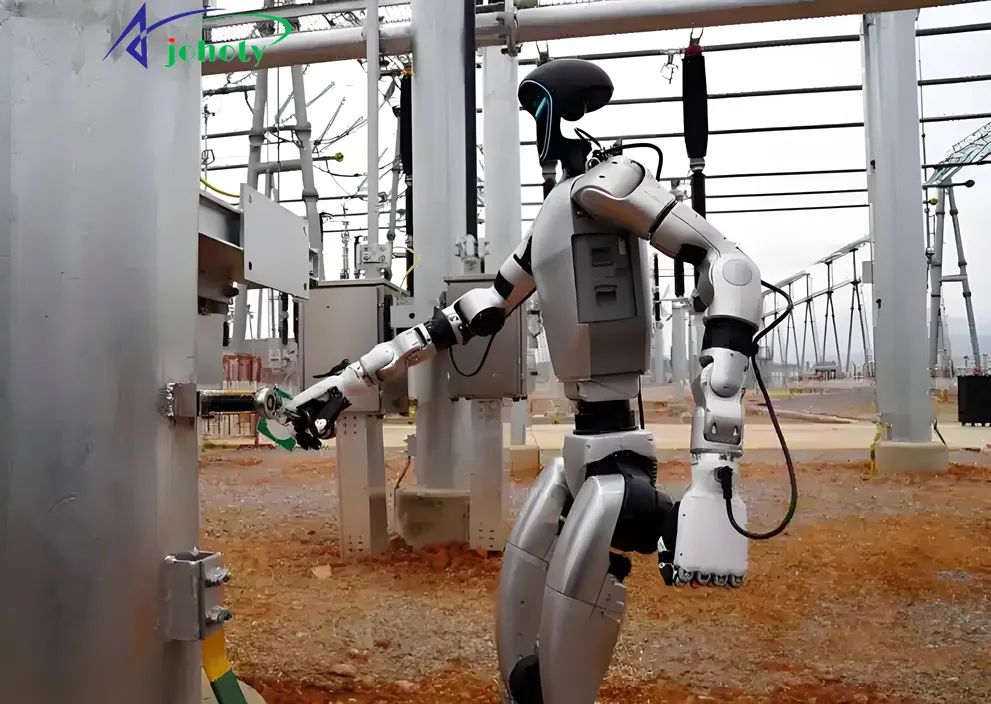

Johoty’s Services of 5 Pin Electrical Connector

Sample 5 pin electrical connector: Provides standard and customized sample services, with sample delivery time of 10-14 working days. Supports multiple specifications and electrical testing, highly meeting customer needs.

Quality assurance: CNC production process and strict 23 quality controls. The performance of each 5 pin connector is stable and has no faults during long-term use.

Delivery time: The standard delivery time is 2-3 weeks, and urgent production and logistics support can be provided for urgent orders. We can shorten delivery time to within 2 weeks to ensure project progress.

MOQ for 5 pin electrical connector: Minimum order quantity of 3,000 pieces, supporting small batch customization to meet the needs of enterprises of different sizes. Flexible adaptation for initial testing or small-scale production.

Logistics methods: We offer sea freight, air freight, truck, railway, and express delivery. Flexible selection based on customer needs to ensure timely delivery. Provide tracking services and real-time grasp of logistics information.

Contact person qualification: Led by a senior engineering team responsible for technical support and project coordination, team members have over 10 years of experience. Ensure the provision of professional solutions in the design, production, and logistics of 5 pin electrical connector

Testing and Certification: The 5 pin connector has undergone rigorous electrical performance testing and environmental adaptability testing. Compliant with RoHS, REACH, UL, ensuring the reliability of customer products in various environments.

Customized service: Provides personalized customization, including different pogo pin layouts, electrical performance requirements, and housing materials. Meet the specific needs of customers.

Customer feedback: Respond to customer issues and suggestions within 8 hours based on customer feedback. Ensure that any issues with the 5 pin electrical connector during use are promptly resolved.

