, life < 200,000 cycles.

- Highly conductive materials provide low resistance.

- Compact design, small footprint for small environments.

- Anti-corrosion, gold plating, with strong antioxidance.

Adapt to vibrations to ensure continuous, stable contact.

7 Pin Connector Series

7 pin connector includes 10 different types of applications, performance, exterior design, and connection methods:

- Standard type with standard pogo pin design.

- IP67/IP68 protection, using sealing rubber rings, O-rings, etc., suitable for waterproof types of underwater equipment, marine equipment, medical equipment, etc.

- High-frequency transfer type that supports up to 10Gbps and reduces signal attenuation and interference.

- Up to 200,000 times, highly durable type with long-term stable contact.

- Ultra-small design, suitable for efficient electrical transfer in small spaces.

- High current type with stability and heat dissipation under 50A current.

- Fully customized pitch, size, customized materials, and surface treatment, providing personalized design and engineering support.

- Bending angle is 30°, 45°, 90°, etc., which can be flexibly configured in limited space.

- Low voltage/low power consumption type that reduces energy loss, and transfers current effectively.

- High-temperature reliability at 250℃ based on high-temperature resistant materials. Johoty offers flexible connectivity solutions based on ASTM, RoHS, REACH, etc.

Structure and Features of 7 Pin Connector

| Structure Type | Description |

|---|---|

| Integrated Housing | Encapsulates pogo pins and housing as one unit for enhanced durability. At least 10,000 mating cycles |

| Magnetic Integrated | Built-in magnetic alignment for auto-connection. fast-assembly use, magnetic force ≥ 0.5N |

| High-Frequency Micro-Array | Micro array with ≥ 1.00mm pitch; supports ≥ 5GHz signal, insertion loss <0.1dB |

| Power+Signal Hybrid | Partitioned power/signal layout reduces crosstalk; supports ≤50A power + ≥ 3Gbps signal simultaneously |

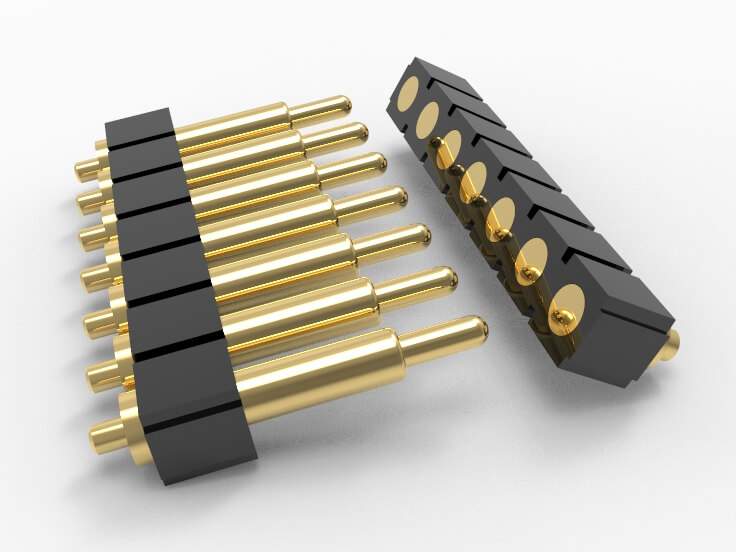

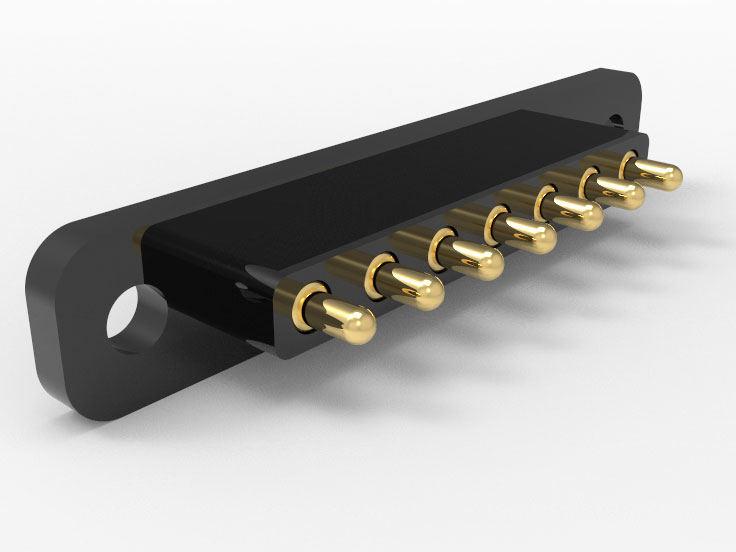

| Single-Line Inline | Simplified layout for narrow linear interfaces. ≥1.00mm pitch (standard 2.54mm) ensures basic signal integrity. |

