Customized 4 Pin Connector China Manufacturer High Quality

4 pin connector refers to a high-precision connector with 4 independent pogo pins to transmit multiple signals and power. Stable electrical connection, vibration resistant, wear-resistant, compact design, space-saving. Customize current, stroke, waterproof, size, magnetism, elasticity, voltage, lifespan, shape, etc. Gold-plated stainless steel brass, corrosion-resistant, shock resistant, and highly stable. Johoty’s professional solutions.

Features:

- High conductivity, gold-plated, low contact resistance.

- Long lifespan of ≤200,000 cycles, reliable and durable.

- Miniaturization, compact design for precision equipment.

- High elasticity, spring self-alignment, stable contact.

- Multi-functional, support power and signal transfer.

- Customizable, flexible adjustment, fully compatible.

4 Pin Connector Series

4 pin connector has 7 categories. Standard series: lifespan of >10,000 cycles, gold-plated brass, good conductivity, corrosion resistance, current 1~3A, 40°C~+85°C, uniform height, consistent spring force. High current series: current 5~10A, up to 50A, big a bit plunger reduces resistance and heat loss, with a three-layer coating that is wear-resistant for high vibrations. Ultra-small series: height of 1.6mm, barrel diameter ≥0.5mm, miniaturized design, high-precision assembly, contact resistance ≤ 50mΩ. Waterproof series: options of IP67&IP68 waterproof, O-ring or special resin packaging, fit humid and dusty, marine equipment, or high humidity environments. Customization series: poto pin pitch, spring strength, housing material, coating thickness to accommodate various PCB boards or cable, SMD, DIP, line to board, board to board. High speed signal series, up to 6GHz, 5Gbps, resistance ≤50mΩ, low dielectric material, reduces signal loss, high anti-interference, adaptable to complex EMI. Threaded locking series: self-locking, suitable for high dynamic application, reliable locking, high current, long-term stability under high vibration.

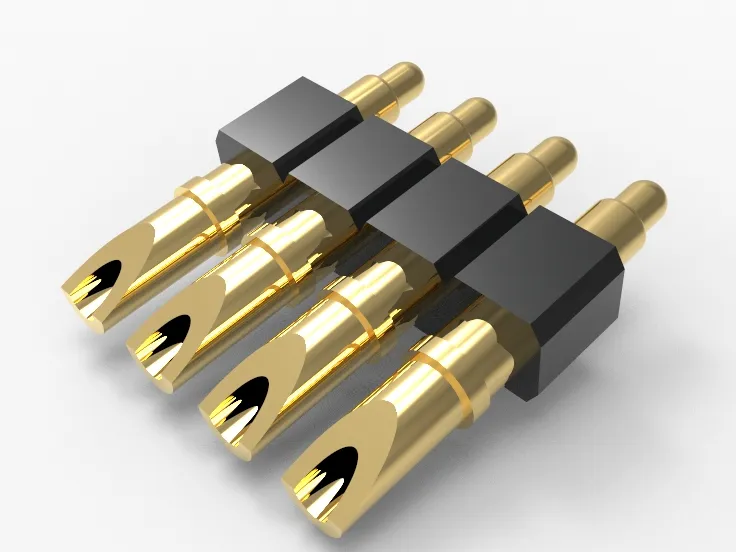

Structure and Function of 4 pin Connector

| Component | Description |

|---|---|

| Plunger | Establishes contact with mating surface, geometry, and finishing affect conductivity and durability. >20 customized shapes. |

| Spring | Maintains downward force to ensure continuous and reliable contact. |

| Barrel | Guides plunger movement and provides electrical path to terminal. |

| Housing | Aligns and insulates 4 pogo pins, supports mechanical integrity. |

| Base Terminal | Solder pad, through-hole, or SMT interface for connecting to the PCB circuit. |

Specifications of 4 pin Connector

| Parameter | Value Range |

|---|---|

| Pogo Pin Number | 4 |

| Contact Resistance | Initial ≤ 50 mΩ; stable working range 20–30 mΩ, Custom |

| Rated Current (per pin) | ≥ 0.10 A, up to 50.0 A, peak 100A, (depends on spring force, plating, and pin size), Custom |

| Operating Voltage (per pin) | ≥ 3.3 V, up to 10,000V DC or 250 V AC(based on insulation spacing and material), Custom |

| Insertion Life | 10,000 – 100,000 cycles (varies by tip wear and plating), Custom |

| Spring Preload Force | ≥ 5gf (standard options: 20gf, 20gf, 50gf, 100gf, 200gf, 300gf ), Custom |

