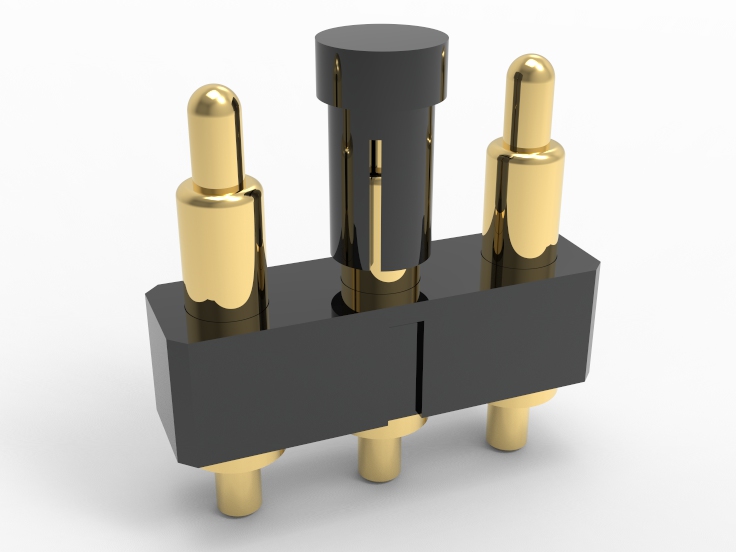

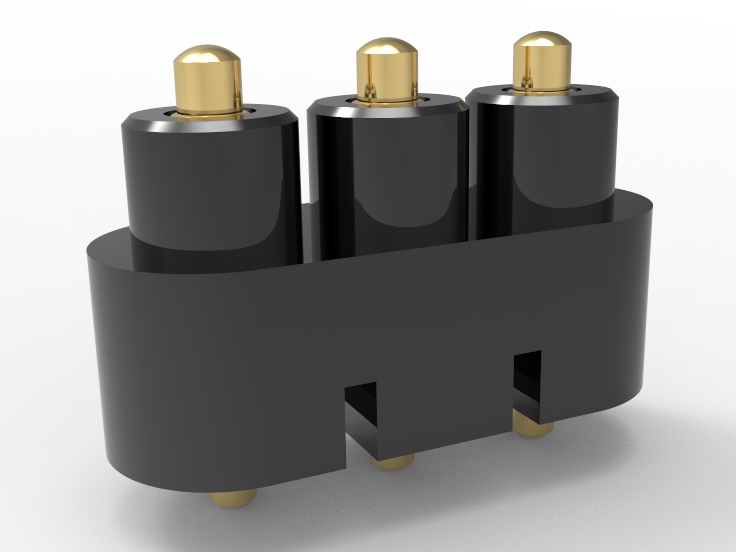

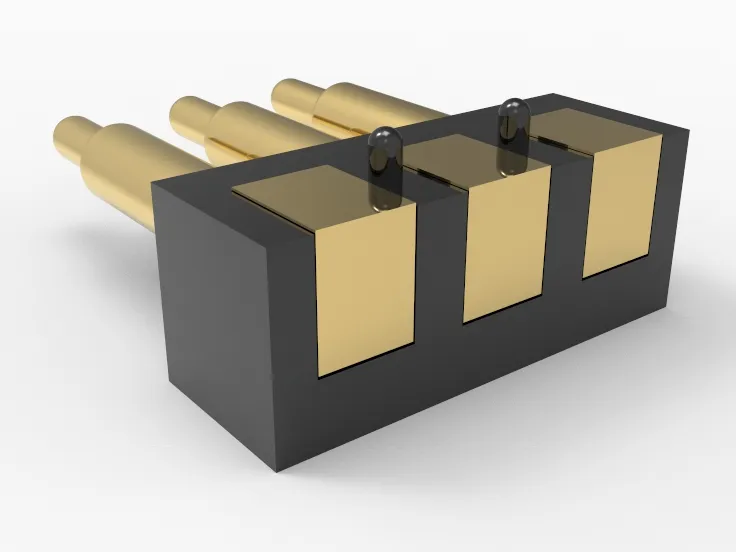

Best 3 Pin Connector China Manufacturer With High Reliability

Features:

- High precision, stable, and reliable electrical transfer.

- Long lifespan, withstand 200,000 precise connections.

- Low resistance, effectively reduces signal transfer loss.

- Anti-oxidation, anti-corrosion, improve contact stability.

- Wide use, suitable for various electrical conduction needs.