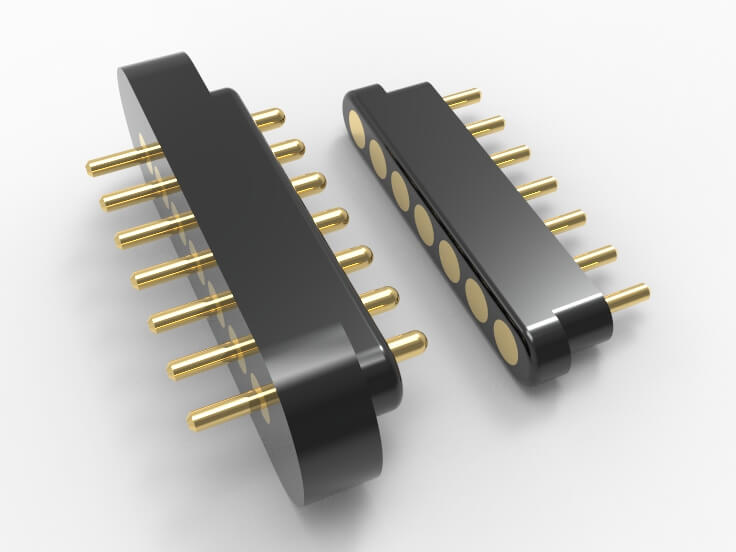

| Dual-Row Matrix | Parallel routing of signal and power. ≥1.00mm pitch (typical 1.27mm pitch) supports high-density compact layout. |