After sales service: Provides a one-year warranty period, and the after-sales service team supports quick response. Resolve client’s any issues during use.

Order management: Provide full process order tracking services. There are dedicated project managers following up on every stage from production to delivery. Ensure that customer needs are accurately met.

Click: More Catalog

Performance Test of 5 Pin Electrical Connector

Electrical performance testing: All 5 pin electrical connectors have undergone 100% electrical performance testing. Including contact resistance, withstand voltage, insulation resistance, etc. A contact resistance as low as 10mΩ meets high-frequency transmission.

Vibration tolerance: Conduct rigorous vibration testing in high vibration environments. The 5 pin connector can operate stably within the mechanical vibration frequency range of 50Hz-500Hz. Meet high requirements for aviation and automotive applications.

Thermal cycle test: Pass the extreme temperature cycle test from -40℃ to +125℃. Reliability under extreme temperature differences and long-term stable operation.

Corrosion resistance test: Salt spray corrosion test is used, which lasts for 48 hours without significant performance degradation. Long term durability in harsh environments.

Mechanical tensile test: The 5 pin electrical connector undergoes a 2,000g tensile test. Pogo pins do not loosen or have poor contact during the insertion and removal process, making them highly suitable for devices that require frequent insertion.

Lifespan test: After 10,000 plug cycles, Johoty’s 5 pin electrical connector maintains stable mechanical contact and electrical performance.

Anti-EMI capability: Conducted EMI immunity testing, does not generate signal interference in electromagnetic environments, used for precision instruments and communication equipment.

Flame retardant performance: All housing has passed UL94 V-0 flame retardant certification and will not pose a fire risk under high temperature conditions. There is high safety in environments with high industrial and safety requirements.

Antistatic performance: Through ESD testing, the 5 pin electrical connector can withstand electrostatic shocks of ≥8kV. Avoid equipment damage caused by static electricity.

Extreme current and power testing: Conduct continuous operation testing under maximum operating current and power conditions. Under extreme working conditions, 5 pin connector has no overheating, short circuit, or performance degradation.

High density slot adaptation testing: Conduct specialized adaptation testing for high-density connection applications with a pitch less than 2.54mm. Accurate insertion and removal with no signal loss.

Reliability verification: Conduct accelerated life testing based on the above tests. Verify the stability of the 5 pin electrical connector during long-term use. Ensure long-term reliable use and worry free safety for customers.