| Working Stroke | ≥ 0.10 mmm (maximum total stroke up to 15.0mm), Custom |

| Pogo Pin Pitch | ≥ 1.00mm (common: 1.00mm, 1.27mm, 2.54m, etc), Custom |

| Plunger Tip Style | Dome, Flat, Cone, Cup, Round, Ball, Star (based on application and wear tolerance), Custom |

| Operating Temperature | -40°C to +105°C (up to +125°C for high-temp models) |

| Mounting Options | SMT, Through-Hole, Press-fit, Magnetic, Solder-Cup, Magnetic Waterproof, Custom |

| Plating Thickness | 1μin – 30μin gold (≥10μin recommended for corrosion resistance, up to 200μin for special project), Custom |

| Housing Material | LCP, PPS, PA9T, Peak, UL94 V-0 compliant high-temperature polymers, Custom |

| Environmental Sealing (opt.) | IP54 ~ IP67, or IP68 Waterproof (requires gasket integration), Custom, Custom |

Pin Configuration of 4 pin Connector

| Configuration | Functional Description |

|---|---|

| Power + GND + Signal + Control | Basic layout for standard supply, single signal, and low-level control line |

| Dual Power + GND + Signal | Designed for redundancy or dual-rail systems, improves supply reliability |

| USB Communication Mapping | VBUS, GND, D+, D-, suitable for USB low-speed charging/data sync |

| Differential Signal + Power + GND | Supports protocols like UART or LVDS, including power and return paths |

| I²C Communication Setup | SCL, SDA, VCC, GND; supports bidirectional master-slave data exchange |

| Multi-Signal Channel | 4 independent data/GPIO lines, used when no power transmission is needed |

| Power + GND + Shield GND + Signal | Adds shield GND to improve EMI robustness in analog or sensitive circuits |

Applications of 4 Pin Connector

Wearable device magnetic interface: suitable for power and signal composite connection of smart watches/health wristbands, with more than 20,000 insertions. Support blind insertion docking and microcurrent transmission, with module thickness control <3mm.

Portable medical diagnostic instrument connector: Supports 1.5A continuous current and low contact impedance requirements. Meet IEC 60601 standard for disposable/quick release sensor interfaces with lifespan ≥10,000 cycles, and material can pass ISO10993.

Industrial ATE testing fixture probe module: used for PCB signal testing and functional power supply connection in testing fixtures. Plug-in life is up to 100,000 times, spring compression is ≥1.2mm, and it can adapt to assembly errors of ±0.1mm.

Hot swappable interface for drone batteries: supports medium current loads of 3~5A, and the vibration resistant structure meets MIL-STD-810 vibration specifications. Barrel uses gold plating for ≥10μin to ensure contact stability in high humidity environments.

IoT terminal modular daughter board connection: used for wireless communication/sensor module docking, with pogo pin pitch of up to 1.00mm. Supports low-speed communication such as I²C/SPI, redundant plug and unplug interfaces can be configured with GND shielding, and has good EMI resistance.

Consumer electronics charging dock docking module: suitable for portable products such as headphones and cameras, with a magnetic structure and circular arrangement of contact pins. The structural height is less than 2.5mm, and the average contact resistance is controlled within 20mΩ.

Vehicle mounted module signal acquisition port: used for quick interface connection in the host box/module housing, meeting the wide temperature range of -40℃~ +105℃ for operation. The plug-in life is over 30,000 times, and the structure is designed for durability and stress.

Robot end tool quick change connection: used for fast electrical/signal switching of end effectors, typically a combination of DC power supply and digital signal. Equipped with a PIN self-correcting floating structure, with an error tolerance of ± 0.3mm.

Medical wearable device data conversion interface: supports low-voltage differential signals (such as BLE), current<1A, and the housing uses LCP to adapt to disinfection and cleaning processes. Meets UL 94 V-0 and IP67 waterproof.

Modular handheld terminal base docking: used for charging and data synchronization interface of industrial handheld terminal base, supporting UART + power configuration. The structure requires more than 50,000 insertions and removals, and the conductive material coating has high wear resistance requirements.

Laboratory detection and analysis equipment port: used for communication interface between biochemical analyzer and control terminal, requiring contact accuracy <± 0.05mm. High spring force stability, supporting experimental level repeated connection testing.

Smart home module replaceable interface: camera module and main control connection point, supporting signal integrity assessment and high-temperature aging testing. The shell design is compatible with UL standards, and the connection reliability MTBF is ≥100,000 hours.

Why Choose Johoty's 4 pin Connector?