- Compact design, space-saving for intensive installation.

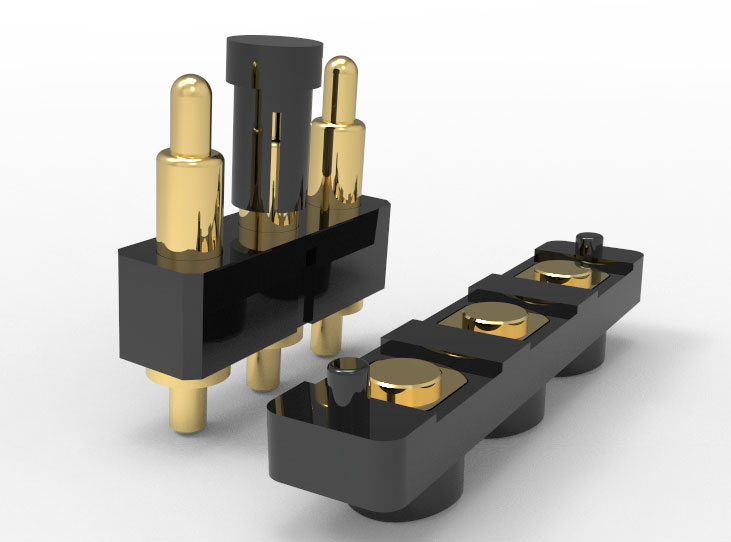

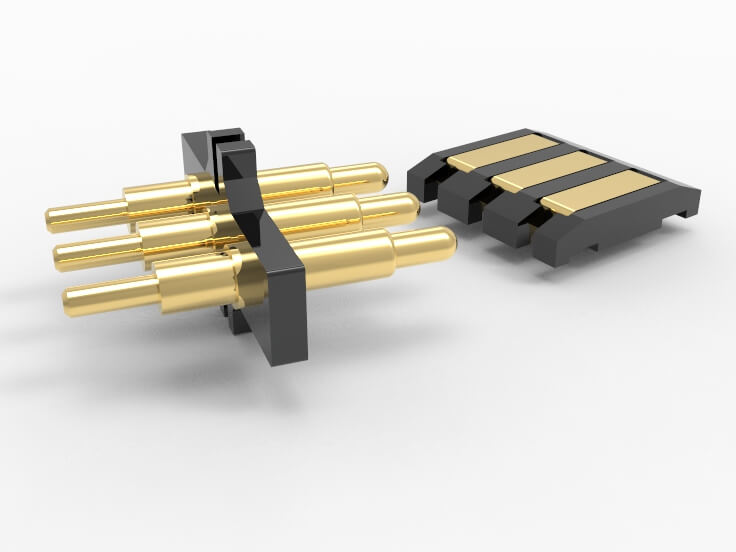

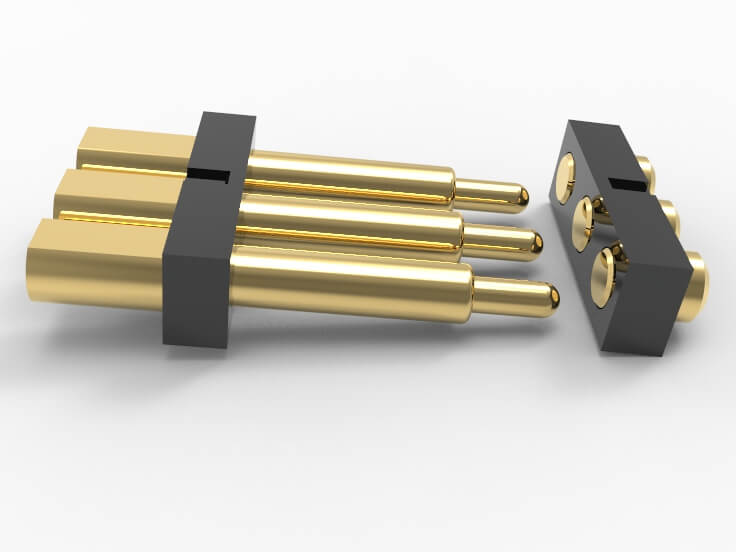

3 Pin Connector Serials

3 pin connector has standard, high-frequency, high-power, waterproof, magnetic, waterproof magnetic, low-power, high temperature, customized, precision series. Pogo pin material is stainless steel 304/316, tellurium, beryllium, brass, copper alloy, etc. Spring material is piano steel, stainless steel. Housing can provide electrical insulation, protect pogo pins, mechanical function. Housing materials offer electrical insulation, mechanical support and protection, waterproof and dustproof, constant pressure of spring loaded pin, temperature resistance, EMI shielding, sealing/leak prevention. Solve customers’ problems in design, manufacturing, long-term use of high-frequency signal transfer, frequent plugging and unplugging, high current carrying, seismic protection, limited space, etc.

