Johoty’s Services of 4 Pin LED Connector

Sample of 4 pin LED connector: Provide STEP files and 2D dimension drawings for confirmation before producing the sample within 14 working days. By default, 3-5 sets of free samples will be provided, and the sample fee will be refunded after a certain quantity. Support welding/assembly testing verification.

Quality system: Johoty controls the entire process referring to IATF 16949 and ISO 9001. The gold plating layer, lifespan, contact resistance, and other full inspection records of each batch of pogo pins can be traced.

Delivery mechanism: Regular inventory samples are delivered within 3 working days, and batch orders <10Kpcs have a delivery time of 15 working days. Support phase delivery and BOM lock point alignment.

MOQ for 4 pin LED connector: The minimum order quantity for the first sample of the standard customized structure is 100 sets, and for mass production it is 3,000 sets. If it is a fully customized pogo pin structure, the complexity of the structure will be discussed separately.

Logistics method: DHL/UPS is optional by default during the sample stage, and customers can specify their account for shipping. Batch orders can be negotiated in multiple modes including EXW, FOB, and DDP.

Material traceability: pogo pin copper material, electroplated gold layer, insulation seat LCP/PPS can all provide ROHS/REACH/MSDS and third-party certification documents.

Test interface: 4 pin LED connector can be provided as a sample for the matching mother socket/fixture interface. Support customers in testing the electrical performance and thermal stability of the entire LED system.

Qualification of project liaison: FAE with over 10 years of experience in designing high-precision 4 pin LED connector. The customer liaison has a bilingual engineering background in both Chinese and English and the ability to collaborate on BOM research.

Change mechanism: Changes to parameters such as pin layout and current specifications require written approval from the customer. All ECN change records for 4 pin LED connector are traceable for 10 years.

Failure response: If contact abnormalities occur during customer testing or import processes, Johoty will provide structural and FA analysis within 48 hours.

Packaging method: Support T&R, vacuum tray, pallet and other packaging according to the customer’s equipment assembly process. The 4 pin LED connector supports labeling coding and scanning traceability.

Intellectual property cooperation: When it comes to customized structures or layout solutions for customers, an NDA will be signed by default. The design details will not be disclosed throughout the entire process.

Click: More Catalog

Performance Test of 4 Pin LED Connector

Contact resistance test: Measured using a 4-wire micro ohmmeter at a constant current of 10 milliamps, the contact resistance of a single pogo pin is ≤20 milliohms. The precision of LED voltage driving can be effectively guaranteed.

Lifespan test: Perform 10,000 reciprocating insertions at a frequency of 1 minute. Evaluate the mechanical structural reliability and electrical continuity changes of the 4 pin LED connector.

Voltage endurance test: Under 500V DC for 60 seconds, verify the insulation structure’s resistance to breakdown under small spacing conditions.

Insulation resistance test: tested at 100V DC, with insulation resistance not less than 100 megohms. The 4 pin LED connector controls the signal without interference or leakage.

Temperature rise test: When working for 1 hour with a rated current of 2A, the temperature rise in the contact area is less than 30 ℃. It is best to use Johoty’s 4 pin LED connector to continuously light up the LED.

Vibration test: According to IEC standards, 10Hz-55Hz sine sweep frequency, 1.5mm amplitude, 3-axis for 2 hours each, with stable contact.

Cold and hot shock test: alternate between -40℃ and +85℃, 10 cycles, and maintain each temperature zone for 30 minutes. Evaluate the stability of the soldering surface and contact structure of the 4 pin LED connector.

Salt spray test: spray for 96 hours at 35℃ and 5% sodium chloride concentration to detect pogo pin oxidation and coating peeling. Verify the reliability of the pogo pin gold plating layer on the 4 pin LED connector.

Drop test: Sample 4 pin LED connector is packaged in the terminal device housing to simulate assembly state, and can be freely dropped from a height of 1 meter on 6 sides once each. Observe the deformation and detachment of pogo pin structure.

Welding temperature curve test: SMT structure pogo pin, confirm 4 pin LED connector to withstand high temperatures of 260℃ for 5 seconds according to JEDEC standards.

Flame retardant rating verification: UL94V-0 material insulation seat requires a third-party testing report to verify the flame retardant rating of the structural plastic.

Dimensional consistency testing: 20 pieces are sampled from each batch, and key dimensions are measured using a 2.5D optical projector and digital micrometer. Confirm that the deviation between the 4 pin LED connector and the drawing is within ± 0.05mm.

