Services of High Current Pogo Pins

Sampling high current connector: Fast response, direct engineering connection

Produce 3D images within 2 days and samples within 2 weeks. Support 3D model or 2D drawing, with one-on-one technical follow-up from R&D engineers. If the drawings are confirmed, ensure first sample can fully meet client’s requirements. Free structural optimization suggestions, compatible with multiple packaging options.

Product quality: Military grade material selection, no attenuation after 10,000 insertions and removals

Contact resistance as low as 50mΩ, tested through 10,000 connection cycles. -40℃ to+125℃ high and low temperature alternating test, CTI >600V insulation material. Suitable for high reliability applications such as EV, medical, and automation equipment.

Delivery guarantee: sampling, batch delivery within 2 weeks

ERP rapid production scheduling + core process self-owned factory (integrated injection molding/pogo pin making/electroplating/assembly/testing), supporting insertion and urgent orders without additional charges. The full process MES system can trace production pace, ensuring stable project rhythm without delay.

MOQ threshold: Supports 5PCS samples, flexibly adapting to project pace

Support extremely small batch sampling to meet pre validation requirements of small batches and multiple types. In the later stage of mass production, there is automated production line with 1M output per day, ensuring worry free delivery.

Logistics method: Global door-to-door controllable delivery

Support DHL/UPS/FEDEX full process visual tracking, with European and American express delivery taking 5-8 days. Customized products support FOB/EXW/DDP/DDU export. Assist clients in resolving tedious customs declaration/value-added tax and other related matters, with a streamlined process.

Exclusive contact person: Senior connector solution consultant with over 10 years of experience

All engineers have English technical communication skills and an average industry experience of over 10 years. Some members have a master’s degree background and have served top clients: Apple, Microsoft, IBM, etc. Understanding high current connectors allows for a better understanding of project pace and implementation risks.

Click: More Catalog

Performance Test of High Current Pogo Pins

Current carrying stability verification: Continuous output of 3A current, 72 hour high-temperature aging test without resistance drift, connection reliability >99.99%. Perfectly adapted to power/signal integrated applications with high reliability requirements.

Consistency of measured contact resistance: 500 samples were randomly inspected, with an average contact resistance of ≤ 50mΩ and a maximum deviation of no more than ± 3mΩ Satisfy high-precision electrical design tolerance control, reduce system heating and energy consumption losses.

Durability verification of plugging and unplugging life: After continuous plugging and unplugging for over 30,000 times, there is no significant deterioration in electrical performance, and the lifespan is >5 years. Superior to industry standards by more than twice, supporting frequent assembly and maintainability design.

Electromagnetic compatibility testing (EMC): Whole machine end is tested with no interference echo and no abnormal radiation. Avoid system EMI hazards and adapt to high-speed signal links.

Thermal distribution and thermal conductivity verification: High precision infrared thermal imaging measurement shows good thermal uniformity in the connection area without local hotspots. Support compact and highly integrated module design, without increasing the burden of heating management.

Coating consistency and corrosion resistance verification: After 96 hours of salt spray testing, there was no pin oxidation or coating peeling. Ensure long-term stable conductivity in extreme environments.

High frequency and low-noise signal transmission test: Conducted 3GHz high-frequency feedback and jitter testing. There is no data loss or signal distortion in the high bandwidth signal path. Used for medical, communication, aviation, and extremely high signal integrity.