Specifications of 3 Pin Connector

| Parameter | Value |

|---|---|

| Plunger diameter | ≥0.50 mm, Custom |

| Pitch | ≥1.00 mm, Custom |

| Total length | ≥3.00 mm, Custom |

| Diameter tolerance | ±0.02 mm |

| Full stroke | ≥0.10 mm, Custom |

| Working stroke | ≥0.10 mm, Custom |

| Spring force | ≥5 gf/pin, Custom |

| Life clcle | 10,000 – 500,000 cycles, Custom |

| Operating temperature | From -40℃ to +85℃, -50℃ to +125℃, Custom |

| Contact resistance | ≤50 mΩ (typ. < 30 mΩ), Custom |

| Rated current | 1A – 50 A continuous, peak 100A, Custom |

| Rated voltage | ≥ 3V, Custom |

| Dielectric withstand voltage | < 500 V DC |

| Insulation resistance | > 1000 MΩ @ 100V DC |

| Plunger plating | Gold (Au) 0.1 – 3.0 μm, Custom |

| Barrel plating | Gold (Au) 0.1 – 3.0 μm, Custom |

| Spring plating | Gold (Au) 0.1μm or no, Custom |

| Plunger material | Brass, Beryllium Copper (BeCu) or Phosphor Bronze, Custom |

| Barrel material | Brass or Stainless Steel (SUS303/316), Custom |

| Spring material | SWP-B, Stainless Steel (SUS304/SUS316), Custom |

Applications of 3 Pin Connector

PLC expansion module docking for industrial automation: 3 pin connector achieves 24V power supply, ground wire and control signal output. Supports a lifespan of ≥100,000 insertions and removals, with a pitch of 1.27mm, suitable for modular design within DIN rail systems.

Portable ECG signal interface for medical equipment: 3 pin connector for power supply positive and negative poles and data synchronization, with a contact resistance of <40m Ω. The anti misoperation structure design meets the IEC 60601-1 safety standard and supports humid and hot sterilization environment.

Consumer electronics headphone charging and detection interface: The 3-pin pogo pin structure is used for the positive and negative poles of the power supply and status feedback. Rated current 1A, suitable for twisting and lateral sliding, meets IPX4 waterproof requirements for daily use.

The battery hot swappable contact unit of the drone: uses 3 pins for +V, GND, and temperature detection signal channels. Withstand voltage of 200V, ensuring constant contact force during module hot plugging, with a seismic rating of IEC 60068-2-6.

Handheld measurement module interface for instruments: 3 pins respectively transmit power supply, electrical signals, and equipment identification codes. Combined with magnetic assisted positioning, the mechanical lifespan exceeds 50,000 cycles. Typically used for power inspection devices.

Signal maintenance port for the central control module of automotive electronics: used for ECU maintenance socket, supporting LIN bus and 5V power channel communication. EMI leakage <30dBuV/m, in compliance with ISO 11452 EMI testing standard.

The wall control module socket of smart home: 3 pins respectively undertake 12V power supply, grounding, and RS-485 signal functions. Easy to replace between modules, meeting UL 94V-0 flame retardant standards and household EMC rating requirements.

The gripper power supply and signal integration port at the end of the robot: an integrated 3-pin power supply and control signal interface, with a needle pressure of 80gf, suitable for multi angle contact. Support the requirement for quick replacement of end of arm tool heads (EOAT) in robotic arms.

Intelligent barcode scanner charging base for warehousing and logistics equipment: Charging, grounding, and status indication feedback are achieved through 3 pins. The fluctuation of contact resistance is less than ± 5m Ω, and the reliability does not decrease under high-frequency placement/removal.

Module level power backup contact for communication base stations: Provides a DC power interface using a 3-pin docking method, supporting -48V input. Satisfy the working environment temperature requirements of -20°C to +70°C, commonly used in BTS module design.

Simple power supply and communication port for educational research and development board: GND/VCC/serial port TX is defined as a three pin configuration, which facilitates simplified wiring and debugging of the prototype board. The interface is matched with a 1.0mm needle pitch for easy miniaturization layout and hot plug experiment operation.

