Best Magnetic Connector China Manufacturer for Reliable Mating

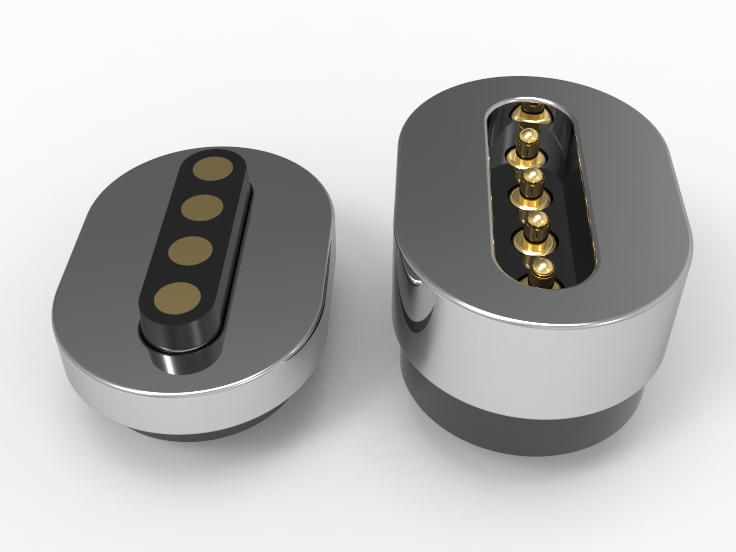

Magnetic connector has strong auto-locking, custom, durable and stable, efficient data transfer and charging speeds. Built-in N52 magnets, it’s for charging, signal, ease attachments. Johoty offers perfect tailor and on-demand production.

Features:

- Strong magnetic attraction.

- Compact and portable, effortless to carry and operate.

- Easily tailored to fit different needs and uses.

- Durable and stable, resistant to long-term damage.

- Efficient data transfer and charging speeds.

- Multiple connection interface options.

Magnetic Connector Series

Magnetic connector achieves fast, precise, and reversible connections through magnetic force, ensuring magnetic strength and positioning accuracy. With gold and silver plating, it supports current, data, and signal transfer. IP67 and IP68. Round, compact design suitable for medical devices or wearable devices. Rectangle, used for industrial equipment, supports high-power transfer and multi-channel signals. Customize interface shape, magnetic strength, or functional modules.

Classification of Magnetic Connector

| Type | Description |

|---|---|

| Pogo Pin Number | Single pin, Dual pin, Small multipin (3–10), Medium (11–30), High density (>30) |

| Magnetic Structure | Single-end magnetic (magnet on one side), Dual-end magnetic, Internal magnet integration |

| Mounting Type | Surface mount (SMT), Through-hole (DIP), Right-angle(90°), Solder-cup, custom |

| Protection Rating | Open type (non-sealed), Dust-resistant (IP40–54), Waterproof (IP67), Submersible (IP68), custom |

Specifications of Magnetic Connector

| Parameter | Value |

|---|---|

| Number of Pins | 1~200 pins, custom |

| Mating Cycles | 10,000~500,000 cycles, custom |

| Spring Force | 5gf~3.0N (per pin), custom |

| Current Rating | 0.1~5.0A (per pin), custom |

| Voltage Rating | 1.0~250V DC, custom |

| Contact Resistance | ≤50mΩ (typ. 10~30mΩ), custom |

| Insulation Resistance | >100MΩ @ 100V DC |

| Operating Temp. | -40°C to +85°C, custom |

| Stroke | ≥0.10mm, custom |

| Tip Diameter | 0.15~10.00mm, custom |

| Pitch | ≥1.00, custom |

| Housing Material | LCP, PA66, PBT, custom |

| Spring Material | SUS304, SUS316, BeCu, custom |

| Plunger Material | Brass, Copper alloy with Ni/Au, custom |

| Magnet Type | NdFeB (N35~N52), custom |

| Magnetic Force | 1~7N, custom |

| Mounting Type | SMT, DIP, Solder-cup, Right-angle, Screw mount, custom |

| Packaging | Tape & reel, Blister tray, Custom tray, custom |

Applications of Magnetic Connector

Magnetic docking charging for medical wearable devices: The magnetic structure is foolproof and prevents misalignment, with a single handed blind insertion success rate of over 98%. IP67 rating ensures waterproof reliability in skin contact areas.

