Johoty’s Services of Spring Probe

Spring Probe custom prototyping: Fast response, completed within 2 weeks. Support small batches of diversified samples to ensure accurate verification of design schemes. Support dual verification of structure/electrical properties to quickly identify the best testing solution.

Quality assurance system: using high-purity gold-plated contact pins and industrial grade wear-resistant and corrosion-resistant materials. Supports lifespan testing >300,000 times, with a machining tolerance of ± 2μm, in compliance with ISO 9001 and IPC. 100% electrical performance testing and mechanical life verification for each batch, with a stability of up to 99.99%.

Delivery commitment: Standard orders will be delivered within 2 weeks, and urgent orders will be shipped within 5-7 days at the earliest. The exclusive production line ensures stable delivery time and no risk of delay. The full process ERP+MES digital system control meets engineering prototype as well as mass production.

Minimum Order Quantity (MOQ): Supports sample and small batch orders, with MOQ as low as 100pcs. Reduce customer inventory pressure, support mixed ordering of multiple specifications, and flexibly match project schedules.

Logistics plan: default air transport of DHL, FedEx, UPS, TNT. Real-time tracking ensures safe and fast delivery of spring probe. Provide dedicated logistics and door-to-door services for bulk orders.

Exclusive liaison qualification: With an industry average of 10 years or more of testing engineering background, FAE directly connects with customers. Full process technical consultant and sales manager provide one-on-one service, with backgrounds covering IC testing engineers and supply chain experts. Having a deep technical understanding and the ability to respond quickly to problems, ensuring efficient and accurate communication.

Immediate response: respond to emails and arrange online technical docking within 12 hours, and provide complete solutions and quotations within 2 days.

Click: More Catalog

Performance Test of Spring Probe

High reliability contact consistency: Contact resistance ≤50mΩ, fluctuation<5% after 100,000 insertions and removals, and stable test data Adapt to ATE and high-speed probe card environments.

Extreme macro precision capture: The dual head design supports a minimum pitch of 0.15mm, making it easy to handle advanced packaging with fine spacing such as BGA/CSP/SIP.

RF level low crosstalk performance: Through S-parameter testing in the 5GHz~10GHz frequency band, ensure high-speed signal integrity and interference-free connection.

Durable life up to 300,000 cycles: precision beryllium copper + gold coating combination, passed elasticity and fatigue resistance tests within the range of 5g~150g, long-lasting and stable without interruption.

Compatible with multiple testing platforms: Handler/Socket/ATE/Load Board, fast integration, and on-site verification pass rate >99.8%.

No virtual soldering or false connections: Each needle undergoes 100% factory impedance scanning and elasticity mean screening, and the batch qualification rate is controlled within the Six Sigma standard.