Click: More Catalog

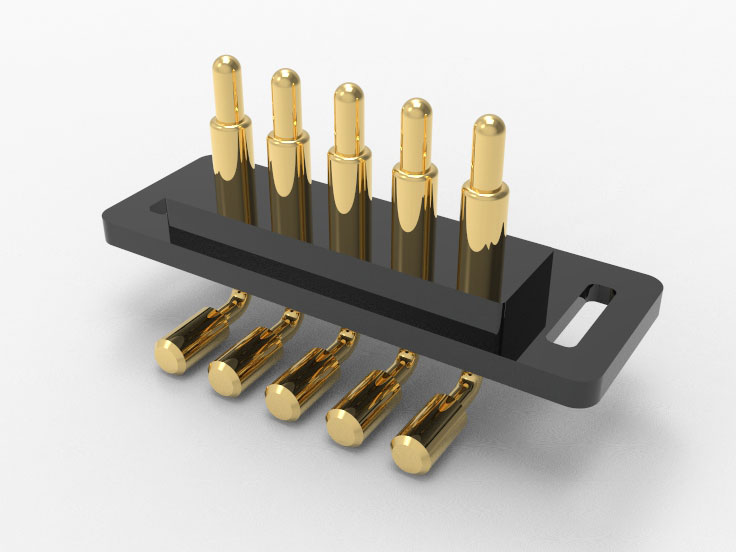

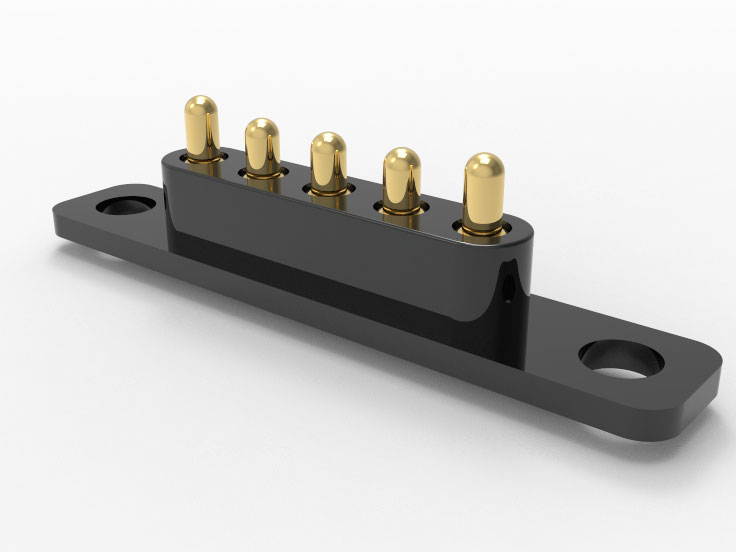

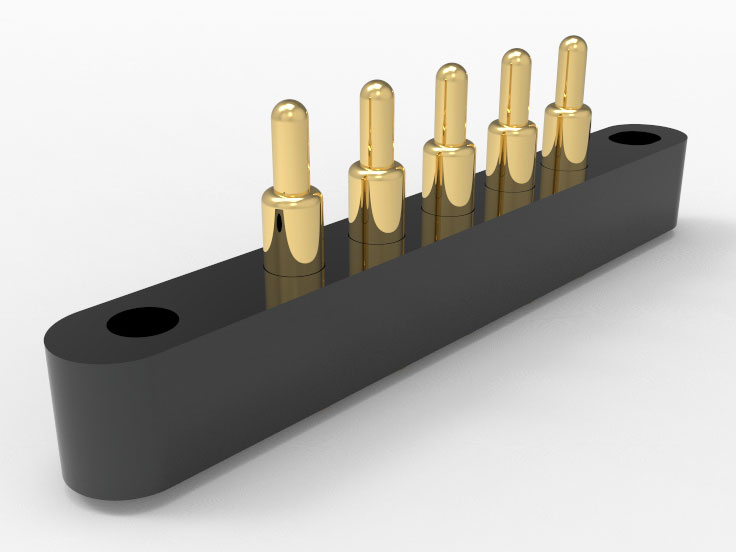

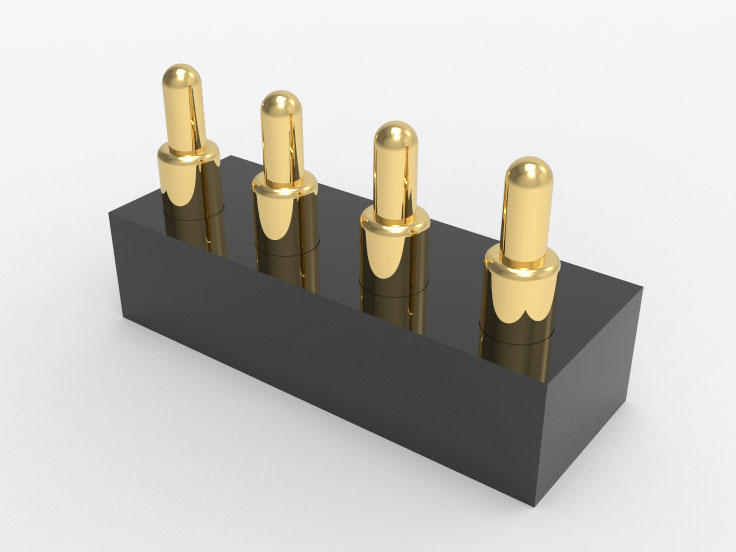

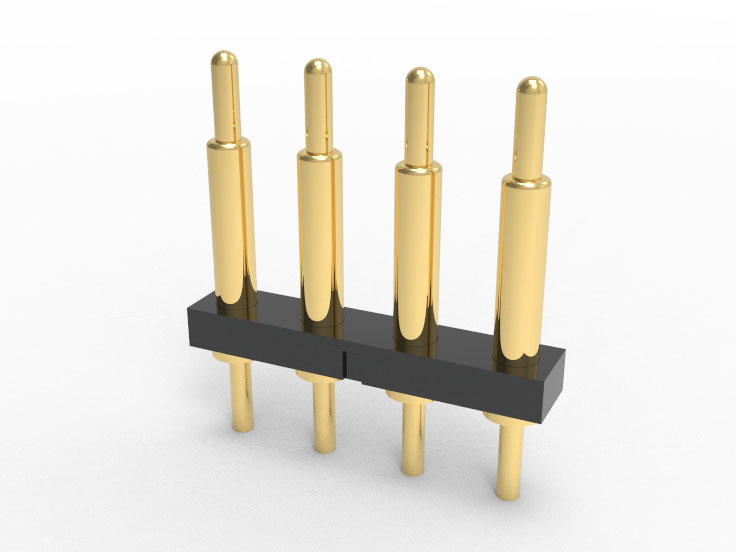