Industrial testing fixture, automatic probe testing interface: 3-pin arrangement applied to functional testing (FCT) platform, used for power on, ground wire and program trigger signal channels, with needle length controlled at 3.0 ± 0.05mm and high repeated contact accuracy.

Why Choose Johoty's 3 Pin Connector?

Choose Johoty’s 3 pin connector because of its high quality, reliability, complete customization, and competitive price. Advanced CAD/CNC/CCD ensures reliability, precision and long durability. Flexible and efficient production capacity, precise delivery. High-value solutions and excellent experiences. Choosing Johoty means choosing a dual guarantee of quality and service!

Raw Materials and Finishing of 3 Pin Connector

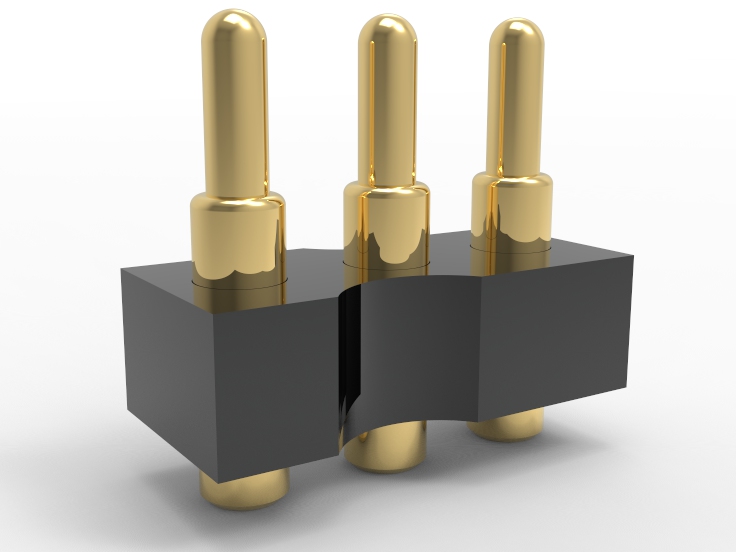

Plunger

Commonly used material is beryllium copper (BeCu), which has excellent conductivity (conductivity up to 22-25% IACS) and fatigue resistance. Suitable for high-frequency plugging. The surface is often coated with hard gold (Au) with a thickness of 0.1 μm-3 μm. To ensure contact resistance is <50mΩ and the corrosion resistance meets the IEC 60068-2-52 standard.

Spring

High carbon steel or SUS304/316 stainless steel is used, with an elastic modulus range of 180-210 GPa. Ensure stable elasticity is maintained over a lifespan of millions of cycles. The surface can be nickel plated to improve corrosion resistance and meet the 48 hour no corrosion point requirement of MIL-STD-810 salt spray test.

Barrel

Generally, brass (CuZn37) is used as the base material, with good mechanical processing performance and a hardness range of 90-120 HV. The surface is nickel plated (2-5 μm) or gold plated to reduce wear and oxidation. Meet the standard of maintaining a contact resistance of <100mΩ after 50,000 insertions.

Housing

Use high-temperature thermoplastic materials such as LCP or PPS, with UL 94 V-0 flame retardant rating. The hot deformation temperature can reach over 260°C, and the long-term working temperature is >150°C. It is suitable for SMT and reflow soldering processes, and the low CTE (<40 ppm/°C) ensures the stability of assembly dimensions.

Selection Suggestions and Customization of 3 Pin Connector

Clients’ challenges:

Poor contact of connectors: for traditional connectors, they easily face poor contact in frequent insertion or vibration. Causing intermittent signals, affecting the stable operation of equipment, and increasing maintenance costs.

Long customization cycle: Customers have diverse customization needs, but the conventional supply chain response is slow. It will prolong the customer’s product development cycle, miss market opportunities, and affect competitiveness.

Size and compatibility limitations: Some connectors have large volumes or single designs, which are not compatible with existing device interfaces. Restrict product design flexibility and system integration efficiency.

Selection suggestion:

Structural stability: 3 pin connector has excellent mechanical stability due to its pogo pin structure. Capable of withstanding over 10000 insertion and extraction cycles, suitable for connecting industrial and electronic devices that require high reliability.

Electrical performance: This pogo pin connector supports a maximum current of 50A and a contact resistance as low as 20mΩ. It guarantees stable signal transfer with low waveform distortion, anti-EMI and low loss. There are advantages in terms of electricity demand for high-frequency and high-precision electronic products.

