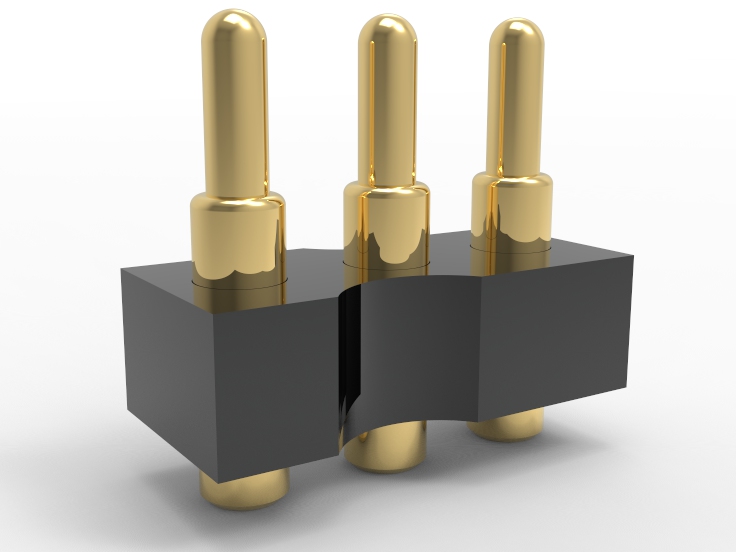

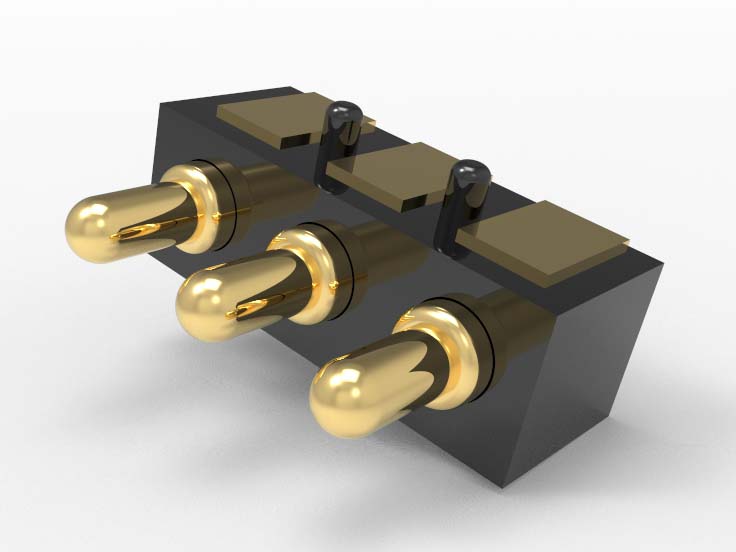

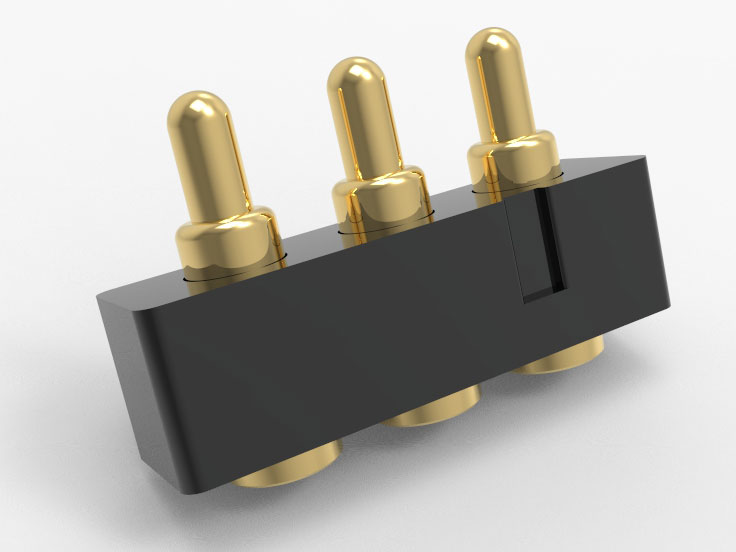

Johoty’s Services of 3 Pin Pogo Connector

Sample 3 pin pogo connector: Confirm the drawing within 3 days and complete the first round of sampling within 2 weeks. Support STEP/IGES format collaborative verification. The standard process supports up to 3 structural optimization feedbacks. The mass production compatibility verification report is delivered synchronously and complies with IEC standards.