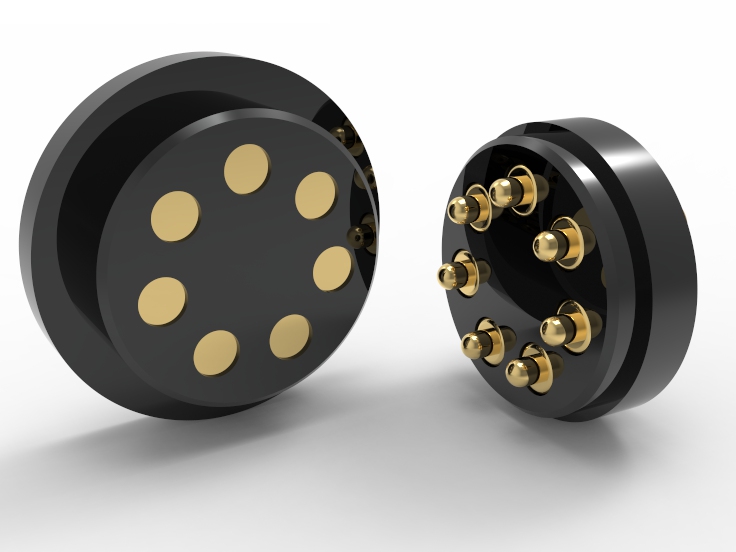

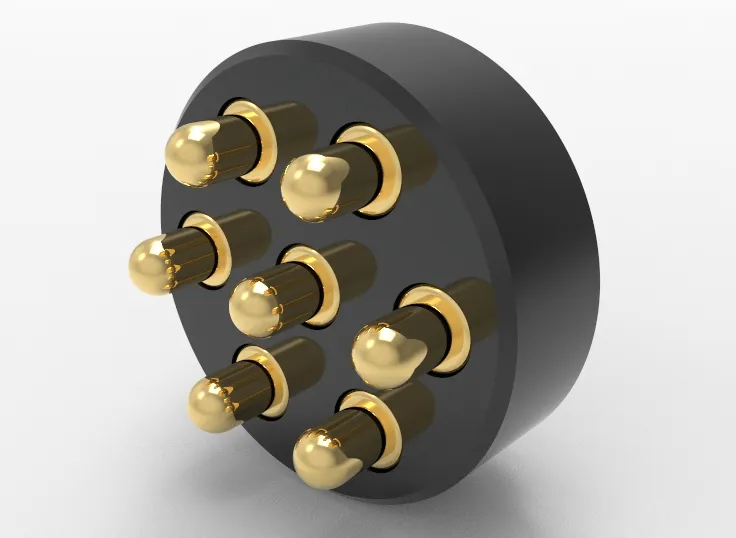

| Radial Circular | Provides 360° uniform contact for rotary mating or circular modules; symmetric layout improves mechanical stability. |

| Custom Irregular Layout | Asymmetric geometry or functional partitioning. Supports mixed signal/power zoning with flexible pitch and distribution. |

Specifications of 7 Pin Connector

| Parameter | Specification |

|---|---|

| Number of Pins | 7 pins |

| Pin Pitch (center-to-center) | ≥1.00mm, 1.27 mm, 2.00 mm, Custom |

| Outer Dimensions | ≥8.40mm × 2.50mm × 3.50mm, depends on structure, Custom |

| Working Stroke | ≥0.10 mm, Custom |

| Initial Spring Force | ≥5gf per pin, Custom |

| Rated Current | ≤50A per pin, Custom |

| Rated Voltage | ≤550V per pin, Custom |

| Contact Resistance | ≤ 50 mΩ, Custom |

| Insulation Resistance | ≥ 100 MΩ @ 100V DC |

| Dielectric Withstanding Voltage | ≥ 250V AC @ 60Hz |

| Operating Temperature | Custom -40℃ to +85℃, -55℃ to +125℃ |

| Mechanical Life | ≥ 10,000 mating cycles,500,000 cycles, Custom |

| Plating Thickness | Au ≥ 3μ″,up to 200μ″, Ni ≥ 80μ″,Custom |

| Material Composition | Brass, Phosphor Bronze, Stainless Steel, Polymer, Custom |

| Mounting Options | SMT, DIP, Solder-cup, Double-Ended, Bending, Right-Angle, Integrated Module, Custom |

| Supported Housing Types | Unibody, Modular, Magnetic, Custom |

| Signal Support | Power, Data, High-Frequency (>5GHz) |

| Insertion Retention Force | ≥0.5N/pin, ≥3.5N total, Custom |

Applications of 7 Pin Connector

Vehicle mounted T-Box communication and maintenance interface: 7-pin irregular arrangement suitable for limited space on the motherboard. The signal integrity has passed ISO 11452-2 testing and can withstand a wide temperature range of -40~105℃. The ability to resist electromagnetic interference meets the vehicle’s ESD and EMI standards.

Rail transit data acquisition module: using a micro high-density pogo pin array, supporting the coexistence and transmission of CAN bus and analog signals. Insertion force <2N, working temperature range -40~125℃. Contact resistance fluctuation<± 5mΩ, suitable for high vibration environments.

Industrial grade sensor module interface: adopts a dual row matrix structure and module hot swappable design. Pogo pin springs have a lifespan of over 100,000 cycles and a working temperature range of -40℃~85℃. Contact stability has passed the IEC 60512 vibration and thermal shock resistance test.

Wearable device charging/communication interface: adopts a magnetic suction + pogo pin array structure, with a single pogo pin supporting 1.5A current. The thickness of the corrosion-resistant gold plating layer is ≥1μm, and the contact impedance does not increase by >10% after 5,000 insertions and removals. Meets IPX7 waterproof requirements.

Portable medical device electrode connection: integrated sealed packaging design. Pogo pin preloading ≥0.4N, contact impedance <30mΩ, supports surface attachment for 7×24 hours. Suitable for continuous measurement devices such as electrocardiogram monitoring and sleep apnea.

Intelligent surgical assistance system interface: 7-pin irregular pogo pin array layout, precision control ± 0.05mm. Medical grade materials support EO and high-temperature sterilization, and the antibacterial coating is stable and non-oxidizing. Contact resistance changes by less than 5% within 5,000 cycles of use.

