Johoty’s Services of Soldering Pogo Pins

Sampling soldering pogo pins: The standard sampling process starts within 48 hours and supports simultaneous review of 3D drawings, process confirmation, and sample drawings. Provide 2 free design iterations, and ship within 2 weeks after the customer confirms the drawings.

Quality control: Meet the testing requirements of MIL-STD-202F. Full inspection standard: pogo pin length tolerance ± 0.05mm, tail welding cup depth consistency <±0.03mm. Surface electroplating thickness ≥ 2μm, nickel ≥0.1μm, gold. Plug and unplug life ≥10,000 times, initial contact resistance <50mΩ.

Soldering pogo pins delivery time: The fastest sampling cycle is 3 days for delivery (limited to standard specifications), and customized parts can be delivered within 14 working days for mass production. Special processes require advance communication to lock in the resource window.

Soldering pogo pins MOQ (Minimum Order Quantity): There is no limit to the sample stage, and the MOQ for formal mass production is 3,000 pcs. Can support customized packaging and shipping in batches of 500/1K/2K, etc.

Logistics method: DHL/FedEx Priority is default for sampling, and FOB Shenzhen can be selected during the mass production stage. Support customer account shipping.

Contact person qualification: Directly connected by bilingual technical sales personnel in Chinese and English with at least 10 years of experience in the precision connector industry. Have knowledge in structural design, project management, and certification processes. Real time integration of soldering pogo pins tracking and drawing updates.

Click: More Catalog

Performance Test of Soldering Pogo Pins

Contact resistance test: The initial contact resistance of soldering pogo pins is ≤ 50 milliohms, and the resistance change after applying pressure is<10 milliohms. According to the IEC 60512-2-2 standard, Johoty can ensure the integrity of microcurrent signals.

Insertion and extraction lifespan test: We will perform insertion and extraction cycles 10000 times, with interval checks every 1000 times. The fluctuation of contact resistance shall not exceed ± 20% of the initial value, and the high-frequency mechanical stability shall be maintained.

Elasticity consistency testing: During the elasticity testing of Soldering pogo pins, the deviation under full load compression is ≤±0.1N. Batch consistency is checked by digital force sensors in batches. Require high load stability for the assembly of Soldering pogo pins.

Welding heat resistance: Soldering pogo pins can be immersed in a 260℃ soldering furnace for 10 seconds without any structural looseness or tail deformation. Refer to J-STD-002B specification for welding end thermal shock testing.

Thickness testing of electroplating layer: Generally, the gold plating of ordinary sol-gel pogo pins is ≥0.1μm, and the nickel plating is ≥3μm. The highest gold plating capacity is 5μm, and batch by batch detection is performed using an XRF fluorescence analyzer. Johoty must ensure that the contact layer of the soldering pogo pins does not peel off or corrode or oxidize.

Anti vibration performance: 10Hz-500Hz sine scan, 4 hours per axis, no contact failure or structural displacement. Essential testing for high reliability applications in aerospace, automotive regulations, and industrial control.

Salt spray corrosion resistance: Soldering pogo pins have a resistance fluctuation of less than 15% after 24 hours of neutral salt spray testing. Evaluate the protective ability of the surface coating of pogo pins in humid environments according to ASTM B117.

Thermal cycle impact test: After 200 cycles from -40℃ to+85℃, the size change of the soldering pogo pins is less than ± 0.02mm. Johoty will ensure that the electrical performance is normal and stable under different environmental conditions.

Structural consistency verification: The image measuring instrument conducts a full inspection of the length, tolerance, welding cup depth, and concentricity of the soldering pogo pins. The detection tolerance control is better than ± 0.03mm, meeting the requirements of precision assembly.

Click: More Catalog

Customization of Soldering Pogo Pins

Scope of structural customization: The minimum total length for customization is 4.60mm, and the depth and inner diameter of the tail welding cup can be accurately adapted according to the specifications of the welding wire. The spring stroke supports a refined setting of ≥0.45mm, with limited adaptability space.

