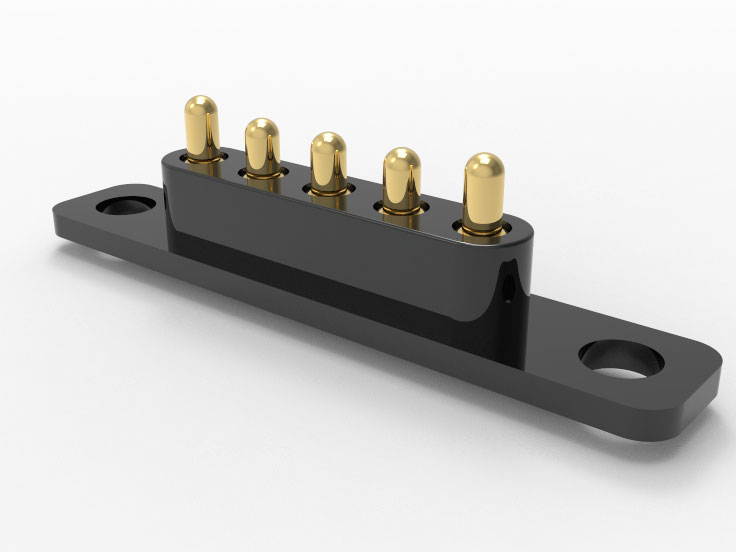

Johoty’s Services of Test Fixture Pogo Pins

If you are the technical leader of high-end connectors, Johoty is your partner who understands delivery, quality, and technical rhythm the most. Not exceeding budget, not waiting for delivery time, and meeting communication needs without barriers.

Sample Test Fixture Pogo Pins: Fast response + sample promise. Respond to sample requirements within 2 hours after the customer places an order. Produce images within 48 hours and samples within 2 weeks at the latest, with dedicated personnel providing one-on-one technical confirmation. Sampling is the standard for mass production, with no deviation between sampling and mass production.

Quality standard: strict control of ±0.05mm tolerance + full inspection for shipment. Adopting CNC + high-precision automatic lathe + gold plating >10μin surface treatment process. Before leaving the factory, it undergoes 500 cycles of plug and unplug life testing, supports 3D inspection, RoHS/REACH reporting, and material certification. Fully meet the European and American terminal application standards.

Delivery commitment: Fast delivery + project synchronization. Small batch samples will be delivered within 2 weeks, while bulk orders are typically shipped within 2-3 weeks. The 10 day express channel for urgent orders seamlessly connects with the bulk plan for sample making. Zero latency switching ensures project pace.

Minimum Order Quantity (MOQ): Flexible trial production without any threshold. Support low quantity sampling during engineering verification/testing phase, with 5pcs sampling. After the sample is approved, the MOQ is 3,000pcs, with no complicated process and direct quotation for shipment. Flexible verification makes it easier to transition to mass production.

Logistics method: multi-channel direct delivery to Europe and America + tax compliance and transparency. DHL/UPS/FedEx/TNT full line cooperation, with European and American dedicated lines arriving on the 5th to 8th. Supports various terms such as EXW, FOB, DAP, etc. FCA, CO, and complete customs declaration documents are available to ensure smooth warehousing.

Contact person qualification: More than 10 years of testing experience, technical coordination + project manager system service. The entire project process is serviced by a dual team of senior technical sales and project engineers. Experience in IBM/Microsoft/Foxconn background/English accessible technical communication/on-site FAE support. Understanding drawings and project pace ensures zero interruption from sampling to mass production.

