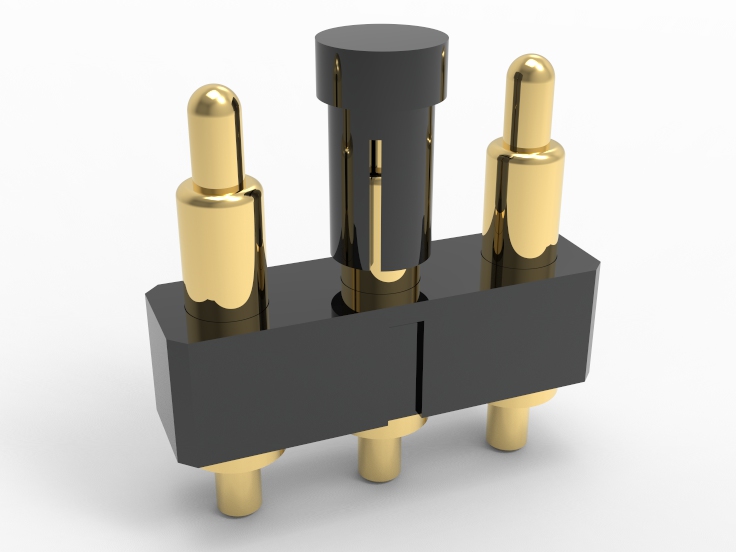

Johoty’s Services of 3 Pin Connectors

Sample 3 pin connectors: The image will be produced within 48 hours and the sample will be submitted within 14 days. The standard process is DFM review + 3D structure confirmation + SPICE simulation + sample drawing. Feedback risk points and deliver verifiable samples within 72 hours after sampling. Adapt to any packaging reservation design. If the customer provides a complete structural diagram, the physical product can be delivered within 10 working days at the earliest.

Quality standard: Contact impedance below 10m Ω, no failure verification after more than 10,000 times. The surface of the Pogo pin is coated with a <5μm gold layer, and the Spring lifespan test has passed the IEC standard. The insertion and extraction cycle is ≥10,000 times, and the stable contact resistance is maintained at 30 ±2mΩ. The barrel material is made of SUS304 + heat treatment to ensure that the elastic recovery force is stable at ≥95%. Perform SPC statistical process control, AOI, and high vibration testing throughout the entire process.

Delivery time: Standard 3 pin connectors take 7 days for mass production, and customized products take 2-3 weeks. All module manufacturing processes are traceable based on ERP/MES transparency nodes. Monthly production capacity ≥1.5 million sets, with a regular configuration structure for backup. The delivery time of the customized end is limited by the completeness of the drawing and the complexity of the processing. The typical processing cycle is delivery within 2-3 weeks (including structural optimization suggestions).

MOQ for 3 pin connectors: Minimum order quantity for standard products is 500 sets, and for customized products it is 1,000 sets. Consider the customer design verification cycle and support engineering verification sampling for up to 50 sets during the NPI phase. Meet the low-risk import requirements. The minimum order quantity for formal mass production is 3,000 sets (negotiable phased supply plan).

Logistics method: 3 pin connectors support DDP air freight/express/FCA factory pickup. Standard export packaging PE + shock absorption foam + part number traceability. FedEx/TNT/DDP air freight is used for regular delivery in North America/European Union. The time limit is controlled within 7-10 natural days. It can also cooperate with customer accounts for shipping or transit warehouse storage, with flexible delivery locations.

Contact person qualification: Full English engineering background, with 10 years of experience in the 3 pin connectors industry. Have a composite background in pogo pin connector design, reliability, and application engineering. Long term service to European and American industrial, automotive, and medical clients. Can quickly understand customer drawing requirements. Provide a one-stop judgment and decision-making path from structural adaptation → testing plan → delivery time resources.

Click: More Catalog

Performance Test of 3 Pin Connectors

Contact resistance test: 50mΩ± 5mΩ, full load current 3A Long term stability at 25℃. Using Kelvin real-time measurement, the reading fluctuation within 10 minutes of thermal stability after power on is <2mΩ. 100% factory sampling, high reliability of low current control signal.

Pogo pin life test: 10,000 insertion cycles, resistance drift <15%. Perform insertion and extraction fatigue tests under simulated structural loading and actual travel environment. Frequency 1Hz, apply 1N stroke pressure, monitor resistance drift within ± 2.5mΩ range. Verify the safety boundary of mechanical and electrical redundancy.

Lateral vibration impact assessment: Zero break under 10g peak acceleration. Simulate sine wave scanning test through a vibration table, with a frequency range of 10Hz to 2,000Hz. The peak acceleration is 10g, and the dynamic sampling voltage is monitored for each contact fluctuation. Zero contact intermittent throughout the entire process, commonly used 3 pin connectors for UAVs and high-speed motion modules.

High and low temperature impact test: No contact failure after 300 cycles from -55℃ to 125℃. The thermal shock test should be switched between -55℃ and +125℃, with more than 300 cycles. There is no abnormal fluctuation in the resistance before and after detection, and the safety of thermal expansion and contraction in extreme environments is very high.