Modular power interface for unmanned aerial vehicles: irregular structure adapted to curved connection positions, mixed signal+power distribution. Each pogo pin supports a maximum current of 5A and an internal resistance of 50mΩ. MIL-STD-810G has no signal loss under shock and vibration conditions.

Storage robot charging dock docking pin: circular radial arrangement design + guide column assisted automatic docking. The tolerance for plug-in deviation is ± 2.5mm, the contact impedance is<20mΩ, and the contact pressure is >0.5N, suitable for automatic docking charging conditions.

Intelligent battery interface for electric tools: adopts an integrated crimping structure, and the pin material is beryllium copper +CNC molding. After gold plating, it can withstand ≥3,000 insertions and removals. Support built-in thermoelectric detection circuit and status feedback signal pins for batteries.

Consumer Electronics Quick Install Test Stand: The structure is arranged in a straight line with rebound limit, and the single insertion and extraction time is less than 0.5s. It is suitable for large-scale testing of smartphones, headphones, and other devices. 10m Ω contact stability, no resistance degradation after ≥20,000 cycles.

Intelligent security sensor power supply point: With a miniaturized design that supports back mounting, it is dustproof and waterproof up to IP65~IP67. After salt spray testing for 48 hours, the contact resistance increased by <10%. The double spring structure at the contact end enhances the stability of high-frequency point-to-point connections.

Satellite communication module interface: using a combination of ceramic base and precision barrel, suitable for signal transmission below 6GHz. Insertion force <3N, working temperature -55℃~125℃. The contact end is coated with Ni+Au double-layer to meet aerospace durability.

Why Johoty's 7 pin Connector As Solutions?

Choose Johoty’s 7 pin connector, you will gain leading technological advantages and reliable quality. Excellent reliability, precision, and durability, providing high-quality performance and reducing failure rates. Meet high-demand applications and create higher value for customers.

Finishing of 7 Pin Connector

Gold cobalt alloy electroplating layer

Widely used for high-speed data connections, supporting signal frequencies up to 6GHz. After 30,000 insertions and removals, the contact impedance changes by less than 5%, indicating high current stability. Wear resistance better than pure gold by 30%, commonly used in communication modules. Of course, this type of coating also poses certain challenges.

Thick gold electroplating (≥ 3μin Au over Ni)

Used for highly reliable aerospace/rail transit, the electrical performance remains stable after 100,000 cycles of plugging and unplugging. The contact resistance is less than 20mΩ, and when the gold plating layer reaches 50uin, the contact impedance can reach 10mΩ. There are no corrosion spots after 96 hours of salt spray, and the friction coefficient is less than 0.3.

Nickel palladium gold three-layer electroplating structure

Has excellent anti-corrosion ability. Long term operation at 85℃/85% RH, with a contact impedance increase of less than 10% after 168 hours of wet heat testing. Commonly used in wearable devices and implantable medical terminals. In the EMS system, it can also adapt to washing machine cleaning.

Ni/Pd/Pt/Pd/Au Five layer Composite Electroplating

This structure is symmetrical and enhances interface stability. Suitable for high-frequency and humid heat composite applications. Contact resistance <10mΩ, operate for 500 hours at 85℃/85%RH. Performance fluctuation <5%, with lifespan of >100,000 insertion cycles. Johoty’s customized 5-layer composite coating has the advantage of solving specialized problems.

Reliability of 7 Pin Connector

High frequency structure: adopts a short pogo pin + low impedance path design. Signal return loop <1.2mm, S11 reflection coefficient <-20dB. Supports complete transmission of differential signals up to 6GHz, suitable for RF and high-speed interfaces.

High insertion and extraction frequency design: Adopting a dual redundant spring system, the loading force is stable at 0.4~0.6N. After 100,000 insertions and removals, the contact resistance fluctuation is less than 8%. Used for ATE fixtures and production testing fixtures.

High current application: using a large diameter barrel and independent power supply contacts. Single pogo pin supports continuous flow ≤50A, with a contact point temperature rise of <30℃. By customizing a 50A current temperature rise test, it is stable and does not melt.

IP67 protection: using silicone O-ring and magnetic positioning assistance for compression, usually using injection molding process. Supports stable operation for half an hour underwater at a depth of 1 meter when plugged in. Meets the IEC 60529 level standard and is compatible with outdoor equipment interface modules.