Johoty’s 4 pin connector allows you to enjoy excellent cost-effectiveness and stable quality. Fast delivery and flexible customization services, our professional CFT team provides you with full support throughout your order process. Johoty makes your project more efficient and reassuring!

Package and Customization of 4 Pin Connector

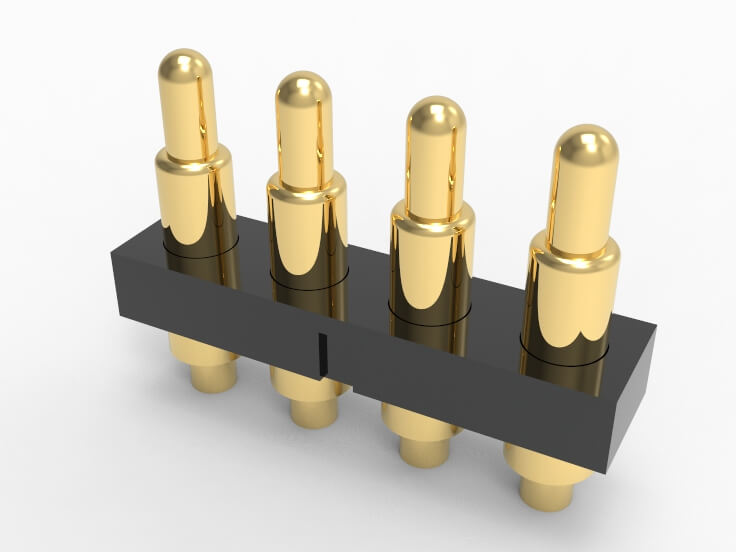

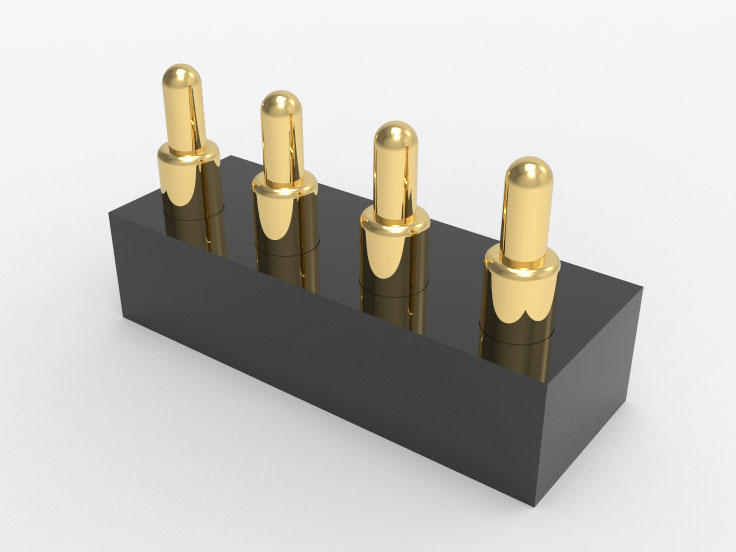

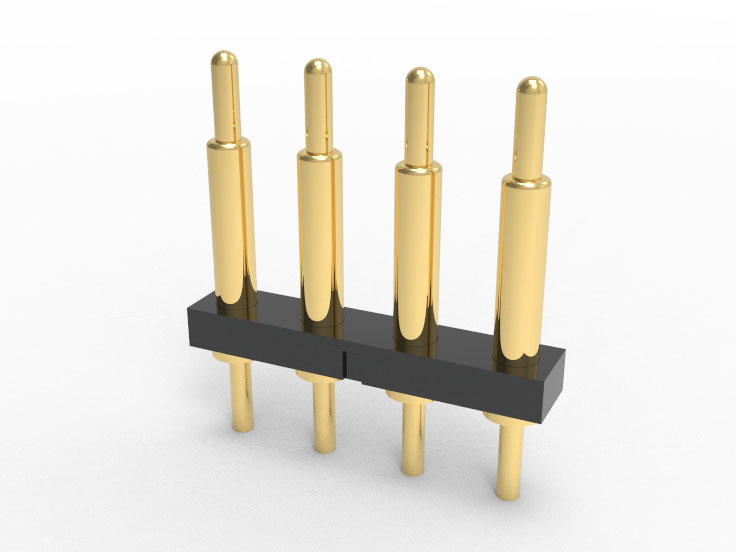

Inline packaging

Adopting a 1 × 4 linear arrangement, suitable for narrow spatial structures. Recommended needle pitch ≥1.00mm, compatible with SMD automatic mounting, right angle, through hole, Or soldering wire. Mostly used for strip module interfaces, supporting simplified PCB wiring paths.

