Johoty’s Services of Pogo Pin Header

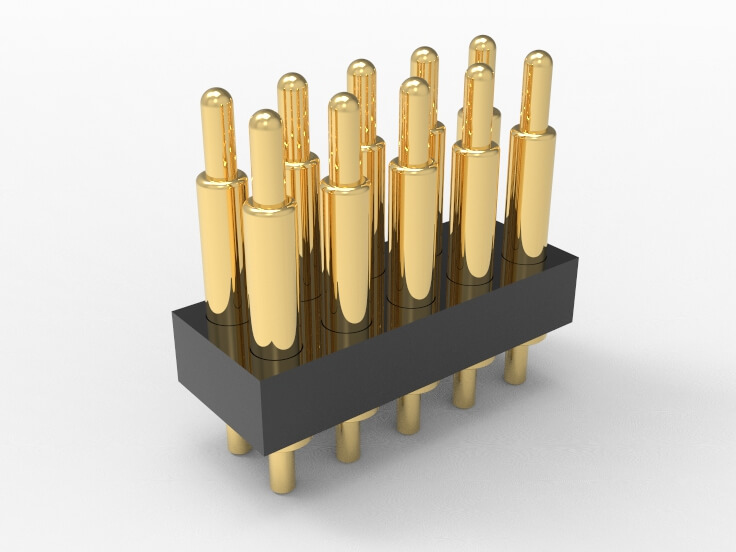

Sample pogo pin header:

Standard engineering sampling process+technical docking window system: Customers provide feasibility feedback within 12 hours after submitting drawings, and provide initial sample drawings and sampling schedules within 48 hours. Support quick pre confirmation of 2D drawing + 3D/STEP drawings. FAE engineers provide real-time response throughout the entire process.

Quality assurance of pogo pin header:

The barrel tolerance control is ± 0.02mm, and the consistency of coating thickness is ≤±0.1μm. Full plunger 100% electrical continuity testing+bi-directional CNC curve testing for insertion and extraction forces. Satisfy a compression life of ≥30,000 times and achieve 200,000 mating cycles through special design.

Pogo pin header delivery time:

First sampling: Shipment within 72 hours (regular materials in stock).

Small batch customized trial production: Packaging and delivery are within 14 working days.

Mass production delivery: Rolling arrangement based on customer BOM lock cycle, supporting JIT/batch supply.

MOQ (Minimum Order Quantity) pogo pin header:

The sampling stage supports a minimum order of 3 sets, and the trial production stage requires a minimum order of ≥100pcs. During the mass production stage, based on the project, support customer agreement tiered pricing system.

Logistics method:

Supports DHL, FedEx, UPS door-to-door services, and can also provide Hong Kong transit or customer designated consolidation solutions. Fully traceable waybill and automatic docking of outbound details.

Qualification of liaison person:

The first level project is supported by FAE+process engineering supervisor with over 5 years of experience in high-speed connectors and dual line docking.

Customized project arrangement exclusive PM+engineering window (optional in Chinese and English).

The docking personnel hold IPC-A-610 or IEC-60512 certification backgrounds and have the ability to collaborate in parallel with research and development, structure, and procurement.

Click: More Catalog

Performance Test of Pogo Pin Header

Insertion and retention force curve test: Using standard 0.5mm/min displacement control, record the full stroke insertion and extraction force curve of the pogo pin header. Insertion force <60gf, holding force >90gf, suitable for automatic assembly and high-frequency plug-in connectors.

Electrical contact resistance stability: Test the initial contact resistance of the pogo pin header and the resistance change after 50 thermal cycles (-40℃~+125℃). According to the IEC 60512 standard, ΔR<10mΩ indicates strong signal integrity and power supply stability.

Compression life fatigue test: Johoty often undergoes 10,000 cycles of compression under standard load (25% stroke). Monitor the deformation and recovery accuracy of pogo pins, requiring a deformation rate of<2%. The compression stroke of pogo pin header has no attenuation and high long-term mechanical stability.