Click: More Catalog

Performance Testing for Test Fixture Pogo Pins

Ultimate contact stability: 0.02Ω ultra-low impedance, precise and lossless signal. Ensure 100% consistency in ATE testing

High cycle life: >10,000 compression cycles. Suitable for high-frequency testing, low maintenance, and cost-effective long-term deployment

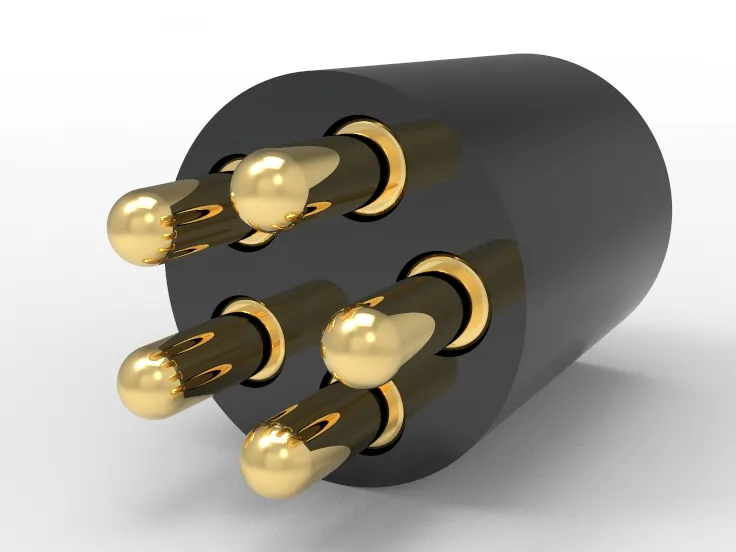

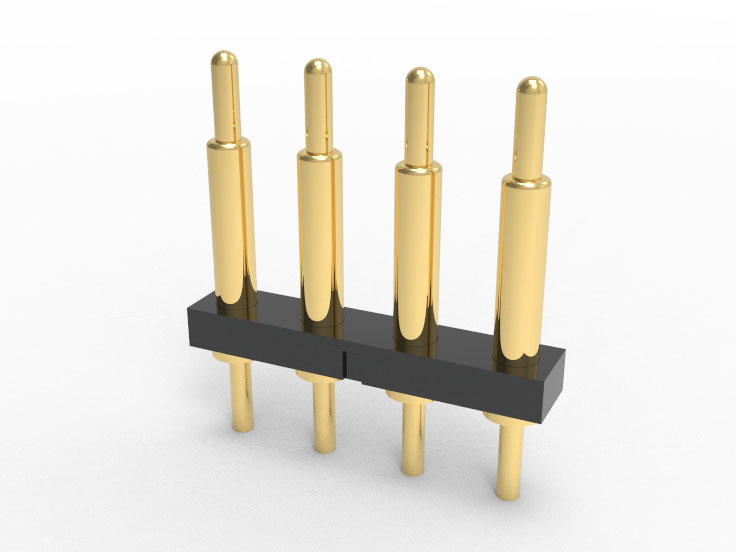

Bidirectional elastic plunger structure: precise alignment, automatic compensation for offset errors. Ensure high stability and reliability for each connection.

Ultimate current carrying capacity: >3A stable current passing capacity. Fearless of high load burnout, suitable for dual-channel power/signal applications

