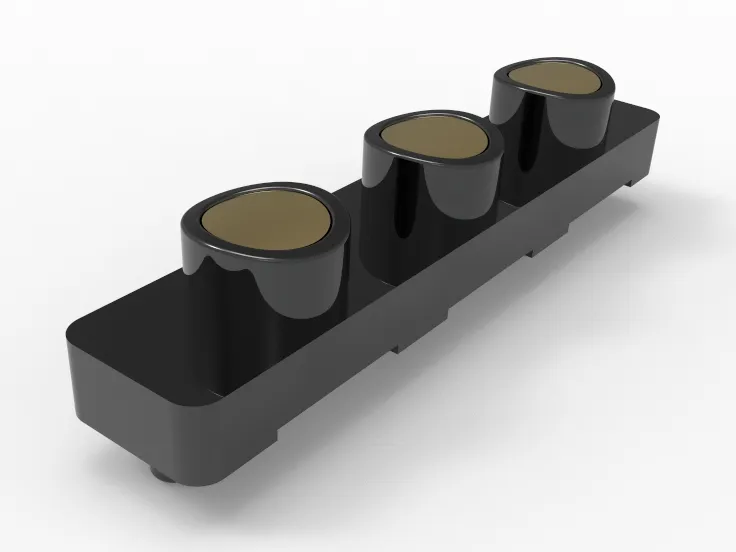

Johoty’s Services of 3 Pin Waterproof Connector

Sample 3 pin waterproof connector: Standard structural samples will be confirmed within 24 hours, customized drawings will be produced within 3 days and samples will be produced within 14 days. General specification samples: In stock, orders placed before 4:00 pm daily will be shipped out on the same day. Customized sampling of customer drawings: Complete structural verification and BOM pricing within 3 days. Complete CNC + packaging + sealing testing integration within 14 days. All sampling processes are visible online, and customers can monitor the process progress in real-time. The sample comes with a test report by default, which includes a description of the waterproof O-ring material.

Quality control: MIL-STD gold plating standard + full inspection of resistors below 50mΩ. All pogo pins undergo impact/vibration testing according to MIL-STD. Each batch is sampled for IP67 immersion test + 5,000 plug and unplug life test. High precision spring loaded pins, 100% sourced from SGS + ISO 9001 certified supply chain. The gold plating thickness is 0.5μm, ensuring stable contact resistance below 30mΩ (both high-frequency and high current stability pass). All factory inspection records can be checked for 7 years.

Delivery time for 3 pin waterproof connector: 7 days for regular parts, 14 days for customized parts with sealed samples, and 20 days for mass production delivery. Standard products will be sampled within 7 working days and part number tracking will be generated within 3 days. Customized requirements will be confirmed within 14 days, and 1,000pcs level trial production delivery will be completed within 20 days. Delivery accuracy of over 97%, based on ERP + MES system node management.

3 pin waterproof connector MOQ: There is no minimum order quantity for standard parts, and a minimum order quantity of 300 pcs for customized parts. Standard products support a minimum order of 5 pieces, with quick verification and spot support. Customized specifications (including pogo pin length, elasticity, contact impedance, rated current, packaging) with a unified minimum order quantity of 300 pcs. All quotations include raw materials, testing, packaging, labeling, and testing fees, with no hidden costs.

Logistics method: FedEx Priority/UPS Expedited, with full tracking for individual/full container shipments. Sample stage: Priority will be given to FedEx, with a delivery time of 5-8 days worldwide. Batch stage: UPS Expedited/customer specified dedicated line, supporting multiple conditions including FOB, DDP, DAP, EXW. Default issuance of bilingual Chinese and English invoices, packing lists, contracts, etc;

Contact person qualification: Provide one-on-one service to personnel with more than 10 years of engineering background, including 3 pin waterproof connector structure/material/EMC. The liaison has over 10 years of project experience in the pogo pin connector industry. Familiar with IEC/IPC standards, able to accurately understand customers’ electrical/mechanical/environmental three-dimensional requirements. Provide bilingual technical communication materials, weekly reports, meeting minutes, and other supporting documents in both Chinese and English.

Click: More Catalog

Performance Test of 3 Pin Waterproof Connector

Contact resistance stability test: fluctuation within 10 mΩ ± 2 mΩ, no degradation after 10000 connections/disconnections. Verify high current stability through 4-wire testing. In mechanical fatigue and micro vibration, the contact resistance remains in the range of 8-12 m Ω without significant contact degradation.

Waterproof sealing level verification: Passed IP68 test under IEC standard. Oil pressure and water depth simulation chamber test, maintaining insulation performance and non-permeable structure under water pressure and insertion. The 3 pin waterproof connector is suitable for outdoor/humid/water vapor environments.