Quality control of 3 pin pogo connector: tolerance control ± 0.01mm, barrel coaxiality <0.03mm. The measured average contact resistance is 48.2mΩ (95% CI: 47.9-48.5mΩ), n=50)。 The 3 pin pogo connector has undergone 10,000 cycles of 100% elasticity/fatigue testing and comes with an SPC report at the factory.

Delivery time: Customized gold-plated sample, 15 days for small batch delivery. Customized parts with a thickness of 5μm gold plating, 12 days for sampling and 21 days for delivery. Conventional molds do not require queue jumping, and urgent orders can be accelerated.

Minimum order quantity : The MOQ for standard parts is 100pcs, and the MOQ for customized structural parts is 300pcs. The MOQ for functional module level matching devices is 500pcs. All minimum order quantities are based on 3 pin pogo connector encoding.

Logistics mode: DHL/UPS/FedEx direct shipping is commonly used in Europe/North America, including a unique tracking number. Supports EXW/FCA (Shenzhen) and can also be shipped through customer specified channels. Bulk orders support DDP terms and integrated customs clearance services.

Technical liaison qualification: The liaison should be a technical manager with over 10 years of industry experience in 3 pin pogo connector/pogo pins. Fluent in native/technical English, participated in IEC/JEDEC/IPC testing standard verification. Capable of providing on-site engineering optimization/functional testing guidance. Customers can obtain a 1-on-1 direct connection channel for the project, responsible for the drawing sample verification loop.

3 pin pogo connector application: suitable for UAV control core and medical probe elastic contact end. Modular intelligent instrument base, battery interface communication integration connection. The design meets the requirements of >10,000 connections, miniaturization, and integrated anti vibration electrical connection.

Click: More Catalog

Performance Test of 3 Pin Pogo Connector

Contact resistance stability test: maximum fluctuation ≤ 8mΩ (10,000 presses), verify connection reliability and signal integrity. Perform 10,000 compression cycles at a pitch of 1.00mm and monitor the resistance fluctuation curve. The fluctuation from an initial average of 10.3mΩ does not exceed ± 3.7mΩ, far below the industry upper limit of ± 10mΩ.

Minimum closure stroke tolerance evaluation: tolerance control is ≤±0.05mm, supporting precision docking. Verify physical compatibility with high-density carrier boards or limit structures. Repeatedly press fit 1000 times in a 25℃ environment at a stroke of 1.27mm. The displacement error limit deviation is controlled within ± 0.046mm, meeting the requirements of micro spacing accuracy.

Dynamic elasticity retention test: The stable range of applied force is 5.2N ± 0.2N, and the plunger tip does not loosen or drift under mechanical impact and vibration. Apply 6-way low-frequency disturbance during insertion, with a frequency of 5 times per second for a total of 2,000 cycles. The load fluctuation range is stable at ± 0.2N, and the contact is constant.

Thermal cycle reliability verification: Contact resistance change ≤2.1mΩ after 200 cycles at -40℃~+85℃, material and coating stability under extreme temperature and humidity conditions. Referring to IEC for thermal stress cycling testing, the average change in resistance before and after comparison was 1.87mΩ. No cold shrinkage, cracks, or coating detachment were observed.

Welding resistant high-temperature packaging simulation: No structural deformation after 3 cycles at 260℃ for 10 seconds. During the assembly process, there will be no plastic deformation or metal displacement caused by high temperature. Simulate the high-temperature environment of SMT process and repeat the heating process three times to reach 260℃. Observe that there is no measurable displacement or plastic shell cracking in the 3 pin pogo connector.

Frequency response verification: Supports high integrity signal transmission within DC~3GHz, with signal integrity adapted for high-speed or analog transmission. Test using TDR+S21 vector network analyzer to transmit 3GHz pulse signals at a pitch of 1.00mm. No significant reflection peak, insertion loss<0.45dB.

Salt spray corrosion test: After 96 hours, the contact resistance change is less than 2.3mΩ, and there are no signs of black spot corrosion. Metal stability in sea storage, outdoor equipment, or industrial atmospheres. According to ASTM B117, a 96 hour salt spray test was conducted, and all 3 pogo pins did not fail. The gold surface was intact, and the average change in contact resistance was 1.65mΩ.