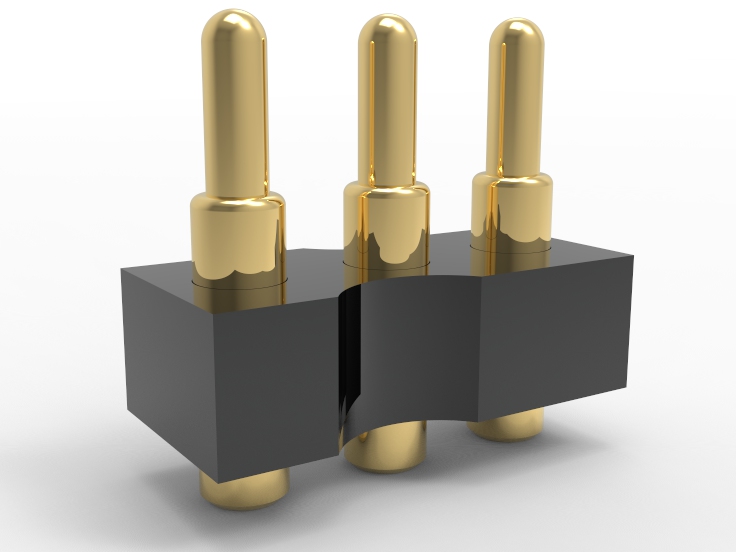

Customization of 5 Pin Electrical Connector

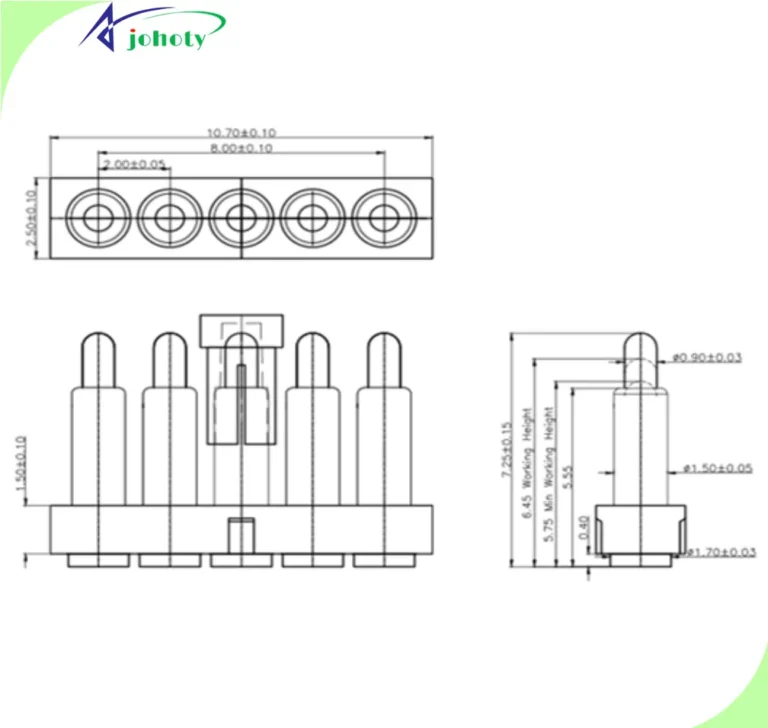

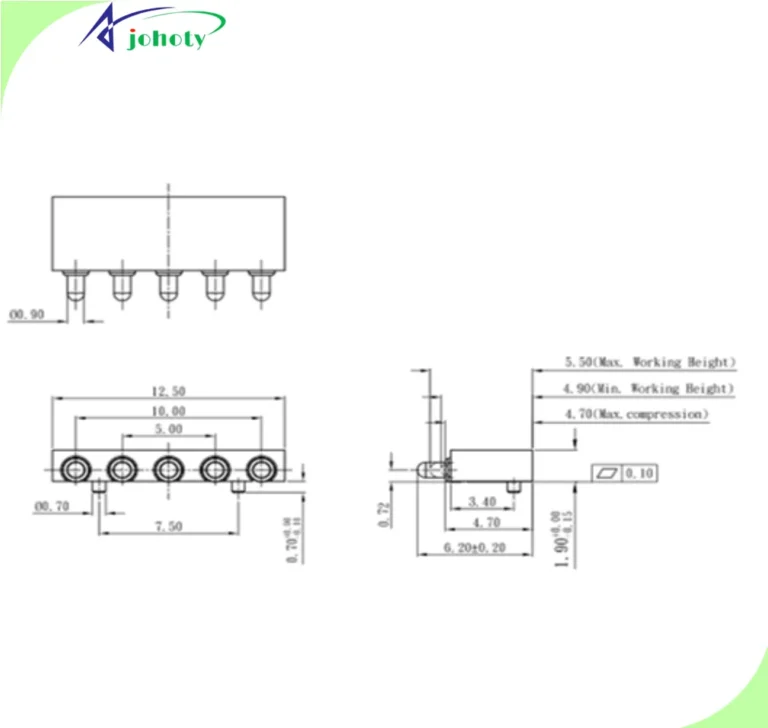

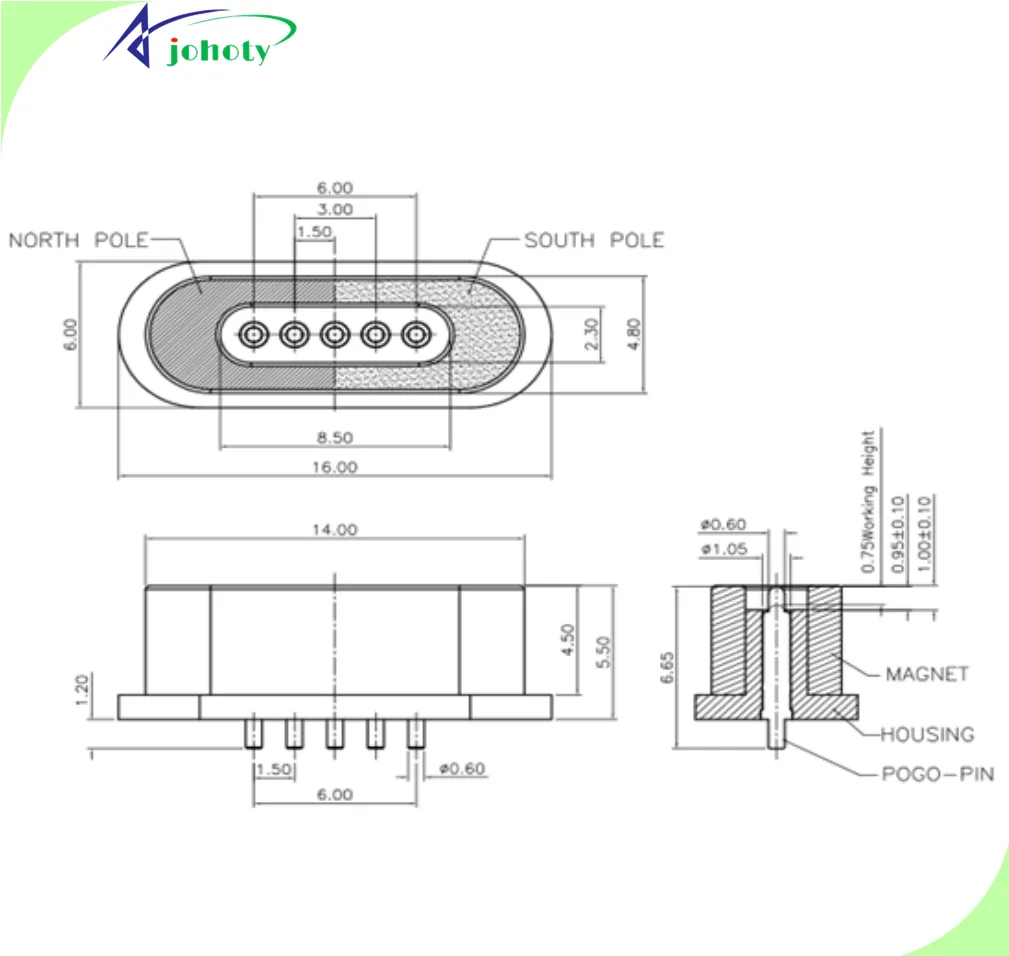