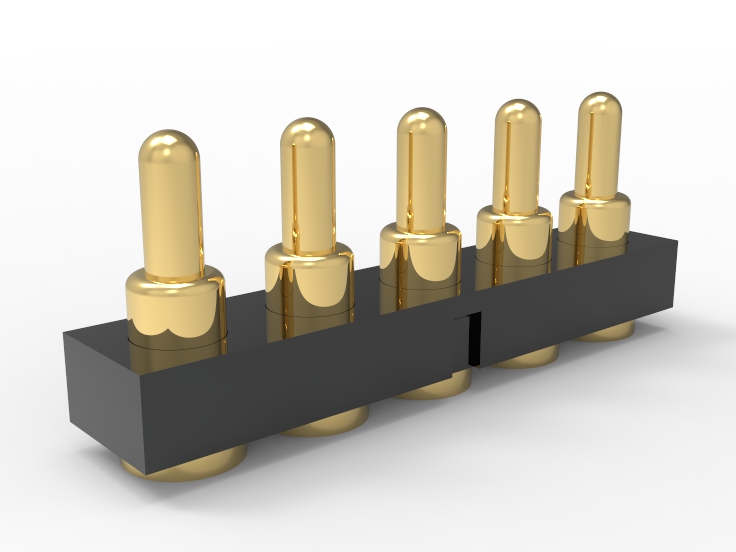

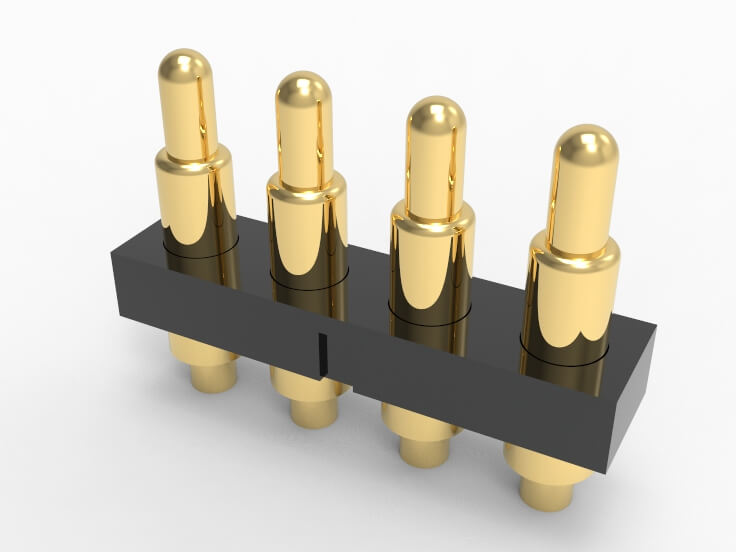

Gold plunger + high elasticity beryllium copper barre: corrosion-resistant and anti-oxidation, maintaining connection reliability even in 24/7 working environment

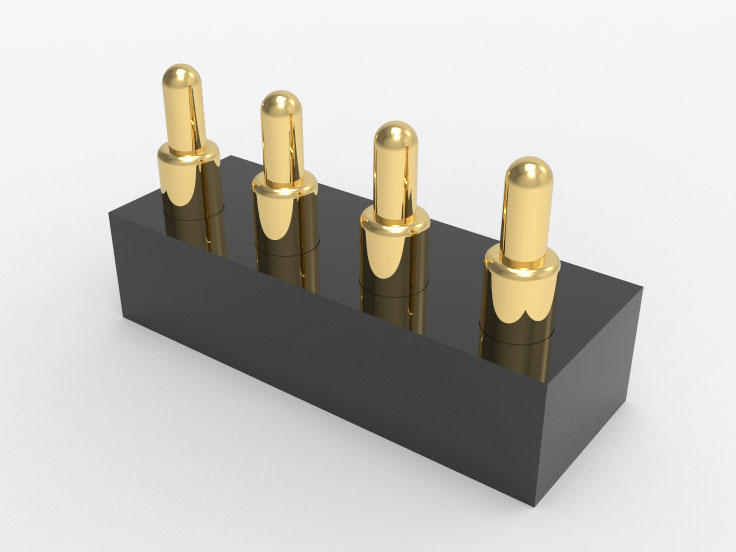

Precision customization options: plunger length/elasticity/diameter/spring force can be fully customized, compatible with PCB B2B connections and various Test Fixture structures