Square Matrix Encapsulation (2x2)

Compact structure, suitable for high-precision docking applications. The typical shape is a 5 × 5mm packaging area, which can achieve a mechanical tolerance of <± 0.10mm in the XY direction. It is conducive to blind insertion positioning and symmetrical stress distribution.

Magnetic packaging module

Integrated NdFeB magnetic steel and positioning structure. Suitable for automatic suction connection of portable devices, combined with guide column control offset <0.3mm. Supports fast insertion and disconnection, suitable for high-frequency plugging and unplugging device interfaces.

Multiple parallel structures

4-pin is the basic unit, supporting parallel connection into composite structure modules such as 8-pin and 12 pin. Commonly used in signal/power partition design, internal grouping has independent GND to enhance EMC isolation capability.

Reliability and Qualification of 4 Pin Connector

Mechanical life test: Evaluate the number of insertion and extraction cycles, with a conventional standard of 10,000 to 200,000 cycles, simulating long-term mechanical wear.

Contact resistance stability test: Monitor impedance changes under constant load current to confirm the stability of connection performance.

Constant temperature and humidity test: temperature of 85℃, humidity of 85%, lasting for 168 hours, used to evaluate the stability of materials and coatings in humid and hot environments.

Cold and hot shock test: alternating cycles from -40℃ to+125℃, used to verify the matching of thermal expansion between structure and material and the stress-strain performance of solder joints.

Salt spray corrosion test: 5% NaCl solution, lasting for 48-96 hours, simulating the impact of marine/sweat corrosion environment on metal coatings.

High Accelerated Life Test (HAST): High temperature, high humidity, and high pressure combined accelerated aging, used to detect potential failure modes in advance.

Insulation resistance and withstand voltage test: used to verify the electrical isolation ability between pins, ensuring that no breakdown or leakage occurs.

Drop and impact testing: Simulate external impacts during transportation and on-site operations to evaluate structural resistance to rupture and contact head retention.

Vibration test: Scan at a frequency of 10-2,000Hz to confirm that the contact structure does not experience intermittent failure under mechanical vibration.

Insertion and retention force testing: Verify whether the required insertion force during connection and the retention force during disconnection are within the design range.

EMI shielding verification: Evaluate the shielding effect of supporting grounding and metal structures on high-frequency signal interference.

Welding heat resistance test: suitable for SMT process structure, ensuring that the terminal has no deformation or contact failure during the peak welding process at 260℃.

FAQ

What is 4 pin connector working principle?

4 pin connector utilizes the contact between pogo pins and contact points to transmit electrical signals. Each pogo pin has a spring inside to ensure a certain level of contact pressure. This pogo pin connector structure ensures stable signal transfer and reduces signal loss or interference. The spring loaded pin of 4 pin connector make direct contact with device contact points, forming a circuit. This design is suitable for chargers, testing equipment, etc.

How does 4 pin connector ensure stability?

The stability of 4 pin connector comes from its spring design and high-quality metal materials. The spring can maintain stable contact pressure and avoid poor contact. Pogo pins are precision machined to ensure good conductivity. Each pogo pin connector has large contact surface, reducing poor contact. Johoty focus on material durability in design, which extends service life.

Is 4 pin connector suitable for high temperatures?

Yes, it uses high-temperature materials that can work stably in high-temperatures. Johoty considered performance stability at high temperatures during design. Pogo pins can ensure the conductivity of this Pogo pin connector at high temperatures. When the temperature changes significantly, Johotys’ 4 pin connector can still operate stably and fit high temperatures or large temperature changes.

How reliable is 4 pin connector?

Its reliability comes from high-quality brass beryllium copper and precision CNC manufacturing. Each 4 pin connector undergoes strict 23 manufacturing processes to ensure performance. Contact surface of pogo pins is large, which can reduce the probability of poor contact. The spring can ensure that it won’t lose spring force after prolonged use. Johoty’s high standard production process ensures that every 4 pin connector meets high reliability.

How to avoid poor contact of 4 pin connector?

By maintaining cleanliness and proper installation, 4 pin connector can avoid poor contact. Pogo pin connector is effective in cleaning contact points to prevent dust and dirt accumulation. It ensures contact points between 4 pin connector and the device are not damaged. Reasonably select and install connectors to avoid uneven pressure. Avoid excessive plugging during use, which can extend service life.

+86 13590816656

+86 13590816656 +86 13590816656

+86 13590816656