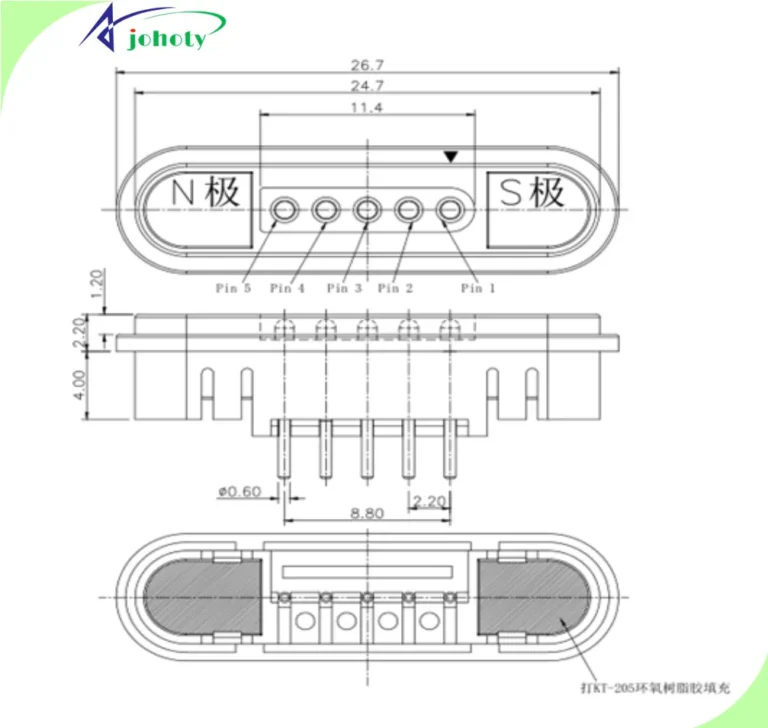

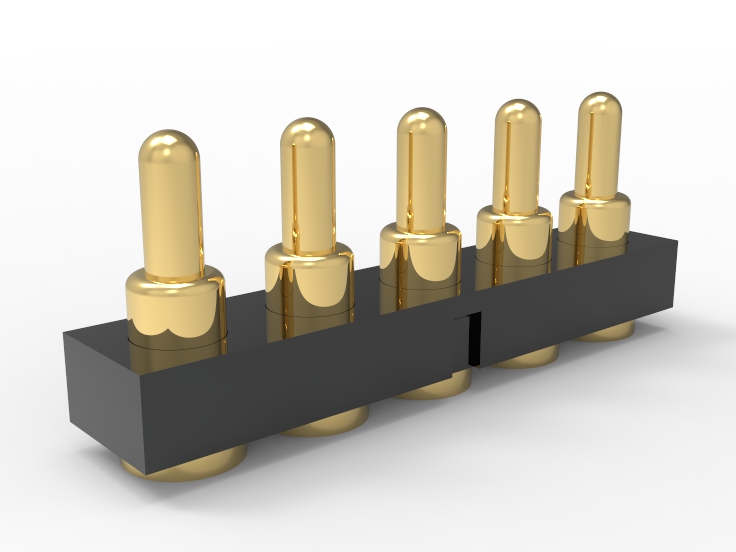

Highly customized pin configuration: Provides customized pin layouts and quantities to meet various special electrical connections. Supports 5 pins or more options to achieve optimal performance in high-density spaces.

Customized materials: PBT, LCP, metal, etc. can be selected according to needs. Optimize the thermal stability, electrical performance, and durability of the 5 pin electrical connector. Ensure reliability in specific environments.

Customized electrical parameters: Customize different currents, withstand voltages, and contact resistances. Meet high-frequency signal, low resistance, as well as high power.