Click: More Catalog

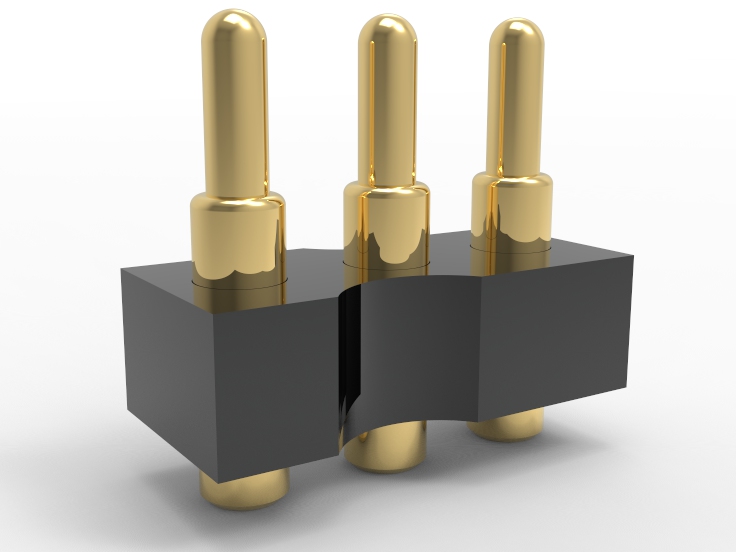

Customization of Test Fixture Pogo Pins

High precision customized matching: length, tolerance, elasticity, electroplating thickness, etc. can be customized according to customer fixture structure, product layout, electrical parameters, etc. All contact requirements from micro connectors to high-density BGA packaging.

Nanosecond level conduction response: signal attenuation less than 0.1dB@1GHz The contact resistance remains stable at<20m Ω, meeting the stringent standards for high-speed/high-frequency signal transmission.

High reliability lifecycle: using high-performance beryllium copper or SK4 materials, with a lifespan of up to 200,000 cycles. Adapt to high-frequency switching in automated testing to avoid losses due to replacement, maintenance, and downtime.

Multi station testing adaptation: supports synchronous triggering of multiple contacts, with a contact accuracy of ± 0.02mm. Ensure consistency and repeatability of multi-channel parallel testing, and assist in stable operation of ATE/FCT production lines and PCBA.

Complete quality certification: Johoty’s test fixture pogo pins have passed RoHS/REACH and 100% factory testing (resistance, electroplating, elasticity, appearance). All test fixture pogo pins are high stability engineering components.

Fast delivery and engineering support: Standard samples can be delivered within 2 weeks, and bulk shipments can be made within 2-3 weeks. Our exclusive FAE team connects testing projects to help clients seamlessly transition from prototype to mass production.

Click: More Catalog

FAQ

Will test fixture pogo pins affect contact stability and lifespan?

We adopt a dual spring independent structure or internal pressure synchronous design (depending on the load selection). Ensure balanced pressure at both ends, with a stable conductivity life of up to 10,000-500,000 cycles. Widely applicable to high-frequency testing scenarios such as BGA, FPC, whole board, interfaces, connectors, etc.

How much current can it withstand? Is high frequency/low impedance guaranteed?

Supports up to 3-50A continuous current conduction, with contact resistance as low as 10-20mΩ. Optional gold pillar, silver pillar, or fully hard gold process to meet high-frequency and low impedance requirements. Widely used in power socket, signal synchronization and other applications.

What are MOQ and delivery? Do you support quick sampling?

Regular specifications in stock can be shipped within 3 days, non-standard customization can be delivered within 2 weeks, and there is no quantity limit for sampling. The minimum order quantity is 300PCS. Provide fast prototyping, collaborative development of drawings, and NDA technical support.

We have certification requirements for high reliability. What quality standards do you meet?

The test fixture pogo pins have fully passed certifications such as RoHS, REACH, ISO9001, salt spray resistance 72H, earthquake and drop resistance, and pin life testing. Support the delivery of quality process documents such as PPAP, FAI, MSA, and adapt to European and American R&D and supply chain management systems.

Can your Test Fixture Pogo Pins accurately adapt to my existing automated testing platform?

We can customize the needle length, elasticity, tail form, and positioning structure 100% according to the customer’s existing fixture platform (such as ATE, probe card, fixture seat, etc.). Ensure that there is no need to modify the entire testing fixture to obtain accurate test fixture pogo pins.

+86 13590816656

+86 13590816656 +86 13590816656

+86 13590816656