Coating wear test: Using a load of 1.5N to perform 10,000 sliding frictions on the plunger tip, the coating thickness wear rate is less than 15%. The contact surface of the pogo pin header has no exposed copper base, and the conductive layer is wear-resistant for a long time.

Simulation test of through-hole insertion tolerance: Simulate PCB through-hole deviation within a tolerance range of ± 0.05mm. Johoty is used to evaluate the consistency between the deformation of the pogo pin header tail and soldering. After welding, the barrel maintains a vertical deviation of less than 3° and is packaged with high density.

Salt spray and wet heat combined aging: According to ASTM B117 and IEC 60068-2-78, perform a 96-hour salt spray +240-hour constant temperature and humidity cycle. After detection, the change in contact resistance was less than 10mΩ, and there were no obvious signs of corrosion.

High frequency performance verification (optional): Conduct a 1GHz~6GHz TDR test on the signal path, with a reflection coefficient S11<-20dB. In this way, the integrity of high-speed data signal transmission is guaranteed.

Click: More Catalog

Customization of Pogo Pin Header

Accurate matching of engineering parameters: The length of pogo pin header is controlled within the range of 8.00~10.00mm. High density board space constraints and deep insertion connections to avoid virtual connections and stress accumulation.

Insertion force/holding force control: It can provide mechanical tuning solutions for initial insertion force <60gf and holding force >90gf. Adapt to automated assembly and high-frequency mating.

Customization of plating process: Supports multiple plating thicknesses or composite electroplating options for Au/Ag/Rh/Pd/Ru/Pt, with a standard of 0.5μm or above. Ensure stable conduction for over 50,000 times and adapt to signal/power dual path requirements.

Adjustable spring curve: Adjust the elastic constant within the range of 5gf/mm~3.5N/mm according to the customer’s compression stroke and contact stroke requirements. Achieve a mechanical fatigue life of 10,000 to 200,000 cycles.

Process adaptability: Compatible with wave soldering/reflow soldering/manual soldering requirements. The shape of Pogo pin header’s tail pin can be optimized according to the hole wall tolerance and flux requirements.

Environmental and reliability testing: Passed -40℃~+125℃ thermal cycling test, 96h salt spray test, and IEC 60512 class contact resistance fluctuation test. Implement long-term stability of pogo pin headers.

Material Traceability: All pogo pin header raw materials (brass HBi59, BeCu, SUS304/316) and coating batches are traceable. Compliant with RoHS/REACH and supporting QMS document control requirements for industries such as aviation and healthcare.

Click: More Catalog

FAQ

What is the mechanical lifespan of Pogo pin header in high-frequency plugging?

Within the effective stroke range of 0.10~1.50mm, the compression life verification under standard load is >10,000 times. The insertion and extraction force is stable without significant attenuation, and the change in contact resistance is controlled within ±10mΩ.

Does Pogo pin header support customized elasticity and retention?

Supports adjusting spring stiffness between 1.2N/mm and 3.5N/mm, allowing for precise setting of insertion and retention forces. Meet different assembly strategies such as automated clamping and seismic resistance. That is to achieve a spring force as low as 5gf, which is commonly requested by customers.

Can pogo pin header be stably inserted into PCB through holes within the standard ± 0.05mm tolerance range?

Can support PCB apertures of 0.30-3.50mm and ±0.02mm. The tail of the pogo pin header is chamfered and designed to resist warping, with through-hole error absorption and unbiased insertion. It can adapt to mainstream processes: wave soldering W/S, reflow soldering, and manual-soldering.

Is the pogo pin header coating optional? How does pogo pin header ensure signal integrity and corrosion resistance?

Optional coatings include Au (default ≥0.5μm), Ag, Rh, or composite coatings. All electrical contact surfaces have undergone wear-resistant design and passed 24h/48/96h salt spray + 240h wet heat aging test. Pogo pin header can meet high reliability electrical transmission in harsh environments.

+86 13590816656

+86 13590816656 +86 13590816656

+86 13590816656