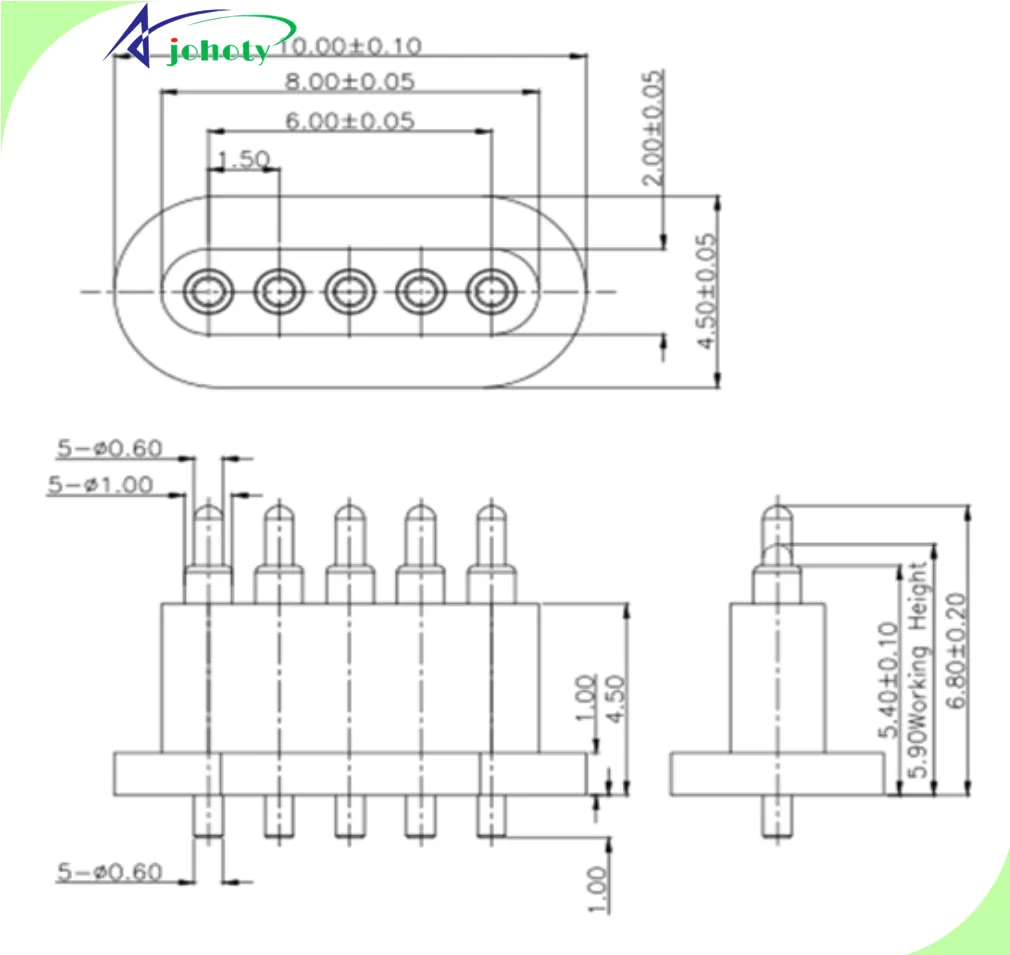

Exclusive size customization: Based on the space of the customer’s device, high-density design with a pitch of less than 2.54mm. Space constrained applications enhance the compactness and performance of the overall device design.

Customized testing plan: Customize specialized performance tests such as vibration, thermal cycling, EMI, ESD, etc. Ensure 5 pin connector stability and reliability in practical applications.

Customized insertion and removal times: The insertion and removal life of customized 5 pin electrical connector can reach up to 500,000, at least 10,000 times. High frequency plugging ensures long-term stable operation of the equipment.

Personalized packaging design: providing customized packaging including anti-static packaging, moisture-proof packaging, etc. Ensure external environmental factors don’t affect 5 pin connector during transportation and storage.

Diversified connection methods: providing through hole, surface mounting, double ended, right angle, solder cup, etc., to adapt to the assembly of different devices.

Rapid prototyping and small batch production: Providing rapid prototyping, customers can obtain customized 5 pin electrical connector within 2-3 weeks. Support small batch production to meet projects of different scales.

Adaptable compatibility design: precise design and development, 5 pin connector compatible with various brands and models of devices. Reduce compatibility risks for customers in practical applications.

Customized design team support: Experienced engineering team provides full support. Assist clients in meeting specific requirements from R&D to mass production.

Customized supply cycle: Provide flexible supply cycles according to customer needs. Quickly respond to urgent orders or long-term cooperative projects to ensure timely delivery.

Click: More Catalog

FAQ

What is the contact resistance of a 5 pin electrical connector and how can we ensure stable signal transmission? Contact resistance can be <50mΩ and has undergone strict electrical performance testing. High frequency signal stability, communication, and precision instruments are commonly used.

Can different pin layouts and sizes be customized? Johoty supports customization of pitches smaller than 2.54mm, with a minimum of 1.00mm. The flexible pogo pin layout and size provide high compatibility with high-density designs.

Is there certification for environmental adaptability and long-term reliability? The 5 pin connector complies with RoHS, REACH, UL, and has undergone thermal cycling and salt spray corrosion testing. Long term reliability in extreme environments to meet the needs of industrial and high-end equipment.

What is maximum current and withstand voltage of a 5 pin electrical connector? The maximum current of 5 pin connector is 10A, and the withstand voltage can reach 250V. It use in high power/voltage, and the electrical connection is stable.

How reliable is 5 pin electrical connector in high vibration? After vibration testing at 50Hz-500Hz, 5 pin electrical connector shows stable performance under mechanical vibration conditions. There will be no poor contact or signal interference for aviation, automotive, and industrial equipment.

+86 13590816656

+86 13590816656 +86 13590816656

+86 13590816656