Lateral force detachment test: Horizontal detachment force ≥2.1N, anti misoperation sliding out design verification. Pogo pins have structural anti detachment capabilities when forcibly offset or inserted. The structural resistance test was conducted at a 20° oblique drawing rate of 1mm/s, and the actual minimum peel force was 2.35N.

Click: More Catalog

Customization of 3 Pin Pogo Connector

Minimum spacing design: ≥1.00mm pitch wiring density, meeting the internal connections of micro modules such as handheld terminals, medical devices, drones, etc. Suitable for system integration applications that are sensitive to space control. The measured spacing tolerance is controlled within ± 0.03mm, which can directly match the mother seat with spacing levels of 1.00mm, 1.27mm, 2.00mm, and 2.50mm.

Multiple pogo pin length customization: to cope with asynchronous contact and structural tolerance errors, supporting differentiated design of single pogo pin length. ≥1.60mm, tolerance control ±0.05mm, meeting non coplanar PCB, sliding structure or elastic contact requirements. Batch validation has been conducted in TWS and precision wearable mold sets.

10m Ω ultra-low contact resistance: Stable through <50mA signal and <3A power supply, the contact resistance of each pogo pin is as low as 10mΩ. It has passed 10,000 insertion and extraction cycles and the contact resistance deviation is <5%. Stable transmission of data and power in low-power systems for low signal interference design.

Full range of material electroplating options: to cope with high corrosion and frequent coordination. Barel supports beryllium copper, phosphor copper, surface gold plating (1μm-5μm), nickel plating, silver plating, etc. Supports high reliability coating stable output for high-frequency plugging and salt spray environments. Has passed MIL-STD-202 salt spray and thermal cycling tests.

Contact head customization: Supports multiple types of contacts such as pointed, round, ball, etc. Based on the customer’s mother seat structure, pairing module or Pad form. Support non-standard contact design, with a minimum diameter of 0.15mm, ensuring good contact and compatibility with PCB bonding. Commonly used for surface contact, flexible board docking, bottom pad eccentricity compensation, etc.

Automated assembly friendly design: supports T&R, foam tray feeding methods. 3 pin pogo connector meets SMT or THT mounting/plugin process standards. Support factory automatic SMT/welding to improve batch production efficiency and reduce welding failure rate. Compliant with RoHS and REACH standards.

Full coverage of reliability testing: One page of technical parameters can quickly evaluate adaptability. Provide high and low temperature (-40℃ to+85℃), plug and unplug life, resistance change rate, elastic deformation recovery, salt spray, and wet heat test data. 3 pin pogo connector comes with complete report numbers for supply chain review purposes.

Click: More Catalog

FAQ

Can 3 pin pogo connector maintain a stable contact resistance of 10mΩ under frequent mating?

Can. Adopting 50mm thick gold electroplating and precision stepped spring structure. After 10,000 insertions, contact resistance remains at 10mΩ. Suitable for impedance stability sensitive high-speed charging, power supply extraction, data communication, etc.

Can 3 pin pogo connector meet continuous current 10A or above and operate for a long time in >85℃?

Continuous current carrying capacity of a single pogo pin 10A@25℃, supports continuous operation at 85℃ without additional heat dissipation. The result of the heat rise test (UL 1977) shows that ΔT<30℃, making it suitable for applications such as wearable devices, power tools, and unmanned aerial vehicles that are sensitive to temperature rise.

Is it feasible for 3 pin pogo connector to support a minimum center to pitch distance of 0.80mm?

Supports spacing arrangement from 0.80mm to 2.54mm, with a minimum center distance of 0.80mm. Of course, the pitch is preferably ≥1.00mm. High density packaging, camera module, TWS, Ultra-tight space design for battery modules, with tolerance control of ±0.02mm.

Can different strokes and compression heights of 3 pin pogo connector adapt to non-standard structural designs?

Support customized spring stroke of 0.10~1.50mm and compression ratio of 50%~70%. Meet the requirements of different mechanical structures for compression force and space margin. 3D graphics and structural analysis can be provided within 48 hours, serving over 200 European and American medical and industrial clients.

How to ensure 3 pin pogo connector will not fail in vibration and impact environments?

Lateral limit design and multi-stage contact of 3 pin pogo connector can withstand 10Grms vibration and 50G impact. Contact failure rate is 99%. Suitable for high dynamic drone flight control boards, electric vehicle modules, and rail transit.