Robot module magnetic connection redundant power supply: supports automatic alignment and self-cleaning function. Reduce the fatigue failure rate of joint cables by 35% and decrease the annual maintenance frequency by about 40%.

Drone battery compartment magnetic quick change structure: magnetic assisted guidance with ±0.3mm tolerance automatic docking, replacement time <5 seconds. The interruption time of homework has decreased by more than 60%.

Car mounted central control magnetic suction module interface: The split type central control module can be quickly assembled/disassembled through magnetic suction. Ensure stable 5A power supply, with a contact lifespan of over 10,000 times.

Consumer grade 3C electronic accessories magnetic assembly: module connection does not require tools, magnetic retention force >1.2kgf. The contact stability within a height of 1.5m against falling is greater than 99%.

Industrial handheld terminal magnetic charging interface: automatic adsorption connection replaces traditional Type-C, supports 3A current. 300,000 on-site uses without power outage feedback.

Modular electric tool battery replacement system: magnetic assisted alignment of battery components + stable power supply with spring top pin. Supports 10A continuous output, saving 45% of loading and unloading time.

Storage and logistics AGV magnetic charging station: automatic adsorption and alignment under unmanned guidance, supporting 8A fast charging. The tolerance for charging contact error is ±0.4mm, and the stability rate during nighttime operation is greater than 99.5%.

Intelligent lighting lamp head magnetic replacement solution: The magnetic connection between the lamp head and the base has a tolerance of ± 0.5mm. It supports hot plugging and split power supply, reducing assembly time by about 60%.

Magnetic connection structure of rail transit information module: magnetic connection and positioning of subway/light rail crew display module. Dual redundant design for signal and power supply, with a <0.03% average annual failure rate.

Design of magnetic interface for military communication terminal: Supports glove wearing operation, magnetic contact resistance to salt spray ≥96 hours, stable contact impedance <40mΩ.

Intelligent glasses magnetic charging and module expansion: The frame has a built-in magnetic positioning structure, allowing for stable connection within ±0.2mm dynamic displacement. Support 2A continuous power supply and stable data link.

Why Choose Johoty's Magnetic Connector for Charging, Connection?

Johoty magnetic connector, you will experience efficient, safe, and convenient charging and connection. Innovative design supports one-handed operation, protects device interfaces, and extends service life. Compatible with multiple devices, meeting various needs, bringing you more efficient, durable, and easy-to-use solutions, helping to improve your quality of life.

Positioning of Magnetic Connector

Point type magnetic pole precise positioning:

By guiding positioning with multiple magnetic points, high-precision positioning of ±0.1mm can be achieved. Commonly used for space limited equipment such as small modules and optoelectronic connectors.

Dual pole misalignment guidance positioning:

North and South pole misalignment attraction achieves directional correction, and the anti reverse function of insertion is significant. Significantly reduce the rate of manual operation errors and improve assembly reliability.

Surface array magnetic matrix positioning:

Multi point magnetic attraction surface array controls XY axis and rotation angle. The docking repeatability is better than 0.05mm. It is suitable for connecting automation equipment and modular systems.

Embedded positioning of circular magnet:

The magnetic ring forms a uniform magnetic field, providing 360° automatic correction positioning. The docking accuracy is controlled within ± 0.2mm, suitable for high-frequency precision docking scenarios.

Precautions and Selection of Magnetic Connector

Current density design: For high current applications, it is necessary to ensure that the contact cross-sectional area is ≥ 0.5mm ² to avoid temperature rise exceeding 20°C. A current should be ≥ 1.5mm ² and carry current 10A@25°C, contact resistance <5mΩ.