Environmental adaptability: The 3 pin connector has an IP67 protection level and can withstand high temperatures up to 125 ℃. Suitable for automotive electronics, medical equipment, and outdoor instruments in complex environments.

Customized solutions:

Precise size customization: Provide millimeter-level size customization based on the interface space of the customer’s device. Ensure a perfect match between the 3 pin connector and the device, improving installation convenience and service life.

Material and surface treatment optimization: Choose corrosion-resistant alloys and gold-plated contacts for different application environments. Improve durability and signal stability to meet high-standard demands in medical, aerospace, and other fields.

Rapid response development: Johoty often adopts modular design and agile manufacturing processes to achieve sample delivery within 2 weeks. Shorten the iteration cycle of customer products and improve research and development efficiency.

Multi-functional integrated design: supports the integration of additional functions on top of the 3-pin foundation, such as anti-misconnection structure and polarity protection design. Meet complex systems’ high requirements for connection security and performance.

FAQ

What is a 3 pin connector?

A 3 pin connector is a small spring loaded pin structure used for electrical connections. This pogo pin connector provides circuit connections through three pogo pins. Each pogo pin has spring and perfectly fits small spaces. Commonly used in portable devices, capable of handling high-frequency use.

What is 3 pin connector working principle?

The 3 pin connector relies on spring pressure to complete circuit transfer. The spring compresses the plunger and the contact surface, and the plunger conducts current through compression. This pogo pin connector can maintain stable connection and reduce resistance. It adapts to different contact surfaces and adjusts its elasticity through springs to ensure reliable connection.

Is 3 pin connector easily affected by environment?

The 3 pin connector has very stable performance in normal use. With gold plating or composite electroplating, and protective design, it can greatly reduce oxidation. Stainless steel or piano steel springs are very durable and can withstand up to 200,000 uses. Plunger has strong corrosion resistance, IP67 and IP68 sealed design can easily cope with moisture. Johoty’s pogo pin connector is perfect for different indoor and outdoor.

What are applications for a 3 pin connector?

This pogo pin connector is widely used in electronic product charging and data transfer interfaces. 3 pin connector is commonly used in smart wearable devices, medical device touchpoints, and battery interface connections. It can support portable tool current transfer and can also fit modular device assembly. Many customers of Johoty request a design with IP67 waterproof and magnetic function. Some customers also requested to add EMI on this basis, and Johoty can always meet their requirements.

What are precautions when installing a 3 pin connector?

Please ensure contact surface is clean and pressure is appropriate, check plunger alignment with contact point, avoid dust affecting contact effect. Control pressure range of installation, avoid excessive stretching of the spring, and ensure connection stability when fixing.

How long is 3 pin connector lifespan?

The lifespan of this pogo pin connector depends on its design, frequency of use, and raw materials. Its standard lifespan is 10,000 cycles, and advanced models can reach 200,000 or even 400,000 cycles. Proper use of 3 pin connector can extend its lifespan. The spring’s strength determines its durability, and the raw material affects its overall lifespan.

What is current range of 3 pin connector?

The current of a 3 pin connector depends on specific design parameters, with a typical current range of 0.5A-3A. The high current design can reach 5A or above, with a specially customized 50A. The spring strength affects current carrying of this pogo pin connector. The pogo pin size determines its current, while raw material affects conductivity efficiency of 3 pin connector.

What are different plunger tips for 3 pin connector?

Yes, Johoty can customize various plunger tips of 3 pin connector to meet different needs. Flat tip provides a larger contact surface, reduces contact wear, and offers stable electrical connections for long-lasting contact. Pointed tip can easily penetrate oxide layer or protective layer, improve conductivity for contact surfaces with surface treatment or coatings.

Ball tip, with a spherical plunger and small but sliding contact points. It is suitable for flexible connection or tolerance for certain misalignment, reducing wear and tear. Cup tip can capture contact points of protruding parts, enhancing stability. Blade tip, similar to the shape of a blade, can be embedded or firmly grasped on contact surface.

This can ensure connection stability under vibration or movement. Conical tip combines penetrating power of pointed tip with stability of flat tip for multifunctional connections. Semi-circular tip refers to a design where plunger top is curved, providing a larger contact area. Star head refers to a design with multiple claw shaped protrusions on plunger top. It is used for contact surfaces that require firm grip.

+86 13590816656

+86 13590816656 +86 13590816656

+86 13590816656