Click: More Catalog

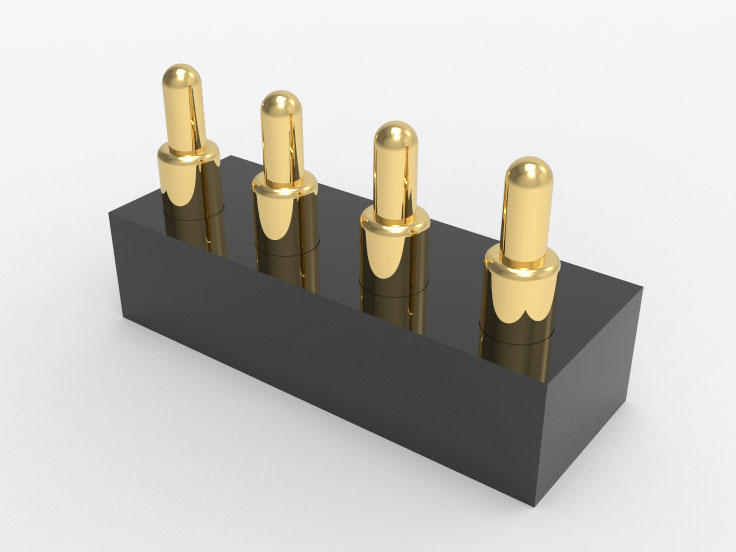

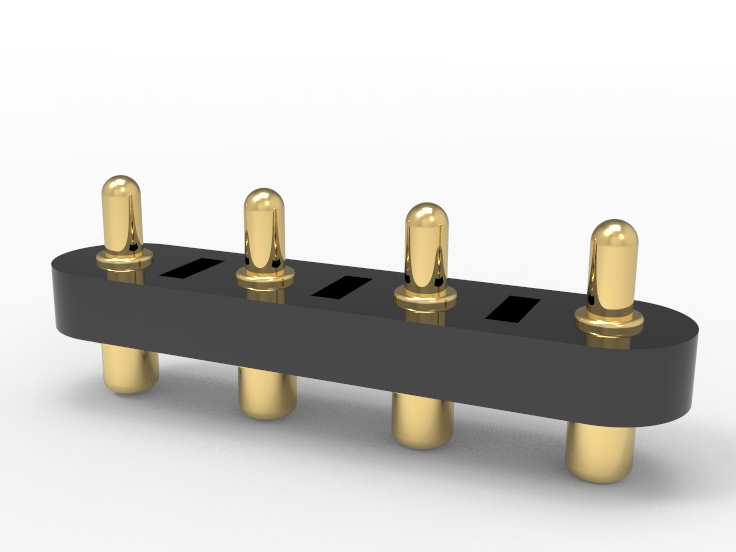

Customization of 4 Pin LED Connector

Pogo pin layout customization: supports non equidistant pin placement, with a minimum center distance of 1.00mm, suitable for irregular LED modules and asymmetric power interfaces.

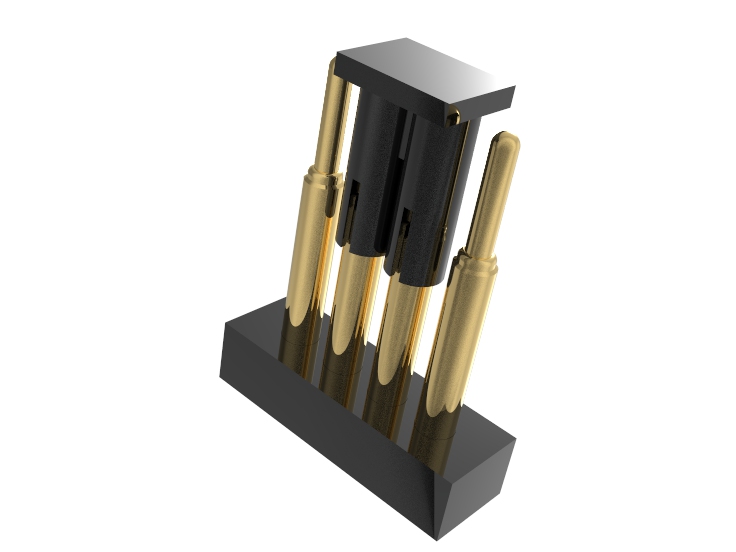

The length and stroke of the pogo pin can be adjusted: the stroke range is 0.10mm to 3.50mm, and the static pogo pin length error is controlled within ± 0.05mm.