Dustproof and anti fouling performance evaluation: Normal contact after 72 hours of exposure to ISO Class 9 dust environment. After static exposure for 72 hours under graphite powder and micro powder dust, perform insertion and electrical testing. The signal is stable without fluctuations, and the Pogo pins’ ability to resist foreign object interference meets the requirements.

Thickness and uniformity testing of electroplating layer: The gold plating thickness is controlled at 1μm ± 0.03 μm, with a cross batch error of less than 5%. Use XRF fluorescence spectroscopy to perform batch by batch sampling to ensure uniform coating in the contact area. Electroplating consistency ensures multi batch stability and avoids contact performance deviation between batches.

Insertion force testing: Insertion force <2.5N, retention force >0.6N, stroke consistency ±0.05mm. Test insertion force to adapt to automated assembly processes. No additional compressive stress will be generated on the board, and the 3 pin connectors are stably fixed in both male and female sockets.

Click: More Catalog

Customization of 3 Pin Connectors

High density connection: Flexible customization with pitch 2.54mm, suitable for limited space. Support customization of standard and non-standard pitches such as 1.00mm, 1.27mm, 2.00mm, 2.54mm, etc. Satisfy the limited design of structures such as drones, wearable devices, module boards, and precision electric drives. Vibration testing above 20G and contact impedance control below 0.015Ω ensure signal and power transmission stability.

Micro structure precise design: The minimum package size supports L3.00 × W0.80 × H1.20mm. Equipped with high-precision CNC and slow wire platform, with a minimum pogo pin diameter of 0.50mm and a tolerance of ± 0.005mm. All structures are designed and calibrated in reverse based on customer PCB board grid drawings and stacking tolerances. Realize 100% adhesion between 3 pin connectors and the carrier, avoiding mismatch and fatigue failure caused by tolerance accumulation.

Reliable electrical performance: ultra-low resistance within 15mΩ, supporting 500,000 mechanical life verifications. All pogo pins are designed with 50mm or more thick gold plating, paired with copper beryllium spring plates and high hardness stainless steel casing. Ensure that pogo pins do not fall off or deform during long-term compression, and the contact resistance is stably controlled within the range of 15~5mΩ. Meet high current and low signal mixed channel transmission, cell balancing, and portable intelligent module.