Click: More Catalog

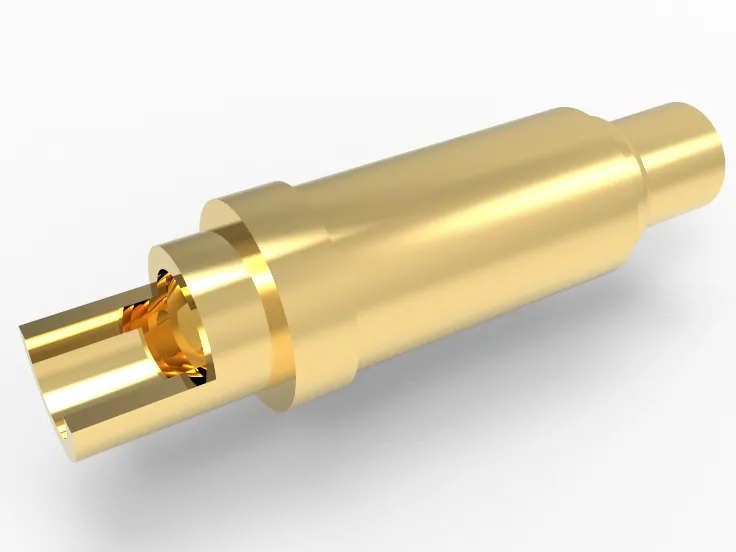

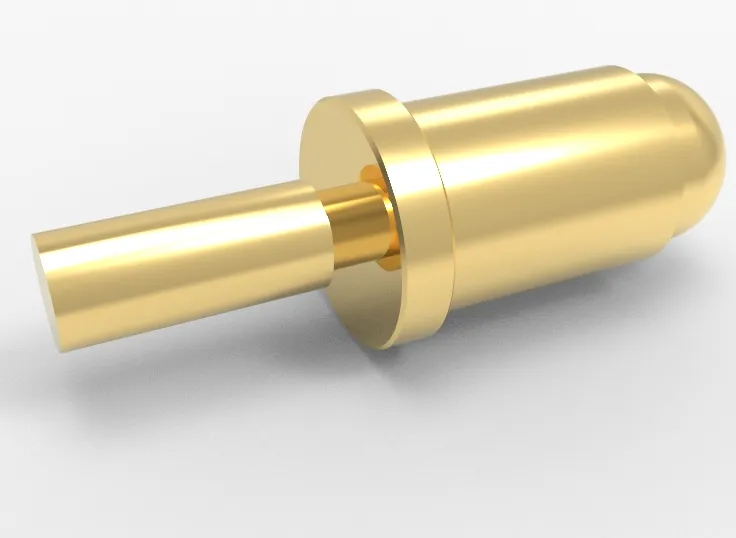

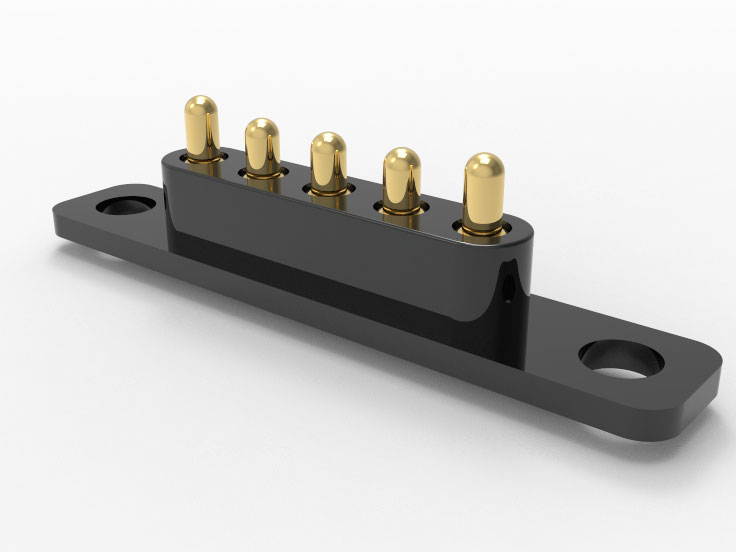

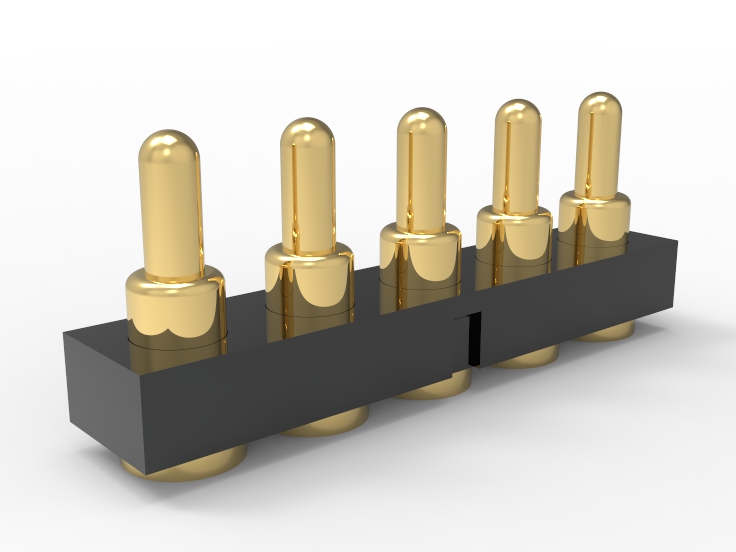

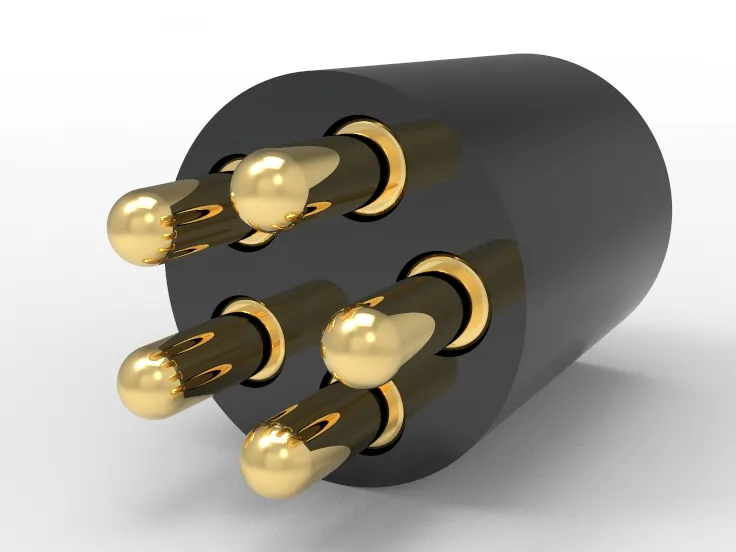

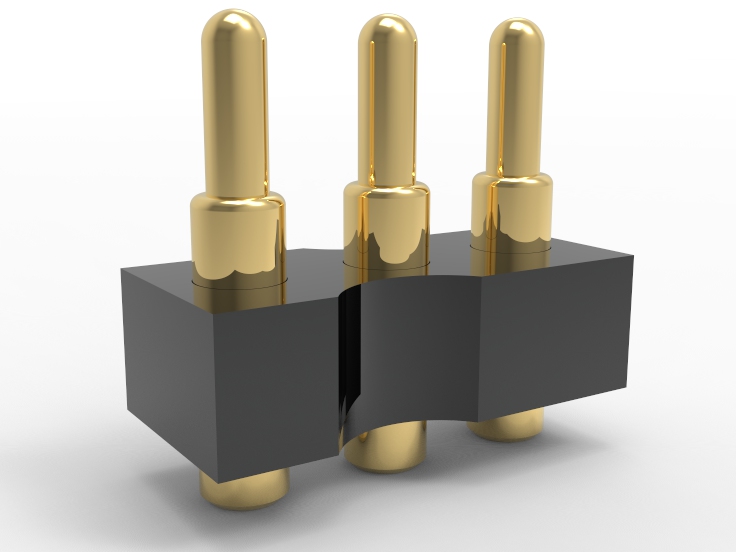

Customization of High Current Pogo Pins

Accurate customization of current levels: supports targeted development of current solutions from 1A to 50A, with 3A as the standard delivery specification. Adjust the elasticity, contact area, and pogo pin length as needed to ensure thermal control and conductivity performance.