The current carrying capacity is designed as needed: a single pogo pin supports different specifications from 0.3A to 50.0A. Match the copper core diameter and spring force constant based on the power density of the customer’s power module.

Customization of structural locking methods: providing friction crimping, positioning hooks, and screw hole matching selection to adapt to customer assembly methods and space constraints.

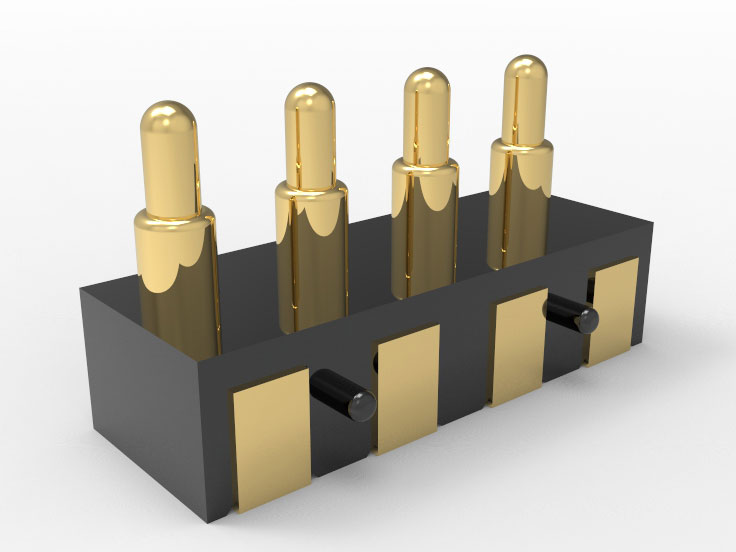

Plastic seat material selection: default LCP (fiberglass reinforced) or PPS, resistant to welding high temperature of 260℃. 4 pin LED connector can be used for reflow soldering or plug-in processes.

PIN material and surface treatment customization: supports phosphor bronze, beryllium copper, and stainless steel materials. The gold plating thickness can be set arbitrarily within the range of 0.5μm to 5μm.

Overall design of external dimensions: The maximum boundary of the terminal shape is ≤5mmx5mm, and it can be embedded into space limited structures such as LED packaging boards and backlight boards.

Female/male seat development: It can simultaneously provide development of docking end components and simulation of docking retention force. The electrical continuity and assembly reliability of the 4 pin LED connector are guaranteed.

Automated assembly coordination capability: Provide design solutions such as pogo pin guide angle, import slope, terminal chamfer, etc. Ensure that the assembly process of the customer’s assembly line can achieve a success rate of over 99.8%.

Packaging methods are customized according to the production line process: blister trays, T&R, trays, bulk packaging and other methods can be selected to meet the customer’s SMT mounting and manual assembly process.

Color and logo customization: Different colors can be provided for injection molding or laser labeling. Used for positive and negative pole recognition, functional position differentiation, and surface mount positioning of 4 pin LED connector.

BOM cascading adaptation: supports customers to directly input the functional positioning and interface of 4 pin LED connector in the entire lamp BOM structure. Conduct integrated customized design and output drawings.

Click: More Catalog

FAQ

What LED driver load current is suitable for your 4 pin LED connector? The rated current of a single pin ranges from 0.5A to 50.0A, and the actual current carrying capacity is proportional to the size, spring force, and material of the pogo pin. Designed to cover most LED backlight/lighting power requirements with a 4 pin LED connector.

How to avoid breakdown or signal crosstalk in 4 pin LED connector with pitch <3.50mm? Adopting a high ratio insulation housing + short pogo pins, the insulation strength has passed the 500V DC withstand voltage test. Pogo pin layout can be optimized directionally to reduce coupling interference.

Can 4 pin LED connector adapt to the non-standard pogo pin layout of our custom LED module? Support, pitch supports a minimum of 1.00mm, and pogo pin positions can be arranged non equidistant. The female seat and structure can be synchronized and co-installed, supporting the docking of irregular modules or bending areas.

How to ensure the lifespan and contact reliability of 4 pin LED connector during repeated connection or mobile assembly? After 100,000 cycles of mating, the increase in contact resistance of 4 pin LED connector is <10%. The theoretical lifespan of the structural elastic failure point is >200,000 times, suitable for frequent insertions.

Has 4 pin LED connector been evaluated for any common assembly and soldering processes? The 4 pin LED connector supports SMT, solder-cup, THT, and right angle processes. The selection of plastic material meets the requirements of 260℃ reflow soldering, with foot length and pogo pin tail shape.