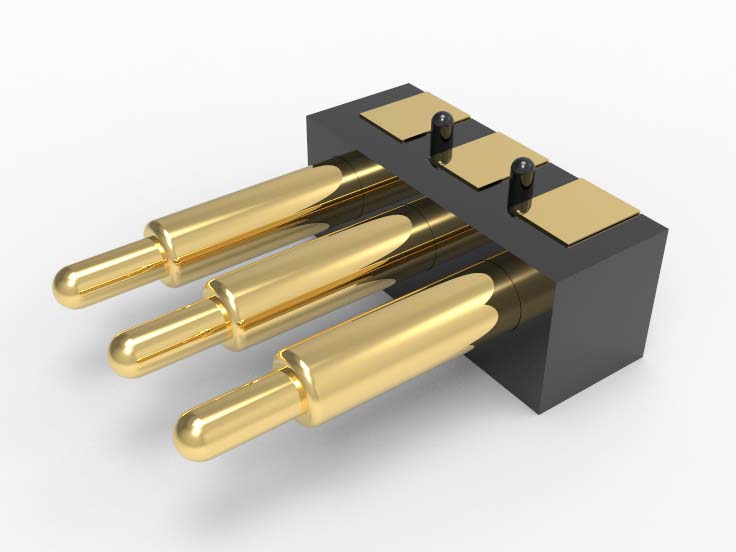

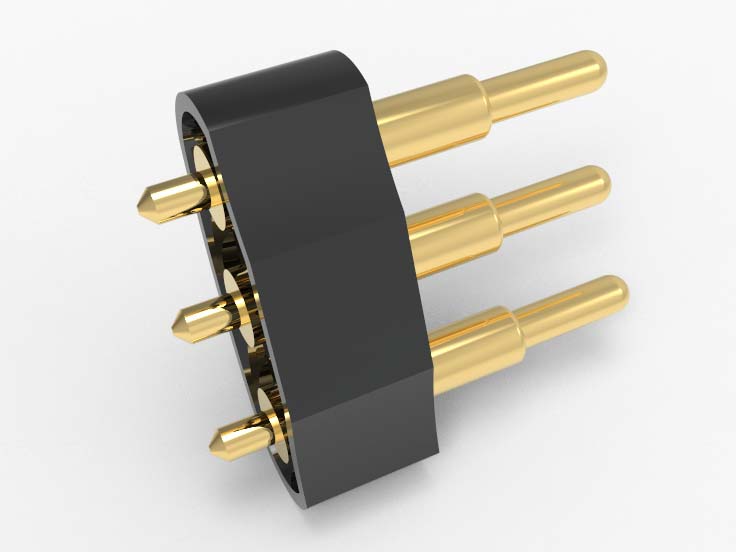

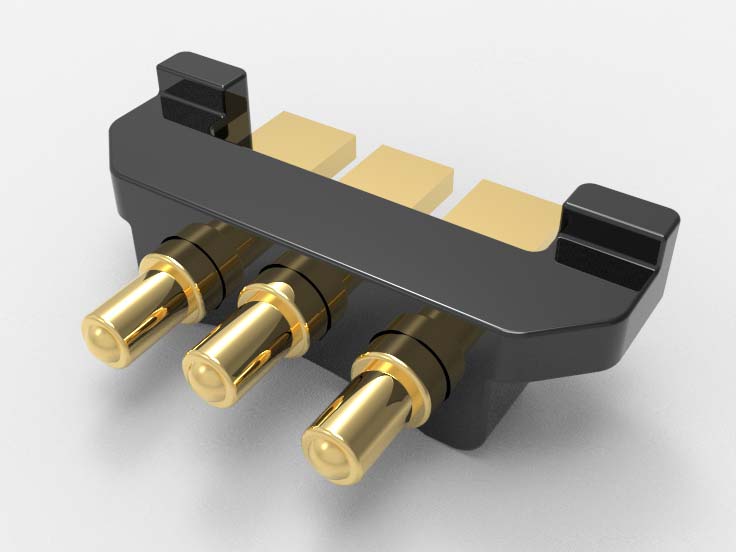

On demand structural customization: supports structural designs such as through holes, side patches, solder wires, magnetic attraction, SMT, etc. We can provide 7 structural forms to meet the assembly process requirements of customer terminals. Quickly connect through automated mounting, manual insertion, and magnetic quick insertion.

Environmental adaptability design: meets the protection requirements of -40℃ to +85℃ and IP67 level. 3 pin connectors have passed 96 hour salt spray testing and high/low temperature cycling testing. All connection areas support various forms of protection such as glue dispensing, sealing rings, and encapsulation. Compatible with outdoor terminals, mobile power, and handheld tools for use in changing climates and water vapor shock environments.

Customer verification data: Stable passing of the indicators requested by customers. German industrial automation customer, 1.00mm pitch magnetic connector, tested for MTBF >20,000h, temperature rise control <20℃. American medical wearable customers, 1.00mm pitch high-frequency plug structure, impedance change <5% after 500,000 cycles. Chinese new energy BMS module customer, 2.00mm plug-in 3 pin connectors, vibration testing(20G@50Hz , After 8 hours, there was no disconnection phenomenon.

Flexible delivery mechanism: Small batch standard 3 pin connectors sampling cycle of 7 days, supporting rapid supply of ≤100 sets during R&D stage. For the initial stage of project development, it can be based on the requirements of drawings or interface structures. Provide fast modeling, structural optimization suggestions, and expedited sampling services. Facilitate customers to conduct functional testing and structural iteration during the validation phase.

Click: More Catalog

FAQ

Is the electrical performance of 3 pin connectors stable? What is the maximum current and resistance under 3-pin configuration?

Supports a single pogo pin current of up to 50A, with a typical contact resistance value of ≤30mΩ. It has passed 10,000 mechanical life tests stably. In practical use, the 3-Pin parallel configuration can ensure a high current carrying capacity of 150A. Power supply redundancy under low-power/medium power/high-power conditions.

Do 3 pin connectors support automated mounting and assembly? Is the connector structure compatible with modern assembly lines?

Of course, it supports SMT pad configuration and plastic positioning seat, which can be combined with high-speed surface mount machine and automatic insertion. Adapt to fully automated production processes on assembly lines. It can significantly reduce the rate of manual intervention and the risk of assembly deviation.

Do 3 pin connectors have mechanical error prevention features? Does the multi pin arrangement support precise positioning and resistance to accidental insertion?

Equipped with precise guiding structure design, including chamfer guidance, limit column, and plastic protective cap. The insertion and extraction tolerance is controlled within ± 0.05mm. It can effectively avoid structural damage or short circuit hazards caused by accidental insertion. Suitable for multiple docking tasks in unmanned environments.

Do the 3 pin connectors meet high-density PCB? Is the pitch <3.00mm design suitable for precision PCBs with limited space?

Satisfied. 3 pin connectors are optimized for high-density applications and support small pitch designs 1.00mm/1.27mm/2.00mm. Adapt to parallel wiring of high-speed signals and power supply. 3 pin connectors are commonly used for portable industrial equipment, medical miniaturization modules, and intelligent sensor arrays.

What is the lifespan and environmental tolerance of 3-pin connectors?

3 pin connectors have undergone standard tests such as salt spray, thermal shock, and high/low temperature cycling. Meets MIL-STD and IEC standards. The pogo pin adopts a gold plating layer of ≥1μm, ensuring a lifespan of 100,000 + insertions. 3 pin connectors are suitable for embedded systems and industrial applications with difficult periodic maintenance.