Adjustable electrical parameters: Supports contact resistance (10-50m Ω) under different elasticity settings, meeting the stability of high-frequency microcurrents or low-voltage power supply.

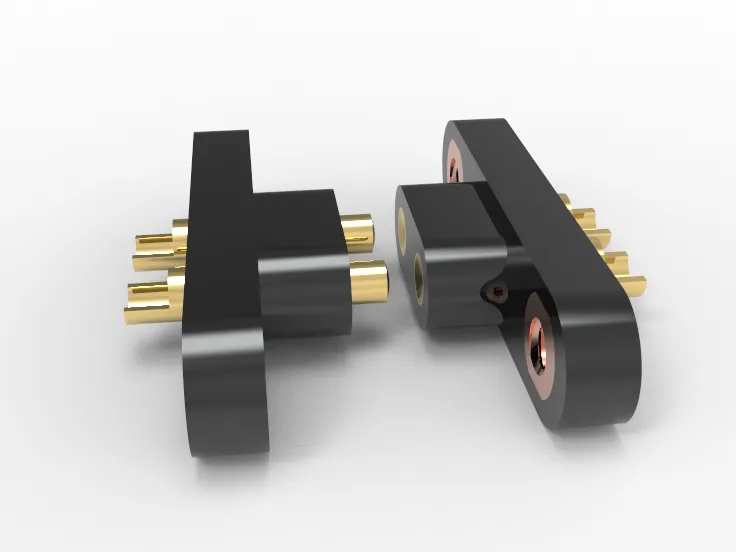

Installation interface docking: The tail welding cup can choose unidirectional/symmetrical inner cone angle structure to improve the efficiency and consistency of hand welding. Supports integrated pogo pins + housing structure, suitable for parallel array or embedded packaging processes.

Material and electroplating customization: Barrel can choose phosphor bronze, BeCu or SUS. The surface supports nickel plating + gold, silver, palladium, platinum, as well as composite electroplating. Meet high temperature, corrosion resistance, or low-cost requirements.

Batch process adaptation: Barrel diameter can be controlled at ≥0.50mm, which can flexibly match different PADs, solder wires, and structural layouts.

Component development capability: Supports pogo pin connectors based on Soldering pogo pins (Pitch ≥1.00mm). Optional concentric compression or step-by-step structure, with batch consistency and assembly compatibility.

Sampling to mass production process: Sampling within 72 hours after structural confirmation, and small batch customization completed within 14 days. All versions of drawings are traceable and meet the change control requirements for R&D iterations.

Delivery support: We can provide customized barrels, limit structures, fixtures, tool molds, etc. Suitable for the design phase of R&D testing platforms and automated fixtures.

Click: More Catalog

FAQ

Is Soldering pogo pins suitable for space constrained scenarios? Pogo pin length is controlled within 7mm, suitable for compact structural design. Suitable for space constrained layouts in portable devices, inter module connections, or embedded systems.

What is the range of wire diameters that can be supported by the tail of the Solder Cup for Soldering pogo pins? Compatible with wire insertion and soldering from 4AWG to 30AWG. Suitable for thin signal lines or low current power supply connections. It can also support current transmission up to 50A.

Is the material and elasticity performance of Soldering pogo pins stable? Plunger adopts copper alloy gold plating treatment to maintain conductivity while also considering wear resistance. The typical lifespan of a spring is ≥10,000 mechanical compression cycles.

Can Soldering pogo pins be suitable for high-frequency or low impedance applications? Pogo pins have an internal resistance of less than 30m Ω. They are commonly used for data signal/power circuit transmission with high signal integrity requirements.

Can Soldering pogo pins meet both manual and automated welding processes? The tail solder cup design of Soldering pogo pins supports precise solder infiltration. Suitable for manual welding and can also be integrated into automated processes such as wave soldering/laser welding.

+86 13590816656

+86 13590816656 +86 13590816656

+86 13590816656