Insertion life and mechanical wear test: ≥10,000 insertion cycles, insertion force maintained at 15-30N, change rate<± 10%. Automatic equipment operates for a long time, with low structural wear and no bending/jamming. Use custom plug and unplug fixtures for standardized validation of 3 pin waterproof connector.

High temperature and high humidity aging test: After continuous 1,000 hours at 85°C/85% RH, the function is complete and the impedance fluctuation is less than 5%. Compliant with JEDEC standards, suitable for harsh environments in new energy, automotive, and outdoor equipment.

Salt spray corrosion resistance test: 5% NaCl concentration, no pogo pin oxidation and contact attenuation after 168 hours of spray. Based on ASTM B117, a 3 pin waterproof connector is used in coastal/highly corrosive areas. The thickness of the Plunger tip coating is ≥1μm gold, and its corrosion resistance is superior to conventional nickel/gold plating combinations.

Current carrying capacity measurement: 3A continuous load, T-rise <30°C, cable end temperature rise <15°C. Temperature measurement record under 1-hour continuous current loading, in compliance with UL and IEC 3 pin waterproof connector thermal stability.

Insulation resistance test: ≥ 1,000MΩ at 500V DC, no decrease after 1,000 hours of environmental aging. Use a megohmmeter to verify insulation materials’ long-term stability. Used for control, signal, and highly integrated interfaces.

Thermal shock cycle test: -40°C to+125°C, with no abnormal fluctuations in contact resistance/insertion force after 100 cycles. According to the MIL-STD method, verify the connection stability of the structure after thermal expansion and contraction. The performance of the 3 pin waterproof connector for UAV, electric vehicles and high vibration is stable.

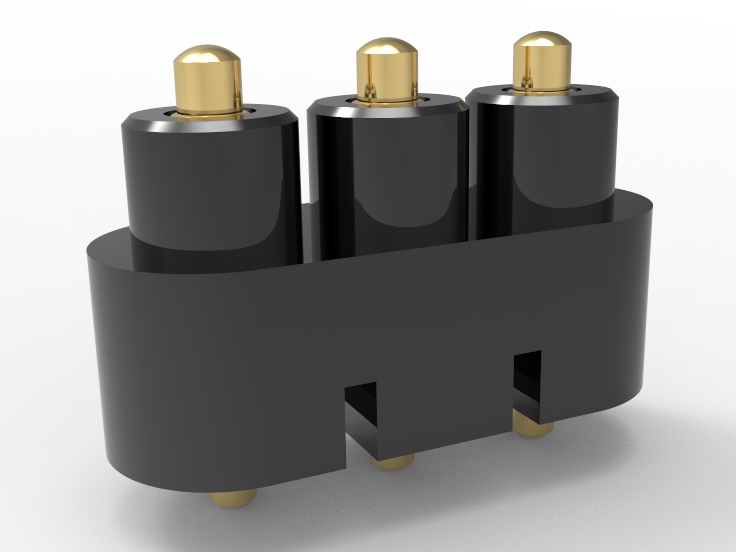

Pin offset tolerance test: within ± 0.05mm, with minimal fit clearance and assembly yield >99.5%. High precision CNC and full inspection process ensure that there is no pin alignment deviation in the automatic insertion and docking module.

Contact integrity under vibration environment: 10Hz-2,000Hz sweep frequency, 50g random vibration, contact voltage fluctuation ≤ 50μV. Simulate vibrations in industrial/transportation vehicles based on EN standards. Verify the transient reliability of the 3 pin waterproof connector connection to avoid micro breakage failure.

Click: More Catalog

Customization of 3 Pin Waterproof Connector

Redundant spacing design for complex structural components: based on multiple 3- pin structure designs ranging from 3.10mm to 11.00mm pitch. Maintain 100% contact continuity stability under the condition of spatial offset >±0.25mm. Compatible with existing thick film ceramic/composite plastic housing reserved hole spacing design.

Waterproof level customization and verification: Supports IP65~IP68 protection levels, has completed 120 hours of salt spray testing and 10 repeated high-pressure flushing experiments. All data is archived according to IEC and DIN standards and supports third-party cross-validation testing.

Anti vibration fatigue life verification: equipped with complete high vibration environment simulation. The contact life of the plunger tip has passed IEC testing and reached 300000 times without dropping the pogo pins or shifting them. Contact resistance stability ≤50mΩ, ΔR<1.5mΩ during insertion and removal, signal integrity.