Anti-vibration structure: Designed with multiple limit points on the barrel and base, in compliance with the IEC 60068-2-6 testing standard. Maintain contact resistance <20mΩ under 3-axis 5g vibration in the frequency range of 10-500Hz, suitable for rail transit.

Wide temperature application design: Adopting beryllium copper pogo pin+high reliability electroplating, the contact performance fluctuates less than ±5mΩ at -55℃ to+125℃ After 100 cycles of thermal shock, there is no deterioration in electrical performance, suitable for vehicle specifications and industrial control ends.

Customization of 7 Pin Connector

Alien plunger tip design: supports spherical, flat head, pointed head, cup head, claw head, star head, etc. Adapt to different contact surfaces and pressure applications. The ball head design showed no significant increase in contact resistance after 50,000 insertions and removals.

Non-standard spacing arrangement: Pitch of 1.00mm to 5mm can be combined arbitrarily. Accurately adapt to high-density or irregular interface requirements, with spacing tolerance controlled within ± 0.02mm.

Corrosion-resistant structure to seawater: nickel plating + gold plating double-layer protection or composite coating, passed ASTM B117 salt spray test for >500 hours without corrosion. Johoty’s 7 pin connector is commonly used for underwater robots and shipborne terminals.

High voltage insulation structure: Optimized needle spring structure and insulation layout, with a withstand voltage of up to DC1500V and a leakage current of <0.1μA. Widely used in high-voltage modules of industrial control and medical equipment.

Non-magnetic all material: The entire structure is made of non-magnetic copper alloy + PEEK plastic parts, with a magnetic flux density of <0.5nT. This pogo pin connector without nickel component is commonly used in MRI and high-sensitivity magnetic sensor applications.

Extreme cold and heat shock tolerance: Operating temperature -55°C to+125°C, 1,500g impact test without structural damage. Stable connection under extreme working conditions such as aerospace and military industries.

High frequency signal compatibility: Built in impedance control design, supporting differential signal transmission up to 3GHz. Insertion loss < -1dB@2.4GHz Used for high-speed communication modules.

Dust and foreign object blocking solution: Built in silicone protective cover + inverted cone structure chip removal design, foreign object intrusion rate <0.1%. Commonly used for complex vehicle mounted and outdoor terminals.

FAQ

Why use 7 pin connector?

7 pin connector provides reliable electrical contact, suitable for high-precision and high-density connections. They are used in mobile devices or computers. Compared to traditional connectors, pogo pins can effectively reduce friction and extend lifespan. During high-frequency contacts, 7 pin connector can also maintain stable performance. It’s very suitable for compact and precise connections.

How does 7 pin connector ensure stable current transfer?

The 7 pin connector achieves stable current transfer through springs. Its contact surface design allows for smooth current without interference from poor contact. The spring force ensures stable contact pressure under long-term use. Every time it is plugged or unplugged, 7 pin connector will make close contact without causing any fluctuations in electrical performance. The transfer of electric current is like passing through an unobstructed channel.

How to avoid contact oxidation of 7 pin connector?

To prevent oxidation, pogo pins are usually plated with gold, nickel, palladium, platinum, etc. The coating can enhances corrosion resistance and improve contact conductivity. Through these protective measures, the lifespan of 7 pin connector is significantly extended. When used in high humidity, oxidation issues can also be effectively avoided. The surface coating of this spring loaded pin is also highly adaptable to environment.

How does 7 pin connector perform in high temperatures?

Johoty’s 7 pin connector can work stably in high temperatures. Internal structure and materials can adapt to high temperatures while maintaining good electrical performance. This pogo pin connector can also keep stable contact force at up to 150°C. Under extreme conditions, pogo pins can continue to provide efficient electrical transfer, avoiding temperature affecting their performance.

Does 7 pin connector support high-frequency transfer?

Certainly, 7 pin connector can support high-frequency signal transfer and fit modern electronics. By optimizing spring, contact area is increased and signal attenuation is reduced. It can maintain low impedance and high stability, ensuring signal transfer is not affected. Johoty’s pogo pin connector can also handle complex high-speed signal and data transfer.

+86 13590816656

+86 13590816656 +86 13590816656

+86 13590816656