Click: More Catalog

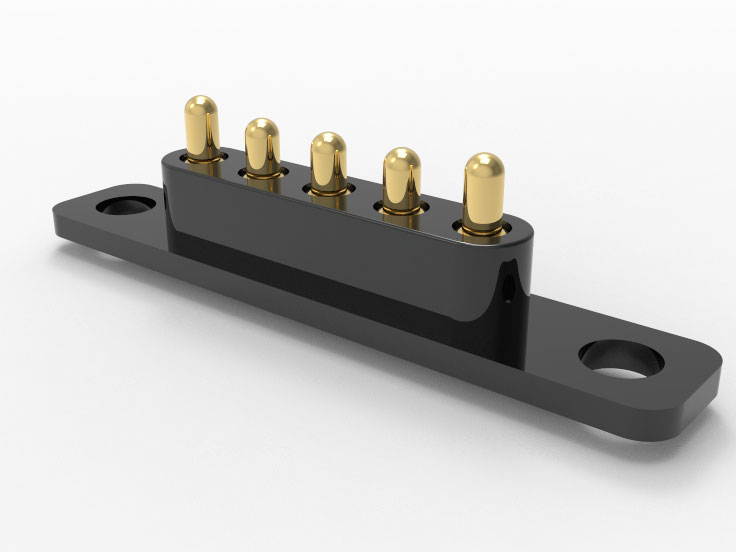

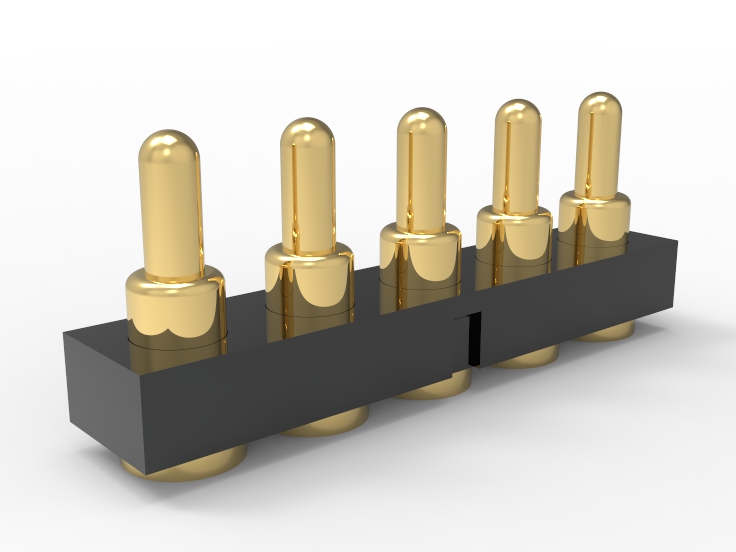

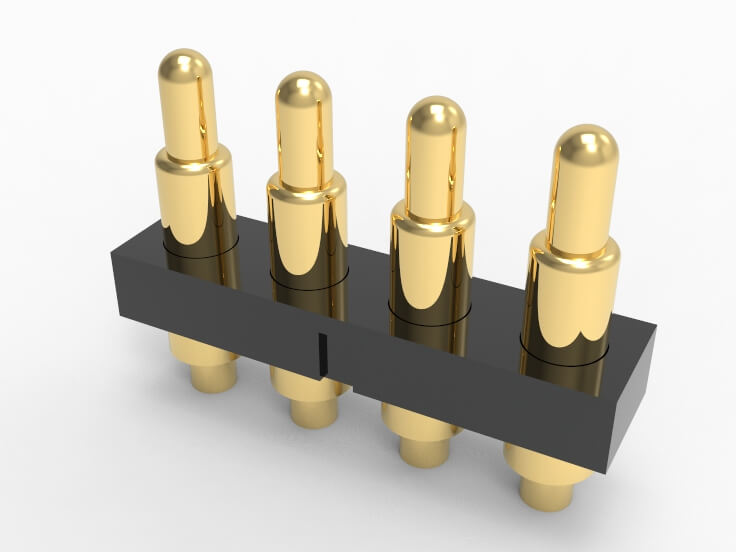

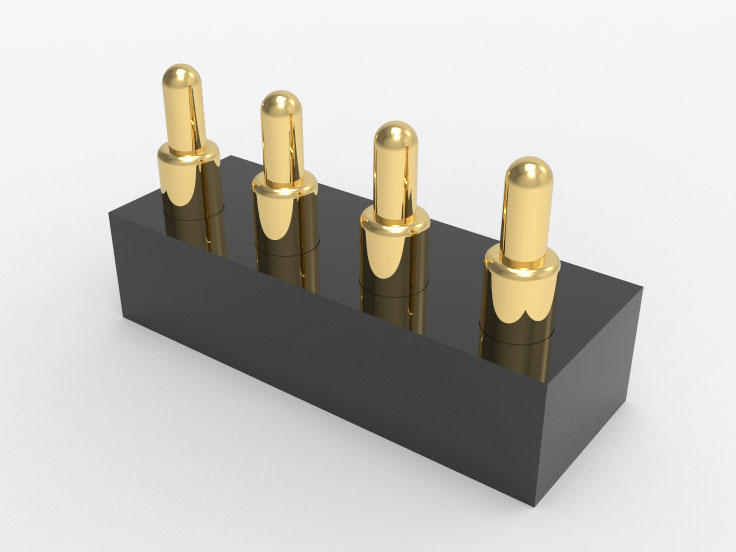

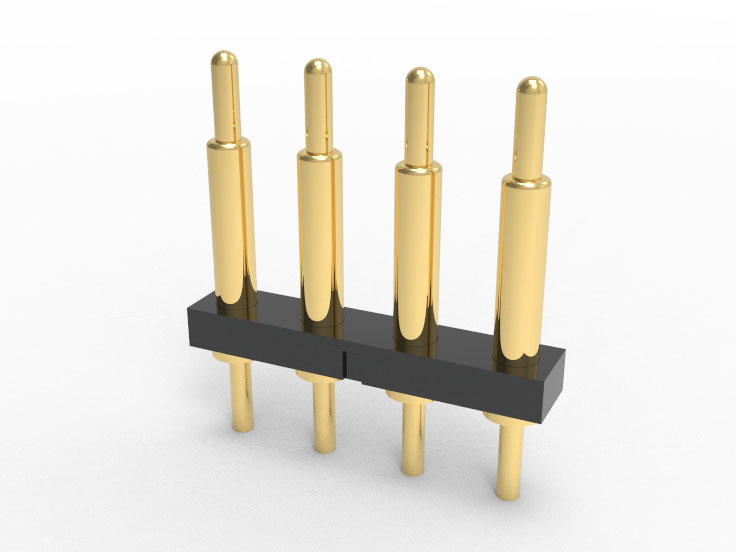

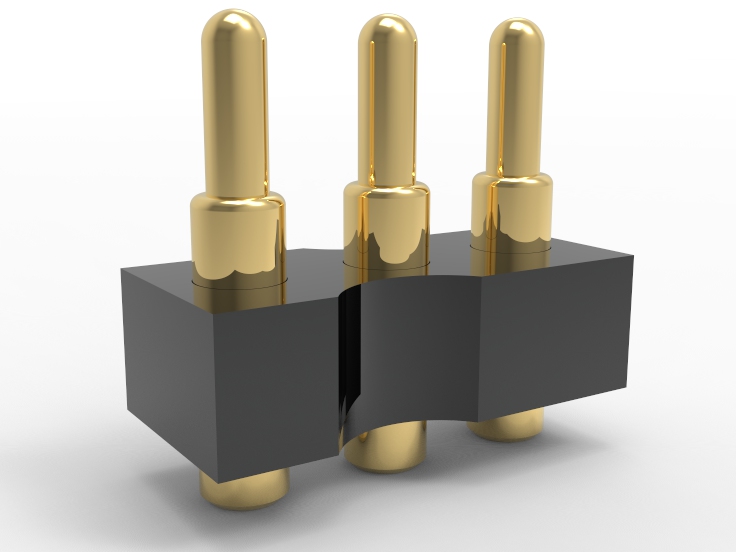

Customization of Johoty’s Spring Probe

Full specification deep customization: supports full range customization of 0.15mm-2.54mm spacing, accurately adapts to high-density BGA, QFN, WLCSP and other packaging structures.

Customer structure diagram or engineering solution: Provide customized structure review diagram within 24 hours, sample delivery within 15 days, and compress NPI cycle by more than 50%.

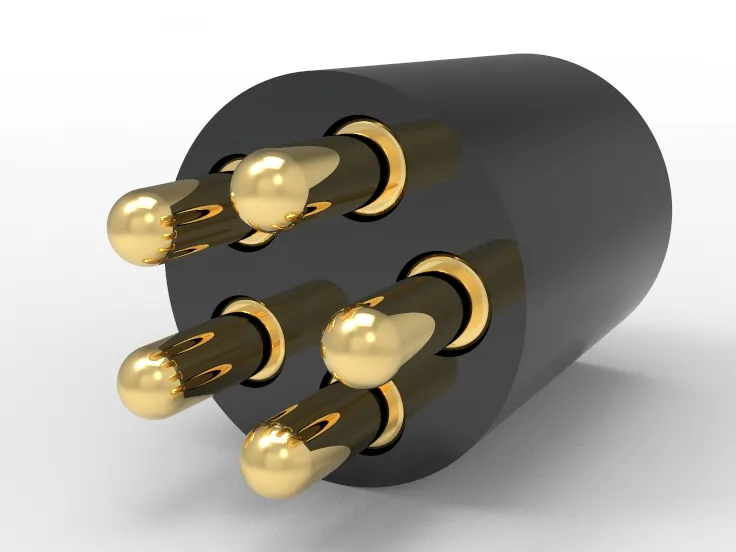

High elasticity/low elasticity/RF/high current full type support: customized stroke, preloading, elasticity, current, contact impedance, coating and needle tip structure. Implement a multifunctional platform integrated solution.

Cross platform one-to-one customization: compatible with mainstream ATE and probe card platforms such as Advantest, Teradyne, Chroma, and Cohu, ensuring full process fit.

Batch consistency control <± 3%: The fully customized solution is validated through structural simulation and process pre validation, with minimal batch deviation, ensuring stable and error free batch import.

Flexible minimum order, fast delivery: Small batch minimum order of 100pcs, 15 day delivery, fast trial production verification, dedicated project manager to follow up the entire process.

Click: More Catalog

FAQ

What package types does spring probe support for IC testing? It fully supports advanced packages such as WLCSP, BGA, QFN, CSP, LGA, etc., and can adapt to a minimum spacing of 0.15mm.

How many times can spring probe withstand plug and unplug lifespan? Structural optimization supports stable plug and unplug of over 3 million times, suitable for high-frequency production verification and ATE automation platforms.

Can spring probes be customized for specific elasticity, length, contact impedance, coating or tip structure? Supports full dimensional customization, with an elasticity range of 5g~150g, precise control of needle length ± 0.05mm, contact impedance ≥ 10mΩ, and optional gold/nickel/rhodium multi-layer coating.

Has the spring probe been validated through high-frequency and high current testing? It has passed the S parameter/RF consistency verification above 5GHz, and can support a maximum current of 10A. It has also passed UL arc resistance and thermal stability testing.

What is MOQ and delivery cycle for spring probes? fastest sample delivery in 10 days, minimum order quantity of 100pcs, batch delivery in 15 days for fast R&D.

+86 13590816656

+86 13590816656 +86 13590816656

+86 13590816656