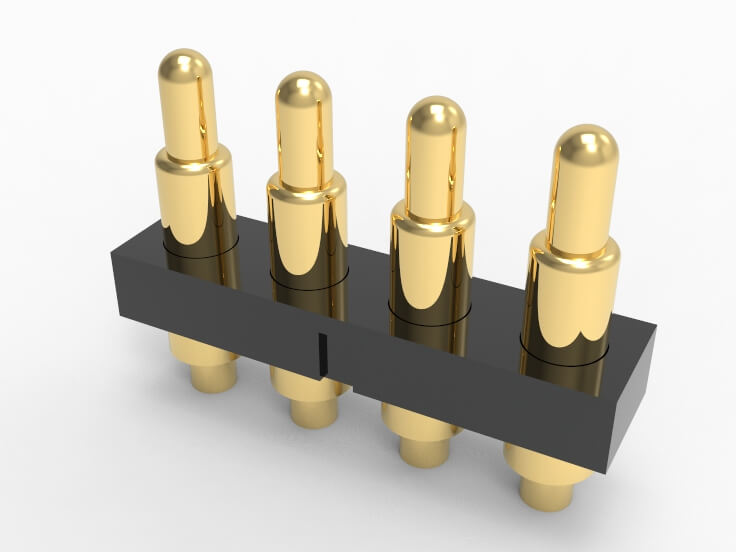

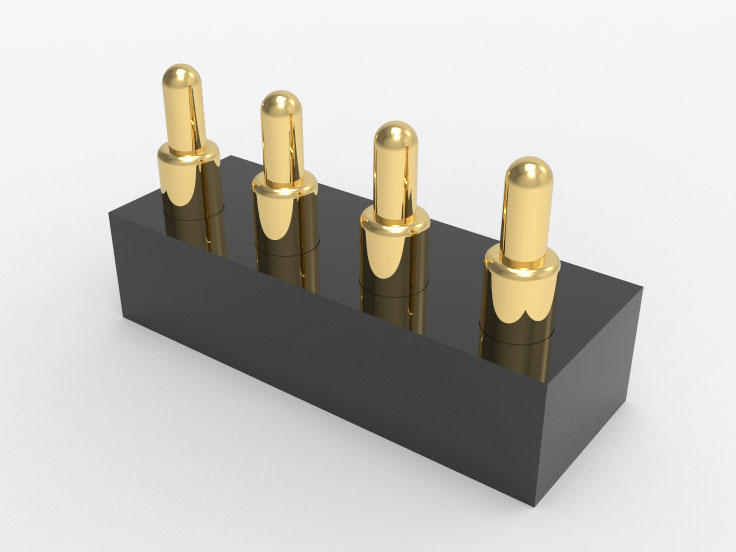

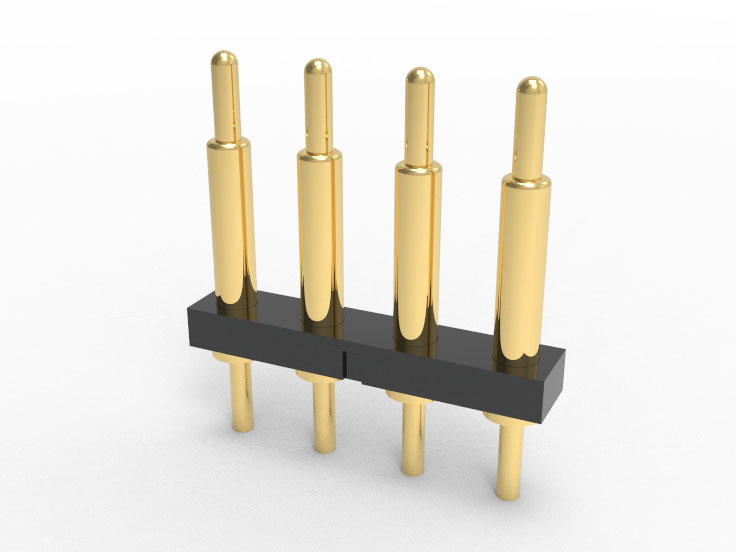

Customized structural dimensions as needed: Supports full dimensional customization of stroke, pogo pin height, barrel diameter, and pitch from 0.10mm to 5.00mm. Compatible with complex spatial structure design, meeting high-density and highly integrated application requirements.

Material/Coating Options: Multiple barrel materials (beryllium copper, phosphor copper, stainless steel) and coatings (gold plating, nickel plating, palladium/platinum/rhodium/ruthenium plating) are available. Meet different requirements for corrosion resistance, conductivity, and contact stability.

Various installation methods are compatible: supporting SMT, DIP, nut fixing solder-cup, right-angle, Multiple installation methods such as module assembly. Directly connect with the customer’s terminal product design system to shorten the project integration cycle.

Quick prototyping and small batch trial production: structural samples can be delivered within 10 days at the fastest, and functional sample validation can be achieved within 14 days. Support flexible collaboration during small-scale trial production and engineering verification stages, bridging the transition from concept to mass production.

Multi to one engineer collaborative development: The project’s dedicated FAE engineering team provides a closed-loop customization process from design input, scheme evaluation, sample validation, reliability testing, and batch import. Shorten the R&D cycle by more than 35%.

Parallel guarantee of quality and delivery: 100% full inspection for shipment, supporting multiple certifications such as UL, RoHS, REACH, ISO, etc. Ensure that customized solutions are quickly implemented under a compliant and traceable system.

Click: More Catalog

FAQ

Do high current connectors support long-term stable operation with high current?

Supports continuous 3A current flow and no performance drift during 72 hour high-temperature aging test. Resistance fluctuation ≤±3mΩ, used for heavy loads in power sockets, battery modules, communication base stations, etc.

Can high current connectors cope with high-frequency plugging or vibration environments?

After 30,000 mechanical life tests, there was no significant increase in contact resistance. Johoty’s pogo pins are commonly used in industrial equipment, medical probes, and vehicle modules for high-frequency use or vibration conditions.

Can high current connectors be customized for extremely small spaces or complex structures?

Support barrel diameter starting from 0.50mm and spacing starting from 1.00mm. PIN from any angle, irregular structure, modular layout customization. Compact structured wearable devices, precision instruments, etc. are very suitable.

Do high current connectors have end-to-end collaborative design capabilities?

Provide integrated customized services including electrical simulation, structural solutions, and thermal analysis. Coordinate with customer product development cycle, support from sample evaluation to bulk delivery.

Do high current connectors meet mainstream certification and supply chain standards in Europe and America?

High current connectors comply with RoHS, REACH, and UL certifications. The factory has passed ISO9001 and ISO14001, and is compatible with the QMS and mass production compliance requirements of European and American end customers.

+86 13590816656

+86 13590816656 +86 13590816656

+86 13590816656