Travel margin optimization: Mechanical travel needs to be ≥0.3mm redundant, compensating for PCB assembly tolerances (±0.1mm). The spring has a stroke of 1.2mm ±0.05mm and a lifespan of 500,000 cycles.

EMI interference suppression: The magnetic structure requires a shielding layer grounded, with RF leakage <-60dB. Equipped with copper shell shielding, the radiation attenuation in the 3GHz frequency band is ≥30dB.

Waterproof level matching: IP68 requires silicone sealing ring compression rate of 30% ±5%. Double O-ring design, no leakage for 72 hours at a water depth of 50m.

Temperature drift control: Contact displacement ≤0.1mm at a temperature difference of 100°C, CTE matching coefficient<5ppm/° C. Beryllium copper alloy spring, displacement<50μm at -40°C ~125°C.

Magnetic strength calculation: The adsorption force should be ≥2N to prevent vibration and detachment, but ≤5N to facilitate manual separation. Neodymium iron boron magnetic group, with a holding force of 3.2N ±0.3N.

Contact material selection: Gold plating layer ≥ 0.5μm, ≤ 50mΩ contact impedance, resistant to 100,000 insertions and removals. Hard gold coating HV ≥200, friction coefficient <0.2.

Vibration environment reliability: Contact resistance fluctuation<10% under random vibration of 5Grms. Our three claw spring structure has no failure in the 20Grms test.

Multi pin alignment tolerance: 12pin array center distance tolerance ± 0.05mm, to avoid misalignment and short circuit. Use a magnetic positioning ring with a self-alignment angle of ± 5°.

Corrosion protection design: Contact resistance change <15% after salt spray testing for 96 hours. Ruthenium nickel plated bottom layer, resistant to 500-hour salt spray.

FAQ

What is magnetic connector?

The magnetic connector is a device that uses a magnet to connect two electronic components. When two components approach each other, the magnet will automatically attract and fix the connection. This design makes device connection very simple and reduces the tedious operation of manual plugging and unplugging.

What are the magnetic connector advantages?

The biggest advantage of magnetic connector is the simplicity. Compared with traditional plug sockets, the magnetic pogo pin connector does not require alignment, and the magnetic force automatically attracts the connection, improving the user experience while reducing wear and tear.

Can magnetic connectors transmit data?

Yes, magnetic connector can transmit electricity and data. Modern magnetic electrical connector use high-frequency signal technology, so it performs well in high-speed data transfer and are suitable for use in multiple devices.

What is the magnetic connector lifespan?

The magnetic connector lifespan is long from 10,000 to 50,000 cycles under normal usage conditions. Its lifespan depends on magnet quality and external environment. In general, magnetic electrical connector can support more than 10,000 insertions and removals.

What applications is magnetic connector suitable for?

Magnetic connector is widely used in smartphones, laptops, headphones, and medical devices, especially in frequent plugging and unplugging. In addition, it is often used in smart homes and automation control systems.

Can magnetic connector prevent current overload?

Yes, the magnetic connector can prevent current overload and equip with built-in overcurrent protection circuits. This can cut off the connection to avoid damaging equipemnt when the current is high. When using, it is still important to ensure that it matches the current range.

What is magnetic connector max load?

The load capacity of a magnetic connector varies depending on the design and the strength of the magnet. Generally speaking, magnetic electrical connector is suitable for withstanding moderate currents and loads, but if very high currents or loads are required, traditional connection methods may be more suitable.

Is the magnetic connector waterproof?

Yes, the magnetic connector waterproof depends on the specific design. The high-quality magnetic electrical connector adopts a good sealed design, reaching up to IP68, which can effectively prevent moisture and dust from entering. It is important to ensure that waterproof equipment suitable for outdoor or special environments is selected.

+86 13590816656

+86 13590816656 +86 13590816656

+86 13590816656