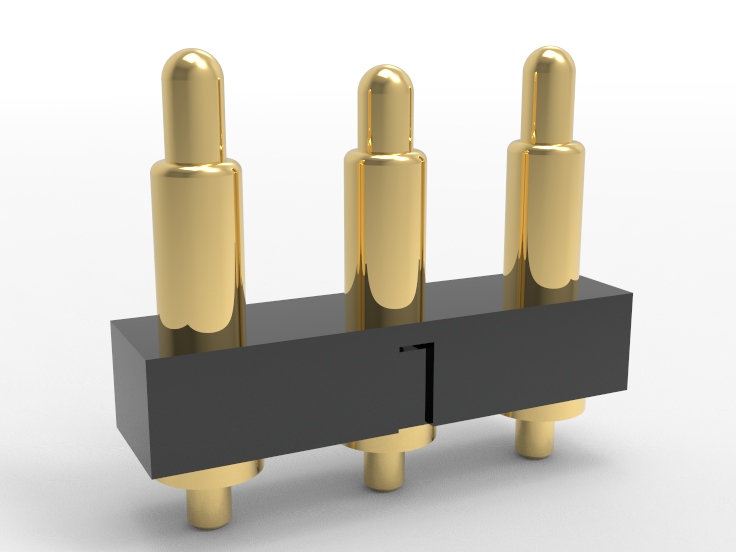

Current carrying and low resistance control: The measured current per pogo pin can reach 50.0A (continuous power on for 60 minutes, temperature rise <30℃). The thickness of the gold plating layer is ≥0.5μm, and the resistance of the 3 pin waterproof connector does not exceed 48mΩ, effectively avoiding voltage drop problems under long-distance power supply.

Environmental adaptation and packaging flexibility: Supports continuous operation testing at 125℃ and low temperature -40℃, meeting the needs of automotive and industrial grade use. Plastic materials can be selected from PBT, PA66, LCP, etc., to match different strength/chemical resistance/aging resistance applications.

Quick prototyping and collaborative engineering development: Provide the initial 3D schematic and structural verification samples within 14 working days after project initiation. We have established a customized response channel for European and American host manufacturers and Tier-1. Support parallel development, transparent sharing of risk analysis and verification reports.

Pogo pins that support structural differentiation encapsulation: using split pogo pins and movable pogo pins. Suitable for oblique insertion, eccentric structure, or special mechanical stroke connections. The connection force between the male and female ends is stably controlled at 1.8-2.2N, meeting seismic requirements while ensuring manual assembly efficiency.

Compatible with electrical and signal dual-use applications: capable of achieving single pogo pin mixed use (power supply + signal recognition). Mass production in robot end effectors, autonomous driving perception devices, and medical portable power supplies. Support the design of directional pogo pin position recognition to prevent accidental insertion.

Click: More Catalog

FAQ

Is 3 pin waterproof connector suitable for high mechanical shock or vibration?

According to the MIL-STD standard, the contact resistance drift under vibration is less than 2mΩ. The 3pin waterproof connector has passed vibration and impact tests. The fluctuation of contact resistance is far below the design limit of 50mΩ, which is suitable for cyclic dynamic load environments. Commonly used for drone propeller electrical connection, AGV communication seat, and three proof mobile power supply.

Does the waterproof capability of the 3 pin waterproof connector reach IP67 or IP68?

Equipped with IP67 protection level, supporting 30 minute operation under 1 meter underwater. Non adhesive structure achieves repeated insertion and extraction sealing. Based on injection molding, an O-ring + sealed cavity double-layer structure is adopted. Not relying on glue to achieve waterproof sealing, avoiding sealing fatigue caused by thermal expansion and contraction. Adapt to frequently maintained outdoor sensor/construction site equipment interface.

How much current can a 3 pin waterproof connector structure withstand?

The maximum single pin can reach 50A, and the 3-pin water proof connector supports 150A instantaneous current transmission. Using high elasticity CuBe material with a gold plating thickness of 5μm, spring force >200gf, compression stroke >1.0mm. Contact resistance change <1.5mΩ after continuous power supply for 5 hours at 60°C, medium/high power electrical transmission system.

What are the advantages of 3 pin waterproof connector with a pitch greater than 3.00mm for customer selection?

Easy to design high-voltage spacing, reduce creepage risk, simplify PCB and housing layout, and enhance electrical safety margin. Pitch can be customized for >3.00mm to meet the creepage distance requirements of 250V systems. Johoty’s 3 pin waterproof connector is commonly used for communication modules between industrial robots and track equipment, which is conducive to automated pin insertion and assembly.

How to evaluate the lifespan and maintenance cycle of 3 pin waterproof connector?

Typical lifespan exceeds 10,000 times, customized 200,000 times. Interval maintenance cycle >3years, supporting lubrication free operation in dry and wet environments. Load insertion and extraction cycle test, after 30,000 insertions and removals under 23±2℃/60% RH conditions. The contact resistance of the 3 pin waterproof connector does not exceed 150% of the initial value. The lifespan far exceeds that of traditional projectile connectors. Long term stable connection for medical equipment and military devices.